Professional Documents

Culture Documents

Shainin Edge Over Other Methods

Uploaded by

shivaprasadmvit0 ratings0% found this document useful (0 votes)

81 views4 pagesq

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentq

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

81 views4 pagesShainin Edge Over Other Methods

Uploaded by

shivaprasadmvitq

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

SHAININ Method: Edge Over Other DOE Techniques

A.K. Verma , A. Srividya A.V. Mannika?, V.A. Pankhawala , K.J . Rathanraj3

Reliability Engineering Group, Indian Institute of Technology, Bombay, India

Automotive Research Association of India (ARAI), Pune, India

BMS College of Engineering, Bangalore, India

Abstract- Shainin methods refer to a collection of

principles, which make up the framework of a continually

evolving approach to quality. After the classical design of

experiments (DOE) and Tagnchi DOE, the third approach

is Shainin DOE, which is a collection of simple, but

powerful techniques invented or perfected hy Dorian

Shaioin of the United States. In this paper, three cases of

Taguchi experiments have been taken from literature and

the above method has been tried to find out whether the

authors have got the positive results from their

experiment. If not, authors emphasize on the importance

of giving the check in the start of the experiment

(screening experiment) with minimum number

experiments prior to the Taguchi approach.

Keywords- Shainin, Taguchi DOE

1. INTRODUCTION

The Shainin method is gaining popularity now

because of the simple tools, which can give substantial

good results at low cost and time. In fact, Motorola has

a saying: Without Deming, the US would not have

had a quality philosophy; without J uran, it would not

have had a quality direction; without Shainin, it would

not have solved quality problems! that sums up the

contributions of Americas three greatest quality gurus

[I]. Unfortunately, like Demings approach and Taguchi

methods, Shainin techniques have not received the wide

publicity and use they deserve.

In this paper, authors would like to emphasize on

the screening test or the pilot test, which is being

carried out at the start of the experimentation. This will

give an initial check to the parameter selection to level

selection. Shainin technique gives a tool to check the

screening test results so that one can think of going

ahead with the full experimentation. This is a limitation

of both classical and Taguchi DOE where experiments

are to be carried out fully before one could realize that

experimental result are of use or not. Thus in this paper,

three cases of Taguchi experiments have been taken

from literature [2,3,4] and the above method has been

tried to find out whether the authors have got the

positive results from their experiment. If not, authors

emphasize on the importance of giving the check in the

start of the experiment (screening experiment) with

minimum number experiments prior to the Taguchi

approach.

11. SHAININ VARIABLE SEARCH METHOD

According to Bhote [1], the variable search method

can be classified into four stages. In the first stage,

objective is to determine and to select the right variable

and the right levels for each variable for the experiment.

Here, after selecting the factors for the experiment,

assign two levels to each factor-a best level, which is

likely to contribute to a best response/output and a

marginal level, indicative of a likely deviation from the

best level in day-to-day production with normal

maintenance. Once the factors and levels are fixed, two

experiments are run, first with all factors at their best

levels, second with all factors at their marginal levels. If

there is a large difference between the response of the

all-best and the all-marginal combinations of factors, it

is an early indication that one has captured the right

factors. If the difference in response is small, the

chances are that one has not captured (1) the right

factors; or (2) the right levels of these factors; or that

(3) the first dominant cause is being cancelled by a

strong second dominant cause; or (4) the first dominant

factor is an interaction among an even number of

factors. Thus necessary corrective action can be taken if

the difference in response is small. If the difference

between the responses is large, for confirmation of the

response values, two all-best levels of all factors and

two more all-marginal levels of all the factors

(randomized to avoid bias) can be conducted. Then Did

ratio is found, which must be greater than or equal to a

minimum of 1.25. (D is the difference between the

median values of the best and the marginal responses

and d is the average of two differences (or ranges)

within the all-best responses and the all-marginal

responses). If Did ratio value is more than the said

value, experiment can be moved to second stage. This

also means that right factors have been captured.

Subsequent stages are similar to other DOE techniques.

111. CASE STUDIES

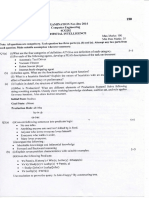

A. Case study 1:

According to Srivastava [2], for the optimization of

resistance spot-weld process, three main parameters

selected were % Heat, weld time and hold time and

1110

0-7803-8519-5/04/$20.00 @ 2004 I EEE

Authorized licensed use limited to: INDIAN INSTITUTE OF TECHNOLOGY BOMBAY. Downloaded on February 9, 2009 at 00:46 from IEEE Xplore. Restrictions apply.

Run No.

Results of which are depicted in the Table 2 [ref2 pp 88

Table 4A], which wnsists of 20 repetition of each run.

Observing the below table and finding the difference

among the run 1 and run 8 which are the Marginal

levels and the Best levels of the orthogonal array.

All best level - Run 1: median value =6.20

Al l marginal level -Run 8: median value =6.185

Therefore, D =6.20 - 6.185 =0.015

d =Average lack of repeatability in each assembly

=((6.28-6.13)+(6.320-5.987))12 =0.2415

Did =0.01510.2415 =0.062, which is less than 1.25:1.

This implies that the other experiments between Run 2

to Run 7 were not required to he conducted.

Mis Alpha Company Parameters

%Heat Weld Hold

Time Time

One can observe that there is a large difference within

the replications than the Run 1 and Run 8. There is no

substantial success achieved out of this experiment in

identifying the influence of variations in weld

parameters. The Shainin technique uses the

fundamentals of the Analysis of variance that ratio of

the difference between the group variability and

variability within must be significant otherwise the

experiment will not achieve the intended result.

B. Case study 2:

Kusiak and Feng [3], considered the tolerance design

problem for the machining dimensional chain and each

dimension includes a nominal value and the tolerance.

Assuming that the nominal values have been selected,

tolerances are to be allocated so that the manufacturing

cost is minimized. In Tolerance synthesis problem

(TSP), the unit of tolerance is p m, and there is no unit

for cost as it is a relative value. The robust TSP is to

assign a tolerance stackup so that the tolerance stackup

is not greater than an upper limit (20 p m) and the total

cost manufacturing does not exceed a preset limit.

From the Table 3 and applying the screening test of

Shainin method

All hest level - Level 0: median value =-1.57

All marginal level -Level 1: median value =-0.41

International Engineering Management Conference 2004 1111

Authorized licensed use limited to: INDIAN INSTITUTE OF TECHNOLOGY BOMBAY. Downloaded on February 9, 2009 at 00:46 from IEEE Xplore. Restrictions apply.

TABLE 3

So D =-1.57 - (-0.41) =1.16

=(9.29 +8.12)lZ =8.71

d =Average lack of repeatability in each assembly

Did =1.1618.71 =0.13, which is less than 1.25:l. So

this experiment might have not yielded significant

result.

One can observe that there is a large difference within

the replications than the level 0 and levell. There might

be an improvement in the form of cost reduction and

tolerance. But one can say that it is not substantial.

C. Case study 3:

Table 4 below from Lin [4] that is a four factor two

level experiments, which discusses about Taguchis

concept of orthogonal arrays. Looking at the below

orthogonal array one can make out the Run 1 which has

all level at -1 and Run 8 which has all level at 1 can be

considered All-best and All-marginal level. Applying

the screening test of Shainin method to below Table 4:

All hest level -Level -1: Average value =32.27

(As min. three values are not available to consider the

median value)

All marginal level -Level 1: Average value =14.8

SOD =32.27 - 14.8 =17.47

d = Average lack of repeatability in each assembly

=(1.64 +0.8)/2 =1.22

Did =17.47i1.22 =14.31, which is greater than 1.25:l

So this experiment is a success.

IV. CONCLUSION

In this paper, three case studies have been discussed

to show that how screening test of Shainin method can

be applied on the Taguchis orthogonal array to assess

the adequacy of the experiment. It is observed that case

1 and case 2 show Did ratio less than 1.25 and therefore

it can be concluded that the experimentation result be

successful in identifying the influence of variations in

parameters. In fact, it goes to assert adequacy of

tolerance levels (i.e. the tolerance variations are not

influencing the quality). However analysis of these two

case studies do emphasis that the additional

experiments conducted were not really required and

could have been eliminated using Shainin variable

search method at screening stage only. While case 3

shows higher ratio of Dld and hence it can be concluded

that the experimentation might give significant result.

Thus the Shainin variable search method can be

effectively used to find and fix the few important

facton as well as its levels by conducting minimum

number of experiments in the screening test.

TABLE 4

1112 International Engineering Management Conference 2004

Authorized licensed use limited to: INDIAN INSTITUTE OF TECHNOLOGY BOMBAY. Downloaded on February 9, 2009 at 00:46 from IEEE Xplore. Restrictions apply.

REFERENCES

[I] Kelii R. Bhote, Adi K. Bhote, World Class

Quality: using Design of Experiments to make it

happen, 2 edition, American Managemenr

Association, New York, 2000.

[2] Srivastava, Bipin B., Reliability studies on

resistance spot weld process parameters in

automobile components Ph.D thesis, UT, Bombay,

Mumbai, 2000.

[3] Kusiak A., Chang-Xue Feng, Robust Tolerance

Design for Quality Journal of Engineering for

Industry, Transactions of the ASME, Vo1.118, Feb

1996, pp 166-169.

[4] Dennis K. J . Lin, Making full use of Taguchis

orthogonal arrays Qualify nnd Reliabiliry

Engineering International, Vol.10, 1994, pp 117-

121.

Internotional Engineering Management Conference 2004 1113

Authorized licensed use limited to: INDIAN INSTITUTE OF TECHNOLOGY BOMBAY. Downloaded on February 9, 2009 at 00:46 from IEEE Xplore. Restrictions apply.

You might also like

- Practical Design of Experiments: DoE Made EasyFrom EverandPractical Design of Experiments: DoE Made EasyRating: 4.5 out of 5 stars4.5/5 (7)

- Design of ExperimentsDocument26 pagesDesign of ExperimentsGaddipati Mohankrishna100% (1)

- 1040 Method Development and EvaluationDocument4 pages1040 Method Development and EvaluationRaposo IreneNo ratings yet

- 2012 Mean ComparisonDocument35 pages2012 Mean Comparison3rlangNo ratings yet

- Design of ExperimentsDocument5 pagesDesign of ExperimentsPhelelaniNo ratings yet

- Classical Test Theory Vs Item Response TheoryDocument42 pagesClassical Test Theory Vs Item Response TheoryFirmanNo ratings yet

- Introductory ExampleDocument11 pagesIntroductory ExampleChristianAslanNo ratings yet

- Design of Experiments - Applications 2013Document120 pagesDesign of Experiments - Applications 2013Daoud IssaNo ratings yet

- Taguchi APPDocument14 pagesTaguchi APPAmey VidvansNo ratings yet

- He Shainin SystemDocument20 pagesHe Shainin SystemSilvia Tria ApsariNo ratings yet

- What Is Design of Experiments (DOE) ?Document8 pagesWhat Is Design of Experiments (DOE) ?karthikspeedNo ratings yet

- Design and Analysis of ExperimentsDocument6 pagesDesign and Analysis of ExperimentsAnonymous SCI5W4qYNo ratings yet

- Taguchi MethoDocument17 pagesTaguchi MethoSaurabh Verma70% (10)

- Design of ExperimentsDocument37 pagesDesign of ExperimentsImtiaz Alam MayoNo ratings yet

- Design of ExperimentsDocument31 pagesDesign of ExperimentsTeka KamNo ratings yet

- 1040 Method Development and Evaluation PDFDocument3 pages1040 Method Development and Evaluation PDFTeresa JeriNo ratings yet

- To Prepare and Validate Instrument in ResearchDocument12 pagesTo Prepare and Validate Instrument in ResearchAchmad MuttaqienNo ratings yet

- Experimental Design and Optimisation 4 Plackett Burman Designs 55 Tcm18 232212Document3 pagesExperimental Design and Optimisation 4 Plackett Burman Designs 55 Tcm18 232212iabureid7460No ratings yet

- DOE Report XinliShaDocument16 pagesDOE Report XinliShaXinli ShaNo ratings yet

- What Is DOEDocument42 pagesWhat Is DOEamalendu_biswas_1No ratings yet

- Unit 10 - Chi-Square TestDocument21 pagesUnit 10 - Chi-Square Testkulhariravindra7No ratings yet

- Unit 4 & Unit 5Document59 pagesUnit 4 & Unit 5Sankeerth Chary0% (1)

- What Is Design of ExperimentsDocument9 pagesWhat Is Design of ExperimentsmakulitnatupaNo ratings yet

- TechniquesDocument5 pagesTechniquesFlash GordonNo ratings yet

- Using Random Test Selection To Gain Confidence in Modified SoftwareDocument10 pagesUsing Random Test Selection To Gain Confidence in Modified SoftwareBogdan NicaNo ratings yet

- Use of Orthogonal Arrays To Improve The Test Strategy: The Taguchi Approach Essentially Covers Four StepsDocument3 pagesUse of Orthogonal Arrays To Improve The Test Strategy: The Taguchi Approach Essentially Covers Four StepsMalini KrNo ratings yet

- Pilot-Pivotal Trials For Average BioequivalenceDocument11 pagesPilot-Pivotal Trials For Average BioequivalenceIoana AntonesiNo ratings yet

- E177 13 Standard Practice For Use of The Terms Precision and Bias in ASTM Test MethodsDocument20 pagesE177 13 Standard Practice For Use of The Terms Precision and Bias in ASTM Test MethodsAlfonso SuaquitaNo ratings yet

- Ranking Test (Final)Document6 pagesRanking Test (Final)Zharifah Bari'ah Basa'ahNo ratings yet

- Introduction To Taguchi TechniquesDocument13 pagesIntroduction To Taguchi TechniquesSreedhar Pugalendhi100% (1)

- TSU Thesis TeacherKit Chapter 3Document7 pagesTSU Thesis TeacherKit Chapter 3Marvin Yebes ArceNo ratings yet

- What Kind of Experimental Design For Finding and Checking Robustness of Analytical Methods?Document7 pagesWhat Kind of Experimental Design For Finding and Checking Robustness of Analytical Methods?Carolin Cacao Leo LaoNo ratings yet

- By Mark J. Anderson and Shari L. KraberDocument32 pagesBy Mark J. Anderson and Shari L. Kraberparwez19661966No ratings yet

- Shainin Approach Experimental Design Using A CatapultDocument8 pagesShainin Approach Experimental Design Using A CatapultAbhishek GuptaNo ratings yet

- Mb0040 SLM Unit10Document21 pagesMb0040 SLM Unit10Smu Sovabazar100% (1)

- Combinatorial Testing: Encyclopedia of Software Engineering, Laplante. Combinatorial Testing, Kuhn Kacker LeiDocument30 pagesCombinatorial Testing: Encyclopedia of Software Engineering, Laplante. Combinatorial Testing, Kuhn Kacker LeiMauricio Ramirez FloresNo ratings yet

- Adaptive Random TestingDocument10 pagesAdaptive Random TestinghalfaiaNo ratings yet

- STVR Shin SurveyDocument60 pagesSTVR Shin SurveyLawine ChiradzaNo ratings yet

- STVR Shin SurveyDocument60 pagesSTVR Shin SurveyLavanyaDoopatiNo ratings yet

- BSI Semester - III - 2020Document3 pagesBSI Semester - III - 2020VISHWA SAHNINo ratings yet

- Application of Taguchi Method For Optimization of Process Parameters in Improving The Surface Roughness of Lathe Facing OperationDocument7 pagesApplication of Taguchi Method For Optimization of Process Parameters in Improving The Surface Roughness of Lathe Facing Operationwww.irjes.comNo ratings yet

- Plackett RL, Burman, JP. (1946) The Design ofDocument17 pagesPlackett RL, Burman, JP. (1946) The Design ofDemo639No ratings yet

- 1design (Cha1) 2012-1Document7 pages1design (Cha1) 2012-1gebremaryamzeleke081No ratings yet

- Imeko WC 2012 TC21 O10Document5 pagesImeko WC 2012 TC21 O10mcastillogzNo ratings yet

- ML Evaluation2Document9 pagesML Evaluation2Hamsaveni ArulNo ratings yet

- Unit 6 BiologyDocument11 pagesUnit 6 BiologyYash Rajpara89% (9)

- Z-test-Two-Sample-mean-test and TtestDocument41 pagesZ-test-Two-Sample-mean-test and TtestJeff YamsNo ratings yet

- Virzi 1992Document12 pagesVirzi 1992Maria IsabelNo ratings yet

- BAYREUTHDocument15 pagesBAYREUTHAjitNo ratings yet

- Effect of Attention, Relevance, Confidence, Satisfaction (ARCS) Model On Motivation and Learning Outcomes of Optics at SMAN 4 Banda AcehDocument5 pagesEffect of Attention, Relevance, Confidence, Satisfaction (ARCS) Model On Motivation and Learning Outcomes of Optics at SMAN 4 Banda AcehBatika KencanaNo ratings yet

- A DEA - ANP Hybrid Algorithm Approach To Evaluate A University's PerformanceDocument15 pagesA DEA - ANP Hybrid Algorithm Approach To Evaluate A University's PerformanceSyah KalyNo ratings yet

- Classical Test Theory vs. Item Response TheoryDocument30 pagesClassical Test Theory vs. Item Response TheoryparbuiNo ratings yet

- Jomo Kenyatta University of Agriculture and TechnologyDocument5 pagesJomo Kenyatta University of Agriculture and TechnologysolocheruicNo ratings yet

- T Test For Independent SamplesDocument29 pagesT Test For Independent SamplesRichard BacharNo ratings yet

- E691 - 99 Standard Practice For Conducting An Interlaboratory Study To Determine The Precision of A Test MethodDocument22 pagesE691 - 99 Standard Practice For Conducting An Interlaboratory Study To Determine The Precision of A Test MethodLupita RamirezNo ratings yet

- Validation of The Calibration Procedure in Atomic Absorption Spectrometric MethodsDocument10 pagesValidation of The Calibration Procedure in Atomic Absorption Spectrometric MethodsaureaborosNo ratings yet

- How To Establish Sample Sizes For Process Validation Using Statistical T...Document10 pagesHow To Establish Sample Sizes For Process Validation Using Statistical T...Anh Tran Thi VanNo ratings yet

- StreckerMemonICST2008Document10 pagesStreckerMemonICST2008lthanhlongNo ratings yet

- DesignDocument6 pagesDesignPujitha GarapatiNo ratings yet

- Industry 4 Readiness Assessment Tool Report Oct 2017Document20 pagesIndustry 4 Readiness Assessment Tool Report Oct 2017shivaprasadmvitNo ratings yet

- FFR125 LectureNotesDocument122 pagesFFR125 LectureNotesshivaprasadmvit100% (1)

- ASQLatam CSQP Insert B1706 PDFDocument12 pagesASQLatam CSQP Insert B1706 PDFshivaprasadmvitNo ratings yet

- VOC To CTQ Conversion SampleDocument5 pagesVOC To CTQ Conversion SampleshivaprasadmvitNo ratings yet

- Shainin Variable SearchDocument30 pagesShainin Variable Searchshivaprasadmvit100% (1)

- ASQLatam CSQP Insert B1706 PDFDocument12 pagesASQLatam CSQP Insert B1706 PDFshivaprasadmvitNo ratings yet

- Doe Shainin Methods TipsDocument12 pagesDoe Shainin Methods Tipsshivaprasadmvit50% (2)

- Factory PhysicsDocument16 pagesFactory Physicssamanvay.agarwalNo ratings yet

- Shainin AmeliorDocument40 pagesShainin AmeliorOsman Tig100% (1)

- Reliability EngineeringDocument5 pagesReliability Engineeringshivaprasadmvit100% (2)

- Fraction Solid Evolution Characteristics of Alsicu Alloys - Dynamic Baseline ApproachDocument22 pagesFraction Solid Evolution Characteristics of Alsicu Alloys - Dynamic Baseline ApproachshivaprasadmvitNo ratings yet

- Physical LayerDocument3 pagesPhysical LayershivaprasadmvitNo ratings yet

- Hydratight Flange Facing MachineDocument30 pagesHydratight Flange Facing MachineDilipNo ratings yet

- In Context: Subject Area: Organic Chemistry Level: 14-16 Years (Higher) Topic: Addition Polymers Source: RSC - Li/2GrwsijDocument5 pagesIn Context: Subject Area: Organic Chemistry Level: 14-16 Years (Higher) Topic: Addition Polymers Source: RSC - Li/2GrwsijRajlaxmi JainNo ratings yet

- A1 - Full Papers PS1 10834 2022Document18 pagesA1 - Full Papers PS1 10834 2022DmitryNo ratings yet

- HowToExcel Ebook - 50 Tips To Master Excel 2017-06-11Document41 pagesHowToExcel Ebook - 50 Tips To Master Excel 2017-06-11Lakshmi MeruvaNo ratings yet

- Danyar Et Al., 2020 - FinalDocument24 pagesDanyar Et Al., 2020 - FinalSardar SaleemNo ratings yet

- Basic Industrial BiotechnologyDocument29 pagesBasic Industrial BiotechnologyBharathiNo ratings yet

- 253 968 2 SPDocument16 pages253 968 2 SPAlvin MRNo ratings yet

- BCA Self Assessment English and TagalogDocument3 pagesBCA Self Assessment English and TagalogReymundo Pantonial Tugbong JrNo ratings yet

- GCT 2015-16 - Final Exam - 2015-12-18 - SolutionDocument9 pagesGCT 2015-16 - Final Exam - 2015-12-18 - SolutionpadrefloNo ratings yet

- AL8860EV2 User GuideDocument8 pagesAL8860EV2 User GuideHans ClarinNo ratings yet

- Visual Basic - Calling Matlab in VBDocument15 pagesVisual Basic - Calling Matlab in VBSanthosh Kumar BaswaNo ratings yet

- HCHEM Notes Enthalpy Entropy and Free EnergyDocument5 pagesHCHEM Notes Enthalpy Entropy and Free Energy^passwordNo ratings yet

- IptablesDocument3 pagesIptablessoomalikNo ratings yet

- RC2 22873Document2 pagesRC2 22873Henok AlemayehuNo ratings yet

- 634904411345780000Document24 pages634904411345780000chintan kapadiaNo ratings yet

- Ee 434L Manual (5-12)Document45 pagesEe 434L Manual (5-12)Saleemullah KhanNo ratings yet

- Minggu 5 Teori AktDocument69 pagesMinggu 5 Teori AktHILDANo ratings yet

- Registro Evaluacion Ergonomica ROSADocument6 pagesRegistro Evaluacion Ergonomica ROSAEryade Grace ValenzuelaNo ratings yet

- Airstage J-IIDocument6 pagesAirstage J-IIBulclimaNo ratings yet

- Vx5 5 ManualDocument76 pagesVx5 5 Manualphoto38911No ratings yet

- Strion Led HL - SupDocument2 pagesStrion Led HL - SupPatrickNo ratings yet

- Section 5 Section 5: Weight and Balance Weight and BalanceDocument36 pagesSection 5 Section 5: Weight and Balance Weight and Balanceandres felipe sandoval porrasNo ratings yet

- Solved Problems in Soil Mechanics: SolutionDocument5 pagesSolved Problems in Soil Mechanics: SolutionMemo LyNo ratings yet

- Ma103 NotesDocument110 pagesMa103 NotesginlerNo ratings yet

- Sainsbury 2010 PDFDocument13 pagesSainsbury 2010 PDFronaldNo ratings yet

- Physics Midterm Review PacketDocument6 pagesPhysics Midterm Review PacketJasper SendraNo ratings yet

- Advanced PHP ManualDocument246 pagesAdvanced PHP Manualkennedy onuzulikeNo ratings yet

- Class 8 Aakash JEE MAINDocument9 pagesClass 8 Aakash JEE MAINrohitNo ratings yet

- IET DAVV 2014 Com2Document12 pagesIET DAVV 2014 Com2jainam dudeNo ratings yet

- Manual Xtable EXCEL LinkDocument7 pagesManual Xtable EXCEL LinkElena Alexandra BeladanNo ratings yet