Professional Documents

Culture Documents

The Facility Files 11 12

Uploaded by

sajuhereOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Facility Files 11 12

Uploaded by

sajuhereCopyright:

Available Formats

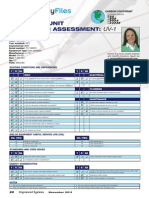

22 Engi neer ed Syst ems November 2012

BY AMANDA MCKEW

Date: November 2012

Building: Pharmaceutical or health care facility

Floor: Special procedure floor

Year installed: 1998

Inspected by: AEM

Serial number: 1110101028

Equipment Type: VAV with hot water reheat

Manufacturer: X-Y-Z

Model: VAVRH-1 through VAVRH 20

Size: 1,500 cfm

EXISTING CONDITIONS AND DEFICIENCIES

STANDARDS AND CODE ISSUES

ENERGY CONSERVATION

NOTES

TheFacilityFiles

Y N NA Y N NA

Does unit meet current codes?

Does unit/system meet current energy code?

Is emergency power a requirement for AHU and the space served by

the VAVRH?

Y N NA Y N NA

Maintain space pressure while fine tuning supply air temperature.

Provide balancer to verify air and water design flows and pressures

are at optimum setting/performance.

Consider adding flow measuring stations on the AHU supply and

return/exhaust air system.

Consider an unoccupied cycle to reduce air changes while maintain-

ing space pressure, temperature control, and humidity control.

Consider adding VFDs to the AHU supply and return fans.

Y N NA Y N NA

1. Unit basically operates 24/7 year-round.

3. Are there energy meters (gpm, etc.)?

2. Are unit controls interactive with building ATC/computer?

McKew is a senior project engineer

with InterPro Solutions. Reach her

at amckew@interprosoft.com.

CARBON FOOTPRINT

Carbon Neutral

Y N NA Y N NA

HVAC

Is there access around equipment?

Is the primary inlet duct installed without obstruction/restriction?

Is there any excess vibration at the unit?

Is the VAVRH damper in good condition and is operator functional?

Is the unit installed with isolators and seismic hangers?

Is the exterior enclosure in good condition?

Overall, does the unit have any air or water leaks?

Is the unit discharge configuration acceptable?

Do all ATC devices appear in good condition?

Does the heating coil appear in good condition? ELECTRICAL

Is the duct insulation installation complete and in good condition?

Are the electrical connections complete (if electric controls)?

Air terminal and piping labeled with applicable tag and flow arrows? MAINTENANCE

Are the flow sensors installed and monitoring flow?

System flow diagram mounted in an appropriate space for quick reference?

Are the temperature sensors installed and functioning?

O&M manual secured at unit or on file?

Is the ductwork installed per detail?

Workorder last completed?

Is the HW piping installed per detail?

Is there a service contract for the VAV boxes and/or associated ATC

devices?

END OF EQUIPMENT USEFUL SERVICE LIFE (USL)

USL (YRS) USL (YRS)

14 Unit is 14 years old 14 Controls USL benchmark 14 years

14 Controls are 14 years old 14 Unit USL benchmark is 14 years

AIR TERMINAL DEVICE

WITH REHEAT: VAVRH-1

You might also like

- The Facility Files 11 11Document1 pageThe Facility Files 11 11sajuhereNo ratings yet

- 28 The Facility Files 5 12Document1 page28 The Facility Files 5 12sajuhereNo ratings yet

- 1102 The Facility FilesDocument1 page1102 The Facility FilessajuhereNo ratings yet

- 1105 The Facility FilesDocument1 page1105 The Facility FilessajuhereNo ratings yet

- 1108 The Facility FilesDocument1 page1108 The Facility FilessajuhereNo ratings yet

- The Facility Files 8 12Document1 pageThe Facility Files 8 12sajuhereNo ratings yet

- TheFacilityFiles8 10Document1 pageTheFacilityFiles8 10sajuhereNo ratings yet

- The Files: FacilityDocument1 pageThe Files: FacilitysajuhereNo ratings yet

- The Files: FacilityDocument1 pageThe Files: FacilitysajuhereNo ratings yet

- Hotel Motel Dorm DBDocument1 pageHotel Motel Dorm DBsajuhereNo ratings yet

- 0807 HVACDesigner TipsDocument1 page0807 HVACDesigner TipspereramjpNo ratings yet

- The Facility Files 6 12Document1 pageThe Facility Files 6 12sajuhereNo ratings yet

- RTWB Iom E4 - 1003Document40 pagesRTWB Iom E4 - 1003nairam2003100% (1)

- VAV Fundamentals ASHRAEDocument24 pagesVAV Fundamentals ASHRAEheartbreakkid132No ratings yet

- AHU Replacement DR ESDocument1 pageAHU Replacement DR ESsajuhereNo ratings yet

- An Introduction To Energy EfficientDocument27 pagesAn Introduction To Energy Efficientabdelbasset khelilNo ratings yet

- Educational Facilities ESDocument1 pageEducational Facilities ESsajuhereNo ratings yet

- Pre-Functinal Checks FormatDocument15 pagesPre-Functinal Checks Formatchakravarthi kanugulaNo ratings yet

- Da ManualsDocument4 pagesDa Manualsalbrgmail0% (1)

- Tech - MAN205-0454003EN Rev BDocument179 pagesTech - MAN205-0454003EN Rev BDimitriNo ratings yet

- VAV Method of StatementDocument6 pagesVAV Method of StatementRanjith KumarNo ratings yet

- Topvent 4209245 en 2012-01Document176 pagesTopvent 4209245 en 2012-01Pecingina Dalia DanielNo ratings yet

- Technical Manual PAC Light Commercial Binnen-Buitendelen Compleet PDFDocument115 pagesTechnical Manual PAC Light Commercial Binnen-Buitendelen Compleet PDFBobi GorgievskiNo ratings yet

- TD1007 Water To Air DatasheetDocument3 pagesTD1007 Water To Air DatasheetMustapha AlaouiNo ratings yet

- Hvac System Commissioning: Heat Exchanger Pre Inspection Checklist & Tab ReportDocument2 pagesHvac System Commissioning: Heat Exchanger Pre Inspection Checklist & Tab ReportMudassar Idris RautNo ratings yet

- DOE DC AssessmentDocument13 pagesDOE DC AssessmentokylimNo ratings yet

- Variable-Speed Water-Cooled Screw Chiller & Heat Pump: $ppmjohdbqbdjuz l8) Fbujohdbqbdjuz l8Document20 pagesVariable-Speed Water-Cooled Screw Chiller & Heat Pump: $ppmjohdbqbdjuz l8) Fbujohdbqbdjuz l8nglong24No ratings yet

- Basis of Hvac Design German Pharma Indusrie ProjectDocument6 pagesBasis of Hvac Design German Pharma Indusrie ProjectclaudiojrriveraNo ratings yet

- New Elevator Acceptance Inspection Installation ChecklistDocument3 pagesNew Elevator Acceptance Inspection Installation ChecklistMohammed Aldaffaie100% (1)

- Sp9907-A - Chiller Statup ProceduresDocument4 pagesSp9907-A - Chiller Statup ProceduresEmerson Penaforte100% (1)

- IQ/OQ Protocol Installation Qualification/ Operation QualificationDocument7 pagesIQ/OQ Protocol Installation Qualification/ Operation QualificationZhaoYun1314No ratings yet

- Service Manual Sap-Krv93ehfp Sap-Crv93ehfp Sap-Krv123ehfp SDocument73 pagesService Manual Sap-Krv93ehfp Sap-Crv93ehfp Sap-Krv123ehfp SIan McPakeNo ratings yet

- GEA Product - GuideDocument72 pagesGEA Product - GuidemunsureshNo ratings yet

- LG LWHD1006R Training ManualDocument44 pagesLG LWHD1006R Training ManualGuillermo HernandezNo ratings yet

- KRV93-123EHN XDocument51 pagesKRV93-123EHN Xprr69No ratings yet

- R011. TAEevoTech PDFDocument40 pagesR011. TAEevoTech PDFphukaifrNo ratings yet

- LFXGH Basic SetupDocument2 pagesLFXGH Basic SetupAlvin Garcia PalancaNo ratings yet

- 28 The Facility Files 3 12Document1 page28 The Facility Files 3 12sajuhereNo ratings yet

- PSD 61af 022 105 - enDocument23 pagesPSD 61af 022 105 - enDavid BlagojevicNo ratings yet

- VLT HVAC Drive - Application Manual PDFDocument83 pagesVLT HVAC Drive - Application Manual PDFRaji PanickerNo ratings yet

- TROX Air Flow Control Design ManualDocument36 pagesTROX Air Flow Control Design Manualiask5275No ratings yet

- Actulux Manual SVM 24V 5A 8A Control Panel PDFDocument11 pagesActulux Manual SVM 24V 5A 8A Control Panel PDFAna Carolina SantosNo ratings yet

- VAV Method of Statement - V1Document7 pagesVAV Method of Statement - V1Ranjith KumarNo ratings yet

- Instrumentation Check Sheet 1Document3 pagesInstrumentation Check Sheet 1renjithv_4100% (1)

- GALANZ RekuperatoriDocument8 pagesGALANZ RekuperatoriOlivera Miletić-BresjanacNo ratings yet

- AHU Integration KitDocument6 pagesAHU Integration KitRicky ViadorNo ratings yet

- 48 50a-10pdDocument114 pages48 50a-10pdJimenez FerchoNo ratings yet

- MaytagatlantiswasherDocument120 pagesMaytagatlantiswasherwesley_lavenderNo ratings yet

- MGE UPS Comissioning GuideDocument19 pagesMGE UPS Comissioning GuideAldo Rodriguez MaturanaNo ratings yet

- Daikin Condensing Units Ecpen11-203 - tcm135-193371Document10 pagesDaikin Condensing Units Ecpen11-203 - tcm135-193371Denise Koh Chin HuiNo ratings yet

- The Facility Files 9 12Document1 pageThe Facility Files 9 12sajuhereNo ratings yet

- Energy Audit Quick ChecklistDocument3 pagesEnergy Audit Quick ChecklistPrasad Kishor NaikNo ratings yet

- Galaxy of Star 8Document8 pagesGalaxy of Star 8bioNo ratings yet

- Installation Manual: System Air ConditionerDocument27 pagesInstallation Manual: System Air ConditionerJavierJMNo ratings yet

- VAV Method of Statement - V2Document7 pagesVAV Method of Statement - V2Ranjith KumarNo ratings yet

- Cgah Chiller IomDocument28 pagesCgah Chiller IomLuong Dao100% (2)

- Prefunctional ChecklistsDocument37 pagesPrefunctional Checklistsrenjithv_4100% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- HPAC Operable Windows - Daly PDFDocument8 pagesHPAC Operable Windows - Daly PDFsajuhereNo ratings yet

- SandBookInterior r1Document16 pagesSandBookInterior r1sajuhereNo ratings yet

- Seidl NCBC08 Paper TR CorrectedDocument10 pagesSeidl NCBC08 Paper TR CorrectedsajuhereNo ratings yet

- Sizing Exhaust System For Refrigerating Machinery Rooms - Seidl, TaylorDocument13 pagesSizing Exhaust System For Refrigerating Machinery Rooms - Seidl, Taylorforevertay2000No ratings yet

- CoolTools ProjectggDocument24 pagesCoolTools ProjectggdaveleyconsNo ratings yet

- Chapter 07Document39 pagesChapter 07kevinmathew27No ratings yet

- Fan SurgingDocument10 pagesFan SurgingPrashant SrivastavaNo ratings yet

- Contracting Business Magazine - Taking Controls in-House-FriedmanDocument2 pagesContracting Business Magazine - Taking Controls in-House-FriedmanBasil OguakaNo ratings yet

- HPAC Article On Specifying VAV BoxesDocument4 pagesHPAC Article On Specifying VAV Boxesjoejex123No ratings yet

- ASHRAE Symposium SE 99-16-3 Kammerud & Hydeman CB Analysis UncertaintyDocument10 pagesASHRAE Symposium SE 99-16-3 Kammerud & Hydeman CB Analysis UncertaintysajuhereNo ratings yet

- ASHRAE-Symposium WSE in Data Centers SteinDocument9 pagesASHRAE-Symposium WSE in Data Centers SteinDiego CMNo ratings yet

- 2014 ASHRAE - Restroom Exhaust Design PDFDocument4 pages2014 ASHRAE - Restroom Exhaust Design PDFAntonio LebrunNo ratings yet

- HPAC A Fresh Look at Fans-FinalDocument10 pagesHPAC A Fresh Look at Fans-FinalsajuhereNo ratings yet

- ASHRAE Symposium HI-02!18!2 Symposium Hydeman & Webb New Chiller ModelDocument10 pagesASHRAE Symposium HI-02!18!2 Symposium Hydeman & Webb New Chiller ModelsajuhereNo ratings yet

- ASHRAE Journal - Select & Control Economizer Dampers in VAV Systems - TaylorDocument7 pagesASHRAE Journal - Select & Control Economizer Dampers in VAV Systems - Taylorsajuhere100% (1)

- ASHRAE Journal - VAV Box Duct Design - TaylorDocument8 pagesASHRAE Journal - VAV Box Duct Design - TaylorsajuhereNo ratings yet

- ASHRAE Symposis Degrading Delta-T-TaylorDocument13 pagesASHRAE Symposis Degrading Delta-T-TaylormondsbaNo ratings yet

- ASHRAE Journal - Stauffer Case StudyDocument5 pagesASHRAE Journal - Stauffer Case StudysajuhereNo ratings yet

- ASHRAE Journal - Staying OnlineDocument6 pagesASHRAE Journal - Staying OnlinesajuhereNo ratings yet

- ASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorDocument6 pagesASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorsajuhereNo ratings yet

- ASHRAE Journal - Return Fans in VAV Systems - TaylorDocument6 pagesASHRAE Journal - Return Fans in VAV Systems - TaylorAntonio LebrunNo ratings yet

- ASHRAE Journal - Return Air Systems - TaylorDocument4 pagesASHRAE Journal - Return Air Systems - TaylorKadiri Olanrewaju100% (1)

- ASHRAE Journal - Retrofitting DDC Controls ASHRAE Journal June 2004Document7 pagesASHRAE Journal - Retrofitting DDC Controls ASHRAE Journal June 2004sajuhereNo ratings yet

- ASHRAE Journal - Underfloor Lessons Learned-DalyDocument4 pagesASHRAE Journal - Underfloor Lessons Learned-DalysajuhereNo ratings yet

- ASHRAE Journal - Series Fan-Powered Boxes-Taylor PDFDocument0 pagesASHRAE Journal - Series Fan-Powered Boxes-Taylor PDFsajuhereNo ratings yet

- ASHRAE Journal - Optimizing Chilled Water Plant ControlsDocument12 pagesASHRAE Journal - Optimizing Chilled Water Plant ControlsAntonio LebrunNo ratings yet

- ASHRAE Journal - Primary-Only Vs Primary-Secondary Variable Flow SystemsDocument5 pagesASHRAE Journal - Primary-Only Vs Primary-Secondary Variable Flow SystemsQaz Zaq100% (1)

- ASHRAE Journal - How To Design & Control Waterside Economizers-TaylorDocument7 pagesASHRAE Journal - How To Design & Control Waterside Economizers-TaylorsajuhereNo ratings yet

- ASHRAE Journal - LEED and Standard 62.1-TaylorDocument4 pagesASHRAE Journal - LEED and Standard 62.1-TaylorNg Khanh100% (1)

- ASHRAE Journal - Humidity Controls in Data CentersDocument8 pagesASHRAE Journal - Humidity Controls in Data CentersAntonio LebrunNo ratings yet

- Lessons (That Should Be) Learned: Case Note On "How A City Slowly Drowned"Document8 pagesLessons (That Should Be) Learned: Case Note On "How A City Slowly Drowned"MichaelMWalter100% (4)

- ANNUAL-ACCOMPLISHMENT-REPORTDocument3 pagesANNUAL-ACCOMPLISHMENT-REPORTLowie Jay Magbanua BuladolaNo ratings yet

- Political: Southeast Asia or Southeastern Asia Is A Subregion of Asia, Consisting of The Countries That AreDocument4 pagesPolitical: Southeast Asia or Southeastern Asia Is A Subregion of Asia, Consisting of The Countries That AreAnne Janelle GuanNo ratings yet

- AC MEC 225 TheoryxDocument182 pagesAC MEC 225 TheoryxayariseifallahNo ratings yet

- Learning - Activity - 4 - Gapoy, Frednixen B.Document10 pagesLearning - Activity - 4 - Gapoy, Frednixen B.Frednixen Bustamante GapoyNo ratings yet

- Thesis Book (2) - 81-100Document20 pagesThesis Book (2) - 81-100Sagar MahatNo ratings yet

- Group 6 ClimateDocument21 pagesGroup 6 ClimateYunaika WardaniNo ratings yet

- Full Text: Physiological Profile of Chris FroomeDocument35 pagesFull Text: Physiological Profile of Chris FroomeNanci GuestNo ratings yet

- 9.final Master Plan - NMPT PDFDocument85 pages9.final Master Plan - NMPT PDFPrajwal BhattNo ratings yet

- Color by Short Vowel Sound PDFDocument1 pageColor by Short Vowel Sound PDFJhai Herrera0% (1)

- Assignment 2Document3 pagesAssignment 2Chioma Miriam ChijiokeNo ratings yet

- 2022 KwaZulu-Natal FloodsDocument6 pages2022 KwaZulu-Natal FloodsVillaErnestNo ratings yet

- Specifying For Performance: EngineeringDocument5 pagesSpecifying For Performance: EngineeringJohn ShaneNo ratings yet

- Bai Tap Tieng Anh Lop 8 Chuong Trinh Moi Unit 7Document8 pagesBai Tap Tieng Anh Lop 8 Chuong Trinh Moi Unit 7Hà Thu NguyễnNo ratings yet

- Rules of Play: Grossbeeren Katzbach Kulm DennewitzDocument42 pagesRules of Play: Grossbeeren Katzbach Kulm DennewitzPaoloViarengoNo ratings yet

- Tes Evaluasi Reading Comprehension 8Document4 pagesTes Evaluasi Reading Comprehension 8YELLY ANDRIANI BARLIANNo ratings yet

- Management Manual For HOtelsDocument47 pagesManagement Manual For HOtelsImee S. YuNo ratings yet

- PPL BriefingsDocument17 pagesPPL Briefingss raman100% (1)

- Cold Weather White PaperDocument17 pagesCold Weather White PaperSemih HürmeydanNo ratings yet

- How Forests Enhance Resilience To Climate Change What We Know About How Forests Can Contribute To Adaptation - 0Document48 pagesHow Forests Enhance Resilience To Climate Change What We Know About How Forests Can Contribute To Adaptation - 0Ariful AlamNo ratings yet

- Tugas Bahasa Inggris Kelas Xii Ips 2Document17 pagesTugas Bahasa Inggris Kelas Xii Ips 2abdulkusnanNo ratings yet

- Arch and GarchDocument39 pagesArch and GarchJovan NjegićNo ratings yet

- Vaca Muerta 18 MesesDocument20 pagesVaca Muerta 18 MesesFelipe MendozaNo ratings yet

- Inggris - WPS OfficeDocument7 pagesInggris - WPS OfficeVika PuspitaNo ratings yet

- Cebuano PhraseDocument24 pagesCebuano PhraseJuan Bago100% (1)

- Indore Bye LawsDocument11 pagesIndore Bye LawsRadhika Munshi50% (2)

- Operation Garden Plot - The United States Civil Disturbance Plan 55-2Document4 pagesOperation Garden Plot - The United States Civil Disturbance Plan 55-2GustavBlitz100% (3)

- SampleDocument6 pagesSamplegoovorunNo ratings yet

- Defining Figurative LanguageDocument3 pagesDefining Figurative LanguageM.ZubairNo ratings yet

- Mock CLAT 06 QuestionsDocument40 pagesMock CLAT 06 Questionsaparnamishra3344No ratings yet