Professional Documents

Culture Documents

Exte Railway

Uploaded by

Madhu KumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exte Railway

Uploaded by

Madhu KumarCopyright:

Available Formats

1

ExTe

Rail Products and References

Securing Cargo. We invented the concept.

2

Index

03 Introduction

04 SR12

17 SR6

20 Maxi

21 Product Descriptions

22 SR12

23 SR8 Timber Bunk

24 SR6 Timber Bunk

24 SR6+ Timber Bunk

25 Return

26 Multi

27 20 Intermodal Cassette

28 Maxi

29 Fastening Systems

31 Support Bolsters and

Grip Protections

33 End Walls

34 Tensioning System

35 Special Design

36 Testing

37 Rail Customers

37 Certificates

40 About ExTe

3

ExTe

Introduction

If you have any interest in the sector of rail transportation of

forest products, you will find this brochure informative and

interesting.

If you also would happen to have interest for the sector of

highway transportation of forest products, you will not be

disappointed by visiting www.exte.se

Welcome to the world of ExTes rail products. Our aim is to

secure cargo as safe as possible at lowest possible LCC.

In the first half of this brochure, youll find a listing of our main

rail customers so far, and in the latter half a little bit more

detailed descriptions of our most common rail products.

As a hint to better understand the following pages, SR 12

stands for a high strength steel timber bunk that is guaranteed

to hold a static and dynamic load of 12 ton per bunk. One

can then only guess what SR 8 and SR 6 stands for. The term

timber bunk means a bolster with two stanchions (hence, it

takes two timber bunks to carry one pile/bundle of logs).

Please do not hesitate to contact us, if you have any questions.

Owe Ljunghammer

MA NAGE R, RA I L B U S I N E S S

ExTe/Extendo

owe.ljunghammer@extendo.se

+ 46 70 5201707

Roger Larsson

D E S I GN A N D SA L E S, RA I L

ExTe

roger.larsson@exte.se

+ 46 70 5593093

4

ExTe

SR12

Rail Freight Company: GC (Green Cargo AB, former Swedish State Railway, SJ)

Technical Details:

Wagon type: Lnps. 22.5 ton axle load.

Approval authorities: Swedish track and safety authorities, Norwegian track and safety authorities

Year of delivery: 1989-1991

Number of wagons: 1,020 two-axle wagons

Number of timber bunks: 5,400

Number of support bolsters: NA

Number of end walls: NA

The SR 12 timber bunk was designed and developed for this operators need in the latter half of the 1980-ties. After some

20 years with around 300 load trips per year in an operational environment considered being one of the roughest in Europe

(both regarding terminal handling and climate), the original equipment is still going strong.

5

ExTe

SR12

Rail Freight Company: GC (Green Cargo AB, former Swedish State Railway, SJ)

Technical Details:

Wagon type: Lnps. 22.5 ton axle load

Approval authorities: Swedish track and safety authorities, Norwegian track and safety authorities

Year of delivery: 2005

Number of wagons: 135 two axle wagons

Number of timber bunks: 810

Number of support bolsters: 270

Number of end walls: 270

6

ExTe

SR12

Rail Freight Company: GC (Green Cargo AB, former Swedish State Railway, SJ)

Technical Details:

Wagon type: Laaps. 25 ton axle load

Approval authorities: Swedish track and safety authorities

Year of delivery: 2004

Number of wagons: 186 twin platform wagons with two axles per platform

Number of timber bunks: 2,232

Number of support bolsters: 744

Number of end walls: NA

7

ExTe

SR12

Rail Freight Company: TGAB (Tgkeriet i Bergslagen AB)

Technical Details:

Wagon type: Sgnss / Sns-x. 22.5 ton axle load and Rps 20 ton axle load

Approval authorities: Swedish track and safety authorities, Norwegian track and safety authorities

Year of delivery: 2005-2011

Number of wagons: 81 bogie wagons

Number of timber bunks: 694

Number of support bolsters: 310

Number of grip protections: 103

Number of end walls: 70

8

ExTe

SR12

Rail Freight Company: Svea Skog (Swedish State Forestry)

Technical Details:

Wagon type: Sgnss 22.5 ton axle load

Approval authorities: Swedish track and safety authorities, Norwegian track and safety authorities

Year of delivery: 2010

Number of wagons: 18 bogie wagons

Number of timber bunks: 180

Number of support bolsters: 126

Number of end walls: 0

9

ExTe

SR12

Rail Freight Company: Peterson Rail AB

Technical Details:

Wagon type: Sgnss. 22.5 ton axle load and Rps 20 ton axle load

Approval authorities: Swedish track and safety authorities, Norwegian track and safety authorities

Year of delivery: 2005 - 2010

Number of wagons: 60 bogie wagons

Number of timber bunks: 548

Number of support bolsters: 368

Number of end walls: 94

10

ExTe

SR12

Rail Freight Company: TX (TX Logistik AB/AG)

Technical Details:

Wagon type: Sgnss. 22.5 ton axle load

Approval authorities: Swedish track and safety authorities, Norwegian track and safety authorities

Year of delivery: 2007-2009

Number of wagons: 75 bogie wagons

Number of timber bunks: 690

Number of support bolsters: 348

Number of end walls: 26

11

ExTe

SR12

Rail Freight Company: Hector (Hector Rail AB)

Technical Details:

Wagon type: Sgnss. 22.5 ton axle load

Approval authorities: Swedish track and safety authorities, Norwegian track and safety authorities

Year of delivery: 2006-2011

Number of wagons: 167 bogie wagons

Number of timber bunks: 1,167

Number of support bolsters: 556

Number of end walls: 170

12

ExTe

SR12

Rail Freight Company: CargoLink AS

Technical Details:

Wagon type: Sgnss. 22.5 ton axle load

Approval authorities: Norwegian track and safety authorities, Swedish track and safety authorities.

Year of delivery: 2009 - 2010

Number of wagons: 41 bogie wagons

Number of timber bunks: 282

Number of support bolsters: 159

Number of end walls: 82

13

ExTe

SR12

Rail Freight Company: Three T

Technical Details:

Wagon type: Srrs. 22.5 ton axle load

Approval authorities: Swedish track and safety authorities

Year of delivery: 2007

Number of wagons: 20 twin platform bogie wagons

Number of timber bunks: 160

Number of support bolsters: 80

Number of end walls: 40

14

ExTe

SR12

Rail Freight Company: Three T

Technical Details:

Wagon type: Sps/Rs. 20 ton axle load and Rps 20 ton axle load

Approval authorities: Swedish track and safety authorities

Year of delivery: 2008

Number of wagons: 37 bogie wagons

Number of timber bunks: 222

Number of support bolsters: 111

Number of end walls: NA

15

ExTe

SR12

Rail Freight Company: Kiwi Rail, New Zeeland

Technical Details:

Wagon type: UK. 14 ton axle load

Approval: Kiwi Rail

Year of delivery: 2011

Number of wagons: 100 bogie wagons

Number of timber bunks: 600

Number of support bolsters: NA

Number of end walls: NA

16

ExTe

SR12

Rail Freight Company: NACCO S.A.S.

Technical Details:

Wagon type: Roos. 20 ton axle load

Approval authorities: Slovak Republic and Austrian track and safety authorities

Year of delivery: 2009

Number of wagons: 1 bogie wagon (test wagon)

Number of timber bunks: 16

Number of support bolsters: 15

Number of end walls: NA

17

ExTe

SR6

Rail Freight Company: Vida Timber AB

Technical Details:

Wagon type: Kbps. 20 ton axle load

Approval authorities: Swedish track and safety authorities

Year of delivery: 2006 - 2010

Number of wagons: 60 two axle wagons

Number of timber bunks: 360

Number of support bolsters: NA

Number of end walls: NA

18

ExTe

SR6

Rail Freight Company: TWA (TRANSWAGGON)

Technical Details:

Wagon type: Laaps. 20 ton axle load

Approval authorities: German track and safety authorities, DB and EBA.

Year of delivery: 2002-2011

Number of wagons: 455 twin platform wagons with two axles per platform

Number of timber bunks: 5,340

Number of support bolsters: NA

Number of end walls: NA

19

ExTe

SR6

Rail Freight Company: FEVE, Spain

Technical Details:

Wagon type: SSgs. 15 ton axle load

Approval body: FEVE

Year of delivery: 2011

Number of wagons: 1 bogie wagon (test wagon)

Number of timber bunks: 8

Number of grip protections: 4

Number of end walls: 2

20

ExTe

Maxi

Rail Freight Company: DB (Schenker), EWS, GC, NSB, NACCO, IBAB

Technical Details:

Wagon type: Roos, Rs, Kbps, Os and Laaps. 20 22.5 ton axle load

Approval bodies: German, English, Norwegian and Swedish track and safety authorities.

Year of delivery: 1996-2011

Number of wagons: 4,500 two axle and bogie wagons

Number of timber bunks: NA

Number of stakes: 108,520

Number of sockets: 50,200

Number of support bolsters: NA

Number of end walls: NA

21

ExTe

Product Descriptions

In the following, ExTes most common rail products are

rudimentary described. It is important to note that the weights

indicated can vary pending on the desired loading gauge

(height and width) and on what type of fastening system that

will be used.

All of ExTes timber bunks, stakes and support bolsters are

manufactured using high strength steel with a tensile between

650 and 1,400.

ExTe Timber Bunks

and ExTe Systems

ExTe has three base models of rail timber bunks with different

characteristics. Height, width and fastening system can vary

pending on customer request and wagon type in question.

The different systems comprise of the Return, Multi, Cassette

and the Maxi.

22

ExTe

SR12 Timber Bunk

Facts:

ExTe SR 12 timber bunk can carry a load of 12 ton each and can be attached to most flat wagons / container wagons. This

even if the wagon type only has two outer frame sills (like most Sgnss designs). The weight is approximately 200-280 kg per

bunk pending loading gauge and fastening system.

The SR 12 timber bunk is very common in Scandinavia. Since 1989, around 14,000 bunks of this type have been delivered and attached

to a great variety of different wagon types.

23

ExTe

SR8 Timber Bunk

Facts:

ExTe SR 8 timber bunk can carry a load of 8 ton each and can be attached to most flat wagons / container wagons. This even

if the wagon type only has two outer frame-sills (like most Sgnss designs). The weight is around 160-190 kg pending

loading gauge and fastening system.

The SR 8 timber bunk (and the SR 6 timber bunk described on the following page), is well suited for the more restrictive

continental European loading gauge. The bolster design of the SR 8 bunk also makes the bunk suitable for only two sill

wagons and for the transport of sawed lumber packages, pressed boards, etc besides timber. The bunk is suitable for the use

in traffic to and from sawmills (timber inbound and finished products outbound).

The SR 8 timber bunk is newly developed and is currently undergoing operative testing. Photo showing the bunk with Scandinavian

loading width.

24

ExTe

SR6/6+ Timber Bunk

Facts:

ExTe SR 6 Timber Bunk can carry a load of 6 ton each and can be attached only to flat wagons / container wagons with a

floor or with four or more longitudinal beams on the wagon (like Rgns, Roos, Sps, Rs, but not for wagons with only two

longitudinal beams, like most Sgnss designs). The weight of this bunk is around 130-140 kg pending upon desired loading

gauge.

ExTe SR 6+ Timber Bunk can carry a load of 6 ton each and can be attached to most flat wagons / container wagons.

This even if the wagon type only has two longitudinal beams (like most Sgnss designs). The weight of this bunk is around

150-160 kg pending on loading gauge.

Since the mid 1990-ties, close to 6,000 timber bunks of the SR 6 design have been delivered to various European customers.

25

ExTe

Return

Facts:

ExTe Return is designed for the use in covered or open lorries or rail wagons. This 8 ton design is very suitable in freight

corridors where i.e. lumber (sawed boards), pressed boards and palleted cargo is transported in one direction, and

timber/pulp wood in the opposite direction. The stanchions are of fold down type.

The weight of this bunk is around 180 kg pending upon desired height and width. A pair of bunks can handle a log pile

weighting 16 ton. The handling concept is as smart as its simple.

The bunks are transported with the stanchions down on top of revenue

cargo in one direction. In the timber direction, the pair of bunks are

placed on the ground and stanchions raised, loaded with timber,

strapped with one belt per bunk and finally lifted onto a freight vehicle.

The spacing between two bunks is freely adjusted on the ground

pending log lengths. The concept is also suitable for the transport of

steel or plastic pipes, etc. The empty bunks can be handled either by

fork lifts or forest cranes.

26

ExTe

Multi

Facts:

ExTe Multi is a flexible solution for the efficient transport of containers, timber and sawed lumber. ExTe has developed this

system, based on the SR 8 timber bunk design, in order to make the transport of timber, containers and lumber possible on

the same wagon without the need for any alterations to the wagon. Due to loading gauge reasons, this design is especially

suitable for the use within Sweden and it meets the most common rail transport needs within the Scandinavian forest industry.

With this equipment, a wagon can in a very flexible manner alter between the transport of timber, containers and lumber.

Handling of containers can be done either by forklifts or reach-stackers.

The weight of one system / wagon comprising of 10 timber bunks, 7 heavy-duty support bolsters and 12 ExTended container spigots

(the equipment pictured above) is around 3.7 ton.

27

ExTe

20 Intermodal Cassette

Facts:

ExTe 20 Cassette, the true intermodal solution for the efficient transport of timber (road-rail-road). ExTe has developed this

concept in order to offer the forest industry new possibilities to make their logistical flows of raw material (round wood

and cut lumber) more efficient. The timber bunks are of the SR 8 design.

The 20 Cassette facilitates the following possibilities:

Fast turnaround times of wagon-sets at rail terminals (or receiving industry)

Lorries feeding rail terminals can be any container trailer or flat bed container lorry

Reduced risk for damages to equipment (rail or road) due to fewer crane handlings

High flexibility. A container rail car or lorry can be a timber transporting unit one day, and its original the next

(without a shop visit or costly assembly / disassembly work).

The 20 intermodal cassette fits any 20 ISO spigot positions on any road or rail vehicle worldwide.

Technical data for

one ExTe 20 Cassette:

Tare per Cassette: 2 ton

Net loading: 18 ton if lifted, or 32 ton if not lifted

Gross: 20 ton if lifted

Timber bunks: 4 pcs. of ExTe SR 8 timber bunks

Pile capacity per Cassette: Two piles of 2-3 meter logs or one

pile of 4-6 meter logs

Protective flooring: Yes

Tie down winches: Yes (three system 602 winches per cassette)

28

ExTe

Maxi

Facts:

This system comprise of the Maxi Stake and the Maxi Socket. The weight of the stake is 23 kg and the weight of the socket

is 11 kg. One stake can hold a load of up to 2.3 ton.

More than 100,000 Maxi Stakes have been delivered since 1996. The Maxi Socket provides for a secure inter-fit between the Maxi Stake and the wagon.

29

ExTe

Fastening Systems

Bolted fastening with or without rubber

pucks or fastening plates. At this time,

around 8,000 bunks with this fastening

system have been delivered.

Clamp fastening is a system used on

around 3,000 timber bunks so far. This

fastening type is also commonly used

on ExTes highway products (exceeding

250,000 bunks world wide).

Yoke fastening with bolts with or

without rubber pucks. Close to 3,000

bunks have been delivered with this

fastening system up till today.

30

ExTe

Fastening Systems

Facts:

The SR 12, SR 8 and SR 6+ timber bunk designs can be used on most, if not all, types of flat wagons and container

wagons. The attachments of the timber bunks onto wagons are done by the use of either clamp fastenings, bolt fastenings

or yokes with bolts. Sometimes attached to a fastening plates bolted or welded to the wagon sills.

For wagons with floors, or with four or more longitudinal wagon beams, the SR 6 timber bunk is attractive. The attachment

of the SR 6 is by the means of welding (wings welded to the outer wagon sills).

Frame welded fastening is the means

of attachment for close to 6,000 SR 6

bunks up to date.

ExTes wagon fastening plate

manufactured in HSS can be bolted

or welded onto the wagon frame.

Timber bunk fastenings of most

types can then be attached to this

plate (expect the welded timber bunk

fastening (SR 6 above).

31

ExTe

Support Bolsters and Grip

Protections

Facts:

ExTes support bolsters and Grip Protections protect wagon frames from the forces of unloading machines and also makes

faster unloading possible.

1. In tests, ExTes heavy-duty bolster withstood vertical loads of 27 ton in the middle (when mounted on a Sgnss alike

frame structure with only two outer frame sills). The weight of this support bolster is between 130-170 kg pending

fastening system and width. The support bolster is attached to the wagon by clamp fastenings or bolt fastenings.

2. ExTes support bolster for wagons with floors or many longitudinal beams is lighter with a weight of just around 60-70

kg. Hardox steel is used here as well.

1.

Close to 3,000 pcs of this heavy duty

support bolster have been delivered

since 2005. The top plate of the

bolster is manufactured in the

extremely durable Hardox steel quality.

2.

This lighter support bolster

is designed for wagons with

structural support in the middle.

32

ExTe

Support Bolsters and Grip

Protections

Facts:

3. ExTes grip protection for wagons with floors or many longitudinal beams is an economic wagon saver when unloading

is done with big machinery. This especially when the outer wagon beams comprises of H-beams. The weight is around

70 kg and it is manufactured in HSS. Normally, the attachment is done by welding.

3.

This design is currently

undergoing revenue field

tests with around

100 pcs in operation.

33

ExTe

End Walls

Facts:

ExTes has two basic designs of end walls. One design is using piping for the grid and high strength steel for the pillar

stanchions and sockets. This is in order to reduce weight and to some extent air resistance. These factors are of importance

especially in regions where the loading gauge allows the loading area to be around 9 m

2

and speeds often are over 90 km/h

and empty haul at 120 km/h.

The second design is entirely manufactured in HSS and is very suitable within regions with more restricted loading gauges

and speeds.

The piping design. The flat wall design.

34

ExTe

Tensioning System

Facts:

The 602 Tensioning System is commonly used by European rail operators. The system includes a ten meter 6 ton belt, a

hook and a triangle. The weight is in total just over 9 kg. Throughout the past ten years, more that 20,000 systems of this

design have been delivered to the rail industry.

This tensioning system is very popular among European rail operators. The braking point for the winch itself is at over 17 ton torch

35

ExTe

Special Designs

Facts:

Beside our mainstream timber securing products, ExTe can also offer none forest related products based on specific

customer requests. Example of such products are bunks for steel pipes and rods (picture 1), stakes for the transport needs

of track authorities / track maintenance companies (picture 2) and container spigot beams for flat wagons modified to

container wagons (picture 3).

As the role, these products are manufactured using high strength steel. For ExTe, the costumer is always king, and we are

listening. If a customers desire is technically and economically feasible, ExTe will design, test and manufacture accordingly.

1 2

3

36

ExTe

Testing

Facts:

Normally, a new design is borne after customer dialog and his approval of final drawings. After that, a FEM-analyzes is

carried out. New products are than always prototyped and tested in ExTes laboratory in order to measure structural behavior

and braking points. After that, the products are tested in field conditions as test units. This always takes place ahead of any

market introduction. Normally, ExTes rail products are approved by rail authorities as integrated parts of a wagon approval

(new wagon designs or after major modifications).

All of ExTes stanchion and bunk designs fulfill TSI requirements regarding high strength stanchions and side mounted

stanchions. This usually with factor two or three.

Tests are important.

The best test laboratory is

sometimes the reality. ExTe

continuously collects information

and experience from mishaps.

At this at speed derailment

(due to track failure) of a loaded

(ExTe) timber train, remarkably

few of ExTes components had

to be replaced. The fastening

type was in this case of clamp

type. The photo to the right

probably shows the Worlds

largest rake, raking deep for

200 meters without a broken

stanchion.

37

ExTe

Rail Customers

ExTe

Certificates

DB / Railion / DB Schenker, SJ / GC, NSB / CargoNet

Nordwaggon / TWA

Exte Vertriebs GmbH

KiwiRail, EWS, FEVE, Hector Rail, Tgab, TXL, Peterson Rail, RailCare

CargoLink, Vida, IGAB, OBAS, Sveaskog, Midwaggon, Banverket

Greenbriar, Gniewczyna, Ovako, Swemaint

AAE, NACCO, ERR, OnRail, NetRail

38

ExTe is the worlds leading manufacturer

and supplier of timber bunks and automatic

tensioning devices for safe and rational

transport of timber by road and rail.

39

Throughout the years, ExTe has globally delivered more than 250,000 timber bunks for highway. ExTes road products are manufactured

in aluminum and / or high strength steel

ExTes innovative Com-90, a fully automated tie down system, is becoming more and more popular. This especially amongst truckers

operating shorter distances with many round-trips per shift

ExTe Fabriks AB, SE-820 41 Frila Sweden. Tel: +46 (0)651 175 00. Fax: +46 (0)651 175 03. E-mail: info@exte.se www.exte.se

Securing cargo. We invented the concept.

More ExTe,

Both on the Web and in Print.

K

I

L

O

M

E

T

E

R

ExTe has the widest product line in the market to meet every need. Product development

that never compromises on safety is your best guarantee.

For more information about ExTe products, you are invited to visit us at www.exte.se.

You might also like

- Katalog PromyDocument32 pagesKatalog Promyалексей петуховNo ratings yet

- Listă Locomotive SiemensDocument44 pagesListă Locomotive SiemensCosoreci Florin100% (3)

- British Diesel & Electric Locomotives Abroad: A Second Life OverseasFrom EverandBritish Diesel & Electric Locomotives Abroad: A Second Life OverseasNo ratings yet

- HTA Contener TerminalDocument9 pagesHTA Contener TerminalMaja LutovacNo ratings yet

- Container Handling InnovationDocument2 pagesContainer Handling InnovationenderikuNo ratings yet

- Stadler Kiss DD SBBDocument2 pagesStadler Kiss DD SBBRodrigo Sampaio100% (1)

- DB Schenker Rail Flyer SteelSolutionDocument2 pagesDB Schenker Rail Flyer SteelSolutionShekher NikhilNo ratings yet

- Low Bed Trailer 80 To SpecsDocument18 pagesLow Bed Trailer 80 To SpecsChiheb BEN ABDALLAHNo ratings yet

- Siemens - Electric LocomotiveDocument44 pagesSiemens - Electric LocomotiveKarthik sp100% (2)

- BRAWA New Items Catalogue 2015Document100 pagesBRAWA New Items Catalogue 2015JorgeAntónioNo ratings yet

- Hobby CatalogueDocument92 pagesHobby CataloguerecutuNo ratings yet

- TGV, A Train Out of Ordinary... Very High Speed: It's Now!!: Photos and Text ©patrick Landmann/LightmediationDocument23 pagesTGV, A Train Out of Ordinary... Very High Speed: It's Now!!: Photos and Text ©patrick Landmann/LightmediationraamonikNo ratings yet

- 08 Talgo PDFDocument31 pages08 Talgo PDFGretchen Burns100% (1)

- Marine Sector: Diesel Sector in SerbiaDocument4 pagesMarine Sector: Diesel Sector in Serbiaajeeit8No ratings yet

- Hino Dutro TruckDocument31 pagesHino Dutro TrucktiaraNo ratings yet

- Guide to Optimizing Axle Load DistributionDocument4 pagesGuide to Optimizing Axle Load DistributionbhukthaNo ratings yet

- GFRDocument41 pagesGFRedyvis100% (1)

- Container SpecificationDocument46 pagesContainer SpecificationEmil Gagiu0% (1)

- SDC 27 eLTU4 Box Liner SpecsDocument1 pageSDC 27 eLTU4 Box Liner SpecsErmin CisicNo ratings yet

- Rolling Center Cantilever Gate Systems and AccessoriesDocument18 pagesRolling Center Cantilever Gate Systems and AccessoriesnagtummalaNo ratings yet

- Van Leusden Catalogue 2008Document66 pagesVan Leusden Catalogue 2008Marcel VanNo ratings yet

- Santa Fe F7 F-Units & ScaleRail ScenariosDocument37 pagesSanta Fe F7 F-Units & ScaleRail ScenariosAlex GeorgeNo ratings yet

- Hiab Loglift Cranes in KareliaDocument4 pagesHiab Loglift Cranes in KareliaGleb BogatskiyNo ratings yet

- Tugs, Work Boats and Coastal FerriesDocument9 pagesTugs, Work Boats and Coastal FerriesVaruna Shantha100% (1)

- Ganz Motor 2012 enDocument9 pagesGanz Motor 2012 eneyslNo ratings yet

- Biogastrain Produktblad 2005Document2 pagesBiogastrain Produktblad 2005adamyogiNo ratings yet

- The Privatisation Classes: A Pictorial Survey of Diesel and Electric Locomotives and Units Since 1994From EverandThe Privatisation Classes: A Pictorial Survey of Diesel and Electric Locomotives and Units Since 1994No ratings yet

- Biglift SpecsDocument6 pagesBiglift SpecsOerip DjajasentosaNo ratings yet

- E-Mosty 4 2016 Arch BridgesDocument84 pagesE-Mosty 4 2016 Arch BridgesFrancisco CabezaNo ratings yet

- APL Equipment GuideDocument56 pagesAPL Equipment Guidesivakumar_ametmbaNo ratings yet

- LLM GuidesDocument21 pagesLLM Guidesgrupa2904No ratings yet

- PatS SMM 2006Document51 pagesPatS SMM 2006tmtt44No ratings yet

- Zacns Fyer Tank WagonDocument2 pagesZacns Fyer Tank WagonStefan Ioan CiobicaNo ratings yet

- KötelekDocument36 pagesKötelekAnonymous oCAPuRfkbJNo ratings yet

- 2013 OrtrDocument96 pages2013 OrtrChris WetzelNo ratings yet

- Reinforcing Bar Couplers For Cryogenic Applications: Tested at - 168°C/-270°F To EN 14620-3 With Cryogenic-Grade RebarDocument4 pagesReinforcing Bar Couplers For Cryogenic Applications: Tested at - 168°C/-270°F To EN 14620-3 With Cryogenic-Grade RebarArun KumarNo ratings yet

- SBB Orders 50 Stadler KISS Electric Double-Deck TrainsDocument2 pagesSBB Orders 50 Stadler KISS Electric Double-Deck TrainsRodrigo SampaioNo ratings yet

- LIFT It 05 01-2012 enDocument20 pagesLIFT It 05 01-2012 enTh NattapongNo ratings yet

- Fire and Rescue Trucks From ScaniaDocument8 pagesFire and Rescue Trucks From ScaniaForum PompieriiNo ratings yet

- Aviation Ground Service Equipment (AGSE)Document8 pagesAviation Ground Service Equipment (AGSE)balancejackyNo ratings yet

- Rotterdam's World-Class Breakbulk Port Specialized in Steel TransportDocument17 pagesRotterdam's World-Class Breakbulk Port Specialized in Steel TransportmarineconsultantNo ratings yet

- Brochure Container Specification en PDFDocument48 pagesBrochure Container Specification en PDFSanjay Gore100% (1)

- Crane RailsDocument4 pagesCrane Railsmuamer1No ratings yet

- Tank Superstructure Technical SpecificationDocument14 pagesTank Superstructure Technical SpecificationAlfian SeptaNo ratings yet

- Containerization and Palletization in Rail TransportDocument37 pagesContainerization and Palletization in Rail Transportshuting2teohNo ratings yet

- Axle LoadDocument17 pagesAxle LoadHendra SaputraNo ratings yet

- Load Fastening, Lashing, SupportingDocument16 pagesLoad Fastening, Lashing, Supportingdsn_sarma100% (1)

- Delta Mar in Tanker ReferencesDocument27 pagesDelta Mar in Tanker ReferenceschmatiasNo ratings yet

- Cat Forklift v40d Schematic Service ManualDocument23 pagesCat Forklift v40d Schematic Service Manualericbowman021099rgo100% (120)

- Salesfolder Carat XXL enDocument20 pagesSalesfolder Carat XXL enNadolu MarianNo ratings yet

- Railway Engineering in Hungary: Companies in The Spotlight Off Ering Their Products, Services and SkillDocument56 pagesRailway Engineering in Hungary: Companies in The Spotlight Off Ering Their Products, Services and SkillAnonymous F3sD9zCANo ratings yet

- Container Specifications Hapag LloydDocument12 pagesContainer Specifications Hapag LloydBeautyma Company siteNo ratings yet

- 2022 - 0919 - Media Release - Innotrans 2022 - Euro9000 - en PDFDocument3 pages2022 - 0919 - Media Release - Innotrans 2022 - Euro9000 - en PDFKakoona2029No ratings yet

- Containerization and Palletization in Rail TransportDocument42 pagesContainerization and Palletization in Rail TransportFahmi_mukhtarNo ratings yet

- Swiss Express Train Wins TenderDocument2 pagesSwiss Express Train Wins TenderRodrigo SampaioNo ratings yet

- Liebherr Brochure Duty Cycle Crawler Cranes HS Series EN PDFDocument40 pagesLiebherr Brochure Duty Cycle Crawler Cranes HS Series EN PDFMadhu KumarNo ratings yet

- Guidance for Tankers at Muuga HarbourDocument23 pagesGuidance for Tankers at Muuga HarbourulasNo ratings yet

- Liebherr Brochure Duty Cycle Crawler Cranes HS Series EN PDFDocument40 pagesLiebherr Brochure Duty Cycle Crawler Cranes HS Series EN PDFMadhu KumarNo ratings yet

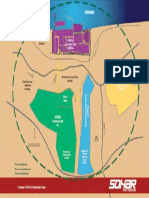

- Sohar Greater Sohar Industrial Zone Map A NewDocument1 pageSohar Greater Sohar Industrial Zone Map A NewMadhu KumarNo ratings yet

- Sohar Seabury White Goods Mini ReportDocument2 pagesSohar Seabury White Goods Mini ReportMadhu KumarNo ratings yet

- National Building Code 2005Document1,161 pagesNational Building Code 2005api-2617216889% (47)

- Is - 2062.2011 PDFDocument17 pagesIs - 2062.2011 PDFN GANESAMOORTHYNo ratings yet

- Sohar Greater Sohar Industrial Zone Map A New PDFDocument1 pageSohar Greater Sohar Industrial Zone Map A New PDFMadhu KumarNo ratings yet

- R Sohar Construction Permit PDFDocument27 pagesR Sohar Construction Permit PDFMadhu KumarNo ratings yet

- Sohar Greater Sohar Industrial Zone Map A NewDocument1 pageSohar Greater Sohar Industrial Zone Map A NewMadhu KumarNo ratings yet

- Sohar Seabury White Goods Mini ReportDocument2 pagesSohar Seabury White Goods Mini ReportMadhu KumarNo ratings yet

- R Sohar Construction Permit PDFDocument27 pagesR Sohar Construction Permit PDFMadhu KumarNo ratings yet

- Sohar Seabury White Goods Mini ReportDocument2 pagesSohar Seabury White Goods Mini ReportMadhu KumarNo ratings yet

- Sohar Seabury White Goods Mini ReportDocument2 pagesSohar Seabury White Goods Mini ReportMadhu KumarNo ratings yet

- Sohar Greater Sohar Industrial Zone Map A New PDFDocument1 pageSohar Greater Sohar Industrial Zone Map A New PDFMadhu KumarNo ratings yet

- API Tank DesignDocument189 pagesAPI Tank DesignDD3NZ91% (11)

- TenderDPRSatellite PDFDocument70 pagesTenderDPRSatellite PDFMadhu KumarNo ratings yet

- Sea Water IntakeDocument29 pagesSea Water IntakeDanang Rahadian100% (1)

- Is 456 2000Document114 pagesIs 456 2000Arun Verma100% (2)

- Sea Water IntakeDocument29 pagesSea Water IntakeDanang Rahadian100% (1)

- Formulas 1 - Section Properties(Area, Section Modulus, Moment of Inertia, Radius of Gyration) Structural calculation, strength of materials PDFDocument4 pagesFormulas 1 - Section Properties(Area, Section Modulus, Moment of Inertia, Radius of Gyration) Structural calculation, strength of materials PDFMadhu KumarNo ratings yet

- APSEC 2006 Proceedings on Design of RC BeamsDocument17 pagesAPSEC 2006 Proceedings on Design of RC BeamsvinthfNo ratings yet

- Calculation and limits of crack width in prestressed concreteDocument7 pagesCalculation and limits of crack width in prestressed concreteJeet DesaiNo ratings yet

- Formulas 1 - Section Properties(Area, Section Modulus, Moment of Inertia, Radius of Gyration) Structural calculation, strength of materials PDFDocument4 pagesFormulas 1 - Section Properties(Area, Section Modulus, Moment of Inertia, Radius of Gyration) Structural calculation, strength of materials PDFMadhu KumarNo ratings yet

- 6125 Low Alloyed Steel For Casting SCM25: Scana Steel Stavanger AsDocument1 page6125 Low Alloyed Steel For Casting SCM25: Scana Steel Stavanger AsMadhu KumarNo ratings yet

- Project Presentation PDFDocument13 pagesProject Presentation PDFMadhu KumarNo ratings yet

- Infram, Pobox 688, 7500 Ar EnschedeDocument15 pagesInfram, Pobox 688, 7500 Ar EnschedeMadhu KumarNo ratings yet

- Hollow Sections Book WardenierDocument199 pagesHollow Sections Book WardenierANUSSBAUMER100% (3)

- 090151b2801f641c PDFDocument93 pages090151b2801f641c PDFMadhu KumarNo ratings yet