Professional Documents

Culture Documents

Slope Paper 148

Uploaded by

Ronan Cayo0 ratings0% found this document useful (0 votes)

29 views9 pagesThe document summarizes a study that compared different methods of collecting discontinuity data from borehole cores. Discontinuity data originally collected from 12 boreholes displayed inconsistencies and inaccuracies, such as angles measured to the nearest 5 or 10 degrees, resulting in an odd "starfish" pattern. Re-examination of core photos and holes revealed issues like multiple reference lines, reference lines not correlating to orientation marks. Televiewer data from some holes correlated well to original data, but other holes showed poor correlation, highlighting uncertainties in the original data collection methods.

Original Description:

ok

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes a study that compared different methods of collecting discontinuity data from borehole cores. Discontinuity data originally collected from 12 boreholes displayed inconsistencies and inaccuracies, such as angles measured to the nearest 5 or 10 degrees, resulting in an odd "starfish" pattern. Re-examination of core photos and holes revealed issues like multiple reference lines, reference lines not correlating to orientation marks. Televiewer data from some holes correlated well to original data, but other holes showed poor correlation, highlighting uncertainties in the original data collection methods.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views9 pagesSlope Paper 148

Uploaded by

Ronan CayoThe document summarizes a study that compared different methods of collecting discontinuity data from borehole cores. Discontinuity data originally collected from 12 boreholes displayed inconsistencies and inaccuracies, such as angles measured to the nearest 5 or 10 degrees, resulting in an odd "starfish" pattern. Re-examination of core photos and holes revealed issues like multiple reference lines, reference lines not correlating to orientation marks. Televiewer data from some holes correlated well to original data, but other holes showed poor correlation, highlighting uncertainties in the original data collection methods.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 9

Proceedings, Slope Stability 2011: International Symposium on Rock Slope Stability in Open Pit Mining and Civil

Engineering, Vancouver, Canada (September 18-21, 2011)

Comparison of Borehole Discontinuity Data Collection Methods

Uncertainty and Quality Concerns

V. Kuppusamy Golder Associates Africa (Pty) Ltd., Midrand, South Africa

C.A. Jermy Golder Associates Africa (Pty) Ltd., Kloof, South Africa

C.P. Fietze Golder Associates Africa (Pty) Ltd., Midrand, South Africa

P. Hornsby Golder Associates Africa (Pty) Ltd., Kloof, South Africa

Abstract

Discontinuity data measured from twelve orientated boreholes was made available by a client for an open pit

investigation. On plotting the data stereographically it became obvious that there was something wrong with it

since most of the pole data exhibited a starfish pattern indicating that the alpha angles had been measured to

the nearest 5 and the beta angles to the nearest 10. The odd appearance of the contoured stereonets also

caused concern about the manner in which the data had been collected. A study of the core photographs

established that in some cases there seemed to be more than one reference line drawn on the core, and the

reference line barbs appeared to point up and down hole. Because it was not possible to contact the

geologist who had originally logged the core it was decided to re-examine the core, establish how the core had

been orientated during drilling and make some sample measurements to compare against the data provided.

After discussions with the drilling contractor it was determined that the larger diameter core through the weaker

overburden material was oriented using a spear and crayon to mark the bottom of the core. A Reflex Act

electronic orientation tool was used for the smaller diameter core, and a point marked on the top of the core,

from which a reference line could be drawn and discontinuity measurements made.

Unfortunately, most of the borehole core had been left laid out in the field, so that in the six month period

between the holes being drilled and re-examined, most of the markings and reference lines drawn on the core

had been lost due to the effects of the sun and elements. The core from three boreholes which had been stacked

could however be examined. In addition to the problems mentioned above, it was clear that the reference line did

not always correlate with the survey instrument mark at the end of each core run; it was not clear whether the

reference line corresponded with the top or bottom of the core; in some cases the upper apical trace of the

discontinuity ellipse had been measured rather than the lower one; and it was clear that sealed foliations had

been logged as discontinuities. Because of the concerns with the reliability of the discontinuity measurements,

optical and acoustic televiewers were used to measure the discontinuities directly from the drilled boreholes,

and the results compared with the original data. In some of the boreholes there was a good correlation between

the measurements, but in others there was not.

1 Introduction

Discontinuities are planes of weakness that frequently control the stability of rock masses. The orientation of

discontinuities is one of the most important characteristics considered in the design of any engineering structure

or excavation face. Therefore a reliable knowledge of the true orientations of these structures is often required.

Orientation data of discontinuities can be measured directly from surface mapping or obtained indirectly from

boreholes. Although each of these methods are accompanied with their own particular limitations and

advantages, the borehole methods are considered to be associated with a comparatively higher degree of

uncertainty since it involves more complex measuring procedures, thus increasing the risk for errors.

In this case study, the discontinuity data was originally obtained from logging orientated boreholes and later

using optical and acoustic televiewers. Stereographic analysis of the logged discontinuity data raised a concern

that the representative orientation of the discontinuities was not accomplished. A study of the core photos and

the site investigation revealed many inconsistencies and inaccuracies in the manner in which the data had been

collected. The odd starfish patterned stereographic plot in conjunction with the evidence from the core photos

contributed substantially to the uncertainty and poor quality of the original discontinuity data set. Subsequent

comparisons between the televiewer data and the original data showed good correlations between some

boreholes, but poor correlations in other boreholes.

2 Discontinuity orientation measurements

Discontinuity data from twelve orientated boreholes were made available by the client for an open pit

investigation. These had previously been logged by other personnel from another consulting company.

2.1 Data uncertainty and quality concerns

A study of the core photos showed errors in the manner in which the data was collected. The errors identified are

predominantly associated with the reference line from which the discontinuity alpha and beta angles are

measured. As a result of uncertainty associated with this reference line, the original orientation data was

considered to be unreliable. Typical problems identified during the core photo study included: more than one

reference line, reference line barbs points both up- and down-hole and the reference line was offset from the end

of core mark (refer to Table 1).

A subsequent site investigation that allowed measurements to be checked suggested that most of the alpha and

beta angles were correct, however a significant percentage of the measurements checked were different. The

alpha angles were different by a maximum of 10. In some of the cases, it appears that the upper apical trace of

the discontinuity ellipse was measured rather than the lower one, which means that the beta angles were out by

180. Using the measured alpha and beta angles to determine which line was actually used to take the

measurements from, established that it was not always the same line being used.

After discussions with the drilling contractor, it was discovered that two methods had been used to mark the

orientation of the core. A spear or crayon was used to mark the bottom of the larger diameter core and a Reflex

Act electronic orientation tool had marked the top of the smaller diameter core, thus increasing the confusion

about the reference line from which the discontinuity measurements were made.

The reference mark at the end of the core run was rarely visible; therefore the correct reference line was not

clear. In addition, the core from some of these holes had been left in their trays laying on the ground at their

collar positions, rather than being stacked. The sun and sand had bleached or abraded most of the markings from

the core, making the checking of alpha and beta angles impossible. These observations further contributed to the

uncertainty associated with the original data set.

2.2 Stereographic interpretation

The stereographical pole plot based on the orientation data from the boreholes displayed an odd starfish

pattern indicating that the alpha angles had been measured to the nearest 5 and the beta angles to the nearest

10, as shown in Figure 1. This starfish pattern indicated a lack of precision during data collection (Priest,

1993; Holcombe, 2008).

As a result of the doubt about whether the reference line drawn on the core represents the top or the bottom of

the core, there were two possible solutions for the calculations of the dip and dip directions of the discontinuities.

The contour plot for the data assuming the reference line was on the top of the core is shown in Figure 2 and

Figure 3 shows a similar plot assuming the reference line was on the bottom of the core.

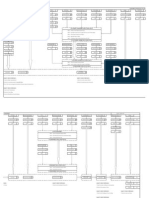

Table 1. Summary of the errors detected on core photos.

Representative Core Photo Description

Some sections of the core had two

reference lines marked along their length,

approximately 130 apart. In some cases,

three reference lines were marked and

these were 60 apart and between 30 and

90 apart. Since the core could not always

be pieced together to provide a continuous

run of core, it was not always possible to

know which line was the correct one.

On a number of occasions two

consecutive pieces of core had reference

line barbs pointing in opposite

directions. In some cases the barb on

the reference line pointed down-hole, in

some cases up-hole.

Reference line not correlating with survey

instrument mark at end of core run.

Figure 1. Stereographic pole plot showing starfish pattern due to the low precision of measurements.

Figure 2. Contour concentration plot showing boreholes for Zone 1, assuming reference line on top of core.

Figure 3. Contour concentration plot showing boreholes for Zone 1, assuming reference line on bottom of core.

Figure 2 shows a higher concentration of poles, but they tend to be congregated in one main orientation

(20/123). Figure 3 has lower pole concentration contours, but five discontinuity sets can be identified:

43/098, 86/161, 86/067, 86/106 and 77/026. It was more likely that Figure 3 is a better representation

of the discontinuity sets within the rock mass.

3 Comparison of televiewer data with the original data

As a result of the above mentioned reservations about the discontinuity measurements there were concerns about

using the data as the basis of the kinematic analysis for the open pit design. In an attempt to obtain some reliable

data, optical and acoustic televiewers were employed to collect discontinuity measurements directly from the

drilled boreholes and were compared with the original discontinuity data.

Comparison of the discontinuity data obtained from the televiewer logs and from the original discontinuity

orientation data revealed that for some drillholes there was a good correlation between the measurements and in

other there was not. An example of the good correlation between the original discontinuity data and the

televiewer data is illustrated by the contour plots shown in Figures 4 and Figure 5 respectively. There appears to

be a reasonable correlation between the data and the stereonet plots for the two sources of structural data.

However, comparison of Figures 6 and 7, together with other drillholes show that the two sources of data

produce quite different stereoplots.

Figure 4. BH1 Original data contour plot.

Figure 5. BH1 Televiewer data contour plot.

Figure 6. BH2 Original data contour plot.

Figure 7. BH2 Televiewer data contour plot.

The stereonets for the discontinuities identified during the original orientated core logging and from the latest

televiewer data, for all the drillholes, showed that more drillholes for which the two sets of data do not correlate,

than those that do correlate. The televiewer data tends to have less steeply dipping discontinuities than the

original data set. There is generally a flat lying set, plus a set with a dip ranging from 40 - 60 and a dip direction

varying between 075 and 120.

The discontinuity data for each of the drillholes have been analysed separately in order to determine the major

joint sets to be used for the pit design. Comparison of the major joint sets identified from the original

discontinuity data and the televiewer data suggests that there is a similarity between some of the sets, despite the

apparent difference between some of the stereonets. The correlation between the joint sets identified is

summarized in Table 2.

Table 2. Correlation between major joint sets identified.

Joint ID Dip Range () Dip Direction

Range ()

Joint ID Dip Range () Dip Direction

Range ()

Original Data Televiewer Data

J 1 16 68 168 238 J 1 0 39 180 - 270

J 3 19 58 056 129 J 2 0 48 079 - 153

J 5 83 90 158 - 195 J 7 60 90 175 - 205

80 90 338 015 72 90 356 025

J 9 63 82 217 229 J 6 51 75 238 285

4 Conclusions

The reliability of the data was questioned because of the concerns regarding its accuracy and precision. The lack

of accuracy is due to the confusion over which reference line the measurements were made from, whether the

reference line represents the top or bottom of the core, and because the reference line barb seems to be

pointing both up- and down-hole. Although the televiewer data showed some correlation with the original

discontinuity data, the confidence level of the data was inadequate for a detailed open pit design. The

recommendation to possibly solve this problem would be to remove the plugs from the holes, determine whether

they were still open throughout their length and use a televiewer to measure the discontinuities downhole.

This case study demonstrates the many errors that can be expected if quality control and assurance are not

incorporated whilst collecting orientation data and how this adversely affects the subsequent design process. The

uncertainty associated with the original discontinuity was too high to confidently use for any detailed design.

The design based solely on the low confidence original discontinuity data would be too conservative to be

economic.

The core orientation data is a valuable source of structural information for any engineering application, therefore

an improvement in collection methods is of great importance. There are many methods that at are currently used

for core orientation, each with different orientation tools and levels of accuracy. A proper understanding of these

methods and their limitations, in conjunction with the ground conditions can improve accuracy and the quality of

data obtained. For example, the traditionally used core stub method makes use of a spear to mark the bottom of

the hole position which can be problematic when the rock is either too hard or too soft to take a mark from the

impacted spear. If the material is very hard, the spear could potentially not leave a mark or bounce across the

surface leaving multiple marks, thus making interpretation difficult. Most spears commonly have attachments

that can be substituted for a crayon or pencil that would make a better mark on hard material than the spear

point, however the driller has to possess the knowledge of when to use the pencil or steel point and be able to

judge and control the impact speed of the spear. The orientation methods that use template tools can eliminate

the above mentioned problems associated with spears, however these template tools are only suitable if the core

stub is irregular and like the spears is not applicable to crumbly core. The more recent core barrel method which

makes use of both pencils and templates is claimed to be a more sophisticated method that significantly

improves the levels of accuracy and reliability. This method makes use of both mechanical and or electronic

tools to determine the gravity vector, however errors are possible if the core at the base of the barrel has been

displaced unknowingly during drilling before the core can be lifted. This can result in largely mismatched

bottom of hole reference lines between adjacent core runs, thus making the measurements incorrect. This method

has been shown to be more successful with good core orientation handling practices and quality assurance

controls (Marjoribanks, 2010).

5 References

Holcombe Coughlin & Associates (2009). Oriented Drillcore: Measurement and Calculation Procedures for Structural and

Exploration Geologist. http://www.holcombecoughlin.com/HCA downloads. pp. 1-25.

Marjoribanks, R. (2010). Geological Methods in Mineral Exploration and Mining. 2

nd

ed. Springer-Verlag, Berlin

Heidelberg, pp. 183-187.

Priest, D.S. (1993). Discontinuity Analysis for Rock Engineering. 1

st

ed. Chapman & Hall, London, pp. 63-71.

You might also like

- Encyclopaedia Britannica, 11th Edition, Volume 11, Slice 6 "Geodesy" to "Geometry"From EverandEncyclopaedia Britannica, 11th Edition, Volume 11, Slice 6 "Geodesy" to "Geometry"No ratings yet

- BlenkinsopDocument10 pagesBlenkinsopJHONNY OMAR LAURA QUISPENo ratings yet

- Interpreting Aerial Photographs to Identify Natural HazardsFrom EverandInterpreting Aerial Photographs to Identify Natural HazardsRating: 2 out of 5 stars2/5 (1)

- Technical Notes.: Determination of Thermal Transport Properties in Ammonium PerchlorateDocument3 pagesTechnical Notes.: Determination of Thermal Transport Properties in Ammonium PerchlorateSharat ChandraNo ratings yet

- Methods of Radar Cross-section AnalysisFrom EverandMethods of Radar Cross-section AnalysisJ.W. Jr. CrispinNo ratings yet

- Balancing The TraverseDocument9 pagesBalancing The TraverseRubie FernandezNo ratings yet

- Structural Data Bias in The Digital Age: M.J. Fowler Pells Sullivan Meynink, AustraliaDocument9 pagesStructural Data Bias in The Digital Age: M.J. Fowler Pells Sullivan Meynink, AustraliaSergio CastroNo ratings yet

- Well - CorrelationDocument19 pagesWell - CorrelationPrithiraj KalitaNo ratings yet

- Structural Interpretation From Televiewer SurveysDocument15 pagesStructural Interpretation From Televiewer Surveysvictor elver guevara cerveraNo ratings yet

- Lab 4aDocument5 pagesLab 4aNur Farhana Ahmad Fuad83% (6)

- Stereocore Article p32-34 Matworldfeb2010Document3 pagesStereocore Article p32-34 Matworldfeb2010api-249136656No ratings yet

- Mapping Geological Features Using Seismic CurvatureDocument10 pagesMapping Geological Features Using Seismic Curvaturehmehmood123No ratings yet

- Comparison of Arching Profiles of Golden Age Cremonese Violins and Some Mathematically Generated CurvesDocument18 pagesComparison of Arching Profiles of Golden Age Cremonese Violins and Some Mathematically Generated Curvesnostromo1979No ratings yet

- Preparing A Survey: - The FocusDocument3 pagesPreparing A Survey: - The FocuslopezfigueroaNo ratings yet

- Empirical Method of Calculating Corona Loss From High-Voltage Transmission LinesDocument8 pagesEmpirical Method of Calculating Corona Loss From High-Voltage Transmission Linesboxeli2281No ratings yet

- Gope Et AlDocument8 pagesGope Et Alapi-3828346No ratings yet

- SEG Newsletter 107 2016ccDocument7 pagesSEG Newsletter 107 2016ccAlvaro MadridNo ratings yet

- 9.WL Unit IXDocument10 pages9.WL Unit IXPahar ChangmaiNo ratings yet

- HCO Oriented Core Procedures PDFDocument25 pagesHCO Oriented Core Procedures PDFOlubi Femi100% (1)

- Ifr: Spe-49061-MsDocument12 pagesIfr: Spe-49061-MsAderobaki GbengaNo ratings yet

- PLOTTING POLES AND CONTOURING OF STRUCTURAL GEOLOGY DATA (LAB 4a)Document8 pagesPLOTTING POLES AND CONTOURING OF STRUCTURAL GEOLOGY DATA (LAB 4a)Ahmad Aizat67% (3)

- Tachymetric Surveys Name: Benmark D. Jabay Score: Course & Year/Section: BSCE-2A Date: November 04, 2020Document3 pagesTachymetric Surveys Name: Benmark D. Jabay Score: Course & Year/Section: BSCE-2A Date: November 04, 2020Benmark JabayNo ratings yet

- Surveying Defination of Terms PDFDocument89 pagesSurveying Defination of Terms PDFstanlee35No ratings yet

- Curtate Cycloid For ArchingDocument5 pagesCurtate Cycloid For Archingmoa memNo ratings yet

- Revision Sheet - FieldworkDocument5 pagesRevision Sheet - FieldworkRhys WallNo ratings yet

- MorphologyDocument16 pagesMorphologyefrain angaritaNo ratings yet

- The Future of Structural Data From Boreholes: Felicia M. WeirDocument6 pagesThe Future of Structural Data From Boreholes: Felicia M. WeirSergio CastroNo ratings yet

- HCO Oriented Core ProceduresDocument36 pagesHCO Oriented Core ProceduresNick Bryce100% (1)

- The Effect of Head Rotation On Cephalometric RadiographsDocument7 pagesThe Effect of Head Rotation On Cephalometric RadiographsDearma KhairunnisaNo ratings yet

- Sub Men To VertexDocument10 pagesSub Men To Vertexvanefranco95No ratings yet

- 2020 Article ApplicationOfMulti-ResolutionGDocument13 pages2020 Article ApplicationOfMulti-ResolutionGinggitalfthhNo ratings yet

- Stereonet AnalysisDocument18 pagesStereonet Analysisnurul ahaddienataNo ratings yet

- Core OrientationDocument20 pagesCore OrientationMandalay Pioneer Geoengineering Services (MPGS)100% (3)

- Usefulness of Stream Order To Detect Stream Sediment Geochemical AnomaliesDocument12 pagesUsefulness of Stream Order To Detect Stream Sediment Geochemical AnomaliessolehNo ratings yet

- Characteriz FracturesDocument11 pagesCharacteriz FracturesrNo ratings yet

- CorrelationDocument14 pagesCorrelationAlekkhyya RoySENo ratings yet

- Survey ManualDocument44 pagesSurvey ManualMonika AcharyaNo ratings yet

- Bit Profile and Gauges Affect Well TrajectoryDocument8 pagesBit Profile and Gauges Affect Well Trajectorydrilling moneytree100% (1)

- Teoria Acerca de Taladros Orientados InglesDocument30 pagesTeoria Acerca de Taladros Orientados Inglesdavid__mine-1No ratings yet

- 4.0 Analysis: 4.1.1 Establishing The Background PopulationDocument23 pages4.0 Analysis: 4.1.1 Establishing The Background Populationgazz1982No ratings yet

- Oriented Drillcore: Measurement, Conversion, and Qa/Qc Procedures For Structural and Exploration GeologistsDocument36 pagesOriented Drillcore: Measurement, Conversion, and Qa/Qc Procedures For Structural and Exploration GeologistsLalo WANo ratings yet

- Rock Slope StabilityDocument28 pagesRock Slope StabilityAe AsyraafNo ratings yet

- Sample Copy of Dissertation ReportDocument47 pagesSample Copy of Dissertation ReportAbdul GhafoorNo ratings yet

- Anker 2020 J. Cosmol. Astropart. Phys. 2020 053Document25 pagesAnker 2020 J. Cosmol. Astropart. Phys. 2020 053Maria MikhailovaNo ratings yet

- PhysRevLett 10 93Document5 pagesPhysRevLett 10 93Moiz AmirNo ratings yet

- Quantitative Analysis by Methods: SpectroscopicDocument4 pagesQuantitative Analysis by Methods: SpectroscopicAmarjeet SinghNo ratings yet

- Convexidade RadicularDocument8 pagesConvexidade RadicularAlin OdorNo ratings yet

- Determination of The Spectroscopic Stellar Parameters For 257 Field Giant StarsDocument17 pagesDetermination of The Spectroscopic Stellar Parameters For 257 Field Giant StarsLucia SuarezNo ratings yet

- Pi Is 0099239906811374Document6 pagesPi Is 0099239906811374Antonis ChaniotisNo ratings yet

- Characterization and Prediction of Meandering Channel Migration in The GIS Environment: A Case Study of The Sabine River in The USADocument11 pagesCharacterization and Prediction of Meandering Channel Migration in The GIS Environment: A Case Study of The Sabine River in The USABiswajit PradhanNo ratings yet

- Corneal topography measured using keratometryDocument6 pagesCorneal topography measured using keratometrytinap_15No ratings yet

- SV 291: Surveying For Engineers I Topic: Compass & Tape SurveyDocument7 pagesSV 291: Surveying For Engineers I Topic: Compass & Tape SurveyIsrael PopeNo ratings yet

- Scottish Qualifications Authority: General Comments On Examination PaperDocument2 pagesScottish Qualifications Authority: General Comments On Examination PapercarmenNo ratings yet

- 2012 HCO Oriented Core ProceduresDocument30 pages2012 HCO Oriented Core ProceduresPancho Perez100% (1)

- Unit 4 qb1 PDFDocument22 pagesUnit 4 qb1 PDFfgfgjjNo ratings yet

- Eddy Current Modeling in Composite Materials: Piers O V NDocument5 pagesEddy Current Modeling in Composite Materials: Piers O V NRobin JamesNo ratings yet

- Waterborne GPR Survey For Estimating Bottom-Sediment VariabilityDocument8 pagesWaterborne GPR Survey For Estimating Bottom-Sediment Variabilityjan3000kowalskiNo ratings yet

- Mutual Interference of Bridge Piers On Local ScourDocument7 pagesMutual Interference of Bridge Piers On Local ScourilyasNo ratings yet

- Study On A Digital Inspection Method For Aircraft Tubing AssemblyDocument8 pagesStudy On A Digital Inspection Method For Aircraft Tubing AssemblyhaceneNo ratings yet

- MS.02 NEW Understanding SSR DataDocument36 pagesMS.02 NEW Understanding SSR DataRonan CayoNo ratings yet

- 89 LopesDocument12 pages89 LopesRonan CayoNo ratings yet

- Bench - Inter-Ramp - Overall: A Guide To Statistically Designing A Rock SlopeDocument8 pagesBench - Inter-Ramp - Overall: A Guide To Statistically Designing A Rock SlopeRonan CayoNo ratings yet

- Gill PaperDocument4 pagesGill PaperRonan CayoNo ratings yet

- Slope Stability 2013 - P.M. Dight (Ed) © 2013 Australian Centre For Geomechanics, Perth, ISBN 978-0-9870937-5-2Document14 pagesSlope Stability 2013 - P.M. Dight (Ed) © 2013 Australian Centre For Geomechanics, Perth, ISBN 978-0-9870937-5-2Ronan CayoNo ratings yet

- Cho Rley PaperDocument11 pagesCho Rley PaperRonan CayoNo ratings yet

- CDocument127 pagesCRonan CayoNo ratings yet

- 55 DegraafDocument12 pages55 DegraafRonan CayoNo ratings yet

- Digi Connect ES Device Server: Hardware Setup GuideDocument23 pagesDigi Connect ES Device Server: Hardware Setup GuideRonan CayoNo ratings yet

- Tutorial 04 Joint Combinations (1) UnwedgeDocument13 pagesTutorial 04 Joint Combinations (1) UnwedgeRonan CayoNo ratings yet

- Gill PaperDocument4 pagesGill PaperRonan CayoNo ratings yet

- 41 HavaejDocument14 pages41 HavaejRonan CayoNo ratings yet

- Contreras PaperDocument7 pagesContreras PaperRonan CayoNo ratings yet

- Dutton PaperDocument10 pagesDutton PaperRonan CayoNo ratings yet

- Slope Paper 289Document13 pagesSlope Paper 289Ronan CayoNo ratings yet

- Slope Paper 296Document12 pagesSlope Paper 296Ronan CayoNo ratings yet

- Slope Paper 197Document11 pagesSlope Paper 197Ronan CayoNo ratings yet

- 90 CheerDocument12 pages90 CheerRonan CayoNo ratings yet

- DodmanDocument8 pagesDodmanRonan CayoNo ratings yet

- Slope Paper 174Document16 pagesSlope Paper 174Ronan CayoNo ratings yet

- WongDocument16 pagesWongRonan CayoNo ratings yet

- WongDocument16 pagesWongRonan CayoNo ratings yet

- Ms TorqueDocument10 pagesMs TorqueRonan CayoNo ratings yet

- 79 Hall PDFDocument6 pages79 Hall PDFRonan CayoNo ratings yet

- DodmanDocument8 pagesDodmanRonan CayoNo ratings yet

- 46 WasanthaDocument10 pages46 WasanthaRonan CayoNo ratings yet

- WongDocument16 pagesWongRonan CayoNo ratings yet

- 29 ClaytonDocument16 pages29 ClaytonRonan CayoNo ratings yet

- BesterDocument16 pagesBesterRonan CayoNo ratings yet

- Slope Stability 2013 - P.M. Dight (Ed) © 2013 Australian Centre For Geomechanics, Perth, ISBN 978-0-9870937-5-2Document14 pagesSlope Stability 2013 - P.M. Dight (Ed) © 2013 Australian Centre For Geomechanics, Perth, ISBN 978-0-9870937-5-2Ronan CayoNo ratings yet

- High Voltage Grease Reduces Wear and ArcingDocument2 pagesHigh Voltage Grease Reduces Wear and ArcingtlnferreiraNo ratings yet

- UDR MANUFACTURE ManufacturesDocument8 pagesUDR MANUFACTURE ManufacturesQuadri Consultancy ServicesNo ratings yet

- Construction Companies in IndiaDocument11 pagesConstruction Companies in Indiashobhit.goel33% (3)

- Online Quiz System DocumentationDocument92 pagesOnline Quiz System DocumentationSultan Aiman100% (1)

- DiGas 4000 Light E 08.02Document2 pagesDiGas 4000 Light E 08.02manit1963No ratings yet

- Thermostats and Dial Thermometers PDFDocument252 pagesThermostats and Dial Thermometers PDFAsep MustopaNo ratings yet

- 350q-5 Operation ManualDocument97 pages350q-5 Operation ManualCesar Mora100% (2)

- Custom Validation ExampleDocument4 pagesCustom Validation ExampleAbdul Bais StanikzaiNo ratings yet

- Internship Report-1Document64 pagesInternship Report-1VIJAY SPNo ratings yet

- Novajet Refference GuideDocument74 pagesNovajet Refference GuideoralbnetworkNo ratings yet

- Electrostatic and Electromagnetic Forces: Electronic Address: Tim - Henley@mail - Utoronto.caDocument9 pagesElectrostatic and Electromagnetic Forces: Electronic Address: Tim - Henley@mail - Utoronto.caTimothy Murray HenleyNo ratings yet

- Genesis of Spalling in Tandem Mill Work-RollsDocument9 pagesGenesis of Spalling in Tandem Mill Work-Rolls54321qazNo ratings yet

- Electric Electronics BrochureDocument8 pagesElectric Electronics BrochurejolualNo ratings yet

- Control Valve and Steam Line PDFDocument19 pagesControl Valve and Steam Line PDFRofi MuhammadNo ratings yet

- Explorador Ww90j6410cwec Version 02Document13 pagesExplorador Ww90j6410cwec Version 02Cristi PopescuNo ratings yet

- Standardization of Welding ElectrodesDocument8 pagesStandardization of Welding ElectrodesAqsa BanoNo ratings yet

- Formulation - Beton - Dreux - Gorisse Good - Fr.enDocument9 pagesFormulation - Beton - Dreux - Gorisse Good - Fr.enRabnawaz ImamNo ratings yet

- Wabco Air Suspension Compressor RepairDocument3 pagesWabco Air Suspension Compressor RepairgarcolNo ratings yet

- Variable Frequency Drive Using IR215xDocument7 pagesVariable Frequency Drive Using IR215xartyomNo ratings yet

- Ejercicios Propuestos Temas Hasta Primer PrevioDocument2 pagesEjercicios Propuestos Temas Hasta Primer PrevioJuan De DiosNo ratings yet

- Multi-disciplinary profile of IS/IT outsourcing researchDocument47 pagesMulti-disciplinary profile of IS/IT outsourcing researchIsabel MirandaNo ratings yet

- AGA-3 Comparison Normal BetaDocument12 pagesAGA-3 Comparison Normal BetahailriqNo ratings yet

- Chapter 4-EDocument42 pagesChapter 4-EMahrouz MadoNo ratings yet

- JV Punj Lloyd - SICIMDocument9 pagesJV Punj Lloyd - SICIMBarock NaturelNo ratings yet

- Pump HydraulicsDocument5 pagesPump HydraulicsSiddharth Kharat100% (1)

- ATS1801 - Interface PC - ImpDocument8 pagesATS1801 - Interface PC - ImpluismantonioNo ratings yet

- 1329804769qno 5,6,7Document94 pages1329804769qno 5,6,7Aman MishraNo ratings yet

- Dual Band Mobile Phone Service ManualDocument40 pagesDual Band Mobile Phone Service Manualأبو عبد الرحمان زهيرNo ratings yet

- Process Level ChartDocument2 pagesProcess Level ChartzaidinNo ratings yet

- d-Copia3500MF 4500MF 5500MFsmY113351-4Document1,051 pagesd-Copia3500MF 4500MF 5500MFsmY113351-4ctecisbNo ratings yet

- A Mathematician's Lament: How School Cheats Us Out of Our Most Fascinating and Imaginative Art FormFrom EverandA Mathematician's Lament: How School Cheats Us Out of Our Most Fascinating and Imaginative Art FormRating: 5 out of 5 stars5/5 (5)

- Basic Math & Pre-Algebra Workbook For Dummies with Online PracticeFrom EverandBasic Math & Pre-Algebra Workbook For Dummies with Online PracticeRating: 4 out of 5 stars4/5 (2)

- Mathematical Mindsets: Unleashing Students' Potential through Creative Math, Inspiring Messages and Innovative TeachingFrom EverandMathematical Mindsets: Unleashing Students' Potential through Creative Math, Inspiring Messages and Innovative TeachingRating: 4.5 out of 5 stars4.5/5 (21)

- Quantum Physics: A Beginners Guide to How Quantum Physics Affects Everything around UsFrom EverandQuantum Physics: A Beginners Guide to How Quantum Physics Affects Everything around UsRating: 5 out of 5 stars5/5 (2)

- Making and Tinkering With STEM: Solving Design Challenges With Young ChildrenFrom EverandMaking and Tinkering With STEM: Solving Design Challenges With Young ChildrenNo ratings yet

- Mental Math Secrets - How To Be a Human CalculatorFrom EverandMental Math Secrets - How To Be a Human CalculatorRating: 5 out of 5 stars5/5 (3)

- Calculus Made Easy: Being a Very-Simplest Introduction to Those Beautiful Methods of Reckoning Which are Generally Called by the Terrifying Names of the Differential Calculus and the Integral CalculusFrom EverandCalculus Made Easy: Being a Very-Simplest Introduction to Those Beautiful Methods of Reckoning Which are Generally Called by the Terrifying Names of the Differential Calculus and the Integral CalculusRating: 4.5 out of 5 stars4.5/5 (2)

- Psychology Behind Mathematics - The Comprehensive GuideFrom EverandPsychology Behind Mathematics - The Comprehensive GuideNo ratings yet

- A Guide to Success with Math: An Interactive Approach to Understanding and Teaching Orton Gillingham MathFrom EverandA Guide to Success with Math: An Interactive Approach to Understanding and Teaching Orton Gillingham MathRating: 5 out of 5 stars5/5 (1)

- Mental Math: How to Develop a Mind for Numbers, Rapid Calculations and Creative Math Tricks (Including Special Speed Math for SAT, GMAT and GRE Students)From EverandMental Math: How to Develop a Mind for Numbers, Rapid Calculations and Creative Math Tricks (Including Special Speed Math for SAT, GMAT and GRE Students)No ratings yet

- Math Magic: How To Master Everyday Math ProblemsFrom EverandMath Magic: How To Master Everyday Math ProblemsRating: 3.5 out of 5 stars3.5/5 (15)

- Build a Mathematical Mind - Even If You Think You Can't Have One: Become a Pattern Detective. Boost Your Critical and Logical Thinking Skills.From EverandBuild a Mathematical Mind - Even If You Think You Can't Have One: Become a Pattern Detective. Boost Your Critical and Logical Thinking Skills.Rating: 5 out of 5 stars5/5 (1)

- Strategies for Problem Solving: Equip Kids to Solve Math Problems With ConfidenceFrom EverandStrategies for Problem Solving: Equip Kids to Solve Math Problems With ConfidenceNo ratings yet

- Fluent in 3 Months: How Anyone at Any Age Can Learn to Speak Any Language from Anywhere in the WorldFrom EverandFluent in 3 Months: How Anyone at Any Age Can Learn to Speak Any Language from Anywhere in the WorldRating: 3 out of 5 stars3/5 (79)

- How Math Explains the World: A Guide to the Power of Numbers, from Car Repair to Modern PhysicsFrom EverandHow Math Explains the World: A Guide to the Power of Numbers, from Car Repair to Modern PhysicsRating: 3.5 out of 5 stars3.5/5 (9)

- Limitless Mind: Learn, Lead, and Live Without BarriersFrom EverandLimitless Mind: Learn, Lead, and Live Without BarriersRating: 4 out of 5 stars4/5 (6)

- Assessment Prep for Common Core Mathematics, Grade 6From EverandAssessment Prep for Common Core Mathematics, Grade 6Rating: 5 out of 5 stars5/5 (1)