Professional Documents

Culture Documents

Unjamming A Granular Hopper by Vibration: EPLA, 2009

Uploaded by

A94leo14hsetmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unjamming A Granular Hopper by Vibration: EPLA, 2009

Uploaded by

A94leo14hsetmaCopyright:

Available Formats

July 2009

EPL, 87 (2009) 24002 www.epljournal.org

doi: 10.1209/0295-5075/87/24002

Unjamming a granular hopper by vibration

A. Janda

1(a)

, D. Maza

1

, A. Garcimartn

1

, E. Kolb

2

, J. Lanuza

2

and E. Cl ement

2

1

Departamento de Fsica, Facultad de Ciencias, Universidad de Navarra - E-31080 Pamplona, Spain, EU

2

Laboratoire de Physique et Mecanique des Milieux Heterog`enes, associe au CNRS (UMR 7636) lESPCI et aux

Universites Paris 6 et Paris 7 - 10 rue Vauquelin, 75005 Paris France, EU

received 20 March 2009; accepted in nal form 30 June 2009

published online 5 August 2009

PACS 45.70.Ht Avalanches

PACS 45.70.Mg Granular ow: mixing, segregation and stratication

Abstract We present an experimental study of the outow of a hopper continuously vibrated

by a piezoelectric device. Outpouring of grains can be achieved for apertures much below the usual

jamming limit observed for non-vibrated hoppers. Granular ow persists down to the physical limit

of one grain diameter, a limit reached for a nite vibration amplitude. For the smaller orices, we

observe an intermittent regime characterized by alternated periods of ow and blockage. Vibrations

do not signicantly modify the ow rates both in the continuous and the intermittent regime. The

analysis of the statistical features of the owing regime shows that the ow time signicantly

increases with the vibration amplitude. However, at low vibration amplitude and small orice

sizes, the jamming time distribution displays an anomalous statistics.

Copyright c EPLA, 2009

Introduction. Since the end of the Middle Ages

sand clocks have been customarily used to measure time

owing (see, for example, an historical monography in [1]).

Nowadays, hoppers are widely used in the industry to store

and deliver granular matter [2]. In both situations one uses

a striking property of granular matter as the owing rate

does not depend on the height of material in the container

but rather, on the size of the orice. This was rationalized

in the 1960s by Beverloo, who proposed a simple scaling

law for the discharge rate essentially based on the free

falling velocity at a scale comparable to the aperture [3,4].

The scaling law includes an empirical modication to

account for small orices (sizes of the order of a few grain

diameters). In this case, one observes blocking of the ow

due to the presence of static vaults forming at the exit [5].

This can be problematic for industrial processes since it

severely limits the possibility to deliver small quantities

of material in a reliable way. In recent years this issue

has been studied in detail with the aim to characterize

more thoroughly the jamming probability and the ow

properties near this limit [59]. One way to deal in practice

with the problem of blockages is to add vibrations in order

to restore the ow by breaking the arches [10]. Previous

works have been devoted to the inuence of vibrations in

a hopper discharge [1115]. In most cases, however, the

main interest was the inuence of vibrations on the ow

(a)

E-mail: ajandaga@alumni.unav.es

rate. As the motivation was usually a practical situation,

these studies often deal with strong vibrations and large

orices, well above the jamming limit. Here we focus on

small orices, which are prone to jamming. Indeed, this

question is not just a technical one, but relates to the

fundamental properties of granular matter and can be put

in framework of current interrogations on the jamming

transition of soft matter [16]. In the present case, deep

interrogations arise about the capability for a granular

packing to ow in a restrained geometry and on the

true nature of the block/unblock mechanisms. From a

theoretical point of view this set of questions can be

framed in the context of the rigidity transition driven by

the existence of a marginal mechanical state, i.e., where

the average number of contacts is just sucient to ensure a

solid structure to the packing (the isostatic limit [17]). In

this case, one observes a large density of so-called soft

modes corresponding to collective granular motion at

low energy cost. At the outlet of a hopper the conning

pressure vanishes, thus giving a situation where, if of

any importance, anomalous critical behavior should be

revealed (at least from a nite size scaling perspective).

In this paper, we present a novel insight on the problem,

with an experimental design of a hopper that allows a

ne statistical study of granular ows in this limit. The

continuous variation of two crucial parameters (diameter

opening and vibration amplitude) allows to deal with the

probability of arch formation and thus, to go well below

24002-p1

A. Janda et al.

P

M

S L

40 60 80 100 120 140 160

-0.2

-0.1

0

0.1

0.2

40 60 80 100 120 140 160

0

0.5

1

time (seconds)

T T

J F

To PC

D

P

T

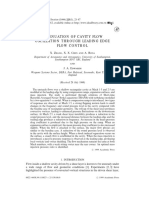

Fig. 1: Experimental setup: M, microphone; S, scale; P, piezo-

electric transducer; T, translation stage. The top of the granu-

lar column is open at the atmospheric pressure. A sketch of the

bottom outlet is also shown with the variables L and D. The

piezoelectric transducer vibrates in the direction perpendicular

to its surface as indicated by the black arrows. Note that the

walls of the hopper are not touching the piezoelectric, but only

the grains. The top right insets show the signal as measured

from the microphone (top, signal level in arbitrary units) and

the binarized signal (bottom).

the usual jamming limit. In this way, we are able to

investigate the properties of the granular ow down to

the physical limit of one grain aperture.

Experimental setup. The silo is made of a

plexiglass cylindrical tube (inner diameter 1.9 cm) and is

specically designed to control continuously two impor-

tant parameters that will allow an extensive study of

the transition to a blocking state, namely, the aperture

opening and the vibration amplitude. To this purpose,

the design of the bottom outlet is special. The cylinders

bottom edge was obtained by a planar cut at 45 deg.

The resulting elliptic area is partially closed by a at

rectangular surface on which a thin piezoelectric trans-

ducer is mounted, its diameter being larger than the silo

diameter. The blocking piece can be moved along the cut

in the direction of the larger diameter of the ellipse via a

micrometric translation stage (see g. 1). The hole hence

produced, is characterized by a minimal opening distance

L (see inset of g. 1). The piezoelectric transducer is

driven with a sinusoidal vibration at a frequency of

350 Hz and it vibrates in the direction perpendicular to

its surface. Note that the vibration is directly applied

to the granular material inside the silo, but not to the

wall, which is not touching the vibrating transducer.

The granular material consists of glass beads, their

diameter being 1.55 0.05 mm. Prior to the experiments,

we measured the energy input due to the vibrations

induced by the piezoelectric device. An accelerometer was

buried at the top of the fully lled silo and for dierent

electric voltage amplitudes, the r.m.s. acceleration was

monitored, with the outlet closed. A linear relation is

obtained between the electric voltage and the acceleration

in the bulk of the granular column. We checked that the

acceleration does not change signicantly when the outlet

is open. The typical measured accelerations are only a

fraction of the gravity acceleration. For the maximum

induced vibration amplitude (a r.m.s. acceleration of

about 1 m/s

2

), the typical kinetic energy is much smaller

(by about ve orders of magnitude) than the potential

energy at the scale of a grain diameter. The mass ux is

monitored by recording the mass of grains that fall from

the silo on an electronic scale interfaced with a computer.

To have a good determination of the time lapses when

the orice is jammed or when it ows, a plastic sheet

with a microphone attached to it is mounted below the

silo outlet. Thus the sound produced by the impact of the

falling grains can be monitored and time lapses inferred.

Dependence of the mean ow with the orice

size. The determination of the mean mass ow Q was

carried out by measuring the time taken to deliver a

large quantity of grains (about 2 10

4

). The conventional

picture for the outpouring of grains through a hole is

embodied in the so-called Beverloos scaling [3,4], that

relates the mean ow rate to the aperture diameter. In

this scenario, grains are released from an imaginary vault

having the same radius as the exit orice. In our case, it is

not clear what is the right length scale controlling the

size of the dynamical vault that actually releases the grains

(and therefore determines the mean ow). So in order to

benchmark our experimental setup, we measured the mean

ow Q (in the absence of vibration) as a function of the size

of the exit orice for the cases where no permanent jams

are observed. We have taken as a characteristic length

the projection of L (see g. 1) on the horizontal axis:

D =

2

2

L. To check whether the Beverloo scaling is valid,

the length scale =(Qg

1/2

1

)

2/5

, where g is the gravity

acceleration and the density of the beads, is computed.

As seen in g. 2, the data without any vibration are

compatible with the Beverloo scaling QD

5/2

. Remark

that we do not intend to discuss here the validity of this

scaling, which is a priori not obvious for small orices

(and especially with the present geometry). This has been

done elsewhere [18]. The relevant point is that although

the shape of the outlet is not circular and its area does

not increase as D

2

, the data follow conspicuously well

Beverloos scaling down to the blockage limit. This seems

to indicate that there is only one structural length scale

24002-p2

Unjamming a granular hopper by vibration

Fig. 2: (Color online) Length scale normalized to the bead

diameter d as a function of rescaled aperture size D for various

vibration amplitudes. The dashed line is a t of the data for

big D; the slope is close to one. The arrows mark the minimum

rescaled orice size D

min

(denition explained in the text).

Inset: value of D

min

/d as a function of .

controlling the granular ux, and that it is directly linked

to the aperture distance D.

The inuence of vibrations. The applied vibration

is quantied through the rescaled acceleration , which is

the r.m.s. acceleration normalized by the gravity acceler-

ation g. Note that the pertinent parameter could also be

the kinetic energy. We do not intend to discuss here the

inuence of the driving frequency, and only the driving

amplitude at a given frequency is changed.

In the absence of vibration and for small apertures,

there are situations where the ow is continuous for some

time and then it can eventually get blocked forever. The

application of a vibration can unjam the ow (it depends

on how energetic the vibration is). With applied vibration,

the ow can also get blocked, but the outpouring can

resume after a nite time. In other words, an intermittent

regime is observed. In order to extract rational ow

properties we must dene a strict and precise working

protocol that involves the nite mass of grains we seek to

deliver and the time we are ready to wait before deciding

that the ow is halted. The protocol chosen involves a xed

amount of grains (approximately 2 10

4

beads); if this

mass is delivered without any jam that lasts for 100 s or

more, then the hopper is considered to be owing. If there

is a jam that lasts for 100 s or more, the run is nished

and the silo is considered to be jammed. The time interval

of 100 s was so chosen because our experiments indicate

that it is very unlikely that the ow will resume by itself

without vibration after that time lapse. For a given and

D, the mean ow Q is calculated as the mass discharged

divided by the total time of measurement. The size of

the orice D is then decreased and the measurements are

carried out again, as long as the waiting time does not

exceed the predened limit. In this way, for each vibration

amplitude we obtain D

min

(), the smallest size of the

orice for which the ow has not been halted during a

time lapse longer than 100 s before the mentioned amount

of material is discharged (i.e. the smallest value of D for

which the hopper is considered to be in a owing state,

as obtained with the mentioned protocol). In some way,

D

min

might be related to the size of the orice above

which jamming is extremely improbable in a non-vibrated

silo [7].

The data are displayed in g. 2, where the values of

D

min

for dierent are indicated by arrows. The rst

salient feature is that for orices of sizes above D

min

(=0)

(corresponding to the black arrow) the inuence of

vibration is negligible, i.e. the mass ux does not change

whatever the value of . Second, the vibrations allow

the possibility of ow below this orice size. The more

energetic the vibration is, the lower is the minimal value

of D for which the silo can ow without getting jammed.

The last striking point is that for a nite value of , one

can reach by linear extrapolation the value D

min

/d =1

below which hard grains cannot go through the aperture

(see inset of g. 2). This result proves conceptually the

design value of such an activated outlet that is able to

deliver granular ow down to the ultimate physical limit

of one grain size (D

min

/d =1). However, we need now

to push the study further and characterize the owing

dynamics because below the value of D

min

( =0) the

mean ow as dened before does not follow anymore a

simple Beverloos scaling.

Intermittency and jamming. In the presence of

vibrations at the outlet, therefore, the usual limitation

of a minimum size to deliver grains from a hopper can

be overcome. However, in this regime the outlet ow

displays a strong intermittent dynamics that needs to be

characterized in more detail. Using the mass recorded on

the scale, we examine directly the exit ow continuously

over time. In g. 3 four time series corresponding to the

mass delivered on the scale are represented for four dier-

ent vibration amplitudes, the exit orice being the same

a certain value below D

min

( =0). As the vibration

decreases, the curves clearly display jam periods of larger

duration. These events are rare or non-existent for aper-

tures larger than the value of D

min

( =0).

From the data series as presented in the inset of g. 1

(impacts of grains on the microphone) and in g. 3

(outow mass delivered on the scale), we propose that this

dynamical issue can naturally be separated into two sets

of questions pertaining to the owing and to the jammed

regimes: i) when the hopper is owing, how long is it going

to ow and what is the ow rate? ii) When it gets jammed,

how long does the blockage persist and what fraction of

the overall experimental time does it spend in that state?

These questions are going to be addressed in detail next.

The owing regime. The time intervals T

F

during

which the hopper is owing are obtained from the impact

24002-p3

A. Janda et al.

Fig. 3: (Color online) The masses delivered by the silo with an

exit orice D =2.42d as a function of time, for four dierent

vibrations as indicated in the legend. The dashed horizontal

lines mark the upper and lower bounds of the zone where the

mean ow has been measured for comparison (see explanation

in the text).

Fig. 4: (Color online) Histogram of the rescaled time intervals

during which the orice D =1.78d has been owing (in semi-

logarithmic scale). Inset: mean owing time as a function of

the rescaled r.m.s. acceleration .

of the out-owing grains on the microphone (see g. 1,

inset) for an experiment at constant D and . As seen in

g. 4, the distribution of T

F

shows an exponential tail.

Therefore, a characteristic time (, D) can be dened.

The inset shows that this characteristic time increases

with acceleration and goes to a nite value when

tends to zero. The fact that one can dene a characteristic

value for the owing intervals T

F

is consistent with the

existence of mean avalanche sizes obtained in [7,8] in the

case of a non-vibrated silo where the discharge through

the small orice is restored by jet of pressurized air.

The remarkable point here is that this is also the case

when vibrations are applied. This hints to an interesting

feature that will be checked next, namely, that when

Fig. 5: (Color online) PDFs of the ow rate (obtained by

averaging in a time window of 1 s) with an exit orice D =2.42d

and for ve dierent vibration amplitudes as indicated in the

legend.

the vibration is applied the restored ow has the same

statistical features that the corresponding ow one would

have without vibration. As noted earlier, this is true

above D

min

( =0). Let us take a closer look at g. 3,

which corresponds to a diameter D inside the intermittent

domain, and in particular, let us consider four stretches in

the plots where the orice is not blocked (as marked with

horizontal dashes). The mean ow for these intervals are

all similar: 4.05, 3.99, 3.88 and 4.10 0.01 g/s, respectively

(the resolution is the least-mean-square t error). To

investigate this point in more detail, we computed the

histograms of the ow rate q corresponding to the same

orice size for ve dierent vibration amplitudes (g. 5).

Note that in this case the ow q is measured as the number

of beads delivered in one second. The most remarkable

feature of g. 5 is that the q PDFs mainly consists of

a Gaussian centered around the same mean value of the

ow rate whatever is. The dierences appear for the low

ow rate events corresponding to the small ow rates. It

seems that a higher vibration amplitude is able to reduce

signicantly those events that seems to bring the system in

the vicinity of blockage. Consequently, the time of ow can

be signicantly increased as noted before. Interestingly,

this distribution is in agreement with previous results for

non-vibrated silos [19].

The jammed regime. Let us now explore the

jamming dynamics due to arch formation at the outlet

of the hopper. These arches are constantly destroyed

by vibrations and then recreated by jamming. The time

intervals during which the outpouring has been halted are

denoted by the variable T

J

(see inset of g. 1). The PDFs

of T

J

for a xed D at several are displayed in g. 6.

A typical time scale to compare with can be obtained

by calculating the time it takes for a bead to fall its own

diameter under the acceleration of gravity, namely

g

=

2d/g 0.02 s. For times larger than

g

the distribution

24002-p4

Unjamming a granular hopper by vibration

Fig. 6: (Color online) Histogram for the time lapses that the

orice has remained blocked, in logarithmic scale, correspond-

ing to D =1.78d. The dashed line has a slope of two. Note that

for the smallest acceleration displayed (triangles) the slope is

smaller than two.

decays as a power law with an exponent that depends

on the vibration amplitude (g. 6). Importantly, for small

holes and low the power law displays an exponent

smaller than 2 (absolute value), and this means that the

rst moment of the distribution does not converge. In

other words, the data show that the distribution of jam

durations can be extremely large and that the mean time

during which the hopper is jammed will depend on the

total time that the experiment has been running. Then

the value of the mean ow can be dominated essentially by

the longest jam. Due to these features, the term anomalous

statistics is used here to describe the situation.

Since the transition to this regime can not be rigorously

dened in terms of an average ow, we propose instead

an alternative characterization. The fraction of time for

which the hopper is jammed is computed inside a time

window of variable length (T

W

). This time window is taken

inside a long time series during which the experiment has

been running. The measurements are carried out for a

xed diameter D =2.42d and for several values of .

In g. 7(a) the values of as a function of T

W

are

displayed on a normal-log representation. It can be seen

that for high acceleration, a steady state is reached after a

short transient, indicating the existence of a well dened

mean time spent in the jammed state. However, for

intermediate accelerations ( =0.042, 0.029 and 0.017),

no steady state is reached and the denition of an average

time for the jams does not make sense. Finally, 1 for

0 because after a nite time the ow is blocked by an

arch at the outlet, which is not likely to be destroyed in

the time scales involved in the experiment. Note that the

slow dynamics (the time is represented in a log scale) have

some features similar to aging processes. An alternative

way to describe this transition is shown in g. 7(b), where

Fig. 7: (Color online) The transition from owing to jammed

regime. (a) Fraction of the time for which the ow is jammed

as a function of the observation time window T

W

. Note

the logarithmic scale on the horizontal axis. Each line is a

single experimental run. (b) The fraction of time that the

system is jammed, calculated for T

W

=1000 s, as a function

of . Each point is the median of 10 dierent runs, with

the error bars corresponding to the median absolute deviation

about the median. The red dash line represents a hypothetic

step function which would be obtained for T

W

. The two

dierent regimes dened by the step function are named by

roman numbers I and II. The value given for

c

is tentative.

the values of at T

W

=1000 s are represented as function

of for D =2.42d. For the statistical description, we plot

the median (which is a more robust locator in the case

of anomalous statistics) of 10 runs, and the error bars

correspond to the median absolute deviation about the

median, or MAD. As is obvious, the transition is not only

evidenced by the values of going from one to zero in the

region 0.01 < <0.06, but also by the large error bars, as

expected.

Now, let us get back to g. 7(a) and in particular

to the data corresponding to intermediate accelerations

( =0.042, 0.029 and 0.017). In those cases, no steady

state is reached and presents a positive slope. Therefore,

it is reasonable to suppose that will tend to 1 for

24002-p5

A. Janda et al.

T

W

. Assuming this supposition,

() would be

a step function with two regimes separated by a critical

acceleration

c

(see g. 7(b)). For >

c

, the mean time

spent in the jammed state would be well dened, and a

steady ow rate would be reached. However, for <

c

,

we could be able to get the silo owing, but the outow

rate would not be well dened, just because the mean time

spent in the jammed state would not be well dened. The

existence of a

c

is in agreement with the transition to an

exponent lower than 2 (absolute value) in the power laws

found for the PDF of T

J

(g. 6).

Conclusions. We presented an experimental study

of the discharge of a granular hopper with an external

vibration applied at the outlet. The design allows a

continuous control of the vibrational energy injected in the

granular packing (via a piezoelectric transducer) as well

as a continuous variation of the orice size. We were thus

able to measure precisely the size D

min

() below which

the ow is halted and its dependence with the vibration

r.m.s. acceleration . In the absence of vibration, the

grains stop owing below an orice size D

min

( =0). We

show that D

min

() decreases with an increasing vibration

and this, down to one grain size, value reached for a

nite vibration amplitude. This would allow, in principle, a

conceptual design suited to deliver individual grains from

a hopper. This surprising feature poses many questions

on the fundamental mechanism at work for blockage; at

the moment, we have no clear theoretical vision or even a

scaling argument to explain the relationship between D

min

and . We intend to explore this question in future works

by changing the frequency of vibration, the grain size and

the hopper geometry.

Below the D

min

( =0) threshold, we have evidenced

an intermittent regime. It consists of owing and jammed

periods. We describe the owing intervals as a stochas-

tic process for the ow rate. Vibrations only aect prob-

abilities to observe low ow rates but hardly change the

distribution around the mean value set only by the hopper

aperture. In a future work we will seek to provide a quanti-

tative description of the ow statistics and its relation with

the stopping probability. The jammed intervals are asso-

ciated with the blockages of the packing, that can last a

very long time before a continuous ow may restart. At low

acceleration, we evidence an anomalous statistics for the

jamming times, characterized by a power law distribution

with no rst moment. More precisely, we characterized the

transition to an anomalous statistics by monitoring the

fraction of time for which the hopper is jammed as a func-

tion of the observation time T

W

. This anomalous statistics

is associated with an elusive value for the blockage thresh-

olds that may actually depend either on the total number

of grains available or the time we are willing to wait for

the ow to resume. This property is strongly reminiscent

of the anomalous dynamics usually observed for creeping

ows of glassy materials. It would be interesting to relate

the ow anomalies described here to the new proposition

that has emerged recently to describe glassy systems and

the contribution of the so-called soft-modes dynamics

to transport properties.

We thank I. Zuriguel and L. A. Pugnaloni for

their suggestions. We acknowledge the Picasso bilat-

eral collaboration program between Spain and France.

Funding for this work was provided by Projects FIS2005-

03881, FIS2008-06034-C02-01 and HF 2006-0234 (Spanish

Government). AJ thanks Fundaci on Ram on Areces for a

grant.

REFERENCES

[1] Junger E., Das Sanduhrbuch (Vittorio Klostermann

Verlag, Frankfurt) 1954.

[2] Brown R. L. and Richard J. C., Principles of Powder

Mechanics (Pergamon) 1970.

[3] Nedderman R. M., Statics and Kinematics of Granular

Materials (Cambridge University Press, Cambridge) 1992.

[4] Beverloo W. A., Leniger H. A. and Van de Velde

J., J. Chem. Eng. Sci., 15 (1961) 260.

[5] To K., Lai P.-K. and Pak H. K., Phys. Rev. Lett., 86

(2001) 71.

[6] Cl ement E., Reydellet G., Rioual F., Parise B.,

Fanguet V., Lanuza J. and Kolb E., Trac and

Granular Flow 99, edited by Helbing D., Herrmann

H. J., Schreckenberg M. and Wolf D. E. (Springer,

Berlin) 2000, p. 457.

[7] Zuriguel I., Pugnaloni L. A., Garcimartn A. and

Maza D., Phys. Rev. E, 68 (2003) 030301.

[8] Zuriguel I., Garcimartn A., Maza D., Pugnaloni

L. A. and Pastor J. M., Phys. Rev. E, 71 (2005) 051303.

[9] Janda A., Zuriguel I., Garcimartn A., Pugnaloni

L. A. and Maza D., EPL, 84 (2008) 44002.

[10] IMechE Seminar Publication, Hopper and Silo

Discharge (Professional Engineering Publishing Ltd.,

London) 1999.

[11] Hunt M. L., Weathers R. C., Lee A. T., Brennen

C. E. and Wassgren C. R., Phys. Fluids, 11 (1999) 68.

[12] Wassgren C. R., Hunt M. L., Freese P. J.,

Palamara J. and Brennen C. E., Phys. Fluids, 14

(2002) 3439.

[13] Veje C. T. and Dimon P., Granular Matter, 3 (2004)

151.

[14] Chen K., Stone M. B., Barry R., Lohr M.,

McConville W., Klein K., Sheu B. L., Morss A. J.,

Scheidemantel T. and Schiffer P., Phys. Rev. E, 74

(2006) 011306.

[15] Pacheco-Martinez H., van Gerner H. Jan and

Ruiz-Su arez J. C., Phys. Rev. E, 77 (2008) 021303.

[16] Liu A. and Nagel S. R. (Editors), Jamming and Rheol-

ogy (Taylor and Francis, London) 2001.

[17] Wyart M., Silbert L. E., Nagel S. R. and Witten

T. A., Phys. Rev. E, 72 (2005) 051306.

[18] Mankoc C., Janda A., Ar evalo R., Pastor J. M.,

Zuriguel I., Garcimartn A. and Maza D., Granular

Matter, 9 (2007) 407.

[19] Janda A., Harich R., Zuriguel I., Maza D., Cixous

P. and Garcimartn A., Phys. Rev. E, 79 (2009) 031302.

24002-p6

You might also like

- Dubbel-Handbook of Mechanical EngineeringDocument918 pagesDubbel-Handbook of Mechanical EngineeringJuan Manuel Domínguez93% (27)

- Principles of Geotechnical Engineering, SI Edition 9th Edition by Braja M. Das, Khaled Sobhan Solution ManualDocument14 pagesPrinciples of Geotechnical Engineering, SI Edition 9th Edition by Braja M. Das, Khaled Sobhan Solution ManualJehan Pahlevi100% (1)

- Harmonic Patterns GuideDocument51 pagesHarmonic Patterns GuideUNSA MANI SAON88% (8)

- Computer Algebra SystemsDocument150 pagesComputer Algebra SystemsA94leo14hsetmaNo ratings yet

- Mass, Stiffness, and Damping Matrix Estimates From Structural MeasurementsDocument7 pagesMass, Stiffness, and Damping Matrix Estimates From Structural Measurementscarlos0094No ratings yet

- SBC Detailed ReportDocument36 pagesSBC Detailed ReportPraneeth Kumar100% (1)

- The History and Physics of Magnetic Particle InspectionDocument51 pagesThe History and Physics of Magnetic Particle InspectiondaemsalNo ratings yet

- Tugas VeigaDocument17 pagesTugas VeigaPutra Tresna100% (2)

- Mesh ShipDocument7 pagesMesh ShipPranshu MalikNo ratings yet

- PDF Manuals Restriction-Mapping-PlasmidDocument23 pagesPDF Manuals Restriction-Mapping-PlasmidAlviro Cosseme0% (1)

- Metrology - Book - Hari PDFDocument212 pagesMetrology - Book - Hari PDFKallol ChakrabortyNo ratings yet

- Introduction to Slag Fundamentals Under 40 CharactersDocument38 pagesIntroduction to Slag Fundamentals Under 40 CharactersNicole Altamirano Catalán100% (1)

- Lyapunov Stability AnalysisDocument17 pagesLyapunov Stability AnalysisumeshgangwarNo ratings yet

- ITP - For Gas Turbine & AuxilliariesDocument12 pagesITP - For Gas Turbine & AuxilliariesAmmar1111186% (7)

- Asymptotic Theory of Supersonic Viscous Gas FlowsFrom EverandAsymptotic Theory of Supersonic Viscous Gas FlowsVladimir NeylandNo ratings yet

- Three problems on mass transfer diffusion processesDocument15 pagesThree problems on mass transfer diffusion processesPasha Tan100% (1)

- 2008 EplDocument6 pages2008 EplA94leo14hsetmaNo ratings yet

- Flow and Clogging in A Silo With An Obstacle Above The OrificeDocument8 pagesFlow and Clogging in A Silo With An Obstacle Above The OrificeA94leo14hsetmaNo ratings yet

- Flow Rate in The Discharge of A Two-Dimensional Silo.: I. Zuriguel, A. Janda, A. Garcimartín and D. MazaDocument4 pagesFlow Rate in The Discharge of A Two-Dimensional Silo.: I. Zuriguel, A. Janda, A. Garcimartín and D. MazaA94leo14hsetmaNo ratings yet

- Dynamic #Ow Behaviour in Bubble Columns: S. Becker, H. de Bie, J. SweeneyDocument7 pagesDynamic #Ow Behaviour in Bubble Columns: S. Becker, H. de Bie, J. SweeneySalwa asyifaNo ratings yet

- Cement Evaluation: Presented To: Dr. Adel SalemDocument21 pagesCement Evaluation: Presented To: Dr. Adel SalemIbrahim elshamiNo ratings yet

- Positive Streamer Propagation in Large Oil: Experimental Characterization of Propagation ModesDocument11 pagesPositive Streamer Propagation in Large Oil: Experimental Characterization of Propagation ModesAlberto OrtizNo ratings yet

- Cement Evaluation Tool: A New Approach To Cement EvaluationDocument7 pagesCement Evaluation Tool: A New Approach To Cement EvaluationMauro CostaNo ratings yet

- Predict Temporal Evolution of Local Scour in Bridge PiersDocument10 pagesPredict Temporal Evolution of Local Scour in Bridge Piersimer_haroNo ratings yet

- PRL 109, 068001 (2012)Document5 pagesPRL 109, 068001 (2012)A94leo14hsetmaNo ratings yet

- Brief Communication: Bubble Coalescence in Turbulent FlowsDocument9 pagesBrief Communication: Bubble Coalescence in Turbulent FlowsCesar AlataNo ratings yet

- NOE0415380416 ch036Document6 pagesNOE0415380416 ch036Umed Abd-alsatarNo ratings yet

- Sonic Logging: M. P. Tixier R. P. AlgerDocument9 pagesSonic Logging: M. P. Tixier R. P. Algersaeed65No ratings yet

- 2011 PRL107 278001Document5 pages2011 PRL107 278001A94leo14hsetmaNo ratings yet

- Acoustic Logging Methods and Applications: Understanding Sonic Log Presentation and LimitationsDocument36 pagesAcoustic Logging Methods and Applications: Understanding Sonic Log Presentation and LimitationsbijupiraNo ratings yet

- 2012 The Effect of Wall Vibrations On The Air Column Inside Trumpet Bells PDFDocument6 pages2012 The Effect of Wall Vibrations On The Air Column Inside Trumpet Bells PDFtitov33No ratings yet

- T. Faug, P. Lachamp, M. NaaimDocument7 pagesT. Faug, P. Lachamp, M. NaaimSonicNo ratings yet

- Roots of MountainsDocument1 pageRoots of MountainsingenieurmechanicalNo ratings yet

- Session B.2 - 3.2Document21 pagesSession B.2 - 3.2sasa.vukojeNo ratings yet

- Effects of Horizontal Vibration On Hopper Flows of Granular Materials (1997)Document12 pagesEffects of Horizontal Vibration On Hopper Flows of Granular Materials (1997)池定憲No ratings yet

- Krylov NOVEM 2005Document13 pagesKrylov NOVEM 2005Lokesh GorantlaNo ratings yet

- Borehole Shear-Wave Surveys for Site InvestigationsDocument14 pagesBorehole Shear-Wave Surveys for Site InvestigationsGEOMAHESHNo ratings yet

- Introduction To Logging Tools: By: Muhammad ZahidDocument7 pagesIntroduction To Logging Tools: By: Muhammad ZahidtayofelaNo ratings yet

- PhysRevFluids 3 012302Document8 pagesPhysRevFluids 3 012302Tapas Kumar Pradhan ce19s014No ratings yet

- Title: Centrifuge Modeling of PGD Response of Buried Pipe: Orourm@rpi - EduDocument11 pagesTitle: Centrifuge Modeling of PGD Response of Buried Pipe: Orourm@rpi - EducosmimthatNo ratings yet

- Interactions of Breaking Waves With A Current Over Cut CellsDocument33 pagesInteractions of Breaking Waves With A Current Over Cut CellsaminhamdipourNo ratings yet

- 1 s2.0 037604219190008R Main PDFDocument71 pages1 s2.0 037604219190008R Main PDFMarcelo GuerraNo ratings yet

- Mankoc PRE (2009)Document7 pagesMankoc PRE (2009)Julian MonteroNo ratings yet

- La 2016534Document9 pagesLa 2016534André Carlos SilvaNo ratings yet

- An MattDocument8 pagesAn MattA94leo14hsetmaNo ratings yet

- De SiltingDocument6 pagesDe Siltingtarang001No ratings yet

- Ijaiem 2014 04 29 086Document5 pagesIjaiem 2014 04 29 086International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Turbulence Reduction by Screens: Byjohan Groth Arne V. JohanssonDocument17 pagesTurbulence Reduction by Screens: Byjohan Groth Arne V. JohanssonhassanakhlaghiNo ratings yet

- Article 5Document10 pagesArticle 5khadija eddahbyNo ratings yet

- Pierson 2020Document20 pagesPierson 2020Hamed Vaziri GoudarziNo ratings yet

- Experimental and Computational Fluid Dynamics Study of Dense-Phase, Transition Region, and Dilute-Phase SpoutingDocument8 pagesExperimental and Computational Fluid Dynamics Study of Dense-Phase, Transition Region, and Dilute-Phase SpoutingHicham HichamNo ratings yet

- Attenuation of Cavity Flow Oscillation Through Leading Edge Flow ControlDocument25 pagesAttenuation of Cavity Flow Oscillation Through Leading Edge Flow ControlRehan NaseerNo ratings yet

- Powder Flow Down A Vertical Pipe: The Effect of Air FlowDocument29 pagesPowder Flow Down A Vertical Pipe: The Effect of Air FlowNkengafac Armstrong menjuaNo ratings yet

- Bell e Mehta 1988Document39 pagesBell e Mehta 1988Nelson LondoñoNo ratings yet

- Turbulent Flow Characteristics Over An Abrupt Step Change in Bed RoughnessDocument17 pagesTurbulent Flow Characteristics Over An Abrupt Step Change in Bed RoughnessSammelan ChowdhuryNo ratings yet

- Wind tunnel tests of conductor modelsDocument1 pageWind tunnel tests of conductor modelsAndres EliasNo ratings yet

- Large-Eddy Simulation of Turbulent Natural-Bed FlowDocument12 pagesLarge-Eddy Simulation of Turbulent Natural-Bed FlowSourabh KumarNo ratings yet

- (Asce) 0733-950X (1992) 118 1Document17 pages(Asce) 0733-950X (1992) 118 1gayathryNo ratings yet

- Convection in A Vibrated Granular Layer: T E P JDocument10 pagesConvection in A Vibrated Granular Layer: T E P JA94leo14hsetmaNo ratings yet

- Thin-Walled Structures: Jianguo Gong, Weisheng Cui, Sheng Zeng, Tao JinDocument6 pagesThin-Walled Structures: Jianguo Gong, Weisheng Cui, Sheng Zeng, Tao JinAnonymous wWOWz9UnWNo ratings yet

- Insulator For 1500kVDocument13 pagesInsulator For 1500kVdc12dcNo ratings yet

- Hull Rimmer Cavity GrowthDocument16 pagesHull Rimmer Cavity GrowthananNo ratings yet

- Larry G. Hill - Development of The LANL Sandwich TestDocument9 pagesLarry G. Hill - Development of The LANL Sandwich TestFraosmNo ratings yet

- Shock-Induced Collapse of A Gas Bubble in Shockwave LithotripsyDocument10 pagesShock-Induced Collapse of A Gas Bubble in Shockwave LithotripsyemadinscribdNo ratings yet

- How To Perform Low Strain Pile Integrity TestDocument6 pagesHow To Perform Low Strain Pile Integrity TestAamirShabbirNo ratings yet

- Determination of The Optimum Crown Pillar Thickness Between OpenDocument8 pagesDetermination of The Optimum Crown Pillar Thickness Between OpenluisparedesNo ratings yet

- Accepted Manuscript: Ultrasonics SonochemistryDocument25 pagesAccepted Manuscript: Ultrasonics SonochemistryHoac Chu KenNo ratings yet

- MTPE22 - High Temperature MaterialsDocument11 pagesMTPE22 - High Temperature MaterialsSatyam GuptaNo ratings yet

- Glossary - LDocument13 pagesGlossary - Lmohan satputeNo ratings yet

- PhysRevLett 132 104004Document6 pagesPhysRevLett 132 104004lpn62261No ratings yet

- Compaction Dynamics of Wet Granular Assemblies: 10.1103/physrevlett.105.048001Document4 pagesCompaction Dynamics of Wet Granular Assemblies: 10.1103/physrevlett.105.048001Jorge Eduardo FiscinaNo ratings yet

- Silo StudyDocument7 pagesSilo Studyshrikant_pesitNo ratings yet

- Field Measurements of Sheet Flow Sediment Transport in The Swash ZoneDocument7 pagesField Measurements of Sheet Flow Sediment Transport in The Swash ZoneAlirezaKhoshkoneshNo ratings yet

- LRFD Design Example Steel Girder Superstructure 2006Document234 pagesLRFD Design Example Steel Girder Superstructure 2006Edson AbnerNo ratings yet

- LRF TxdotDocument70 pagesLRF TxdotjhsalaverriaNo ratings yet

- Csi BridgeDocument11 pagesCsi BridgeA94leo14hsetmaNo ratings yet

- MnDOT LRFD 12-20-10Document898 pagesMnDOT LRFD 12-20-10Dan GatzNo ratings yet

- Redox Reactions in Non-Aqueous Media: Determination of Organic Is T I Yanates Alone, in Formulations and in Important MixturesDocument5 pagesRedox Reactions in Non-Aqueous Media: Determination of Organic Is T I Yanates Alone, in Formulations and in Important MixturesA94leo14hsetmaNo ratings yet

- 2002 EpjbDocument11 pages2002 EpjbA94leo14hsetmaNo ratings yet

- Invictos 2012-2,2013-1Document54 pagesInvictos 2012-2,2013-1Eloy Condori HuillcaNo ratings yet

- Cuencos DisipadoresDocument19 pagesCuencos DisipadoresFlor LuceroNo ratings yet

- Algebra 2012-IDocument2 pagesAlgebra 2012-IMarcial HernandezNo ratings yet

- 2002 Pre65Document5 pages2002 Pre65A94leo14hsetmaNo ratings yet

- Travel Instabilities in Lateral HeatingDocument6 pagesTravel Instabilities in Lateral HeatingA94leo14hsetmaNo ratings yet

- 0950 5SDocument4 pages0950 5SA94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: Heating Module (5 Cai + Cal) Ref: 0940/5SDocument3 pagesItem Reference Description Qty.: Heating Module (5 Cai + Cal) Ref: 0940/5SA94leo14hsetmaNo ratings yet

- 0950Document4 pages0950A94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: PLC S Module Ref: 0940/PLCDocument2 pagesItem Reference Description Qty.: PLC S Module Ref: 0940/PLCA94leo14hsetmaNo ratings yet

- 0932 PLCDocument2 pages0932 PLCA94leo14hsetmaNo ratings yet

- 0950 5SDocument4 pages0950 5SA94leo14hsetmaNo ratings yet

- 0933 PLCDocument2 pages0933 PLCA94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: Heating Module Ref: 0940Document3 pagesItem Reference Description Qty.: Heating Module Ref: 0940A94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: Heating Module (5 Cai + Cal) Ref: 0940/5SDocument3 pagesItem Reference Description Qty.: Heating Module (5 Cai + Cal) Ref: 0940/5SA94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module Ref: 0933Document3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module Ref: 0933A94leo14hsetmaNo ratings yet

- 0932Document3 pages0932A94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: Heating Module (5 Cai + Cal) Ref: 0940/5SDocument3 pagesItem Reference Description Qty.: Heating Module (5 Cai + Cal) Ref: 0940/5SA94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module (10 Cai + Cal) Ref: 0933/10SDocument3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module (10 Cai + Cal) Ref: 0933/10SA94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module (5 Cai + Cal) Ref: 0933/5SDocument3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module (5 Cai + Cal) Ref: 0933/5SA94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module (10 Cai + Cal) Ref: 0933/10SDocument3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module (10 Cai + Cal) Ref: 0933/10SA94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: PLC S Module Ref: 0931/PLCDocument2 pagesItem Reference Description Qty.: PLC S Module Ref: 0931/PLCA94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module Ref: 0933Document3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module Ref: 0933A94leo14hsetmaNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module (5 Cai + Cal) Ref: 0933/5SDocument3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module (5 Cai + Cal) Ref: 0933/5SA94leo14hsetmaNo ratings yet

- Rh35v-Zik DC 1R 113466Document3 pagesRh35v-Zik DC 1R 113466José Hildo PereiraNo ratings yet

- Mobil SHC Gear 320 WTDocument3 pagesMobil SHC Gear 320 WTAnonymous F2TxS3YoaNo ratings yet

- dm16 RRDocument16 pagesdm16 RRioan dumitrescuNo ratings yet

- Impulse 4.0 Users Guide SI PDFDocument554 pagesImpulse 4.0 Users Guide SI PDFalberto fuentealbaNo ratings yet

- DB Concept NehasishDocument23 pagesDB Concept NehasishNehasish SahuNo ratings yet

- Turning FlightDocument12 pagesTurning FlightD ARUL KUMARESANNo ratings yet

- CE 313-Lecture-1 (Course Description)Document43 pagesCE 313-Lecture-1 (Course Description)Yasser Alghrafy100% (1)

- Temprature Controlled Fan: Sunrise University Alwar (Raj.)Document5 pagesTemprature Controlled Fan: Sunrise University Alwar (Raj.)XtremeInfosoftAlwarNo ratings yet

- IwnDocument76 pagesIwnAzizur RahmanNo ratings yet

- Questions On Concepts Q5.1) : and andDocument23 pagesQuestions On Concepts Q5.1) : and andAlejandra Fajardo ApoloNo ratings yet

- Roses Amend 12Document477 pagesRoses Amend 12Koert OosterhuisNo ratings yet

- Leven William F 200605 PHD PDFDocument132 pagesLeven William F 200605 PHD PDFDeni ChanNo ratings yet

- Aircraft Flight Dynamics 2015 - 04 - 13 PDFDocument34 pagesAircraft Flight Dynamics 2015 - 04 - 13 PDFShoeb Ahmed SyedNo ratings yet

- American University of Ras Al Khaimah Chemical Engineering Lab ReportDocument12 pagesAmerican University of Ras Al Khaimah Chemical Engineering Lab ReportRashedul IslamNo ratings yet

- Review Problems: Ppendix GDocument22 pagesReview Problems: Ppendix Givan ivanaNo ratings yet

- Applied Mecanics Lab ManualDocument52 pagesApplied Mecanics Lab ManualHasnain BukhariNo ratings yet