Professional Documents

Culture Documents

85 - 05-Biomass Popwer Gen by CFB Boiler Japan

Uploaded by

preecha limOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

85 - 05-Biomass Popwer Gen by CFB Boiler Japan

Uploaded by

preecha limCopyright:

Available Formats

Biomass Power Generation by CFB Boiler

Koji Yamamoto*

* Manager, Solution Engineering Center

Plant-derived biomass is now considered as one of the most prospective energy sources in the future for reducing

carbon dioxide emissions and conserving fossil fuel resources. The effective utilization of biomass includes such

biomass wastes as waste paper, waste building material wastes and agricultural wastes. CFB (Circulating Fluidized

Bed) boilers provide the best solution for biomass power generation because they can accommodate a wide range of

fuels and their environmental impact is small. It is expected that CFB Biomass power plants will be widely used in

the future.

1.3 Carbon cycle on the earth

Both biomass and fossil fuels are organic substances,

and thus both generate carbon dioxide upon combustion.

However, their effects on increasing atmospheric carbon

dioxide concentration are different.

Fig.1 shows the location and flow of carbon in zone of

the earth. This figure was developed from the 1994 IPCC

(Intergovernmental Panel on Climate Change) report1).

The arrows in the figure represent the flow carbon in terms

of Gt/y (giga tons per year), where one giga ton is equal to

one billion tons. The numbers in the squares represent

carbon stocks in terms of giga tons.

1. Significance of biomass power generation

1.1 Definition of biomass

The word biomass is originally an ecological term

meaning the entire stock of biological resources. However,

this paper focuses on biological resources as a category of

energy resource and limits the term biomass to any fuel

derived from plants or vegetables. In addition to fuels

converted directly from plants, such as firewood and

charcoal, biomass in this paper includes such plant-derived

wastes as waste paper, wood-derived wastes and agricultural wastes.

Fossil fuel, which is a general term covering coal, petroleum and natural gas, is in contrast to this concept of

biomass. Fossil fuel is believed to be originated from organisms that lived a long time ago and is a non-renewable

energy source representing a stock of past biological activity. On the other hand, the biomass is a renewable energy

source that can be consumed within the volume of production. This renewability makes biomass fuel markedly different from fossil fuel.

Atmosphere 750

92

90

Net plant

primary

production

(photosynthesis)

61.4

1.2 Renewable energy

Renewable natural energy includes biomass, solar energy (photovoltaic power generation and solar thermal

electric power generation), geothermal energy, wind energy, wave energy, tidal energy, ocean thermal energy and

hydraulic energy.

Biomass is the only one of these energy types that is

composed of organic substances. From the viewpoint of

power generation, this means that the existing power generation systems developed for fossil fuels can also be used

for biomass fuel.

Ocean surface

layer

1020

Fig.1

5.5

Biomass electric

power generation

Respiration

Decay

Decomposition

60

Fixation to

soils and

rocks

0.5

Earths total surface

Plants

Soils and rocks

2190

610

1580

Release by

forest destruction

and other

causes

1.6

Consumption

of fossil fuels

Cement production

Carbon flow on the earths surface layer

Carbon on the earth surface lays in three zones: the atmosphere, ground and ocean. Carbon flows in the system

encompassing these three zones interact with each other,

each having functions of both absorption and release. In

effect, the overall function of the system is to keep the at-

29

NKK TECHNICAL REVIEW No.85 (2001)

Biomass Power Generation by CFB Boiler

second IPCC2) report. The estimate forecasts that the total

primary energy consumption by industrialized countries

over the next 100 years will stay virtually unchanged,

while that by developing countries will increase sharply.

On the other hand, the consumption of the fossil energy

will decrease in both industrial and developing countries,

while that of renewable energy, notably biomass, will increase.

Cultivation of biomass for harvesting energy could compete with agricultural production of food and feeds, as well

as industrial use of fibers and wood. To avoid such

competition, biomass could be used in a cascaded fashion

covering various uses that include fuel, instead of using

biomass exclusively for fuel. Some good examples are

given below.

(1) Waste paper made from plants should be recycled back

to paper several times before finally being used as fuel.

(2) Wood-derived wastes should be cut into chips. The

better quality will be used for making paper or plywood,

and the poor processed into fuels.

There is a guidelines for thermal recycling of waste paper, as well as for material recycling (recycled paper)3).

The papermaking industry has initiated thermal recycling

of waste paper4). For industrialized countries, including

Japan, the use of waste biomass for power generation is

the most practical and desirable way of using biomass as

an energy source.

mospheric carbon dioxide concentration within a certain

level. Combustion of fossil fuel, by contrast, releases carbon that was stored underground and to the cycle. This

represents an irreversible flow of carbon to the atmosphere

and should be regarded as a disturbance to the balance of

global circulation of carbon.

The consumption of biomass can never exceed the

production. Moreover, the concept of renewability

assumes that there will be reproduction corresponding to

the amount consumed. The liberation of carbon dioxide by

the combustion of biomass is an element of the carbon

cycle between the atmosphere and plants and is not a

disturbance that could disrupt the balance of the system.

Hence, biomass is considered to be an effective fuel for

the following two reasons:

(1) The carbon dioxide generated as a result of combustion

constitutes one of the elements of the carbon cycle between the atmosphere and the plant kingdom and therefore

does not affect the atmospheric carbon dioxide concentration.

(2) The use of biomass as fuel helps reduce consumption

of fossil fuel, thereby reducing disturbances to the carbon

cycle.

1.4 Concept of biomass power generation

Biomass is one of the most promising sources of renewable energy. Fig.2 shows an estimate of the future

primary energy supply by source, as excerpted from the

800

Hydrogen originating from solar energy

Intermittently available renewable energy

Biomass

Hydro power/geothermal power

Nuclear power

Natural gas

Petroleum

Coal

700

500

Renewable energy

Unit: 1016 Joules per year

600

400

300

200

Fossil fuel

100

0

1990

2025

2050

2075

World total

Fig.2

2100

1990

2025

2050

2075

Industrialized countries

2100

1990

2025

2050

Developing countries

Primary energy supply forecast for biomass promotion case (source: IPCC 1995 report)

NKK TECHNICAL REVIEW No.85 (2001)

30

2075

2100

Biomass Power Generation by CFB Boiler

the combustion efficiency (reduction of heat loss due to

incomplete combustion) and implementing low excess air

combustion (reduction of excess air ratio). The application

of these measures depends largely on the fuel properties

and combustion system.

The technology developed for traditional thermal power

generation, such as rising temperature and pressure to

higher level, shall be used to improve the steam cycle efficiency. However, the minimum size of a steam power

generation is considered to be 10 MW in terms of economical viability.

Efficiency will also be evaluated on whole system including pretreatment process. If the fuel requires pretreatment, such as a gasification or liquefaction, the energy

consumed through such process should be counted as an

energy loss. Accordingly, if biomass can be utilized directly, the use of biomass would have higher advantage in

overall efficiency than that of fuels that require gasification or liquefaction process.

Biomass power generation, problems and

countermeasures

2.1 Biomass power generation problems

2.

The followings are prospective biomass fuel.

(1) Waste building materials

Wood-derived wastes with inadequate quality for recycling as raw materials for plywood or papermaking.

(2) Miscellaneous waste paper

Paper having problems with too poor quality to be recycled as paper.

(3) Paper sludge

Organic wastes produced in paper making processes.

(4) Agricultural wastes

Rice husks, straws, bagasse (residue of sugar cane), oil

palm bunch (residue of palm oil manufacturing process).

These biomass fuels have the following problems compared to fossil fuels.

(1) Quality is unstable, and water contents are high.

(2) Production is thinly widespread, limiting large-scale

consumption. This is particularly true with agricultural

waste.

(3) Availability varies in seasons.

(4) Agricultural wastes are commonly burned in the open

or in simple incinerators that deteriorate the surrounding

environment.

2.2.4

Features of circulating fluidized bed combustion

Table 1 compares various combustion systems, and

Fig. 3 shows their interrelationships.

The circulating fluidized bed combustion system enables the fuel particles to be fluidized the combustion air.

This combustion system is characterized by quick fluidization and installation of the duct at the outlet of the flue gas

to collect particles. This combustion system has the following advantages compared to other combustion systems.

(1) Wide applicability of fuels

The combustion time is comparatively long for the incineration in the entire area and also for the recirculation.

This feature improves the combustion efficiency and

makes this system applicable to a wide range of fuels as

well as mixture combustion. In addition, particles circulating in the furnace retain sufficient heat to dry even fuel

with high moisture content. Thus such fuel can be utilized

without preliminary drying.

(2) Limited impact for environment

Feeding limestone to the furnace provides desulfurization. Also multi-stage air injection, along with the lower

combustion temperatures of 850 to 950, makes low

level of NOx emission.

(3) Low-excess-air combustion

As high-speed fluidizing flow is applied, the relative

velocity of particle speed and air molecule speed will be

great, and is promoting gas-solid reactions. This enables

the excess air ratio to be set at a low level.

2.2 Conditions for power generation facilities

All biomass power generation must clear the following

conditions.

2.2.1 Stable supply

Stable power supply is vital for power plant. Multi fuel

combustion contributes to stable power generation, especially because the availability of biomass is seasonally unstable.

2.2.2 Reduction of impact for the environment

A great deal of reduction of carbon dioxide, nitrogen

oxides and sulfur oxides emission has to be expected.

2.2.3 High efficiency

The gross thermal efficiency (ratio of the electric power

output to the input fuel energy) should be maximized. In

the case of steam power generation using a boiler and a

steam turbine generator, the efficiency of power generation depends on both the boiler efficiency and the steam

cycle efficiency. The former is the ratio of the effective

thermal output of the steam to the calorific values of the

input fuel, while the latter is the ratio of the electric power

output to the effective thermal output of the steam.

Boiler efficiency is generally improved by increasing

31

NKK TECHNICAL REVIEW No.85 (2001)

Biomass Power Generation by CFB Boiler

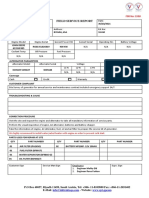

Table 1

Combustion system

Stoker combustion

Comparison of various solid combustion schemes

BFB (Bubbling fluidized bed)

CFB (Circulating fluidized bed)

Burner combustion

Mechanism of combustion

Flow of solid fuel

Transported on stoker

Fluidized by combustion air

in a layer of the bed material

Fluidized by combustion air

and circulated through

the combustion chamber and cyclone

Moving in association

with the combustion air

Combustion zone

On the stoker

Within and on the surface

of the bed material

Entire area

of the combustion furnace

Entire area

of the combustion furnace

Slow

Limited within

the concentrated zone

Active vertical movement,

and associated with heat transfer

Limited to

the direction of gas flow

Slow response

Medium response

Quick response

Quick response

Difficult

Possible

Possible

Possible

Fair

High

High

Limited

Generally not necessary

Generally not necessary

Lumps must be crushed

Fine crushing necessary

Mass transfer

in the combustion chamber

Controllability of combustion

Low excess air combustion

Fuel

Applicability to various fuels

Fuel pretreatment

Environmental load

Low SOx combustion

In-furnace desulfurization

not possible

Poor in-furnace desulfurization

High rate of in-furnace

desulfurization

In-furnace desulfurization

not possible

Low NOx combustion

Difficult

Not compatible

with in-furnace desulfurization

Compatible with in-furnace

desulfurization

Low NOx burners

available (limited applicability)

Others

Appropriate facility size

Small

Fig.3

NKK TECHNICAL REVIEW No.85 (2001)

Small to medium

Medium to large

Combustion gas velocity for various solid combustion schemes

32

Large

Biomass Power Generation by CFB Boiler

(4) High equipment economics

As the environmental impact of this system is low, no

special exhaust gas treatment facility is required. This results in a simpler configuration of the facilities, which, in

turn, reduces the initial investment. This effect is particularly eminent in medium-scale power plants.

These advantages of the system contribute to the solution of problems unique to biomass power generation.

Amount utilized for construction work

To recycling Recycling 36%

Material 39% facilities

facilities

246

from

production sites

632

60%

To terminal

disposal sites

377

Amount

terminally

disposed of

387

2.2.5

Biomass combustion by CFB for power

generation

Gasification and liquefaction fuel conversion technologies have been proposed for effective biomass utilization.

These technologies are, however, all in the developmental

stage.

The relations of the problems unique to biomass, the

requirements for power generation, and the features of

CFB combustion is summarized in Fig.4. This figure

shows that CFB boilers system is the most effective

method for biomass power generation.

3.

Amount reused after treatment

at recycling facilities 225

1%

2%

Used as fuel chips

Amount reduced

11

Amount terminally disposed of after treatment

by recycling facilities

10

Unit : 10000 tons

Fig.5

Volume and distribution of waste building materials

Building material waste fed to recycling facilities are first

crushed and compacted. Higher quality chips are recycled as

raw material for making plywood or paper. Low quality

chips are also created. At present, the amount processed by

recycling facilities is limited because the system of such recycled product is not sufficiently established. In other words,

the limited demand for low-quality chips is a constraint on

the recycling of building material waste as a whole.

If the use of these low-quality chips for fuel is disseminated, the recycling of waste building materials will be realized. Moreover, this application can accommodate the

larger amount of building material waste in the near future.

With this background, NKK developed a plan for a biomass power plant using CFB boiler to burn low-quality

wood chips, and has also presented this plan to various

parties concerned.

Example of biomass power generation plan

An example of a biomass power generation plan is presented below.

In Japan, the volume of building material waste is assumed to increase as the numbers of private houses rebuilt

increases. The Ministry of Construction reported that 6.32

million tons of building material waste was generated in

fiscal 20005). This number is expected to increase four-fold

by fiscal 20106). Fig.5 shows the volume and distribution

of building material waste.

Requirements by power

generation business

Features of CFB boiler

Problems with biomass

1%

Wide applicability

Seasonal fluctuations of availability

Suitable for burning mixtures of various fuels

Wide variation of properties

High adaptability to fuel property fluctuations

Stable supply

High fuel drying ability

High efficiency combustion

High thermal efficiency

High moisture content

High efficiency

Low excess air combustion

Suited for distributed medium-scale power generation

Thinly distributed production

Combustion with low environmental load

Frequently burned in open and simple

incinerators

Fig.4

Low SOx combustion

Low NOx combustion

Low environmental load

Biomass power generation problems and countermeasures

33

NKK TECHNICAL REVIEW No.85 (2001)

Biomass Power Generation by CFB Boiler

As a result of this effort, the Japan Wood Preserving

Society awarded NKK, jointly with NKKs affiliate in

Osaka, a project entitled Development of Appropriate

Recovery and Treatment System by Recycling and Combustion of Wood-based Wastes Including Wood Treated

for Preservation. In this project, NKK participated in a

feasibility study for a thermal power generation project

using wood-based wastes. Table 2 introduces an outline of

this study7).

References

1) Environment Agency. Quality of Environment in Japan 1997. Printing Bureau. Ministry of Finance. p.477 (1997).

2) Kumasaki, M. Role of Bioenergy in a Society Based on Sustainable

Resource Use. JAPAN TAPPI JOURNAL. Vol. 154, No. 11, pp.69

74 (2000).

3) Ministry of International Trade and Industry. Technical Guideline for

Facilities for Thermal Recycling of Paper Containers and Packages.

Tokyo,

NTT

DATA

INSTITUTE

OF

MANAGEMENT

CONSULTING INC, p.23 (1999).

Table 2

Outline of the thermal power station using

4) Noma, T. Significance of Waste Paper Thermal Recycling in Paper

wood-based wastes

Amount of waste

building materials recycled

and Pulp Industry. JAPAN TAPPI JOURNAL. Vol. 53, No. 1, pp.83

Total

Power generation

130 thousand tons/year

Environmental

impact

Combustion system

Power generation efficiency

(generating terminal)

Capacity

141 GWh/year

Reduction in carbon dioxide

emission

Resource saving

(Diesel fuel equivalent)

5) Construction Byproducts Recycling PR and Promotion Council.

20 MW

Electric power sold to the grid

Power generation

facility

91 (1999).

180 thousand tons/year

CFB

Comprehensive Construction Byproducts Measures. Tokyo, Ad-

31%

vanced Construction Technology Center, p.47 (1999).

56.6 thousand

tons/year

37.2 thousand kiloliters/year

6) Council for Study of Measures for Demolition Debris. Promotion

Conference for Reporting and PR of the Study Committee for Demolition and Recycling System. Tokyo, Taisei Publishing Co., Ltd.,

p.162 (1998).

7) Japan Wood Preserving Association. Development of Appropriate

4.

Conclusion

Recovery and Treatment System by Recycling and Combustion of

The use of plant-derived biomass as fuel will be expected as one of the most important primary energy

sources for reducing carbon dioxide emissions and conserving fossil fuel resources. The effective utilization of

waste paper, waste building materials, and such biomass

wastes as agricultural wastes are particularly important.

CFB boilers have many advantages including wide

adaptability of fuels, low environmental impact, and ideal

methods for direct combustion of biomass. CFB biomass is

an effective measure for the dissemination of utilization of

biomass energy.

NKK is confident to see the bright future of CFB biomass power plant.

NKK TECHNICAL REVIEW No.85 (2001)

Wood-based Wastes Including Wood Treated for Preservation. 2001.

<Please refer to>

Koji Yamamoto

Solution Engineering Center

Tel. 045 (510) 4700

E-mail address : Yamamokr@nkp.tsurumi.nkk.co.jp

34

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- F125-1 Wiring Diagram.Document1 pageF125-1 Wiring Diagram.Captive Power100% (1)

- TU 515R - Technical Specification - DocxDocument24 pagesTU 515R - Technical Specification - Docxpreecha limNo ratings yet

- Kunak Jaya - Final - 14 - 4 - 08Document108 pagesKunak Jaya - Final - 14 - 4 - 08preecha limNo ratings yet

- Armcon EngineeringDocument20 pagesArmcon Engineeringpreecha limNo ratings yet

- Haapanen - 120905-MWH Wood PDFDocument30 pagesHaapanen - 120905-MWH Wood PDFpreecha limNo ratings yet

- Processing Characteristics, PhysicalDocument48 pagesProcessing Characteristics, Physicalpreecha limNo ratings yet

- FMC FmcmetidmhsmetricbrochureDocument6 pagesFMC FmcmetidmhsmetricbrochureSrini KumarNo ratings yet

- I Et (Sy) 221111034123Document5 pagesI Et (Sy) 221111034123rakesh_pal_3No ratings yet

- System Loss Process and ResultsDocument42 pagesSystem Loss Process and ResultsAlvin Garcia PalancaNo ratings yet

- Nuclear Engineering and Design 342 (2019) 10-19Document10 pagesNuclear Engineering and Design 342 (2019) 10-19viveksingh061No ratings yet

- Informe Mercado Electrico GlobalDocument368 pagesInforme Mercado Electrico GlobalHernan WaldbilligNo ratings yet

- Ans. Machines Are Result of Human Beings Innovative Mind That Helped Them To Reduce TheirDocument2 pagesAns. Machines Are Result of Human Beings Innovative Mind That Helped Them To Reduce TheirANAS NOORNo ratings yet

- Wind Turbine Power PlantDocument8 pagesWind Turbine Power PlantShailesh SankdasariyaNo ratings yet

- 1558-301021-National Care HospitalDocument1 page1558-301021-National Care HospitalRizwanNo ratings yet

- Proper Design ConsiderationsxDocument4 pagesProper Design ConsiderationsxLTE002No ratings yet

- Ficha Motores UMA 150Document2 pagesFicha Motores UMA 150frcarras11No ratings yet

- Piezoelectric GeneratorDocument42 pagesPiezoelectric GeneratorSean RamosoNo ratings yet

- Sources of Radiant EnergyDocument1 pageSources of Radiant EnergyRjvm Net Ca Fe100% (1)

- NTPC Report FinalDocument165 pagesNTPC Report FinalShankar ChowdhuryNo ratings yet

- Project Owner Contractor Inspection Surveillance Report (Isr)Document20 pagesProject Owner Contractor Inspection Surveillance Report (Isr)destri_742053763No ratings yet

- ĐỀ SỐ 4Document7 pagesĐỀ SỐ 4Thảo NguyênNo ratings yet

- Case Study of Micro Hydro Power Plant PDFDocument79 pagesCase Study of Micro Hydro Power Plant PDFMuhammad Ali100% (1)

- CHEM2122 General Chemistry Week 11 - 19 by Querubin Cabalida GR12Document14 pagesCHEM2122 General Chemistry Week 11 - 19 by Querubin Cabalida GR12Cesar TuñacaoNo ratings yet

- Enersys DataSafe HX 12V Telecom Battery Range SummaryDocument2 pagesEnersys DataSafe HX 12V Telecom Battery Range Summaryingchester24No ratings yet

- CEER Benchmarking Report ON THE QUALITY OF ELECTRICITY SUPPLY 2011Document260 pagesCEER Benchmarking Report ON THE QUALITY OF ELECTRICITY SUPPLY 2011mhpourarab4129No ratings yet

- Boost ProjectDocument13 pagesBoost ProjectAbdur RahmanNo ratings yet

- Jaguar I-Pace Price and Specifications - EV DatabaseDocument8 pagesJaguar I-Pace Price and Specifications - EV DatabaseGheorghe OlarescuNo ratings yet

- Gas Insulated Transmission Lines GILDocument2 pagesGas Insulated Transmission Lines GILممشط100% (1)

- Catalogo Thompson MOTORESDocument23 pagesCatalogo Thompson MOTORESJulio VolcanNo ratings yet

- DCG 146013 PDFDocument132 pagesDCG 146013 PDFMesseňger HệŢhốngNo ratings yet

- Environment Conservation and Hazard ManagementDocument3 pagesEnvironment Conservation and Hazard ManagementKID'S ENTERTAINMENTNo ratings yet

- 403A-15G2 ElectropaK PN2009Document2 pages403A-15G2 ElectropaK PN2009Md ShNo ratings yet

- Global Trends in Renewable EnergyDocument16 pagesGlobal Trends in Renewable EnergyGorakh Raj JoshiNo ratings yet

- Sunny Tripower 15000TL / 20000TL / 25000TLDocument4 pagesSunny Tripower 15000TL / 20000TL / 25000TLEng-gamal MahmoudNo ratings yet

- Bio-Energetic Devices - The Egely Wheel Vitality Meter by Gyorgy Egely, PDFDocument7 pagesBio-Energetic Devices - The Egely Wheel Vitality Meter by Gyorgy Egely, PDFEgely György0% (1)

- TNEI Transmission and Distribution Services Brochure B2Document4 pagesTNEI Transmission and Distribution Services Brochure B2royclhorNo ratings yet