Professional Documents

Culture Documents

Design of LNG Plant Facilities.: N.Bandyopadhyay - Consulting Engineer

Uploaded by

Hoàng KakaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of LNG Plant Facilities.: N.Bandyopadhyay - Consulting Engineer

Uploaded by

Hoàng KakaCopyright:

Available Formats

Inlet Gas

From Field

1250

MMSCFD

Design of LNG Plant Facilities.

N.Bandyopadhyay . Consulting Engineer

1

3 Phase

Separator

Mole Sieve

Glycol

Dehydrator

Gas /Gas !eat

"#chan$ers

Cold Separator

%&r'o

"#pander

(o&le

%hompson

)alve

De propaniser

De ethaniser

*i+ propane

(23

CF!yr"

*i+ ethane

(#$

CF!yr"

De methaniser

*i+ methane

LNG(#%&

CF!year"

%&r'o e#pander

Driven compressor

Fin,an Coolers

-esid&al lean $as

%o shipment

,or sale or

internal &se

a,ter

re$assi,ication

Process loss

12.#10/0 1%2

Propane

33 #10/0 1%2

"thane

1.0#10/0 1%2

*4G

1120#10/0 1%2

Feed Gas

1.5.#10/0 1%2

*ean Gas

3.#10/0 1%2

'her(al Balance on Daily throughput.

Free 6ater

7noc8 o&t

4G* o&t

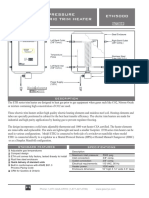

)i(plified Process Flo* Diagra( of LNG Plant

n'andyopadhyay9yahoocom

)ynopsis .

*i+&e,ied 4at&ral Gas :*4G; is a means o, transportin$ lar$e vol&me o, nat&ral $as in li+&id ,orm

thro&$h properly desi$ned '&l8 tan8ers to a distant location %he ,easi'ility o, settin$ &p o, s&ch a plant

needs to 'e st&died in details as it involves hi$h capital investment and re+&ires e#treme health < sa,ety

and environmental sa,e$&ards %he process is e#pensive 'eca&se o, needs ,or settin$ &p &pstream and

do6nstream ,acilities ,or li+&e,action < transportation at the prod&ction end and re$assi,ication at the

receivin$ terminals %he paper 6ill to&ch some ,a&ndamentals o, the ,acilities to 'e set &p ,or prod&ction

and re&se o, *4G %hease are 'ased on the +uthor,s past e-perience on such plants

Funda(entals of LNG .

*4G is prod&ced 'y li+&e,yin$ Methane component : C= ; o, nat&ral $as 6hich constit&tes 50> to 02>

'y vol&me o, the $as prod&ced %he appro#imate ratio o, $as vol&me to li+&id vol&me is 325 to 350 <

dependin$ on the $as composition %h&s < it is possi'le to transport lar$e vol&me o, $as as *4G %here

are several technolo$ies availa'le ,or prod&ction o, *4G ,rom nat&ral $as these are< Cascade Cycle

process :CCP; ,or li+&e,yin$ the methane component 'y a com'ination o, %&r'o e#pansion and

re,ri$eration thro&$h li+&e,ied methane < ethane and propane circ&its < Propane Mi#ed -e,ri$eration

process :PM-P;6hich is the most commonly &sed technolo$y and the latest D&al Mi#ed -e,ri$eration

:DM-P; process developed 'y Shell %he schematics o, the Process Flo6 Dia$ram &sin$ Cascade Cycle

process and a typical %hermal 1alance < are sho6n a'ove

Design of the Facilities .

%he main ,acilities incl&de the 2pstream < Mid stream and Do6nstream &nits %he 2pstream ,acilities

incl&de Gas -eceivin$ and Meterin$ &nits < Field Separators < M"? and %"G &nits ,or separation o, S@2 <

C@2 < 6ater < Molec&lar Sieve < -esid&al Gas %reatin$ &nits < disposal o, 6aste 6ater and ,lare o, these

$ases or s&lph&r recovery :e#cl&ded ,rom the scope o, *4G ;

%he Midstream ,acilities incl&de the main prod&ction &nits 6hich incl&de inlet $as coolin$ < cold

separators < t&r'o e#pansion < mi#ed re,ri$erant coolin$ in three circ&its < ,iltration and *4G prod&ction

%he Do6nstream ,acilities incl&de collection and stora$e o, *4G < *i+&,ied "thane and *PG :Propane

and 1&tane ,ractions; and their evac&ation

Common services ,or all the streams incl&de 6ater < po6er < compressed air < pipin$ < '&ildin$s < sa,ety

e+&ipment < str&ct&res < pipe s&pports < ,ire ,i$htin$ < internal roads < paved areas < storm 6ater draina$e <

sec&rity ,encin$ and concrete constr&ction

%he capacities and n&m'er o, e+&ipment re+&ired ,or *4G plants 6ill depend &pon the re+&ired

prod&ction capacity < $as composition and evac&ation o, the prod&cts

'he Plot Plan .

2

Inlet Gas Meterin$ Separator S@2 / C@2 *PG "thylene *4G

Strippers Stora$e Stora$e Stora$e

Sec&rity

@,,ice -e,ri$eration 2nits

Plant "ntrance Mole Sieve

Cold 1o#

Service

Aor8shop "lectrical

?dmin @,,ice S&'station

"#pander B Compressor 2nits *ean Gas

Fin Fan Coolers

Sec&rity Fence / Compo&nd Aall

Facilities re.uired for a 23& 'PD LNG Plant. :?ll appro#imate;

*and 12<000 S+m : 20 ?cres;

Pieces o, maCor process e+&ipment B machineries 30

Process pipin$ o, vario&s siDes and materials 3500 Dia Ein

Po6er and Instr&mentation ca'lin$ vario&s siDes and ratin$s 1200 m

Fire Fi$htin$ e+&ipment and accessories 1 lot

"lectrical po6er 500 76Fhr / D

!ealth < Sa,ety and "nvironmental control 1 lot

Aater s&pply :4o process 6ater re+&ired ; 20 7ls /D

)ario&s '&ildin$s :?dmin o,,ice < stores < sec&rity etc; .00 S+ m

First aid post 1 2nit

Maintenance 6or8shop 6ith vario&s machineries 1.0 s+ m

Plant roads and paved areas 3500 s+ m

Plant str&ct&res < pipe s&pports < tan8s < plat,orms etc 500 %

4at&ral $as s&ply :Inc&des prod&ction ,eedstoc8; 550 < 000 C&m / D

Plant Capital Cost :200. 'ase "#cl&des land and $as ; 2S G 250 Million

Constr&ction period ,rom rceipt o, land and all clearances 2H to 30 months

Pro/ect 0(ple(entation Planning .

Conclusions.

Present technolo$y has made it possi'le to desi$n and constr&ct *4G plants o, vario&s siDes and $as

compositions 6ith ma#im&m e,,iciency Small s8id mo&nted plants at 6ell heads or on o,,shore

plat,orms can &tilise mar$inal $as ,ields and 'rin$ ret&rns on investments to the e#tent o, 30 > to 30 >

!o6ever < lon$ term contracts ,or sale o, *4G need to 'e made 'e,ore a plant is set &p

'he +uthor.

Mr 4irmalend& 1andyopadhyay is an Indian Civil "n$ineer < $rad&ated ,rom Calc&tta 2niversity :India;

in 1050 !e has over .. yearsI international e#perience in maCor "PCM proCects ,or oil < $as < po6er<

hydrocar'on processin$ plants < iron and stel plants < mines development < mineral procesin$ plant and

in,rastr&ct&re ,acility desi$n and constr&ction in vario&s co&ntries across the 6orld !e has 6ritten many

papers 6hich have 'een p&'lished in leadin$ ?merican and Indian ma$aDines ?t present he is a Freelance

Cons<in$ "n$ineer and can 'e contacted at "Mail J n'andyopadhyay9yahoocom

3

Period in months 0 3 12 15 2. 30

-eceipt o, land B Clearances

Collection o, all In,ormation

F""D B Detailed "n$ineerin$

1ids and a6ard ,or civil 6or8s

Civil Constr&ction

1ids and a6ard ,or maCor Plants

Man&,act&rin$ < delivery and

Field erection o, maCor plants

Inte$ration o, all prod&ction plant

Facilities

PreFprod&ction testin$

Final Commissionin$ and hand

over

'he +uthor

.

Amine

Mole

Sieve

Treater

Stabiliser

Inlet Scrubber

Fin Fan Coolers

Fuel Gas for Internal

use

Turbo Expanders

Heat

Exchangers

Methane

Ethane ropane

!G" #ut $eceiver

5

FEE% Gas

from Field

Tan& 'apour $ecover(

"!G

ump

"!G Storage

"!G Tan&er

"oading

3

You might also like

- Layout Plans For Installation of LPG Autogas StationsDocument15 pagesLayout Plans For Installation of LPG Autogas StationsEjaz Ahmed RanaNo ratings yet

- Training Procedure - Training Manual For WWTP (03.12.2018)Document10 pagesTraining Procedure - Training Manual For WWTP (03.12.2018)Bebe BucătaruNo ratings yet

- Latest Best PracticeDocument4 pagesLatest Best PracticeJohn Kennedy FernandesNo ratings yet

- Hidraulic 320CDocument2 pagesHidraulic 320CValeria Ramirez100% (17)

- Essential Practices for Managing Chemical Reactivity HazardsFrom EverandEssential Practices for Managing Chemical Reactivity HazardsNo ratings yet

- JC1 Chemistry Tutorial on Reaction KineticsDocument32 pagesJC1 Chemistry Tutorial on Reaction KineticsMr TanNo ratings yet

- Pre-Commissioning ManualDocument32 pagesPre-Commissioning ManualfernandoNo ratings yet

- Teg ContactorDocument4 pagesTeg ContactorrepentinezNo ratings yet

- Gas Dehydration Using Glycol: Processes, Design, TroubleshootingDocument25 pagesGas Dehydration Using Glycol: Processes, Design, TroubleshootingBaha Eddine GharbiNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Estimate BOR in LNG Type C TankDocument14 pagesEstimate BOR in LNG Type C TankNgoVietCuongNo ratings yet

- Crude Distillation & Desalting-IICHE Online Summer Training-05.06.2020 7 PMDocument30 pagesCrude Distillation & Desalting-IICHE Online Summer Training-05.06.2020 7 PMHarish GojiyaNo ratings yet

- Technical PaperDocument6 pagesTechnical PaperCJ CHNo ratings yet

- Process Selection v7Document90 pagesProcess Selection v7VaanNo ratings yet

- LPG 11ahmadDocument36 pagesLPG 11ahmadJackk SparoowwNo ratings yet

- MySep Software Brochure PDFDocument7 pagesMySep Software Brochure PDFoverlord5555No ratings yet

- Natural Gas Processing from Midstream to DownstreamFrom EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNo ratings yet

- Gas Treatment SLDocument68 pagesGas Treatment SLwahyuriansyahNo ratings yet

- Nitrogen RejectionDocument7 pagesNitrogen RejectionOmar TocmoNo ratings yet

- RP 158 PDFDocument40 pagesRP 158 PDFDeependra SinghNo ratings yet

- Stratification and Rollover in LNG TanksDocument14 pagesStratification and Rollover in LNG Tanksleak100% (2)

- LNG Pumps, CMDocument11 pagesLNG Pumps, CMRachitNo ratings yet

- Module 2 of PlumbingDocument12 pagesModule 2 of PlumbingDJNo ratings yet

- On The Design of Thermal BreathingDocument6 pagesOn The Design of Thermal BreathingLizbeth Fiallos AvilaNo ratings yet

- OLPG S1-01 - OESA LPG Depots and Filling PlantsDocument38 pagesOLPG S1-01 - OESA LPG Depots and Filling PlantsGogne Rodolph100% (1)

- Replace Gas-Assisted Glycol Pumps with Electric for Efficiency and EmissionsDocument11 pagesReplace Gas-Assisted Glycol Pumps with Electric for Efficiency and EmissionsAmji ShahNo ratings yet

- Integrated NGL and LNG ProcessDocument16 pagesIntegrated NGL and LNG ProcessD K SNo ratings yet

- 1.1.1 LPG 1.1.2viscosity 1.1.3 Vapor Pressure 1.1.4 Specific Gravity 1.1.5 Flame Temperature 1.1.6 Flash Point 1.1.7 Odorization of LPG 1.1.8 Colour 1.1.9 ToxicityDocument6 pages1.1.1 LPG 1.1.2viscosity 1.1.3 Vapor Pressure 1.1.4 Specific Gravity 1.1.5 Flame Temperature 1.1.6 Flash Point 1.1.7 Odorization of LPG 1.1.8 Colour 1.1.9 ToxicityzeyadNo ratings yet

- Trim Heater PDFDocument2 pagesTrim Heater PDFsaadashfaq100% (1)

- Glycol Dehydration Systems PsDocument3 pagesGlycol Dehydration Systems Psedgardiaz5519No ratings yet

- Propylene StorageDocument2 pagesPropylene StorageMarnel Roy Mayor0% (1)

- DDPS Manway Covers & AccessoriesDocument4 pagesDDPS Manway Covers & Accessoriesnandhamech25No ratings yet

- PIG TRAP DESIGN GUIDEDocument6 pagesPIG TRAP DESIGN GUIDEDouGPhillips999100% (1)

- GTL Process Design and Economic AnalysisDocument41 pagesGTL Process Design and Economic AnalysisthuythukopaiNo ratings yet

- Gpa 2002 LNGDocument19 pagesGpa 2002 LNGHoàng KakaNo ratings yet

- Gpa 2002 LNGDocument19 pagesGpa 2002 LNGHoàng KakaNo ratings yet

- PHASE DIAGRAMDocument7 pagesPHASE DIAGRAMMustika Dewi IkhtiariantiNo ratings yet

- Comparison of Present Day Peakshaving Liquefaction TechnologiesDocument18 pagesComparison of Present Day Peakshaving Liquefaction Technologiesfericoolabiss100% (1)

- Natural Gas ProcessingDocument6 pagesNatural Gas ProcessingsgrsthNo ratings yet

- Thermal Design of A Fluidized Bed Steam Boiler Using Refuse Derived Fuel (RDF) in Organic Rankine Cycle (#487643) - 612964 PDFDocument17 pagesThermal Design of A Fluidized Bed Steam Boiler Using Refuse Derived Fuel (RDF) in Organic Rankine Cycle (#487643) - 612964 PDFnemochuNo ratings yet

- Gas Tech 2008 FLN G Business PresentationDocument25 pagesGas Tech 2008 FLN G Business PresentationNirma Afrisanti KinasihNo ratings yet

- LNG - Storage - Tank - Rollover PDFDocument7 pagesLNG - Storage - Tank - Rollover PDFchemsac20% (1)

- IMF Pressure Regulation SolutionsDocument8 pagesIMF Pressure Regulation SolutionsMohamed MahmoudNo ratings yet

- 9 4 Sludge DryingDocument17 pages9 4 Sludge Dryingkosmc123No ratings yet

- Full Thesis PDFDocument109 pagesFull Thesis PDFTanjib Rahman NiloyNo ratings yet

- High Performance Trays PDFDocument9 pagesHigh Performance Trays PDFAlan ChewNo ratings yet

- Vpci-337 (1-6-11)Document5 pagesVpci-337 (1-6-11)ravichandraNo ratings yet

- Liquefaction Process EvaluationDocument15 pagesLiquefaction Process Evaluationapi-3715370100% (1)

- LPG T4S-Original Reg-15.02.2019Document179 pagesLPG T4S-Original Reg-15.02.2019Abdul Kareem0% (1)

- Minor Project Report On: "LPG Detector"Document28 pagesMinor Project Report On: "LPG Detector"Gaurav SharmaNo ratings yet

- 245 NGL Deethanizer Capacity ExpansionDocument1 page245 NGL Deethanizer Capacity ExpansionRafeek Emad AbdElkader0% (1)

- CV Parul WordDocument5 pagesCV Parul Wordkkrish_nits867182No ratings yet

- Selecting: A Suitable ProcessDocument6 pagesSelecting: A Suitable ProcesstermdoxaNo ratings yet

- Presentation Michael HackingDocument29 pagesPresentation Michael HackingpoupoularyNo ratings yet

- Natural Gas Production, Transportation - StorageDocument36 pagesNatural Gas Production, Transportation - StorageNeeraj YadavNo ratings yet

- Linde LNG Material Safety DatasheetDocument11 pagesLinde LNG Material Safety DatasheetSANo ratings yet

- LNG Tank Design Analysis with LUSASDocument7 pagesLNG Tank Design Analysis with LUSASMelvin MagbanuaNo ratings yet

- BOIL OFF GAS ANALYSISDocument8 pagesBOIL OFF GAS ANALYSISJetul PatelNo ratings yet

- Bulk Water SeparationDocument1 pageBulk Water SeparationSean MiddletonNo ratings yet

- LNG Operations Manual Final Draft - 010515 - Web PDFDocument34 pagesLNG Operations Manual Final Draft - 010515 - Web PDFSushilNo ratings yet

- A Project Work: Study of Carbon Emission in Transportation ProblemDocument37 pagesA Project Work: Study of Carbon Emission in Transportation ProblemGaurav BajpaiNo ratings yet

- Fire Engulfment of LPG Storage TanksDocument20 pagesFire Engulfment of LPG Storage TanksKhan Lala100% (1)

- NGL Extraction TechnologiesDocument10 pagesNGL Extraction Technologieswylie010% (1)

- Some Recent Advances in Liquefied Natural Gas (LNG) Production, Spill, Dispersion, and SafDocument31 pagesSome Recent Advances in Liquefied Natural Gas (LNG) Production, Spill, Dispersion, and Safbala11ap4598No ratings yet

- Hot High Pressure SeparatorDocument2 pagesHot High Pressure SeparatorKhai NguyenNo ratings yet

- Desalination Plant of TobrukDocument21 pagesDesalination Plant of TobrukMotaz ZgogoNo ratings yet

- LNGDocument6 pagesLNGFahd HatemNo ratings yet

- The Supply of A Seawater Injection System For 30,000 BWPD ServiceDocument30 pagesThe Supply of A Seawater Injection System For 30,000 BWPD ServiceAnonymous O0lyGOShYGNo ratings yet

- Properties and Reliability of LNG OperationsDocument3 pagesProperties and Reliability of LNG OperationsHoàng KakaNo ratings yet

- 2 Equipment 2Document34 pages2 Equipment 2Hoàng KakaNo ratings yet

- PS4 7 DurrDocument18 pagesPS4 7 DurrHoàng KakaNo ratings yet

- Bai Tap Cad 3DDocument42 pagesBai Tap Cad 3DKieen LeeNo ratings yet

- PS4 7 DurrDocument18 pagesPS4 7 DurrHoàng KakaNo ratings yet

- Bai Tap Cad 3DDocument42 pagesBai Tap Cad 3DKieen LeeNo ratings yet

- Rated Capacity, Gal/Min (Dm3 /min) Rated Net Head, Psi (Kpa) Approximate Power Required, HP (KW)Document2 pagesRated Capacity, Gal/Min (Dm3 /min) Rated Net Head, Psi (Kpa) Approximate Power Required, HP (KW)Mohamed KhaldiNo ratings yet

- Test Separator: Calculation SheetDocument10 pagesTest Separator: Calculation SheetAffian WidjanarkoNo ratings yet

- Hazmat S 23 16698Document40 pagesHazmat S 23 16698Ngô Ích SơnNo ratings yet

- Unit 2: 1. Riser System 2. Sprinkler System 3. Spray SystemDocument11 pagesUnit 2: 1. Riser System 2. Sprinkler System 3. Spray Systemnimish ugemugeNo ratings yet

- Cryogenic Systems Introduction - Joule-Thomson CryocoolerDocument9 pagesCryogenic Systems Introduction - Joule-Thomson CryocoolerGanesh ThoratNo ratings yet

- An Introduction To Turbulence Models - DavidsonDocument48 pagesAn Introduction To Turbulence Models - DavidsonamoNo ratings yet

- Wave Breaking Resistance of Ships: Eiichi BabaDocument16 pagesWave Breaking Resistance of Ships: Eiichi Babagauthams309No ratings yet

- Journal Pre-Proofs: Applied Thermal EngineeringDocument32 pagesJournal Pre-Proofs: Applied Thermal EngineeringPavan Kumar NarendraNo ratings yet

- 2D Heat Transfer TutorialDocument180 pages2D Heat Transfer Tutorialsanojk_2000No ratings yet

- The Boiler HouseDocument9 pagesThe Boiler Housemeijon pelayerNo ratings yet

- 02-Chemical Kinetic - Telegram - @JEE - BOOKSDocument11 pages02-Chemical Kinetic - Telegram - @JEE - BOOKSRdNo ratings yet

- IVS - Fluid - Xover (1) - Oil Coss ReferenceDocument1 pageIVS - Fluid - Xover (1) - Oil Coss ReferenceJORGE OTALORANo ratings yet

- Thermodynamics 2 - Chapter 5 Part1Document29 pagesThermodynamics 2 - Chapter 5 Part1Amir SallehNo ratings yet

- TPXData SheetDocument4 pagesTPXData Sheetrameshkarthik810No ratings yet

- DPP FluidDocument23 pagesDPP FluidAditya SinhaNo ratings yet

- Automotive Grade Urea Solution Process AdBlue and DEF Application Note B212053ENDocument2 pagesAutomotive Grade Urea Solution Process AdBlue and DEF Application Note B212053ENMynthan MoorthyNo ratings yet

- IITD Study of Compressible Flow and Cooling Pack PerformanceDocument6 pagesIITD Study of Compressible Flow and Cooling Pack PerformanceramsastryNo ratings yet

- IGCC For Power Generation - An Environmentally Benign and Energy Efficient TechnologyDocument22 pagesIGCC For Power Generation - An Environmentally Benign and Energy Efficient TechnologySyed YousufuddinNo ratings yet

- Lecture 10. DryingDocument4 pagesLecture 10. DryingHirun ManujayaNo ratings yet

- 10 Mechanical Properties 2020Document23 pages10 Mechanical Properties 2020nadliriNo ratings yet

- Smart - Ar-G2 (Ta Instruments) : Device Specifications Temperature Control GeometriesDocument1 pageSmart - Ar-G2 (Ta Instruments) : Device Specifications Temperature Control GeometriesArvind Kumar ChaurasiaNo ratings yet

- Hydraulic CalculationDocument46 pagesHydraulic CalculationBader ShrbajiNo ratings yet

- Commercial Survey AUV: Valve AbbreviationsDocument8 pagesCommercial Survey AUV: Valve AbbreviationsMario StrašniNo ratings yet