Professional Documents

Culture Documents

02 - BMS DEMO Help File Siemens

Uploaded by

LRSC66Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02 - BMS DEMO Help File Siemens

Uploaded by

LRSC66Copyright:

Available Formats

BMS DEMO Help File Siemens.

docx

2012 Siemens Industry Inc.

Burner Management System DEMO

Operating instructions

BMS DEMO Help File Siemens.docx

2012 Siemens Industry Inc.

Burner Management System DEMO Operating Instructions

Startup Summary - Normal startup is accomplished in four basic steps:

1. Leak Test

a. Safety Valve Leak Test

b. Gas Valve Leak Test

2. Purge

3. Pilot Ignition

4. Main Flame Ignition

Sequence of Operation

5. Leak Test is performed

a. Test 1 - Vent valve is closed and the pressure transmitter is checked for a

rise in pressure. The pressure must be less than 10 PSI for the entire

test. A pressure rise indicates a leaking safety valve

b. Test 2 After Test 1 is successful the safety valve opens and allows the

area after the safety valve and before the gas valves to fill with gas. Then

the safety valve is closed and the pressure transmitter is checked for a

pressure drop. The pressure must be greater than 30 psi for the entire

duration of test 2. A pressure drop indicates a leaking gas valve or vent

valve.

6. Purge is performed Purge fan is turned on and modulating valve is set to the

full open position. The purge is then executed for the required purge time.

7. Post purge window opened After successful purge, the post purge window is

opened. Given normal startup, the post purge window is the final required

permissive to start the burner operation

8. Automated Burner Startup

a. Burner receives startup signal when all interlocks and permissives are

satisfied.

b. Burner starts transformer and opens pilot gas valve

c. Pilot flame check is performed after time for ignition is expired.

d. When pilot flame is present, main gas valve is opened.

e. Main flame check is performed after time for main flam is expired.

9. Burner operates until fault is detected or until burner off command is given

BMS DEMO Help File Siemens.docx

2012 Siemens Industry Inc.

Error Handling

1. If an error occurs during any process the process is automatically aborted.

2. Burner will not start while errors are present.

3. Errors are cleared with a global acknowledgement from the alarm screen.

BMS DEMO Panel Hardware Errors

1. All the analog switches are labeled with a range. If range is undershot system

will execute an abort until sensors are back in range and error is cleared from

alarm screen.

2. Digital switches should be left in the normal position. Changing the position of

the digital switches will demonstrate the safety PLCs hardware error handling.

BMS DEMO Help File Siemens.docx

2012 Siemens Industry Inc.

BMS OVERVIEW HELP

Autostart PC Version This button performs an automated start sequence with

simulated inputs. The required inputs are simulated and set to the proper set points at

the proper point in the operation.

BMS DEMO Help File Siemens.docx

2012 Siemens Industry Inc.

Autostart DEMO PANEL This button performs an automated start sequence and

requires the user to set the inputs during the startup sequence as follows:

1. Preset

a. PT200 LPS GAS TRAIN Set knob greater than 70

b. PT300 HPS GAS TRAIN Set knob between 20 and 90

c. PT AIR D POS SENS Set knob between 30 and 90.

d. PT-201B LEAK TEST PT Set knob so that pressure sensor on screen

reads less than 10.

2. Press Autostart DEMO PANEL

3. LEAK TEST STARTS

a. Watch the screen till gas valve turns green. When gas valve is green,

adjust PT-201B so that pressure sensor on screen reads greater than

30.

4. LEAK TEST FINISHES LEAK TEST OK light turns green

5. PURGE STARTS

a. Fan turns on and air damper moves to full open position

b. Purge lasts 5 seconds

6. PURGE FINISHES POST PURGE WINDOW light turns green

7. Burner Ignition Process Begins

a. Igniter transformer starts and pilot valve opens

b. Set PT-201A to greater than 90

c. After ten seconds pilot flame lights

d. Set TT-500 to greater than 90

e. After ten seconds main flame lights

f. Set PT-201A to less than 90.

8. Press Burner Stop to extinguish flame

a. Set TT-500 to less than 90

BMS DEMO Help File Siemens.docx

2012 Siemens Industry Inc.

DEMO Panel Inputs

BMS DEMO Help File Siemens.docx

2012 Siemens Industry Inc.

MANUAL MODE PC HELP

Manual Mode PC Version allows for a step by step startup of the burner without the

requirement to manipulate the actual inputs on the demo panel. The startup sequence

is performed as follows:

BMS DEMO Help File Siemens.docx

2012 Siemens Industry Inc.

1. Set PC MANUAL MODE to ON

2. Presets

a. Toggle HPS and LPS to safe state, indicated by green switches and a

green SAFE PRESSURE STATUS light. If not toggled correctly a box will

appear around the switches and ask for toggling.

b. Toggle air damper to start position. If not toggled properly a box will

appear around the air damper and ask for toggling.

3. Press Set Low P Button Pressure displayed in on screen transducer should

be less than 10.

4. Press Start PC Leak Test Leak test 1 starts

5. When the safety valve opens press Set High P

6. When the safety valve closes leak test 2 starts. After 10 more seconds, leak

test is complete and LEAK TEST OK light turns green.

7. Press Start Purge Purge fan powers on and air damper moves to full open.

8. After purge finishes, air damper moves back to starting position and post

purge window opens.

9. While post purge window is open, press Burner Start

10. Ignition transformer starts firing

11. Press Toggle IGN Sens

12. After time for ignition expires, pilot flame lights.

13. Press Toggle Flame Sens

14. After time for main flame expires, main flame lights.

15. Press Toggle IGN Sens to reset to low position.

BMS DEMO Help File Siemens.docx

2012 Siemens Industry Inc.

Leak Test Overview Help

The Leak Test Overview Screen allows the leak test to be performed on demand, using

the demo panel inputs. Leak test is performed as follows:

1. Preset PT-201B LEAK TEST PT Set knob so that pressure sensor on screen

reads less than 10.

2. Press Leak Test Start - Vent valve is closed and the pressure transmitter is

checked for a rise in pressure. The pressure must be less than 10 PSI for the

entire test. A pressure rise indicates a leaking safety valve

3. Test 2 Watch the screen till gas valve turns green. When gas valve is green,

adjust PT-201B so that pressure sensor on screen reads greater than 30. Then

the safety valve is closed and the pressure transmitter is checked for a pressure

drop. The pressure must be greater than 30 psi for the entire duration of test 2.

A pressure drop indicates a leaking gas valve or vent valve.

BMS DEMO Help File Siemens.docx

2012 Siemens Industry Inc.

PURGE OVERVIEW HELP

Purge Overview Screen allows the purge to be executed on demand. Purge can only

performed when the leak test has been successfully completed.

BMS DEMO Help File Siemens.docx

2012 Siemens Industry Inc.

Burner Overview Help

The Burner Overview Screen allows the burner to be started on demand

using the demo panel.

To start the burner the leak test must be complete, the post purge window must be

opened, the damper valve must be in start position and the pressure switches must be

in a safe state. Burner startup is as follows:

1. Press Burner Start - Burner Ignition Process Begins

2. Igniter transformer starts and pilot valve opens

3. Set PT-201A to greater than 90

4. After ten seconds pilot flame lights

5. Set TT-500 to greater than 90

6. After ten seconds main flame lights

7. Set PT-201A to less than 90.

8. Press Burner Stop to extinguish flame

9. Set TT-500 to less than 90

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Maths Note P1 and P3Document188 pagesMaths Note P1 and P3Afeefa SaadatNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Coating Inspector Program Level 1 Studen 1Document20 pagesCoating Inspector Program Level 1 Studen 1AhmedBalaoutaNo ratings yet

- Visualizing PI System Data: Version 2017 R2Document202 pagesVisualizing PI System Data: Version 2017 R2Amit TiwariNo ratings yet

- Admission:Discharge Criteria in Speech-Language Pathology - ASHADocument16 pagesAdmission:Discharge Criteria in Speech-Language Pathology - ASHANádia MarquesNo ratings yet

- SEM 3037E Tower Piping.Document52 pagesSEM 3037E Tower Piping.Kodali Naveen KumarNo ratings yet

- CD1 ISO/IEC 17000 Conformity Assessment - Vocabulary and General PrinciplesDocument26 pagesCD1 ISO/IEC 17000 Conformity Assessment - Vocabulary and General PrinciplesMAC CONSULTORESNo ratings yet

- Shop SupervisionDocument38 pagesShop SupervisionSakura Yuno Gozai80% (5)

- Super-Critical BoilerDocument32 pagesSuper-Critical BoilerAshvani Shukla100% (2)

- On The Road To Industry 4.0 - Solutions From The Leading-Edge Cluster It S OWLDocument24 pagesOn The Road To Industry 4.0 - Solutions From The Leading-Edge Cluster It S OWLLRSC66No ratings yet

- MagPi 31Document70 pagesMagPi 31Teddy MouraNo ratings yet

- pcs7 Plcsim PDFDocument25 pagespcs7 Plcsim PDFLRSC66No ratings yet

- S7jli70b eDocument648 pagesS7jli70b eLRSC66No ratings yet

- Automation Solution Guide 2008-En WebDocument310 pagesAutomation Solution Guide 2008-En WebLRSC66No ratings yet

- 1935 Standard MechanismsDocument44 pages1935 Standard MechanismsLRSC66No ratings yet

- WinCC User ArchivesDocument94 pagesWinCC User Archiveswww.otomasyonegitimi.comNo ratings yet

- This White Paper Is Brought To You By:: in Instrumentation and How To Avoid ThemDocument7 pagesThis White Paper Is Brought To You By:: in Instrumentation and How To Avoid ThemLRSC66No ratings yet

- Checklist Safety ManualDocument24 pagesChecklist Safety ManualLRSC66No ratings yet

- IPA Assignment Analyzes New Public AdministrationDocument8 pagesIPA Assignment Analyzes New Public AdministrationKumaran ViswanathanNo ratings yet

- University Reserch Worksheet PDFDocument7 pagesUniversity Reserch Worksheet PDFapi-410567922No ratings yet

- Materials For Oxygen ServicesDocument4 pagesMaterials For Oxygen Services陳0鴻No ratings yet

- UN Habitat UPCL Myanmar TranslationDocument254 pagesUN Habitat UPCL Myanmar TranslationzayyarNo ratings yet

- Calculating Molar MassDocument5 pagesCalculating Molar MassTracy LingNo ratings yet

- Comparison of Waste-Water Treatment Using Activated Carbon and Fullers Earth - A Case StudyDocument6 pagesComparison of Waste-Water Treatment Using Activated Carbon and Fullers Earth - A Case StudyDEVESH SINGH100% (1)

- Limits, Fits and Tolerances: Prof. S. S. PandeDocument31 pagesLimits, Fits and Tolerances: Prof. S. S. PandeM PankajNo ratings yet

- Influence of Oxygen in Copper - 2010Document1 pageInfluence of Oxygen in Copper - 2010brunoNo ratings yet

- Understanding Otdr Understanding-otdr-po-fop-tm-aePo Fop TM AeDocument1 pageUnderstanding Otdr Understanding-otdr-po-fop-tm-aePo Fop TM AeAgus RiyadiNo ratings yet

- 1136 E01-ML01DP5 Usermanual EN V1.2Document11 pages1136 E01-ML01DP5 Usermanual EN V1.2HectorNo ratings yet

- HRM Assignment Final - Case StudyDocument7 pagesHRM Assignment Final - Case StudyPulkit_Bansal_2818100% (3)

- Critical Thinking Essay-Animal Testing: Rough DraftDocument10 pagesCritical Thinking Essay-Animal Testing: Rough Draftjeremygcap2017No ratings yet

- Transportation Geotechnics: Tirupan Mandal, James M. Tinjum, Tuncer B. EdilDocument11 pagesTransportation Geotechnics: Tirupan Mandal, James M. Tinjum, Tuncer B. EdilDaniel Juan De Dios OchoaNo ratings yet

- Employees' Job Satisfaction and Organizational Performance A Case of KSRTCDocument4 pagesEmployees' Job Satisfaction and Organizational Performance A Case of KSRTCEditor IJTSRDNo ratings yet

- The Production and Interpretation of Ritual Transformation Experience: A Study on the Method of Physical Actions of the Baishatun Mazu PilgrimageDocument36 pagesThe Production and Interpretation of Ritual Transformation Experience: A Study on the Method of Physical Actions of the Baishatun Mazu PilgrimageMinmin HsuNo ratings yet

- Holacracy FinalDocument24 pagesHolacracy FinalShakil Reddy BhimavarapuNo ratings yet

- Unit 3.1 - Hydrostatic ForcesDocument29 pagesUnit 3.1 - Hydrostatic ForcesIshmael MvunyiswaNo ratings yet

- Individual Moving Range (I-MR) Charts ExplainedDocument18 pagesIndividual Moving Range (I-MR) Charts ExplainedRam Ramanathan0% (1)

- Empowerment Technology - Week 2Document3 pagesEmpowerment Technology - Week 2yahgieNo ratings yet

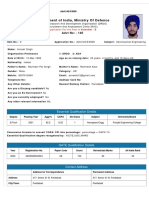

- DrdoDocument2 pagesDrdoAvneet SinghNo ratings yet

- The Critical Need For Software Engineering EducationDocument5 pagesThe Critical Need For Software Engineering EducationGaurang TandonNo ratings yet

- Tomas Del Rosario College: Department: EDUCATIONDocument12 pagesTomas Del Rosario College: Department: EDUCATIONveehneeNo ratings yet

- DLP Din8Document2 pagesDLP Din8KOUDJIL MohamedNo ratings yet