Professional Documents

Culture Documents

Lineduino Report Final

Uploaded by

api-255235794Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lineduino Report Final

Uploaded by

api-255235794Copyright:

Available Formats

Fall

2013

Lineduino

ME190 MECHATRONICS TERM PROJECT

SAN JOSE STATE UNIVERSITY, DEPARTMENT OF MECHANICAL ENGINEERING

DAMION ENGELBART

ERIC TSE

12.9.2013

1 | P a g e

Contents

Summary ...................................................................................................................................................... 2

Introduction .................................................................................................................................................. 3

Modeling ....................................................................................................................................................... 4

Simulation ..................................................................................................................................................... 6

Design ............................................................................................................................................................ 8

Results ......................................................................................................................................................... 11

References .................................................................................................................................................. 13

Appendix ..................................................................................................................................................... 13

A. Drawings ......................................................................................................................................... 13

B. Source Code .................................................................................................................................... 16

C. Bill of Materials ............................................................................................................................... 19

D. Data sheet links ............................................................................................................................... 19

E. YouTube Link ................................................................................................................................... 19

2 | P a g e

Summary

The Lineduino is a three wheeled autonomous line following robot that utilizes closed loop

feedback PID control to track and follow a black line. Using sensors to constantly read the position of

the robot relative to the line, Lineduinos control system is able to make corrections to individual motor

speed to keep it on track. Conventional line following robots use an on-off or bang-bang hysteresis

controller that execute a predefined motor correction response when it begins to deviate from the line.

The Lineduino differs from conventional line following robots in that it utilizes a PID controller to track

position. Using PID allows the robot to correct its trajectory, store information about previous offset

and predict how the line will change. This allows it to reach higher speeds while oscillating less about

the line.

Figure 1. The Lineduino autonomous line following robot

The control system of the Lineduino was modeled as a closed-loop feedback system with PID

control. Its operation begins with the sensor array reading the individual IR sensor values representing

the robots position relative to the line. This offset information is sent to the Arduino microcontroller

where error is calculated and corrective commands are sent to the two rear servo motors with the use

of a PID algorithm. The input used in this control system is the IR arrays determination of line offset

while output is a differential corrective voltage applied to the motors to correct the robots trajectory.

The PID variables K

p,

K

i

and K

d

were experimentally derived by iterative tuning. By recognizing that

system overshoot is characterized by wobble while steady state error is represented by the robot falling

off the line completely, parameters can be tuned following standard techniques.

The implementation of PID control in the Lineduinos control system was evident in that it

tracked the line better than a bang-bang controlled system. Wobble was reduced along straight lines

due to the proportion and integral terms, while curved paths were negotiated much quicker due to the

derivative term. Before the PID variables were tuned, the robot was unable to accurately track the line

and its trajectory often fell off completely. However, through experimental parameter tuning the robot

was able to navigate the track much quicker and with increased precision.

Through this project, a greater understanding of control systems and mechatronic concepts was

obtained. The opportunity to implement knowledge of closed-loop PID control theory in a real life

3 | P a g e

system was beneficial to the understanding of the subject. This project illustrated how the individual

proportional, integral and derivative components of the controller affected the systems overall

performance.

Introduction

The use of control systems in the automation industry has risen in proportion with the

complexity of mechatronic systems and the wider accessibility of powerful, miniaturized technology.

The incorporation of microcontrollers allows machines to become smarter by making decisions based on

external input. The Lineduino robotic line follower was designed and fabricated for fulfillment of the

SJSU ME190 term project following a set of guidelines. The requirements stipulates that the device use

a microcontroller as the primary means for system operation, as well as implementation of a closed-

loop control system.

Following these prerequisites, the Lineduino is designed to be a line following robot using an

Arduino Uno R3 microcontroller and a closed-loop PID control system to navigate along a road or a

solid black line. These conditions were acknowledged throughout all stages of design. A microcontroller

is a miniature computer that can be programmed to provide output actuation as well as input sensing.

Microcontrollers are classified as miniature computers due to the fact that their processing, memory, as

well as input/output components are contained in one small package. The need for microcontrollers in

autonomous systems is critical due to their ability to be programmed to make decisions based on

dynamic input. The Arduino R3 Uno microcontroller shown in figure 2, was selected due its ease of use

and expandability.

Figure 2. Arduino Uno R3 Microcontroller

http://arduino.cc/en/uploads/Main/ArduinoUno_R3_Front_450px.jpg

Unlike a traditional bang-bang controlled line following robot that only adjusts direction when

the line is hit, the Lineduino utilizes a PID style control algorithm to improve performance and

responsiveness illustrated in figure 3. A bang-bang controlled system refers to the way that a system

deals with external disturbances. If a sensor used to detect an instantaneous deviation from the

systems normal operation representing the first bang, a predefined corrective action will execute

representing the second bang. A PID or Proportional Integral Derivative control system was chosen

due to its ability to not only make trajectory corrections, but to store information about previous offset

and predict potential change in the line.

4 | P a g e

Figure 3. On-Off vs PID controller

Modeling

The Lineduino utilizes a closed loop control system with a PID controller to increase system

responsiveness and reduce error. A closed loop system is defined as one that contains a feedback loop

that is compared to the input or set point to influence the systems operation. A typical closed loop

system is shown below in figure 4.

Figure 4. Closed loop system with feedback

Proportional Integral Derivative controllers or PIDs work to reduce error by manipulating error

signals with three different operators. The standard model for a closed loop control system with PID

control is shown below in figure 5. The output of a PID controller is a summation of the Proportional,

Integral and Derivative terms shown below.

5 | P a g e

Figure 5. Closed loop PID controller block diagram

The proportional term multiplies the error of a system by a proportional gain K

P

and typically

contributes the greatest change to an output. A high value of K

P

means that a quicker correction of

error seen in the output will occur. However, due to this quick correction, the possibility of the

response overshooting its target is possible. A value of K

P

that is too low will cause the output response

to become too low and create steady state error.

The integral term multiplies the integral gain, K

i

, by the integral of error over time. The result is

a term that takes into account how long the error has been occurring. By taking the integral of error,

the system can reach the desired set point more quickly due to the error backing up and

accumulating, generating a heavier influence on the output. However, due to the nature of the integral

term, if error has been accumulating over time, the systems response may overshoot the set point

during that time interval.

The final derivative term multiplies the derivative gain K

d

, by the slope or difference between

the current error and the last. This contributes to the PIDs output by measuring the rate at which the

error is changing and predicting what the next error will be. The derivative term can benefit system

response performance by speeding up the response if error begins to trend in one direction. This

however is prone to errors that jump quickly, causing a derivative kick in control signal of the opposite

direction. This can be detrimental to systems where noisy signals are controlled.

The Lineduinos control system takes inputs in the form of line position offset and outputs a

correcting control signal to actuate the rear motors. Using an array of IR reflectance sensors placed at

the front of the vehicle, line position can be tracked by the readings taken from the IR sensors. The IR

line sensing array outputs a single number to define its location as shown below in figure 6. Their values

range between -1 representing maximum left offset and 1 representing maximum right offset. An

6 | P a g e

output of zero represents being centered over the line, while intermediate values -0.5 and 0.5 represent

smaller offsets left and right, respectively.

Figure 6. Three reflectance sensors form an array that output a number between -1 and 1 to define position

This signal can be fed into a difference junction where it is compared with a set point value

equal to zero and an error is calculated. The error signal is then fed into a PID controller block where

the proportional, integral and derivative components are calculated and summed. The resulting control

signal is passed to the microcontroller where it is used to actuate individual motors with pulse width

modulated or PWM signal in order to get the robot back on the desired path. A block diagram modeling

this is shown below in figure 7.

Figure 7. Control system block diagram

Simulation

In order to simulate the response of the control system, certain assumptions and simplifications

must be used. In order to simplify the simulation of the Lineduinos control system, it was assumed to

be initially moving directly over a straight portion of the line moving at a default speed. Input to the

system is in the form of offset angle from the line and output is the differential correction PWM signal

applied to the motors.

7 | P a g e

The IR sensor outputs values ranging from -1 when only the left sensor is hit, to +1 where only

the right sensor is hit representing a -/+ 6.328 degree offset, respectively shown below in figure 8. This

number is subtracted from the set point chosen to be zero representing no offset. The resulting error is

passed through the PID controller where a manipulating offset value is generated.

Figure 8. Deviation from the line is characterized as an angle of offset that the motor velocities must compensate

In order to obtain the relationship between a specific PWM signal applied to the motor and the

distance the wheel will travel in a time interval, the motors K

v

value or RPM per volt was first

determined. This value was experimentally obtained to be 6.88 RPM/volt. The 6 volt motor is attached

to a 42mm wheel that operates on PWM signal from 0 to 255 via the Arduino. This means that an

applied voltage of 6V is equivalent to a PWM signal of 255 or 0.0235 volts per 1ms pulse width. Using

this value, the relationship between PWM signals to linear velocity was obtained as follows.

6.88

6.88

1

60

42

60

2.19 /

255

6 .0235

. 161

. 352 /

In order to compensate for a 6.328 vehicle tilt, one wheel must speed up by a distance of 6.029

mm ahead, while the other must slow down by the same amount. This distance equates to

approximately 0.0456 of one full rotation for a 42 mm wheel. Since the other wheel is still moving, this

correction must be performed in the shortest time possible in order to reduce wobble and overshoot.

At any speed, if a side IR sensor was triggered, for a correction to happen in one second, one motors

PWM value must be powered up by 17 ms, while the other powered down by 17 ms. Times for one and

one-half theta correction are plotted against PWM in figure 9.

8 | P a g e

Figure 9. Correction time for one and one-half theta offset for different PWM signals

Tuning the PID parameters was performed experimentally by first setting all variables equal to

zero. Since K

p

has the greatest effect on the instantaneous direction of the vehicle, it was tuned first. As

stated before, a K

P

that is too low will cause it to fail in controlling error by falling off the line.

Conversely, a K

P

that is too high will cause oscillation due to the amplification of the error signals. Once

the vehicle was able to follow a line, the K

d

parameter was set to 1 and increased until it began to

wobble. This wobble is due to the fact that as the gain is increased and differential error flips back and

forth as each IR sensor was triggered.

Design

The mechanical design began by identifying the major subsystems of the vehicle which can be

seen below in figure 10. These included a power system, a microcontroller, the drive system (a motor

driver board and two motors), and a sensor array. Regardless of the final configuration of the vehicle,

the sensor array, drive system, and microcontroller will utilize the same components. The components

were selected and purchased before the design was finalized so features could be built into the

manufactured parts which accommodated the purchased components. A list of all the materials used in

this project along with some information on each one can be found in the appendix.

0

200

400

600

800

1000

1200

10 60 110 160 210

T

i

m

e

t

o

c

o

r

r

e

c

t

(

m

s

)

PWM Signal

PWM vs Correction Time

Theta

0.5 Theta

9 | P a g e

Figure 10. Major subsystems of LineDuino robot. This block diagram shows each major subsystem and how they

integrate into the whole system. Red lines represent power while green lines represent signal.

The component selection process began by choosing a sensor which could detect either a black

or white line. A QRD1114 reflectance sensor was chosen because it is readily available, and there are

many tutorials available online regarding its use. An inverting Schmitt trigger was utilized on the output

of the phototransistor in order to help eliminate low amplitude noise and generate a square wave. Once

the sensor was identified and sourced, a sensor array was designed around the dimensions of the sensor

and the width of standard black electrical tape, because that is what was used to create the path for the

robot to follow. The width of standard electrical tape is 19 mm, so the center to center distance of the

sensors was chosen to be 12 mm. While directly over the line, the center sensor can detect the line

without the side sensors hitting. While falling off the line, the center sensor and one side sensor can also

detect the line without the third sensor hitting. This enables higher resolution detection of the line by

allowing three sensors to detect five different states. Once the sensor spacing was decided upon, a

printed circuit board (PCB) was designed to hold all three sensors at the desired spacing and to house

and connect the rest of the components used to properly drive the sensors. A single stage of this circuit

can be seen below in figure 11.

Figure 11. Single stage of line sensor circuit. This circuit features a QRD1114 reflectance sensor which is

filtered by an inverting Schmitt Trigger. The output of the reflector is located at the junction labeled 12.

Figure 12. QRD1114 IR Reflector Array. This circuit includes all components necessary to run the sensors.

5 volts goes into the bottom left pad, then ground. The final three pads are the outputs for each sensor.

10 | P a g e

Two brushed DC motors that operate at 6 volts and have attached 298:1 gearheads were bought

from the internet. They were advertised as having 50:1 gearheads, but upon measuring the RPM to

voltage relationship, it was discovered that these motors match the characteristics of the motors with

298:1 gearheads. These motors also have 42mm diameter rubber wheels attached to the output shafts

which is convenient for integration with a vehicle. A mounting bracket was designed around the motor

using SolidWorks and 3D printed using a Stratasys Dimension 1200es printer; a detailed drawing can be

found in the appendix. This bracket was used to mount the motor to a central chassis that houses all the

electronics and various components. An omnidirectional roller ball from SparkFun placed at the front of

the robot provides stability and allows the distance from the sensor to the surface to be adjusted. The

chassis was then designed, again using SolidWorks, around all the components including the

microcontroller, the motor adapters, the battery holder, the omnidirectional roller, and the sensor PCB.

This part was designed to be laser cut out of 0.125 inch thick acrylic, and was cut on a Trotec Speedy 300

laser cutter. A detailed drawing of the chassis can be found in the in appendix. The 3D model of the line

following robot can be seen next to the final product below in figure 13.

Figure 13. 3D model of line following robot (left) and a picture of final line following robot (right).

Because an Arduino Uno microcontroller was going to be used to implement the control system,

an Arduino Motor Shield was chosen as the motor driver. It is a simple piggy-back style shield which

plugs into the Arduino and allows access to all of the unused pins. This particular model is capable of

delivering 2 Amps per channel at 5 to 12 volts; however the motors used draw a max of only 300 mA.

Finally, a power system was required for the LineDuino robot. An adjustable voltage regulator (LM317)

was chosen because it is capable of regulating the output to 1.5 Amps at between 1.2 and 37 volts. A 9

volt battery was wired to the input of the LM317, and the output of the LM317 was wired to the

Arduino Motor Driver Shield, which also supplied to the Arduino Uno with power. The complete circuit

diagram of the LineDuino robot is shown below in figure 14. The diagram is slightly simplified as an L298

driver chip (which is the driver chip used in the Arduino Motor Driver Shield) is used to represent the

whole motor driver shield. The L298 requires some passive components in order to properly function,

which the Arduino Motor Driver Shield has built in.

11 | P a g e

Figure 14. Circuit Diagram of LineDuino robot. Arduino Motor Driver Shield not included in its entirety for

simplification.

Results

Before beginning this project some design specifications were laid out in a project proposal.

These design specifications include:

The vehicle will be able to quickly and accurately follow a continuous path generated by

anyone, including self-crossing paths and those with sharp directional changes.

Two brushed DC motors with gear heads will be used to drive the two rear wheels, with a

third passive omnidirectional wheel to provide stability. A suite of QRD1114 Reflective Object

Sensors will be used to sense the line and allow for detection of deviations in the path.

A calibration mode will be implemented which will allow the vehicle to learn the

characteristics of the line it is supposed to follow. This will be accomplished by measuring the

reflectivity of the line and surrounding surface before attempting to follow, and using these

values to set thresholds within the code.

The device will be very compact.

The total cost of the project should be very low (<$75).

Due to time constraints only three of these five goals were met. The vehicle is able to quickly and

accurately follow a continuous path, even with very sharp directional changes, however, the operation

of the robot could be greatly sped up by using motors with lower gear ratios. There are many motors

available in the exact same form factor with lower gear ratio gearheads that would be drop-in solutions.

It is also able to follow a path which is self-intersecting about 75% of the time, however, the other 25%

12 | P a g e

of the time it follows the wrong line. The two brushed motors with gearheads, omnidirectional caster,

and the Reflective Object Sensors were used successfully in the final design. The calibration mode was

not implemented, and the robot can only follow a non-reflective line on a reflective surface currently,

but that allows it to follow a black line on a white surface very effectively. The final design of the device

was very compact, the overall dimensions are 120 mm long, 120 mm wide, and about 75 mm tall, which

allows it to follow a relatively small line. The overall cost of the device ended up exceeding the $75

mark, and actually ended up at $100 instead. This was largely due to the fact that the components were

bought in small quantities, and generally chosen for simplicity. The motor driver shield alone cost

$30.00, and could have easily been replaced by an H-bridge or a discrete motor driver IC which would

have been much less expensive.

Most of the features which were not implemented in the Lineduino robot can easily be added in

to the existing code by spending some time to develop it. The ability to follow self-intersecting lines can

be improved by adding logic which specifically handles the case of a self-intersecting line. Currently, if

the intersection is not at a 90 degree angle to the line being followed, the robot reacts to the

intersection the same way it does a turn. Implementing a calibration mode would be very simple,

especially with the addition of an input button that would enter the Lineduino into a calibration mode.

The cost can be reduced in many different ways. By sourcing components from low-cost markets such as

eBay, all the electronics could have been procured for half of the cost.

The PID control system which was implemented in the Lineduino robot worked extremely well.

The robot is able to follow a line without using a bang-bang style method; the output of the Lineduino is

very smooth when compared with non-PID line following robots. Without using PID the robot could

follow a curve, but the time per lap was generally about 5 seconds longer than when using PID. The PID

constants were tuned by setting the constants to different values and observing how long the robot

takes to complete a lap on a given track. Even with extensive tuning, the lap time was only improved by

about 1.5 seconds. With more time, a more accurate model could be developed which would allow for

the derivation of better PID constants for smoother and faster operation. From the simplified model of

the PWM controlled DC motor we can conclude that when one of the far sensors hits the line, if a PWM

value of 245 is used, it will take approximately 70 ms to return to the line. This would imply that it would

take a little less than one tenth of a second to correct back to the line. There is currently no way to verify

this operation quantitatively, however, by observing the operation of the robot, it seems that 70 ms is

probably not enough time for it to fully return to the line. This could be due to the fact that the model

assumes no mass and no friction of any of the components, which would lead to a shorter return time.

Further work on the model is needed, along with an apparatus to verify the operation of the robot

quantitatively.

Due to the method of problem solving utilized for this project, very few issues arose. The basic

mechanical design was based around parts that were already purchased, which helped to ensure that

there would be no interference or fitment issues. All parts that were manufactured were first drawn in

3D CAD and checked for errors or problems. The sensing circuit was built on a breadboard and

extensively tested before drawing it in CAD to be fabricated. Because everything was designed using

CAD from the ground up, there were no surprises while assembling this robot, which was very helpful

13 | P a g e

when it came time to build and program everything. The only real uncertainty was how the code would

run with the robot, and it only took a little tuning to get everything running effectively.

References

http://arduino.cc/en/Main/ArduinoMotorShieldR3

http://www.nteinc.com/specs/7400to7499/pdf/nte74HC14.pdf

http://www.fairchildsemi.com/ds/LM/LM317.pdf

http://www.fairchildsemi.com/ds/QR/QRD1114.pdf

Appendix

A. Drawings

Overall Dimensions of vehicle:

14 | P a g e

Chassis:

Motor Mount:

15 | P a g e

Motor Mount Spacer:

Lineduino sensor array:

16 | P a g e

B. Source Code

#include <PID_v1.h>

//----Sensor Pin Definitions

#define lir 4 //left IR sensor

#define cir 5 //center IR sensor

#define rir 6 //right IR sensor

/*----Motor shield pin config

dir=polarity(forward(1)/backward(0))

pwm=speed(0-255)

brake=engage(1)/disengage(0) brake

*/

#define lmotor_dir 12 //left motor direction pin

#define lmotor_PWM 3 //left motor PWM pin

#define lmotor_brake 9 //left motor brake pin

#define lmotor_sense A0 //left motor current sense pin

#define rmotor_dir 13 //right motor direction pin

#define rmotor_PWM 11 //right motor PWM pin

#define rmotor_brake 8 //right motor brake pin

#define rmotor_sense A1 //right motor current sense pin

//----PID Variables

float kp=40; //proportional constant

float ki=1; //integral constant

float kd=10; //derivative constant

double Isum, last_input, output; //used for error tracking

int motorMinSpeed = 20; //minimum motor speed

int motorMaxSpeed = 250; //maximum motor speed

#define min_out -motorMaxSpeed*2 //Isum min

#define max_out motorMaxSpeed*2 //Isum max

int outputScaleFactor = 3; //used to scale output to have greater effect on vehicle

int IRScaleFactor = 5; //used to scale output from sensor array

double errorDivideFactor = 2.25; //used to drive error to zero when only center sensor is activated

int motorStartSpeed = motorMaxSpeed; //speed to start running motor at

int loopDelay = 50; //sets frequency of main loop

int lastpos = 0; //variable tracks last direction in case vehicle falls off line

int constrainedPWML = motorStartSpeed; //speed used in PID control

int constrainedPWMR = motorStartSpeed;

int constrainedPWM = motorStartSpeed;

int motorOffsetR = 255 - motorMaxSpeed; //used to correct for difference between motors

void setup(){

//IR Sensor Setup

pinMode(lir, INPUT);

pinMode(cir, INPUT);

pinMode(rir, INPUT);

//Motor Pin Setup

pinMode(lmotor_dir, OUTPUT);

pinMode(lmotor_PWM, OUTPUT);

pinMode(lmotor_brake, OUTPUT);

pinMode(lmotor_sense, INPUT);

pinMode(rmotor_dir, OUTPUT);

pinMode(rmotor_PWM, OUTPUT);

pinMode(rmotor_brake, OUTPUT);

pinMode(rmotor_sense, INPUT);

digitalWrite(lmotor_dir, 1);

digitalWrite(rmotor_dir, 0);

digitalWrite(lmotor_brake, 0);

17 | P a g e

digitalWrite(rmotor_brake, 0);

//Start motors driving forward to look for line

forward(motorStartSpeed);

}

void loop(){

//find position of line relative to sensor

double ir_pos=get_position();

//Compute error setpoint(0)-input(ir_pos)

double error=0-ir_pos;

if (error==0){

//drive error to zero if only center sensor is active

Isum-=Isum/errorDivideFactor;

}

else{

//accumulate error

Isum+=(ki*error);

}

//Prevent Integral Windup

Isum = constrain(Isum, min_out, max_out);

double dterm=(ir_pos-last_input);

//output is Kp*error + sum of error - Kd * rate of change of the error

output=constrain((kp*error+Isum-kd*dterm),(-255*2)/outputScaleFactor,(255*2)/outputScaleFactor);

//remember last directoin turned

last_input=ir_pos;

//Drive robot in correct direction, scaling output to have a greater effect

navigate(output*outputScaleFactor);

//set loop frequency

delay(loopDelay);

}

/* Function to drive robot in desired direction. */

void navigate(double output){

if(output>0){

left(motorStartSpeed, output);

}

else if(output<0){

right(motorStartSpeed, -output);

}

else if(output==0){

forward(motorStartSpeed);

}

}

/*Function to detect line position.

Value returned is between -1(directly under the left IR sensor) and 1(directly under the right IR sensor)

Values of -.5(left & center) and +.5(right & center) are retunred for intermediate positons.

*/

double get_position(){

double pos;

int left, right, center;

left=digitalRead(lir);

center=digitalRead(cir);

right=digitalRead(rir);

if((left==0)&&(center==1)&&(right==1)){

pos=-1;

}

else if((left==1)&&(center==1)&&(right==0)){

pos=1;

}

else if((left==1) && (center==0) && (right==1)){

pos=0;

18 | P a g e

output = 0;

//Isum = 0;

}

else if((left==0)&&(center==0)&&(right==1)){

pos=-0.5;

}

else if((left==1)&&(center==0)&&(right==0)){

pos=0.5;

}

else if((left==1)&&(center==1)&&(right==1)){

pos = lastpos;

}

else if((left==1)&&(center==1)&&(right==1)){

pos = lastpos;

}

else

pos=0;

//scale the output of the IR sensor array

return pos*IRScaleFactor;

}

/* Function to drive robot left. One motor is sped up while the other motor is slowed down in order to turn

quickly */

void left(int current_pwm, int dir_pwm){

constrainedPWML = constrain((current_pwm - dir_pwm/2),motorMinSpeed,motorMaxSpeed);

constrainedPWMR = constrain((current_pwm + dir_pwm/2),motorMinSpeed,motorMaxSpeed) +

motorOffsetR;

digitalWrite(rmotor_dir, LOW);

digitalWrite(lmotor_dir, HIGH);

digitalWrite(rmotor_brake, LOW);

digitalWrite(lmotor_brake, LOW);

analogWrite(lmotor_PWM, constrainedPWML);

analogWrite(rmotor_PWM, constrainedPWMR);

//remember last direction

lastpos = -1;

}

/* Function to drive robot right. One motor is sped up while the other mode is slowed down in order to turn

quickly */

void right(int current_pwm, int dir_pwm){

constrainedPWML = constrain((current_pwm + dir_pwm/2),motorMinSpeed,motorMaxSpeed);

constrainedPWMR = constrain((current_pwm - dir_pwm/2),motorMinSpeed,motorMaxSpeed +

motorOffsetR);

digitalWrite(rmotor_dir, LOW);

digitalWrite(lmotor_dir, HIGH);

digitalWrite(rmotor_brake, LOW);

digitalWrite(lmotor_brake, LOW);

analogWrite(lmotor_PWM, constrainedPWML);

analogWrite(rmotor_PWM, constrainedPWMR);

//remember last direction

lastpos = 1;

}

/* Function to drive robot forward. Both motors are driven forward at the same speed with a small offset to

account for slight mechanical differences. */

void forward(int pwm){

constrainedPWM = constrain(pwm,motorMinSpeed,motorMaxSpeed);

digitalWrite(rmotor_dir, LOW);

digitalWrite(lmotor_dir, HIGH);

digitalWrite(rmotor_brake, LOW);

digitalWrite(lmotor_brake, LOW);

analogWrite(rmotor_PWM, constrainedPWM + motorOffsetR);

19 | P a g e

analogWrite(lmotor_PWM, constrainedPWM);

//remember last direction

lastpos = 0;

}

/* Function to drive robot backwards. Both motors are driven forward at the same speed with a small offset

to account for slight mechanical differences. */

void backward(int pwm){

constrainedPWM = constrain(pwm,motorMinSpeed,motorMaxSpeed);

digitalWrite(rmotor_dir, HIGH);

digitalWrite(lmotor_dir, LOW);

digitalWrite(rmotor_brake, LOW);

digitalWrite(lmotor_brake, LOW);

analogWrite(rmotor_PWM, constrainedPWM + motorOffsetR);

analogWrite(lmotor_PWM, constrainedPWM);

//remember last direction

lastpos = 0;

}

C. Bill of Materials

D. Data sheet links

3299-3/8 Square Trim Potentiometer

http://www.bourns.com/pdfs/3299.pdf

LM317 3-Terminal Regulator

http://www.ti.com/lit/ds/symlink/lm117.pdf

NTE74HC14 Schmitt Trigger

http://www.nteinc.com/specs/7400to7499/pdf/nte74HC14.pdf

QRD1114 Reflectance Sensor

http://www.fairchildsemi.com/ds/QR/QRD1114.pdf

E. YouTube Link

https://www.youtube.com/watch?v=Dzxty2CPiTU Operational video

Component Count Supplier Web link to product Unit Cost Total Cost

0.1 uF capacitor 1 Spark Fun https://www.sparkfun.com/products/8375 0.25 0.25

1.0k ohm resistor 1 Spark Fun https://www.sparkfun.com/products/8980 0.25 0.25

10k ohm linear potentiometer 1 Spark Fun https://www.sparkfun.com/products/9939 0.95 0.95

10k ohm resistor 3 Spark Fun https://www.sparkfun.com/products/8377 0.25 0.75

330 ohm resistor 3 Spark Fun https://www.sparkfun.com/products/8377 0.25 0.75

9V Alkaline Battery 1 Spark Fun https://www.sparkfun.com/products/10218 1.95 1.95

Adjustable voltage regulator (LM317T) 1 Spark Fun https://www.sparkfun.com/products/527 1.95 1.95

Amico 6V N20 298:1 geared motor + wheel 2 Amazon http://www.amazon.com/gp/product/B00BG9L8YG/ref=oh_details_o00_s00_i00?ie=UTF8&psc=1 12.26 24.52

Amico 9V battery holder 1 Amazon

http://www.amazon.com/Amico-Replacement-Battery-Holder-

Connector/dp/B0087ZU4UG/ref=sr_1_3?ie=UTF8&qid=1386385497&sr=8-

3&keywords=9V+battery+holder 4.57 4.57

Arduino Motor Shield R3 1 Amazon http://www.amazon.com/gp/product/B006UTE70E/ref=oh_details_o00_s00_i00?ie=UTF8&psc=1 25.95 25.95

Arduino Uno R2 1 Amazon http://www.amazon.com/gp/product/B004CG4CN4/ref=oh_details_o00_s01_i00?ie=UTF8&psc=1 29.95 29.95

Ball Caster - 3/8 in 1 Spark Fun https://www.sparkfun.com/products/8909 2.95 2.95

Inverting Schmitt Trigger (74HC14) 2 Amazon

http://www.amazon.com/microtivity-Pack-74HC14-Schmitt-Trigger-

Inverter/dp/B0092CRLBS/ref=sr_1_1?ie=UTF8&qid=1386588204&sr=8-

1&keywords=schmitt+trigger 1.50 2.99

IR Reflective Sensor (QRD1114) 3 Spark Fun https://www.sparkfun.com/products/246 1.13 3.39

M2 hex nut 4 McMaster Carr http://www.mcmaster.com/#94150A305 0.05 0.21

M2 x 12mm machine screw 4 McMaster Carr http://www.mcmaster.com/#90116A022 0.10 0.42

M3 hex nut 8 McMaster Carr http://www.mcmaster.com/#94150A325 0.03 0.25

M3 x 14mm machine screw 8 McMaster Carr http://www.mcmaster.com/#90116A157 0.08 0.63

Total: 102.68

Bill of Materials

You might also like

- PID Controller Based DC Motor Speed ControlDocument4 pagesPID Controller Based DC Motor Speed ControlEditor IJRITCCNo ratings yet

- LAB 1 ArduinoDocument11 pagesLAB 1 ArduinoShaikhan NadzemiNo ratings yet

- Optimization of Path Tracking RobotDocument5 pagesOptimization of Path Tracking Robotsyclops3No ratings yet

- Mydcmotorcontrol: Applying Control Theory To A Real DC Motor System in An Open-Loop ConfigurationDocument5 pagesMydcmotorcontrol: Applying Control Theory To A Real DC Motor System in An Open-Loop ConfigurationnorickespinosNo ratings yet

- Thermal Characteristics of Pid Controller Water HeaterDocument10 pagesThermal Characteristics of Pid Controller Water HeaterEhab QabashNo ratings yet

- A Fuzzy Logic Control Project For A Real-Time Microprocessor LaboratoryDocument6 pagesA Fuzzy Logic Control Project For A Real-Time Microprocessor LaboratoryZelalem TarekegnNo ratings yet

- Seminar ReportDocument19 pagesSeminar ReportdfkoejfiNo ratings yet

- Application of LabView Vision and Fuzzy Control For Controling A Gantry CraneDocument4 pagesApplication of LabView Vision and Fuzzy Control For Controling A Gantry CraneJournalofICTNo ratings yet

- Auto Tuning PID Controller Using Chaotic PSO Algorithm For A Boost ConverterDocument6 pagesAuto Tuning PID Controller Using Chaotic PSO Algorithm For A Boost ConverterAbhimanyu YadavNo ratings yet

- Lab 1 Control (Closed Loop Angular Position)Document18 pagesLab 1 Control (Closed Loop Angular Position)Farid Asyraf100% (1)

- PID ControllersDocument9 pagesPID Controllerszs94qjqcx7No ratings yet

- PID Drone Longitudinal Stabilisation: Control System - Ece2010 Project ReportDocument20 pagesPID Drone Longitudinal Stabilisation: Control System - Ece2010 Project Reportlahari jagarlamudiNo ratings yet

- Control EngineeringDocument19 pagesControl EngineeringAmirul Zahim AzharNo ratings yet

- Design and Simulation of DA Based PID Controller Using Verilog CodingDocument6 pagesDesign and Simulation of DA Based PID Controller Using Verilog Codingjamal2877No ratings yet

- Real Time Speed Control of DC Motor With Unknown Transfer Function Through PIDDocument6 pagesReal Time Speed Control of DC Motor With Unknown Transfer Function Through PIDArbab HaiderNo ratings yet

- DC Motor Closed LoopDocument11 pagesDC Motor Closed Looprichard chombaNo ratings yet

- Advances in PID ControlDocument286 pagesAdvances in PID ControlDavid GonzalezNo ratings yet

- CD-24-Main Doc Pid Using ArduinoDocument63 pagesCD-24-Main Doc Pid Using Arduinogxge50% (2)

- Implementing A PID Control System On A Microcontroller: Using The Example of A Microchip PIC 18F4550Document12 pagesImplementing A PID Control System On A Microcontroller: Using The Example of A Microchip PIC 18F4550Venkatesan SundaramNo ratings yet

- Auto-Tuning Loop-Shaping Ideas: R Do DiDocument5 pagesAuto-Tuning Loop-Shaping Ideas: R Do DiAdithya ChandrasekaranNo ratings yet

- BOGDANLaurean 1Document9 pagesBOGDANLaurean 1Ricardo Villagomez DominguezNo ratings yet

- Microprocessor Based Digital PID Controller For Speed Control of D.C. MotorDocument6 pagesMicroprocessor Based Digital PID Controller For Speed Control of D.C. MotorSwapnica GarreNo ratings yet

- GAIN SCHEDULING CONTROLLER DESIGN FOR AN ELECTRIC DRIVE Final PDFDocument6 pagesGAIN SCHEDULING CONTROLLER DESIGN FOR AN ELECTRIC DRIVE Final PDFGlan DevadhasNo ratings yet

- MX009 - Proportional Integral Derivative Control PDFDocument5 pagesMX009 - Proportional Integral Derivative Control PDFjorgemdp5No ratings yet

- Study of Fuzzy-PID Control in MATLAB For Two-Phase Hybrid Stepping Motor ZHANG Shengyi and WANG XinmingDocument4 pagesStudy of Fuzzy-PID Control in MATLAB For Two-Phase Hybrid Stepping Motor ZHANG Shengyi and WANG XinmingMadhusmita BeheraNo ratings yet

- Tarea2 Investigacion-Mcca-190090Document13 pagesTarea2 Investigacion-Mcca-190090Christian MendezNo ratings yet

- Implementation of PID Controller PWM Module On FPGADocument5 pagesImplementation of PID Controller PWM Module On FPGAEditor IJTSRDNo ratings yet

- PID ReportDocument38 pagesPID ReportNishiya Vijayan100% (1)

- Project 2: DC Motor ControlDocument7 pagesProject 2: DC Motor ControlhunnbajajNo ratings yet

- DC Motor Speed Control Using PID Controller in Lab View: January 2015Document5 pagesDC Motor Speed Control Using PID Controller in Lab View: January 2015EngidNo ratings yet

- Automation of Tank Level by Using PLC and SCADA / HMI: ISSN: 2454-132X Impact Factor: 4.295Document9 pagesAutomation of Tank Level by Using PLC and SCADA / HMI: ISSN: 2454-132X Impact Factor: 4.295Nils BickelNo ratings yet

- Traffic Density Data Acquisition and Traffic Flow ControlDocument4 pagesTraffic Density Data Acquisition and Traffic Flow ControlgopikrishnaraoNo ratings yet

- Iterative Learning Control ReportDocument20 pagesIterative Learning Control ReportHoàng HứaNo ratings yet

- LAB 1 ArduinoDocument11 pagesLAB 1 ArduinoShaikhan NadzemiNo ratings yet

- FPGA Implementation of High Speed PI Like Fuzzy Control System For Industrial Automation ApplicationsDocument7 pagesFPGA Implementation of High Speed PI Like Fuzzy Control System For Industrial Automation ApplicationsIJMERNo ratings yet

- Basic TheoryDocument5 pagesBasic TheoryzakiNo ratings yet

- Step by Step Modeling and Tuning For Fuzzy Logic ControllerDocument12 pagesStep by Step Modeling and Tuning For Fuzzy Logic ControlleraymanNo ratings yet

- Result PPRDocument5 pagesResult PPRMayuri Chauray-shindeNo ratings yet

- International Journal of Engineering Research and Development (IJERD)Document7 pagesInternational Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- Lapres P4Document19 pagesLapres P4zakiNo ratings yet

- Project Synopsis Digital Controller Using Matlab: Deptt. of Electronics and InstrumentationDocument9 pagesProject Synopsis Digital Controller Using Matlab: Deptt. of Electronics and InstrumentationSaumya TripathiNo ratings yet

- Speed Control of DC Motor Using Pid Controller ThesisDocument7 pagesSpeed Control of DC Motor Using Pid Controller ThesisWriteMyPaperForMeTucson100% (2)

- DC Motor Speed Control Using PID Controller in Lab View: February 2015Document5 pagesDC Motor Speed Control Using PID Controller in Lab View: February 2015Muhdnursalam ZolkepliNo ratings yet

- Autotuning Fuzzy PID Controller For Speed Control of BLDC MotorDocument8 pagesAutotuning Fuzzy PID Controller For Speed Control of BLDC MotorZikra ElninoNo ratings yet

- Lab View Based Speed Control of DC Motor Using PID Controller-1582Document6 pagesLab View Based Speed Control of DC Motor Using PID Controller-1582user01254No ratings yet

- Line Follower LEGO NXT RobotDocument10 pagesLine Follower LEGO NXT RobotMohammad Johirul IslamNo ratings yet

- Lab 6 Engineering Measurement and Lab SampleDocument11 pagesLab 6 Engineering Measurement and Lab Sampletk_atiqahNo ratings yet

- PID Control For Two-Wheeled Inverted Pendulum (WIP) System: January 2015Document7 pagesPID Control For Two-Wheeled Inverted Pendulum (WIP) System: January 2015ban bekasNo ratings yet

- Design and Simulation of Speed Control of DC Motor by Fuzzy Logic Technique With Matlab/SimulinkDocument4 pagesDesign and Simulation of Speed Control of DC Motor by Fuzzy Logic Technique With Matlab/SimulinkHakanBolatNo ratings yet

- Digital Control (Unit-1)Document52 pagesDigital Control (Unit-1)osantqvrzxNo ratings yet

- PID Theory From WikipediaDocument7 pagesPID Theory From Wikipediaputra-tzuNo ratings yet

- Thesis Pid ControllerDocument5 pagesThesis Pid Controllerjanaclarkbillings100% (2)

- PIIIDDocument12 pagesPIIIDLionel81No ratings yet

- Low Power VLSI Architectures For Digital PID Controller ApplicationsDocument8 pagesLow Power VLSI Architectures For Digital PID Controller ApplicationsAbrar Ul HaqNo ratings yet

- The Working Principle of A PID Controller For BeginnersDocument15 pagesThe Working Principle of A PID Controller For BeginnersSaber AbdelaalNo ratings yet

- Diseño-Guia 7Document9 pagesDiseño-Guia 7RhinometalI&CNo ratings yet

- Module 4.scilabDocument13 pagesModule 4.scilaborg25grNo ratings yet

- Color Making and Mixing Process Using PLCDocument5 pagesColor Making and Mixing Process Using PLCInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Advanced Techniques and Technology of Computer-Aided Feedback ControlFrom EverandAdvanced Techniques and Technology of Computer-Aided Feedback ControlNo ratings yet

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- Peraturan Markah Simbol Komponen Aktif PasifDocument13 pagesPeraturan Markah Simbol Komponen Aktif PasifIzlaikha AzizNo ratings yet

- EMCSDocument40 pagesEMCSbillalNo ratings yet

- DRV5055 Ratiometric Linear Hall Effect Sensor: 1 Features 3 DescriptionDocument32 pagesDRV5055 Ratiometric Linear Hall Effect Sensor: 1 Features 3 DescriptionGavinNo ratings yet

- A Finite Difference Numerical Analysis of Galvanic Corrosion For Semi-InfiniteDocument7 pagesA Finite Difference Numerical Analysis of Galvanic Corrosion For Semi-InfiniteThiagoCarvalhoNo ratings yet

- Pioneer ddj-s1 rrv4168 DJ Controller PDFDocument134 pagesPioneer ddj-s1 rrv4168 DJ Controller PDFWilliam Rangel GarciaNo ratings yet

- Scan-Speak Technote01 TS-measurementDocument5 pagesScan-Speak Technote01 TS-measurementVladimir SimicNo ratings yet

- RemoteDocument30 pagesRemoteGhidaa SalahNo ratings yet

- Mos FabricationDocument35 pagesMos FabricationNhật HoàngNo ratings yet

- ToneLab LE ManualDocument128 pagesToneLab LE ManualArturo ContrerasNo ratings yet

- Bhel RSC VaranasiDocument29 pagesBhel RSC Varanasishobhan1984No ratings yet

- Yaesu FT-680R Instruction ManualDocument50 pagesYaesu FT-680R Instruction ManualYayok S. AnggoroNo ratings yet

- Sensor and TransducerDocument15 pagesSensor and Transducerrashmi patil100% (1)

- Sensors and Instrumentation ProjectDocument9 pagesSensors and Instrumentation ProjectSai Sandeep RayanuthalaNo ratings yet

- Declencheur MT320CDocument4 pagesDeclencheur MT320CFou DelleNo ratings yet

- 721 Speed ControlDocument102 pages721 Speed Controlbondan_pertamaxNo ratings yet

- Voltage Transformer National GridDocument5 pagesVoltage Transformer National GridBruce CoxNo ratings yet

- Coupled Mode and Parametric Electronics W.H. Louisell 1960 Forward-ContentsDocument12 pagesCoupled Mode and Parametric Electronics W.H. Louisell 1960 Forward-ContentsHank ReardenNo ratings yet

- Simotras HD FaultDocument600 pagesSimotras HD FaultsantoshNo ratings yet

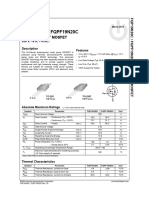

- FQP19N20CDocument10 pagesFQP19N20CVinicio VieiraNo ratings yet

- Pre-Board 2020 - Physics PDFDocument9 pagesPre-Board 2020 - Physics PDFYASH PRANESHNo ratings yet

- UC384XA-BW Current Mode PWM Controller: (UC3842A-BW/ 43A-BW/ 44A-BW/ 45A-BW)Document10 pagesUC384XA-BW Current Mode PWM Controller: (UC3842A-BW/ 43A-BW/ 44A-BW/ 45A-BW)Damir SkarepNo ratings yet

- Denon AVR 1905 Owners ManualDocument46 pagesDenon AVR 1905 Owners ManualDzoroNo ratings yet

- TR-UP - X-Band REPLACEMENT PROCEDURE OF MAGNETRON PDFDocument8 pagesTR-UP - X-Band REPLACEMENT PROCEDURE OF MAGNETRON PDF2by2 BlueNo ratings yet

- Lighting Design TechniquesDocument11 pagesLighting Design TechniquesMohammed Azharuddin SulaimanNo ratings yet

- Stamford Ucdi274kDocument7 pagesStamford Ucdi274kSilver SilverNo ratings yet

- Safe Flame Scan I (Manual)Document0 pagesSafe Flame Scan I (Manual)ntpckanihaNo ratings yet

- Failure 1819 PDFDocument184 pagesFailure 1819 PDFpadma devi100% (1)

- The Fluorescent Lighting System BY - Frank DurdaDocument97 pagesThe Fluorescent Lighting System BY - Frank Durdawas00266No ratings yet

- 216B, 226, 232B, 236, 242, 246, 248, 252, 262, and 268 Skid Steer Loaders and 247, 257, 267, 277, and 287 Multi Terrain Loader Sist. Elect.Document4 pages216B, 226, 232B, 236, 242, 246, 248, 252, 262, and 268 Skid Steer Loaders and 247, 257, 267, 277, and 287 Multi Terrain Loader Sist. Elect.Pablo PorrasNo ratings yet

- Manual Servomex Xendos 1800Document20 pagesManual Servomex Xendos 1800Josh MoralesNo ratings yet