Professional Documents

Culture Documents

Doosan BMT Holder

Uploaded by

أحمد دعبسOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Doosan BMT Holder

Uploaded by

أحمد دعبسCopyright:

Available Formats

1

Technical Information

Any information can be changed without notice

BMT & New BMT tool holder

Application

Turning Center

2

Technical Information

Any information can be changed without notice

A tool holder is the deciding factor between a machine tool and the quality of the manufactured part, i.e.

realizing a machines potential requires top tool holder performance.

The cost effectiveness of single operation machining on mill/turn centers depends to a high degree

on the functionality of the tool holder itself. In order to meet the requirements, Daewoo has applied BMT

Turret concept(BMT55, 65, 75, 85) and BMT type rotary tool holder.

Recently we have upgraded rotary tool holder which can offer simultaneous dual contact between the rotary tool holder

face and tool holding insert flange face as well as the rotary tool holder pocket taper and tool holding insert taper shank.

This new holder has also the same current BMT concept. Namely, there is no any change in current BMT turret concept.

We call this new holder BMT55P, 65P, 75P, 85P as optional application.

BMT Application to machines (STD)

-BMT55 : PUMA230M,MS

PUMA1500/2000/2500 Y, SY

-BMT65 : PUMA300M,MS

TX200M,Y,YY

- BMT75 : PUMA400M

- BMT85 : PUMA600M

PUMA700M

In BMT55, 65, 75, 85 :

To put rotary tools into the tapered pocket of

Rotary tool holder, Coupling nuts and collets with

ER standard are generally used.

BMT P Application to machines (Opt.)

-BMT55P : PUMA230M,MS

PUMA1500/2000/2500 Y, SY

-BMT65P : PUMA300M,MS

TX200M,Y,YY

- BMT75P : PUMA400M

- BMT85P : PUMA600M

PUMA700M

In BMT55P, 65P, 75P, 85P(option) :

To put rotary tools into the tapered pocket of

Rotary tool holder, Coupling nuts and collets with

ER standard as well as tool holding inserts can be

used together

3

Technical Information

Any information can be changed without notice

BMT Turret & Holders

4

Technical Information

Any information can be changed without notice

BMT Concepts

4 Keys Guide

5

Technical Information

Any information can be changed without notice

VDI vs. BMT Features

BMT : Base Mounted Tool

- More rigid

- More accurate

- 12 rotary tool stations

- Not interchangeable

between competitors

toolings due to their own

special designs

BMT Turret

- Less rigid

- Less accurate

- 6 rotary tool stations

- Not interchangeable

between competitors

toolings due to their own

special designs

VDI Turret

6

Technical Information

Any information can be changed without notice

Accuracy Comparison of VDI vs. BMT

Items VDI BMT

1. Positioning Accuracy(Holder) 0.03 0.01

2. Positioning Accuracy(Machine) 0.05 0.03

3. Repeatability(Machine) 0.015 0.005

* Positioning accuracies include all geometric tolerances such as center height deviation and parallelism

1

Holder

Machine

2

3 3

Extreme changeover accuracy of

+/-0.005 mm in each tool pocket of BMT

7

Technical Information

Any information can be changed without notice

The smart Design

Synthesizes on the popular Collet Chuck

according to DIN 6499 and by the way offers the

ideal tool clamping by the exertion of several

appropriate inserts

New Tool Holder

(BMT55P, 65P, 75P, 85P)

NEW

Coupling nut and collets

Tool holding insert

One of the most important features of new tool holder,

BMT P series is the interchangeability with existing BMT

tool holders. Alternatively, new tool holders can be

utilized in machines equipped with conventional

Daewoo BMT turret. The innovative design allows one

to gain the benefit of new holder without the need to

discard the existing.

8

Technical Information

Any information can be changed without notice

Best rigidity by Cone / Face Contact

Extremely compact

Cone/Shoulder guarantee High Accuracy and

Repeatability

Insert are pre-setted externally of machine to

optimise Set Up Time

Short and simple Tool Change

The Choice of best appropriate Tooling

Clamping leads to a improvement of tooling

Live Time

Usable for Static and Driven Tool Holder

Perform the Lathe Capability

Reduce the total Tooling Investment Costs

Tool Holding Inserts

9

Technical Information

Any information can be changed without notice

New tool holding inserts for BMT P series

10

Technical Information

Any information can be changed without notice

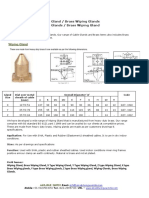

New BMT Test Results (Key slot milling)

1 2 3 4 5 5.5 6 6.5 7 8 9

A (Current) x x x x x x x

HSS B (New Collet) x x x

End Mill 16 C (New Weldon) x x x

2 Flutes A (Current) x x x x x x x

B (New Collet) x x x x

C (New Weldon) x x

A (Current) (Milling tool broken at 4mm depth)

Carbide B (New Collet) x x x x

End Mill 16 C (New Weldon) x x x x

2 Flutes A (Current) (Milling tool broken at 3mm depth)

B (New Collet) x x

C (New Weldon) x x

Holder : BMT55P Work : C45 Steel

Machine : P2000SY(#55) Tested : Feb. 04 ~ Feb. 13. 2003

Cutting Depth [mm]

Angular

Milling Unit

Straight

Milling Unit

Angular

Milling Unit

V : 50 m/min

S : 1000 rpm

F : 0.2 mm/rev

F : 200 mm/min

V : 200m/min

S : 3850 rpm

F : 0.2mm/rev

F : 750 mm/min

Holder Tool

Cutting

Condition

Straight

Milling Unit

Workpiece (C45 Steel)

Key Slot Collet (Current) Collet (New) Weldon (New)

Holder Type

: OK , X : Chatter

You might also like

- 00 - Contents Heidenhain Iso Programming - Very GoodDocument40 pages00 - Contents Heidenhain Iso Programming - Very GoodStefan IstratescuNo ratings yet

- VT1150Document14 pagesVT1150camb2270No ratings yet

- Doosan BMT65 ToolingDocument28 pagesDoosan BMT65 Toolingmarcos lemosNo ratings yet

- M800-M80 Series PLC Programming Manual - IB1501271-C (ENG) PDFDocument780 pagesM800-M80 Series PLC Programming Manual - IB1501271-C (ENG) PDFXavier TorrasNo ratings yet

- Doosan TT Series CNCDocument7 pagesDoosan TT Series CNCRevolusiSoekarnoNo ratings yet

- Heidenhain 920Document68 pagesHeidenhain 920Angel Alvarez CarrilloNo ratings yet

- Glodanje - Heidenhain iTNC530 - 4Document42 pagesGlodanje - Heidenhain iTNC530 - 4josipNo ratings yet

- Diagnostics GuideDocument588 pagesDiagnostics GuidejeronimostNo ratings yet

- Gls 150 SeriesDocument20 pagesGls 150 SeriesHâlid ŞenNo ratings yet

- Mori Seiki ZT 1000 y enDocument16 pagesMori Seiki ZT 1000 y enOswald muñoz100% (1)

- COM - Doosan TX Series Servo Drive Operation Manual (Rev B01) - 131204 PDFDocument92 pagesCOM - Doosan TX Series Servo Drive Operation Manual (Rev B01) - 131204 PDFHakan Blg100% (1)

- FANUC F0i-D Spec E-13 SpecificationsDocument14 pagesFANUC F0i-D Spec E-13 Specificationsmt7038No ratings yet

- DNM ENG Series PDFDocument24 pagesDNM ENG Series PDFLevi BriceñoNo ratings yet

- Programming TT Series CNCDocument6 pagesProgramming TT Series CNCRevolusiSoekarnoNo ratings yet

- Tsugami B0205 206 III Focus BrochureDocument8 pagesTsugami B0205 206 III Focus BrochureBakhtiar Permana50% (2)

- Doosan Servo Driven Tail Stock MANUAL - ENGDocument5 pagesDoosan Servo Driven Tail Stock MANUAL - ENGmarkoskitp100% (1)

- THB360Document581 pagesTHB360Favoreel PatrickNo ratings yet

- FANUC 16,18 IPA Parameter ManualDocument76 pagesFANUC 16,18 IPA Parameter ManualJohan SneiderNo ratings yet

- Tncremont enDocument58 pagesTncremont enMohamed DahabNo ratings yet

- COM - Doosan TX Series Servo Drive Operation Manual (Rev B01) - 131204Document92 pagesCOM - Doosan TX Series Servo Drive Operation Manual (Rev B01) - 131204Tombong100% (1)

- Genos-En CNC OkumaDocument13 pagesGenos-En CNC Okumahggil380250% (2)

- 38M21C-1809EN Instruction ManualDocument396 pages38M21C-1809EN Instruction ManualCoptil NicolaeNo ratings yet

- Matsuura 24 MX 520 MethodsDocument12 pagesMatsuura 24 MX 520 MethodssunhuynhNo ratings yet

- DNC Operation Management Package PDFDocument120 pagesDNC Operation Management Package PDFVìAi0% (1)

- Mitsubishi ManualsDocument4 pagesMitsubishi ManualsRevolusiSoekarnoNo ratings yet

- Sinumerik One: The CNC For Highest ProductivityDocument28 pagesSinumerik One: The CNC For Highest ProductivityAshish PatwardhanNo ratings yet

- Module 2 Part 1Document147 pagesModule 2 Part 1FRANCIS THOMASNo ratings yet

- Doosan Puma MX Series PDFDocument68 pagesDoosan Puma MX Series PDFGuillermo RamirezNo ratings yet

- Doosan Puma MX Series BrochureDocument28 pagesDoosan Puma MX Series BrochuremarkoskitpNo ratings yet

- Fagor 800T Manual 2 PDFDocument224 pagesFagor 800T Manual 2 PDFniksa77No ratings yet

- Mazak Multiple Pull Transfer Example - Towmeup Console SwivelDocument3 pagesMazak Multiple Pull Transfer Example - Towmeup Console SwivelArturo LopezNo ratings yet

- Mazak Multiplex 620 CNC TurningDocument2 pagesMazak Multiplex 620 CNC TurningRevolusiSoekarnoNo ratings yet

- Maintenance and Safety Manual For I-Series Machines v388ENDocument126 pagesMaintenance and Safety Manual For I-Series Machines v388ENzotya54No ratings yet

- Vt-1150 User ManualDocument22 pagesVt-1150 User ManualAnne RodriguesNo ratings yet

- Ponz Controller Fanuc Oi PF ManualDocument89 pagesPonz Controller Fanuc Oi PF ManualRose Ann C. RofuliNo ratings yet

- Stama MC010Document28 pagesStama MC010Alexander BrazhnykNo ratings yet

- c16 PDFDocument4 pagesc16 PDFcmgankl0% (1)

- Diagnostic r0111-401Document23 pagesDiagnostic r0111-401M Farhan100% (2)

- Leadwell NV-Serie 2015 PDFDocument8 pagesLeadwell NV-Serie 2015 PDFLevi BriceñoNo ratings yet

- Haas AlarmsDocument46 pagesHaas AlarmsKar GayeeNo ratings yet

- Mori SeikiDocument7 pagesMori SeikimachineCanNo ratings yet

- Sinumerik 840D SL Operate OPC UA 4 5Document9 pagesSinumerik 840D SL Operate OPC UA 4 5Sam eagle goodNo ratings yet

- Manual de Instalacao Comando New990tdcaDocument100 pagesManual de Instalacao Comando New990tdcaAstrumosNo ratings yet

- CNC G and M codes guideDocument2 pagesCNC G and M codes guideSandeep Singh KohliNo ratings yet

- 1 - Ad-R Series - User ManualDocument79 pages1 - Ad-R Series - User Manualنعيم سلمان100% (1)

- Linear Scales (Encodes) : 1.1. HH: Microcontrol: Cross-Reference ComparisonDocument4 pagesLinear Scales (Encodes) : 1.1. HH: Microcontrol: Cross-Reference Comparisonognen88No ratings yet

- Puma Work Ejector Tip ReplacementDocument3 pagesPuma Work Ejector Tip ReplacementpaulNo ratings yet

- VMC 4020Document11 pagesVMC 4020Arul SakthiNo ratings yet

- Haas CNC Lathe and Mill G Codes ListDocument51 pagesHaas CNC Lathe and Mill G Codes ListpptmnltNo ratings yet

- Mori - ATC38 - 50 Installation - Maintenance Manual PDFDocument54 pagesMori - ATC38 - 50 Installation - Maintenance Manual PDFTheo SouzaNo ratings yet

- Makino 3Document90 pagesMakino 3maneesh100% (1)

- Specification - MechanicalDocument5 pagesSpecification - MechanicalEDEN FALCONINo ratings yet

- Programming Fanuc OtDocument13 pagesProgramming Fanuc OtsaminziNo ratings yet

- Mikron VCP 1000 Duro enDocument19 pagesMikron VCP 1000 Duro enAlexander DobbieNo ratings yet

- Field Service Hurco1990 1999 PDFDocument491 pagesField Service Hurco1990 1999 PDFNestor German PissoniNo ratings yet

- Climax FF6000 Portable Flange FacerDocument8 pagesClimax FF6000 Portable Flange Facerjromero_rpgNo ratings yet

- Japan South Asia Korea Taiwan China Europe-Germany Citizen Machinery Europe GMBH Europe-Uk AmericaDocument8 pagesJapan South Asia Korea Taiwan China Europe-Germany Citizen Machinery Europe GMBH Europe-Uk AmericaRaghav ZyoNo ratings yet

- Turning Tools - Tooling SystemsDocument94 pagesTurning Tools - Tooling Systemssaotinhyeu307783No ratings yet

- Production Engineering: Jig and Tool DesignFrom EverandProduction Engineering: Jig and Tool DesignRating: 4 out of 5 stars4/5 (9)

- ExperimentosDocument680 pagesExperimentosGerardo Lopez100% (4)

- Design of Machine Tool Gearboxes Driven by Double Speed Electric MotorsDocument10 pagesDesign of Machine Tool Gearboxes Driven by Double Speed Electric Motorsأحمد دعبسNo ratings yet

- 1000 Cuvinte EnglezaDocument10 pages1000 Cuvinte EnglezaNotar SorinNo ratings yet

- Basics of Pneumatic Control ValvesDocument2 pagesBasics of Pneumatic Control ValvesMuhammad Attiq Ur RahmanNo ratings yet

- البثقDocument2 pagesالبثقأحمد دعبسNo ratings yet

- Belt and Pulley SystemsDocument5 pagesBelt and Pulley SystemsNBRellos50% (2)

- Optymyze Helps Leading Bank Improve Sales Outcomes, Leverage Referral Programs EffectivelyDocument2 pagesOptymyze Helps Leading Bank Improve Sales Outcomes, Leverage Referral Programs Effectivelyأحمد دعبسNo ratings yet

- Adaptive Design of Machine Tool GearboxesDocument9 pagesAdaptive Design of Machine Tool Gearboxesأحمد دعبسNo ratings yet

- Top Ten Mistakes in IELTSDocument9 pagesTop Ten Mistakes in IELTSFadheel MosahebNo ratings yet

- Development of Elevator Ropes: Tech Tip 15Document2 pagesDevelopment of Elevator Ropes: Tech Tip 15أحمد دعبسNo ratings yet

- 1000 Cuvinte EnglezaDocument10 pages1000 Cuvinte EnglezaNotar SorinNo ratings yet

- Machinery Vibration Signals Analysis and Monitoring For Fault Diagnosis and Process Control PDFDocument8 pagesMachinery Vibration Signals Analysis and Monitoring For Fault Diagnosis and Process Control PDFأحمد دعبسNo ratings yet

- Advancing The 5G Wireless Standard at Convida - Wireless - An Insider LookDocument3 pagesAdvancing The 5G Wireless Standard at Convida - Wireless - An Insider Lookأحمد دعبسNo ratings yet

- Pulley SystemDocument9 pagesPulley Systemvaithsr0% (1)

- Design Calculation of Pulley Belt DriveDocument8 pagesDesign Calculation of Pulley Belt Driveأحمد دعبس100% (4)

- N-T Coordinate System (A) 635410672717374182Document14 pagesN-T Coordinate System (A) 635410672717374182HNGH100% (1)

- Theory of Machine - Ii - 012110050121 - 1Document15 pagesTheory of Machine - Ii - 012110050121 - 1Subrat BeheraNo ratings yet

- Shear and Moment Diagrams For FramesDocument4 pagesShear and Moment Diagrams For FramesBasma GamalNo ratings yet

- Mechanics For 1 Year Students - Mechanical DepartementDocument4 pagesMechanics For 1 Year Students - Mechanical DepartementBasma GamalNo ratings yet

- Dynamic Force Calibration Methods For Force Transducers PDFDocument16 pagesDynamic Force Calibration Methods For Force Transducers PDFأحمد دعبسNo ratings yet

- N-T Coordinate System (A) 635410672717374182Document14 pagesN-T Coordinate System (A) 635410672717374182HNGH100% (1)

- Machinery Vibration Signals Analysis and Monitoring For Fault Diagnosis and Process Control PDFDocument8 pagesMachinery Vibration Signals Analysis and Monitoring For Fault Diagnosis and Process Control PDFأحمد دعبسNo ratings yet

- Chapter 04Document36 pagesChapter 04Son TranNo ratings yet

- Machinery Vibration Signals Analysis and Monitoring For Fault Diagnosis and Process Control PDFDocument8 pagesMachinery Vibration Signals Analysis and Monitoring For Fault Diagnosis and Process Control PDFأحمد دعبسNo ratings yet

- Differentiating and Integrating Vectors for Engineering ApplicationsDocument9 pagesDifferentiating and Integrating Vectors for Engineering ApplicationsKamenriderNo ratings yet

- Dynamic Force Calibration Methods For Force Transducers PDFDocument16 pagesDynamic Force Calibration Methods For Force Transducers PDFأحمد دعبسNo ratings yet

- Differentiating and Integrating Vectors for Engineering ApplicationsDocument9 pagesDifferentiating and Integrating Vectors for Engineering ApplicationsKamenriderNo ratings yet

- Beams Solution PDFDocument7 pagesBeams Solution PDFأحمد دعبسNo ratings yet

- Shaper MachineDocument19 pagesShaper MachineMark Joseph Nambio Nieva0% (1)

- العدد والادوات المستخدمة في صيانة أجهزة الجوال PDFDocument7 pagesالعدد والادوات المستخدمة في صيانة أجهزة الجوال PDFأحمد دعبسNo ratings yet

- 2016 CPRA Log - Grand TerraceDocument3 pages2016 CPRA Log - Grand TerraceBeau YarbroughNo ratings yet

- Resource Kit GuideDocument44 pagesResource Kit GuideSrikanth GobburuNo ratings yet

- 3bc899b9-e56d-40c4-a304-1cc5edf4b6c7Document4 pages3bc899b9-e56d-40c4-a304-1cc5edf4b6c7Swamy Dhas DhasNo ratings yet

- Donnelly Erp SuccessDocument4 pagesDonnelly Erp SuccessvishalNo ratings yet

- Indian Standardization Report - Dec 2017 PDFDocument115 pagesIndian Standardization Report - Dec 2017 PDFIshan AnejaNo ratings yet

- Keston 30C ManualDocument80 pagesKeston 30C Manualstainless12No ratings yet

- Minitab SPCDocument11 pagesMinitab SPCCoCon GaloenkNo ratings yet

- FormulatingDocument123 pagesFormulatingRaju100% (2)

- WCL Lock WasherDocument46 pagesWCL Lock Washertravis8zimmermannNo ratings yet

- Bulletin: Toyota Textile MachineryDocument8 pagesBulletin: Toyota Textile MachineryKannan Krishnamurthy100% (2)

- Csms PQ Emp Group PublicDocument16 pagesCsms PQ Emp Group PublicAfif Said Hadjin100% (2)

- Strategic Mine Planning Integrating Computer Software, Simulation, and Social ResponsibilityDocument66 pagesStrategic Mine Planning Integrating Computer Software, Simulation, and Social ResponsibilityLuis BNo ratings yet

- Structural and Geotechnical Guidelines For School Design MOE NZDocument44 pagesStructural and Geotechnical Guidelines For School Design MOE NZTuroy100% (1)

- ITIL Incident Management 101Document6 pagesITIL Incident Management 101Sushmita IyengarNo ratings yet

- Cut-Off Points For Private Sponsorship 2023-2024Document7 pagesCut-Off Points For Private Sponsorship 2023-2024elijahshalomtumushabeNo ratings yet

- Vision and Scope Document Final by M UmairDocument6 pagesVision and Scope Document Final by M UmairDilini Dakshika HerathNo ratings yet

- Comp 5120Document40 pagesComp 5120Román Arturo Guerrero Uc100% (1)

- Guide to Cleaning Underground TanksDocument26 pagesGuide to Cleaning Underground TanksAhmed FodaNo ratings yet

- SD TicketsDocument2 pagesSD TicketsSUDHIRNo ratings yet

- Electrolux Clothes Dryer ManualDocument18 pagesElectrolux Clothes Dryer ManualMartinaNo ratings yet

- Wiping Gland Brass Wiping Glands ManufacturerDocument3 pagesWiping Gland Brass Wiping Glands ManufacturerUjjwal ShahNo ratings yet

- Chapter - 1 - Intro To Software Project ManagementDocument26 pagesChapter - 1 - Intro To Software Project ManagementVasudevan Sundararaman100% (1)

- SKF India financial analysisDocument12 pagesSKF India financial analysisAmaan Manzoor RatherNo ratings yet

- BEC Vantage Reading Part 1 - Teacher's Notes: 45 MinutesDocument15 pagesBEC Vantage Reading Part 1 - Teacher's Notes: 45 MinutesLy Nguyen Thi NhuNo ratings yet

- Methods, Standards & Work Design: An IntroductionDocument14 pagesMethods, Standards & Work Design: An IntroductionAngelaPinkanNo ratings yet

- STM - Grp4 - Sec - B - ThedaCare..... Ques OneDocument3 pagesSTM - Grp4 - Sec - B - ThedaCare..... Ques OneAdam MorganNo ratings yet

- Production Supervisor/ Dairy Companies /milk, Cheese, YougourtDocument2 pagesProduction Supervisor/ Dairy Companies /milk, Cheese, YougourtkaramzahiNo ratings yet

- NEW Atlanta PPR - TRI FOLD - 2021Document2 pagesNEW Atlanta PPR - TRI FOLD - 2021Aldrex ValerosNo ratings yet

- Sample Job Description QMR PDFDocument2 pagesSample Job Description QMR PDFHilario AlinabonNo ratings yet

- TOCBooksDocument15 pagesTOCBooksinfaredmailmanNo ratings yet