Professional Documents

Culture Documents

General: Ipe and IPE Ittings

Uploaded by

Noushad P Hamsa0 ratings0% found this document useful (0 votes)

46 views5 pagesThis document provides guidelines for pipe, pipe fittings, and accessories for various types of piping systems. It specifies approved materials for above ground and underground piping for systems including drainage, ventilation, plumbing, hydronics, steam, and civil piping. Requirements are defined for pipe sizes, joint types, insulation, and accessories depending on the application and system. Professional judgment may be used to modify the guidelines as needed for each unique project.

Original Description:

hjk

Original Title

15060 1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides guidelines for pipe, pipe fittings, and accessories for various types of piping systems. It specifies approved materials for above ground and underground piping for systems including drainage, ventilation, plumbing, hydronics, steam, and civil piping. Requirements are defined for pipe sizes, joint types, insulation, and accessories depending on the application and system. Professional judgment may be used to modify the guidelines as needed for each unique project.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

46 views5 pagesGeneral: Ipe and IPE Ittings

Uploaded by

Noushad P HamsaThis document provides guidelines for pipe, pipe fittings, and accessories for various types of piping systems. It specifies approved materials for above ground and underground piping for systems including drainage, ventilation, plumbing, hydronics, steam, and civil piping. Requirements are defined for pipe sizes, joint types, insulation, and accessories depending on the application and system. Professional judgment may be used to modify the guidelines as needed for each unique project.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

15060

PIPE & PIPE FITTINGS

15060

APRIL, 1995 PAGE 1 OF 5

PIPE AND PIPE FITTINGS

General

In general, follow the guidelines below when designing and specifying pipe, pipe fittings, and

accessories. Unless specifically indicated otherwise, these guidelines are not intended to restrict or

replace professional judgment.

Related Sections

Refer to Tab 2 - Sitework for additional Civil requirements

Refer to Section 15250 - Mechanical Insulation for piping insulation requirements

General Pipe Material Requirements

Eccentric Fittings

Shall be used where piping sizes reduce on horizontal runs. Reducing fittings shall be couplings; no

bushing will be allowed.

Tees in Welded Pipe

Saddle and nipple type tees are permitted in welded pipe if made with Weld-O-Lets or Thread-O-

Lets and branch size does not exceed 1/2 the size of the main size. All branches in excess of 1/2 of

main size shall be made using welding tees.

Solder in Copper Piping Joints

Solder for all piping shall be lead-free. 50/50 solder is not permitted.

Dielectric Protection

Where dissimilar piping materials (steel and copper) are connected, install a threaded brass nipple

for pipe sizes 2 and less. For sizes 2 1/2 and above, install isolating flanges. Do not use dielectric

unions.

Flanges

Shall be standard weight forged steel, welding neck, 150 pound A.S.A. Flanges shall have raised

or flat face as required to match valve or equipment face.

Unions

15060

PIPE & PIPE FITTINGS

15060

PAGE 2 OF 5 APRIL, 1995

Generally, unions shall be malleable iron, ground joint type, 300 pound test. Unions in galvanized

piping systems shall be galvanized. Unions in copper piping systems shall be wrought copper or

brass sweat ends.

Watertight Sleeves

Where underground piping penetrates foundation walls, provide steel sleeve with water tight seal.

A/E shall locate wall penetrations on construction documents.

Fire Protection Pipe Material Requirements

Refer to Section 15300 - Fire Protection

Drainage and Vent Pipe Material Requirements

Storm and Non-Laboratory Waste and Vent Piping

(Including toilet rooms and custodial closets)

Above ground piping shall be service weight "No-Hub" cast iron pipe with drainage pattern cast

iron fittings, and with heavy duty stainless steel clamps. Vent piping shall be the same as waste

piping.

Underground piping shall be extra heavy weight bell and spigot or no-hub cast iron with drainage

pattern cast iron fittings All clamps for no-hub piping shall be stainless steel.

Refer to Tab 2 - Sitework for underground drainage tile piping.

Laboratory Sanitary Waste and Vent Piping

(Excluding toilet rooms and custodial closets)

Above ground piping shall be corrosion resistant polypropylene Schedule 40. Joints shall be

mechanical type. Glass piping may be considered on a case-by-case basis, especially where high

temperature waste may be present. All sink P-traps shall be of the same material as the waste pipe.

Underground piping shall be corrosion resistant polypropylene Schedule 80. Joints shall be

mechanical type. High silicon cast iron may be considered if the application warrants the added

expense. Piping shall be considered on a case-by-case basis where high temperature waste may be

present.

Equipment Drains

Shall be Type "L" hard drawn copper piping with wrought copper solder DWV type fittings.

Pressurized Plumbing Pipe Material Requirements

Compressed Air and Natural Gas Piping (0 - 125 psig)

15060

PIPE & PIPE FITTINGS

15060

APRIL, 1995 PAGE 3 OF 5

Above ground piping shall be Schedule 40 ASTM A-120 black steel pipe with 150 pound screwed

malleable iron fittings and screwed 300 pound malleable iron unions up to 2 inch size. Above 2,

piping shall be schedule 40 black steel with welded fittings. Copper piping with soldered joints may

be used for branch compressed air piping 3/4 and smaller.

Distilled and Deionized Water Piping

Shall be PVC Schedule 80 and in accordance with ASTM D2467 (cement socket type connection

fittings) and ASTM D785 piping.

High purity - Shall be white-line polypropylene, Schedule 40, ASTM D2447 or thermoseal fusion

depending on application.

Domestic Hot and Cold Water Piping

Above ground piping shall be type "L" hard temper seamless copper, ASTM-88 for pipe sizes 4

and smaller. Piping over 4 shall be flanged galvanized steel with flanged galvanized steel fittings.

Underground piping shall be type K copper for pipe sizes 2 1/2 and smaller, and ductile iron for

pipe sizes 3 and above.

Nitrogen Piping

Shall be seamless copper, cleaned, ASTM B88 with silver solder joints. Use brazed joints using (B

Cup) filler metal, where required by NFPA 99.

Vacuum Piping

Shall be Type "L" hard drawn copper with wrought copper solder type fittings. Provide a plugged

cross at all turns greater than 45 degrees, slope in the direction of flow and provide hose end drain

valves at all low points for cleaning the system.

Hydronic and Steam Pipe Material Requirements

Chilled Water and Hot Water Heating Piping

Above ground piping shall be type L copper with wrought copper fittings for pipe sizes 4" and

smaller. Piping larger than 4" shall be Schedule 40 black steel with butt welded fittings. Flanged

connections may be used, standard weight with bolts and gaskets (similar to flanges on steam

piping).

Underground piping shall be installed using a preinsulated piping system. Carrier pipe shall be

Schedule 40 black steel with butt welded fittings. Jacket pipe shall be minimum 10 gauge steel, with

butt welded fittings, and a fiberglass reinforced urethane elastomer coating. Refer to section 15250

for insulation requirements.

15060

PIPE & PIPE FITTINGS

15060

PAGE 4 OF 5 APRIL, 1995

Condensate Piping

Above ground condensate piping shall be Schedule 80 black steel piping with extra heavy cast iron

or malleable iron fittings.

Underground condensate piping shall be schedule 80 black steel with extra heavy fittings in a

preinsulated system as described for underground chilled water and hot water heating piping.

Condensate piping shall not be run in common jacket pipe with other carrier pipes.

Condenser Water Piping

Above ground condenser water piping shall be Schedule 40 black steel, ASTM A-53. Fittings shall

be butt welded black steel ASTM A-284.

Underground condenser water shall be ductile iron.

Refrigeration Piping

Shall be type "L" hard temper seamless copper, ASTM B88, ACR cleaned.

Steam Piping

Above ground steam piping up to 125 psig shall be Schedule 40 black steel pipe with 125 pound

screwed cast iron fittings up to 2 inch size and 125 pound black steel welded fittings for 2-1/2 inch

size and larger. Welding flanges shall be 150 pound forged steel. Flanged fittings shall be 125

pound cast iron. Screwed unions shall be 300 pound forged steel, ground joint brass to steel.

Underground steam piping up to 125 psig shall be Schedule 40 black steel with butt welded fittings,

in a preinsulated system as described for underground chilled water and hot water heating piping.

Civil Pipe Material Requirements

Generally, underground piping 5 feet or more from building exterior walls is considered to be Civil

Piping. The following piping materials apply to Civil piping only, and may indicate that a change in

pipe material takes place at this point. Refer to Tab 2 - Sitework for additional requirements.

Storm Sewer

Shall be reinforced concrete pipe (RCP), ASTM C-76, Class IV, with rubber gasketed joints,

ASTM C-443, or High Density Polyethylene with rubber gasketed joints. For small projects with

piping limited to 6 and 8, Schedule 80 PVC pipe may be used.

Sanitary Sewer

15060

PIPE & PIPE FITTINGS

15060

APRIL, 1995 PAGE 5 OF 5

Shall be extra strength vitrified clay pipe (VCP) with O-ring joints. Sewers 15 and larger shall be

reinforced concrete pipe (RCP), ASTM C-76, Class IV, with rubber gasketed joints, ASTM C-

443

City Water Mains (for domestic water and fire protection)

Shall be Ductile Iron Class 52 with Polyethylene wrap.

Under Drainage Tubing

Shall be corrugated polyethylene tubing (AASHTO M 252) or corrugated polyvinylchloride tubing

(ASTM F 800, with holes conforming to (AASHTO M 252)

Lawn Sprinkler Piping

Coordinate irrigation system design (including sizing water main, backflow preventer, and water

meter) and installation with the University Landscape Architects Office and the UM Plumbing shop,

via the University Project Coordinator.

01/26/00 11:34 AM

You might also like

- IEEE STD 3001.2 - 2017: Power Systems DesignDocument76 pagesIEEE STD 3001.2 - 2017: Power Systems DesignAldrin100% (3)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Backplane White Paper OpenVPXDocument11 pagesBackplane White Paper OpenVPXnusha a100% (1)

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- MechanicalDocument173 pagesMechanicalKerx EndranoNo ratings yet

- Chilled Water Pipe SizingDocument2 pagesChilled Water Pipe SizingLarry Bea77% (13)

- Pipe PresentationDocument68 pagesPipe PresentationOk OhNo ratings yet

- Fuel Consumption ParametersDocument8 pagesFuel Consumption ParametersdanutspataruNo ratings yet

- 15-1-6 - Chilled Water Piping SystemDocument10 pages15-1-6 - Chilled Water Piping Systemfarshan296015No ratings yet

- Design Calculations MalidduwaDocument72 pagesDesign Calculations MalidduwaUmesg100% (1)

- Hanger & Support - SpecificationDocument6 pagesHanger & Support - SpecificationParwez KhanNo ratings yet

- Plumbing Material Drainage Pipes: Horizontal Asbestos Cement PipeDocument9 pagesPlumbing Material Drainage Pipes: Horizontal Asbestos Cement PipeKevinNavidad100% (2)

- Piping Systems and AccessoriesDocument16 pagesPiping Systems and AccessoriesYoussef100% (1)

- Astm f1155 1998Document25 pagesAstm f1155 1998nerissaloveNo ratings yet

- Fire Fighting Specs - 20181228155441Document25 pagesFire Fighting Specs - 20181228155441Sudipto KumarNo ratings yet

- Construction Materials E-BookDocument98 pagesConstruction Materials E-BookNoushad P Hamsa100% (1)

- Steel Water Pipe Specs 06Document7 pagesSteel Water Pipe Specs 06Astri NgentNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

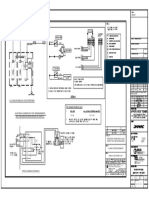

- 003-Ansul R-102 System P & I D-P&IDDocument1 page003-Ansul R-102 System P & I D-P&IDNoushad P HamsaNo ratings yet

- 23 22 00 - Steam and Condensate Piping and PumpsDocument6 pages23 22 00 - Steam and Condensate Piping and PumpsDiana SoareNo ratings yet

- SF - Domestic Water PipingDocument16 pagesSF - Domestic Water PipingJahat AtencioNo ratings yet

- Blacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithFrom EverandBlacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithNo ratings yet

- 15-23 MEP GuidelinesDocument9 pages15-23 MEP GuidelinesChandrakant Tiwari100% (1)

- 5026-PS-001 - 0 Supply of Piping MaterialsDocument17 pages5026-PS-001 - 0 Supply of Piping MaterialsCARLOS OLIVEROSNo ratings yet

- Cement-Mortar Lined & Coated Steel PipeDocument5 pagesCement-Mortar Lined & Coated Steel Pipenay denNo ratings yet

- 11/20/2018 /conversion/tmp/scratch/402494814Document13 pages11/20/2018 /conversion/tmp/scratch/402494814Anonymous NR3qZ30No ratings yet

- 10.00 Heinrich Höse, Aumund Fördertechnik GMBHDocument25 pages10.00 Heinrich Höse, Aumund Fördertechnik GMBHMohd Ali100% (1)

- Division 15 - Mechanical 15000 - Basic Mechanical RequirementsDocument24 pagesDivision 15 - Mechanical 15000 - Basic Mechanical RequirementsNagiahTNo ratings yet

- 15510Document13 pages15510uddinnadeemNo ratings yet

- 15510Document13 pages15510mahaboobptmNo ratings yet

- 15060S02-Pipe and Pipe-Fitting ScheduleDocument5 pages15060S02-Pipe and Pipe-Fitting ScheduleNoushad P HamsaNo ratings yet

- Pipe and Pipe FittingsDocument21 pagesPipe and Pipe FittingsAdamNo ratings yet

- 1/27/2019 /conversion/tmp/scratch/407716113Document10 pages1/27/2019 /conversion/tmp/scratch/407716113Maki DizonNo ratings yet

- Section 15100 - Valves, Pipe Fittings, and Piping: Part 1 - General 1.1 Related Sections: 1.2 Scope of SectionDocument5 pagesSection 15100 - Valves, Pipe Fittings, and Piping: Part 1 - General 1.1 Related Sections: 1.2 Scope of SectionAamir Abdul RahmanNo ratings yet

- Syabas Guideline Ss Pipe and Water Meter StandDocument5 pagesSyabas Guideline Ss Pipe and Water Meter StandAhmad Faiz At-TamimiNo ratings yet

- Plumbing SpecificationsDocument38 pagesPlumbing SpecificationsAbdulaziz Al-FarsiNo ratings yet

- 12/1/2021 /conversion/tmp/activity - Task - Scratch/561025520Document10 pages12/1/2021 /conversion/tmp/activity - Task - Scratch/561025520htanhNo ratings yet

- Section 15100 - Valves, Pipe Fittings, and Piping: Part 1 - General 1.1 Related Sections: 1.2 Scope of SectionDocument11 pagesSection 15100 - Valves, Pipe Fittings, and Piping: Part 1 - General 1.1 Related Sections: 1.2 Scope of SectionNoushad P HamsaNo ratings yet

- Section 605 Materials, Joints and ConnectionsDocument10 pagesSection 605 Materials, Joints and ConnectionsMuhammadIqbalMughalNo ratings yet

- Specification For Support and HangerDocument6 pagesSpecification For Support and Hangerdee1985No ratings yet

- Basic Piping Material and MethodsDocument7 pagesBasic Piping Material and MethodsArdy PrasetyoNo ratings yet

- 22 10 00 - Plumbing Piping and Pumps: Design & Construction Standards, Revised January2014 22.10.00-1Document8 pages22 10 00 - Plumbing Piping and Pumps: Design & Construction Standards, Revised January2014 22.10.00-1Teguh SetionoNo ratings yet

- Mimimum SizesDocument2 pagesMimimum SizesRomeo Dequito JrNo ratings yet

- Csi 2018 Mechanical Division 15Document303 pagesCsi 2018 Mechanical Division 15Taner Demirezen100% (1)

- STD 15080Document4 pagesSTD 15080dineshinnaci123No ratings yet

- Astm f1155 1998Document25 pagesAstm f1155 1998ttplan800No ratings yet

- Awwa C200 PDFDocument6 pagesAwwa C200 PDFangel darioNo ratings yet

- HVACPipingandPumps 03Document1 pageHVACPipingandPumps 03Ficry JabeerNo ratings yet

- PipingDocument7 pagesPipingAshar HassanNo ratings yet

- SECTION 15100 ValvesDocument10 pagesSECTION 15100 ValvesintequabNo ratings yet

- Underground Chilled Water System August 132014Document12 pagesUnderground Chilled Water System August 132014umair186No ratings yet

- Dartmouth College Design January 3, 2012 & Construction GuidelinesDocument6 pagesDartmouth College Design January 3, 2012 & Construction GuidelinesSalman AkramNo ratings yet

- 23 - 05 - 29 - Hangers and Support For HVAC Piping and EquipmentDocument8 pages23 - 05 - 29 - Hangers and Support For HVAC Piping and EquipmentVo Kien CuongNo ratings yet

- Copper Tube Federal and Astm SpecificationsDocument4 pagesCopper Tube Federal and Astm SpecificationsSai PrasathNo ratings yet

- 00 AWWA StandardsDocument3 pages00 AWWA Standardsliviu_dovaNo ratings yet

- Hvac PipingDocument6 pagesHvac PipingSkylarNo ratings yet

- Chilled Water Pipe Sizing Study PDFDocument34 pagesChilled Water Pipe Sizing Study PDFNajam24No ratings yet

- Lesson 2 - Plumbing Pipes and FittingsDocument39 pagesLesson 2 - Plumbing Pipes and FittingsNicholas Bonn SingNo ratings yet

- 23 05 29 - HVAC Hangers and SupportsDocument9 pages23 05 29 - HVAC Hangers and SupportsperezismaelNo ratings yet

- Ductile Iron CastingsDocument6 pagesDuctile Iron CastingsSusan Sue Berrospi MerinoNo ratings yet

- Sewer Pipes and FittingsDocument8 pagesSewer Pipes and FittingsMaan Valencia - RevillaNo ratings yet

- Features Flanged DIP and Fittings4Document4 pagesFeatures Flanged DIP and Fittings4Sohail HanifNo ratings yet

- Section 221116 - Domestic Water Piping-PexDocument16 pagesSection 221116 - Domestic Water Piping-PexChase GietterNo ratings yet

- AC 140 HangerSupportDocument4 pagesAC 140 HangerSupportjames_chan2178No ratings yet

- Technical Catalouge PDFDocument41 pagesTechnical Catalouge PDFDhanish KumarNo ratings yet

- Valves For Steam ServiceDocument17 pagesValves For Steam ServiceqaiserNo ratings yet

- SECTION 15060 Hangers and Supports General 1.1Document8 pagesSECTION 15060 Hangers and Supports General 1.1fatREVITNo ratings yet

- RWV Balancing Valve TrainingDocument33 pagesRWV Balancing Valve TrainingNoushad P HamsaNo ratings yet

- KX SeriesDocument24 pagesKX SeriesNoushad P HamsaNo ratings yet

- Energy Planning A Guide To PractitionersDocument75 pagesEnergy Planning A Guide To PractitionersNoushad P HamsaNo ratings yet

- A Guide To Air FiltrationDocument50 pagesA Guide To Air FiltrationNoushad P HamsaNo ratings yet

- Copper Tube DesignDocument34 pagesCopper Tube DesignNoushad P HamsaNo ratings yet

- Energy Planning A Guide To PractitionersDocument75 pagesEnergy Planning A Guide To PractitionersNoushad P HamsaNo ratings yet

- Ventilation Systems Equal Friction Method Date ProjectDocument2 pagesVentilation Systems Equal Friction Method Date ProjectNoushad P HamsaNo ratings yet

- Mechanical Draft Cooling TowerDocument6 pagesMechanical Draft Cooling TowerNoushad P HamsaNo ratings yet

- Bic Sodio Tongbai Malan MSDSDocument7 pagesBic Sodio Tongbai Malan MSDSFIORELLA VANESSA MAITA MUCHANo ratings yet

- CHAPTER 1 Basic Concepts in Audit Sampling PDFDocument10 pagesCHAPTER 1 Basic Concepts in Audit Sampling PDFJovelle LeonardoNo ratings yet

- VSphere Troubleshooting and TricksDocument46 pagesVSphere Troubleshooting and TricksManoj KumarNo ratings yet

- Batch Adsorption Process of Metals and Anions For Remediation ofDocument331 pagesBatch Adsorption Process of Metals and Anions For Remediation ofCesar Orlando Villalobos HipolitoNo ratings yet

- Uvm Test TerminationDocument24 pagesUvm Test TerminationRajesh NandiNo ratings yet

- SKF BSD 2047 CGA - VT105 SpecificationDocument4 pagesSKF BSD 2047 CGA - VT105 Specificationugucua.01No ratings yet

- Digital Technology Revives ..Document6 pagesDigital Technology Revives ..Chien C TschangNo ratings yet

- Pro Net On Amazon Web Services Guidance and Best Practices For Building and Deployment 1St Edition William Penberthy 2 Full Download ChapterDocument52 pagesPro Net On Amazon Web Services Guidance and Best Practices For Building and Deployment 1St Edition William Penberthy 2 Full Download Chapterraymond.fryar721100% (19)

- Helzberg's Diamond Shops Inc V Valley West Des Moines Shopping Center Inc. 2012)Document10 pagesHelzberg's Diamond Shops Inc V Valley West Des Moines Shopping Center Inc. 2012)GenUp SportsNo ratings yet

- Between The Wars - Global CrisisDocument3 pagesBetween The Wars - Global CrisisShivani RameshNo ratings yet

- Consumer EducationDocument24 pagesConsumer EducationAnthonatte Castillo SambalodNo ratings yet

- International Sport Events DebateDocument2 pagesInternational Sport Events DebateHương LyNo ratings yet

- Shell Energy Transition Strategy 2024Document33 pagesShell Energy Transition Strategy 2024Antoine lazarus MaomyNo ratings yet

- Lesson 6 Similarities KNNDocument25 pagesLesson 6 Similarities KNNDyuti IslamNo ratings yet

- Export AssistanceDocument15 pagesExport AssistanceGaurav AgrawalNo ratings yet

- Office of The Registrar: Class List - First Semester Sy 2021-2022Document1 pageOffice of The Registrar: Class List - First Semester Sy 2021-2022Greggy LawNo ratings yet

- Module 7Document76 pagesModule 7Solaiman III SaripNo ratings yet

- Soal Soal Bahasa InggrisDocument14 pagesSoal Soal Bahasa Inggrisnur hidayahNo ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document1 pageIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)shah mananNo ratings yet

- Acs JPCC 5b06515Document20 pagesAcs JPCC 5b06515hemedi kitilaNo ratings yet

- 56 Vosniakos KaryotisDocument6 pages56 Vosniakos Karyotiskamal aldeemNo ratings yet

- Migracion WAS8Document472 pagesMigracion WAS8ikronos0No ratings yet

- Data BaseDocument8 pagesData BaseoolalaiNo ratings yet

- Lec6w Processintegration Ee143 CTNDocument15 pagesLec6w Processintegration Ee143 CTNstansilawNo ratings yet