Professional Documents

Culture Documents

795-PEEK Muliti - and Monofilament Woven Scaffolds

Uploaded by

Rafaella PreckerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

795-PEEK Muliti - and Monofilament Woven Scaffolds

Uploaded by

Rafaella PreckerCopyright:

Available Formats

Polyetheretherketone Multifilament and Monofilament

Woven Tissue Engineering Scaffolds

1

Edwards, S.L.,

2

Werkmeister, J.A.,

2

Ramshaw, J.A.M.,

2

McLean, K.,

3

Jarman-Smith, M.L.

1

CSIRO Materials Science and Engineering, Geelong, 3216, Australia

2

CSIRO Molecular and Health Technologies, Clayton, 3164, Australia

3

Invibio Ltd., Thornton-Cleveleys, UK

contact: Sharon Edwards

phone: (61) 3 5246 4736

email: sharon.edwards@csiro.au

web: http://www.csiro.au/people/Sharon.Edwards.html

Materials and Methods

Implantable grade PEEK Optima (Invibio Ltd.; UK) monofilament (10.2 tex) and

multifilament (7.5 tex/15 filaments) yarns, and PET multifilament yarn (8.3 tex/36

filaments), were woven into plain weave scaffolds. Following standard methods

fabrics were assessed for their physical and mechanical properties.

All scaffolds were washed and sterilised (autoclaved) prior to cell seeding. Mouse

L929 fibroblast cells (passage 13) were suspended in supplemented Dulbeccos

modified Eagles medium at a concentration of 6.5 x 10

4

cells/mL. Cell suspension

(1.37 mL) was statically seeded onto scaffolds, secured using polymer ring holders.

Samples were incubated for up to 16 days in vitro, changing the medium three times

per week. Prior to conducting the assays scaffolds were rinsed in phosphate

buffered saline to remove non-adherent cells. At regular intervals an MTS assay

(CellTiter 96

, Promega) was performed to give an indication of cell attachment and

proliferation. Cell viability was assessed using a viability assay (Live/Dead

,

Molecular Probes), using fluorescent microscopy to visualise live, calcein AM

stained (green) cells and dead, ethidium homodimer-1 stained (red) cells. Scanning

electron microscopy (SEM) was used to observe cell morphology, using standard

sample preparation procedures.

Introduction

Polyetheretherketone (PEEK) is a semi-crystalline thermoplastic polymer. It

combines good strength and stiffness with excellent thermal stability and good

chemical resistance. Studies have found good biocompatibility with fibroblasts and

osteoblasts in vitro [1, 2], with no cytotoxic effects in vivo [3]. Given these properties,

PEEK has been used in a number of biomedical applications, including spinal disc

fusion, bone trauma repair, and craniomaxillofacial repair [4]. PEEK medical devices

are typically produced by manufacturing methods like injection moulding [5], laser

sintering [6], and machining. To meet the demands of more flexible implant devices,

other methods of manufacture are required.

The aim of this work was to fabricate flexible woven PEEK scaffolds. Scaffolds were

characterised in terms of their physical and mechanical properties and biologically

assessed, culturing with L929 mouse fibroblasts for up to 16 days in vitro. Results

were compared to those obtained for fabricated polyethylene terephthalate (PET)

woven scaffolds.

a

References

1. Sagomonyants KB. Biomaterials. 2008;29: 1563-1572.

2. Hunter A. Biomaterials. 1995;16:287-295.

3. Rivard CH. J Biomed Mater Res. 2002;62:488-498.

4. Jarman-Smith ML. Medical Device Tech. 2008;19:12-15.

5. Nieminen T. J Biomed Mater Res. 2008;84A:377-383.

6. Tan KH, Bio-Med Mater and Eng. 2005;15:113-124.

Conclusions

Multifilament PEEK woven scaffolds were lighter, thinner and stronger than

monofilament PEEK scaffolds. Woven PEEK scaffolds supported fibroblast cell

attachment and proliferation, and ECM production. Cells were found to orientate with

the filament direction, and in places, span the inter-filament and inter-yarn pores of the

multifilament scaffold. The results of this study indicate that fibrous PEEK structures

have potential as scaffolds for tissue engineering.

Results

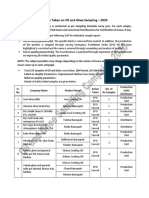

The multifilament PEEK scaffold was found to be of lower mass/area, thinner, with

smaller inter-yarn pores, compared to the PEEK monofilament scaffold. This was due

to the multifilament yarn possessing a lower linear density (mass per unit length), and

smaller filament diameter. The smaller inter-yarn pores were a consequence of yarn

flattening within the woven structure. The multifilament scaffold was found to be

stronger and slightly less extensible (in both directions) than the monofilament

scaffold, with higher burst strength. See Table 1.

Monofilament PEEK

scaffold

Multifilament PEEK

scaffold

Mass/area (g/m

2

) 74.82 (1.03) 55.03 (0.44)

Thickness (mm) 0.69 (0.01) 0.18 (0.01)

Max. pore size (m) 336.75 (4.84) 111.01 (8.60)

Burst Strength (N) 401 492

Tensile load at break (N)

534L (14.48)

366W (38.74)

657L (51.36)

548W (14.43)

Tensile strain at break (%) 40L (0.89) 21W (1.63) 18L (1.81) 18W (1.05)

Table 1: Properties of fabricated PEEK scaffolds.

Results expressed as mean (standard error of the mean).

L denotes warp direction and W denotes weft direction.

SEM micrographs revealed cells to be flattened with processes extending onto the

PEEK substrate (Figure 2a), with extracellular matrix (ECM) deposition. Cells were

observed to span across neighbouring filaments (Figure 2b) and partially infiltrate the

inter-yarn pores (Figure 2c) of the multifilament scaffolds. Conversely, the larger inter-

yarn distances of the monofilament scaffold did not appear to permit cell spanning.

See Figure 2d.

All scaffolds were found to support cell attachment, with proliferation up to day 8 of

culture. The MTS assay determined the PET multifilament scaffold to sustain slightly

higher cell numbers in the early stages of culture. This was likely due to smaller inter-

yarn pores (average of 73 m), which may have resulted in a higher cell seeding

efficiency, and a higher scaffold surface area for cell growth. With increased

incubation time similar cell numbers were found on all scaffolds, with slightly lower

numbers on the PEEK monofilament scaffold by day 10 of culture.

Figure 1: Fluorescent micrographs of viable (green) and dead (red) fibroblasts on (a)

PEEK monofilament, (b) PEEK multifilament, and (c and d) PET multifilament

scaffolds on days (a-c) 6 and (d) 10 of culture.

a

d c

b

The viability assay revealed few dead cells on the scaffolds throughout the culture

period. Little infiltration into the large pores of the monofilament PEEK scaffold was

observed by day 10. Conversely, the smaller pores of the multifilament scaffold

were partially filled (Figures 1a-b). Cells were found to be aligned with the filament

direction on the multifilament scaffolds (Figures 1c-d), but not the monofilament

scaffolds.

Figure 2: SEM micrograph of fibroblasts on (a and d) PEEK monofilament scaffold

and (b and c) PEEK multifilament scaffold, on day 8 of culture.

b a

d c

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Material Safety Data Sheet: Wonder Gel™ Stainless Steel Pickling GelDocument2 pagesMaterial Safety Data Sheet: Wonder Gel™ Stainless Steel Pickling GelTrần Thùy LinhNo ratings yet

- Issue of HomosexualityDocument4 pagesIssue of HomosexualityT-2000No ratings yet

- Rigging: GuideDocument244 pagesRigging: Guideyusry72100% (11)

- Complaint: Employment Sexual Harassment Discrimination Against Omnicom & DDB NYDocument38 pagesComplaint: Employment Sexual Harassment Discrimination Against Omnicom & DDB NYscl1116953No ratings yet

- Total Elbow Arthroplasty and RehabilitationDocument5 pagesTotal Elbow Arthroplasty and RehabilitationMarina ENo ratings yet

- TM - 1 1520 237 10 - CHG 10Document841 pagesTM - 1 1520 237 10 - CHG 10johnharmuNo ratings yet

- Shizhong Liang, Xueming Liu, Feng Chen, Zijian Chan, (2004) .Document4 pagesShizhong Liang, Xueming Liu, Feng Chen, Zijian Chan, (2004) .Kiệt LêNo ratings yet

- Chapter 7 Unemployment, Inflation, and Long-Run GrowthDocument21 pagesChapter 7 Unemployment, Inflation, and Long-Run GrowthNataly FarahNo ratings yet

- A V N 2 0 0 0 9 Airspace Management and Air Traffic Services Assignment 1Document2 pagesA V N 2 0 0 0 9 Airspace Management and Air Traffic Services Assignment 1Tanzim Islam KhanNo ratings yet

- Gay Costa Del Sol - 2010Document2 pagesGay Costa Del Sol - 2010gayinfospainNo ratings yet

- Endothermic Gas Production Overview: Tmosphere Ngineering OmpanyDocument6 pagesEndothermic Gas Production Overview: Tmosphere Ngineering OmpanyJhon ChitNo ratings yet

- Manual of GardeningDocument812 pagesManual of GardeningPrakash PatelNo ratings yet

- Hodgkin LymphomaDocument44 pagesHodgkin LymphomaisnineNo ratings yet

- ClistDocument14 pagesClistGuerraNo ratings yet

- Paterno Report: Dr. Fred S. Berlin, M.D., PH.D Final Report 2-7-2013Document45 pagesPaterno Report: Dr. Fred S. Berlin, M.D., PH.D Final Report 2-7-2013The Morning CallNo ratings yet

- Dryer Regenerative Blower Purge DBP 02250195 405 R00 PDFDocument84 pagesDryer Regenerative Blower Purge DBP 02250195 405 R00 PDFjennyNo ratings yet

- Action Taken On Oil and Ghee Sampling - 2020Document2 pagesAction Taken On Oil and Ghee Sampling - 2020Khalil BhattiNo ratings yet

- FSSC 22000 V6 Guidance Document Environmental MonitoringDocument10 pagesFSSC 22000 V6 Guidance Document Environmental Monitoringjessica.ramirezNo ratings yet

- An Energy Saving Guide For Plastic Injection Molding MachinesDocument16 pagesAn Energy Saving Guide For Plastic Injection Molding MachinesStefania LadinoNo ratings yet

- Catalogue CV. Traka Abadi UniversalDocument15 pagesCatalogue CV. Traka Abadi UniversalHackers StevenNo ratings yet

- Group 5 - Ethical PrinciplesDocument11 pagesGroup 5 - Ethical Principlesvirgo paigeNo ratings yet

- Distress Manual PDFDocument51 pagesDistress Manual PDFEIRINI ZIGKIRIADOUNo ratings yet

- CFPB Discount Points Guidence PDFDocument3 pagesCFPB Discount Points Guidence PDFdzabranNo ratings yet

- L Addison Diehl-IT Training ModelDocument1 pageL Addison Diehl-IT Training ModelL_Addison_DiehlNo ratings yet

- Full Test Bank For Health Economics and Policy 7Th Edition Henderson PDF Docx Full Chapter ChapterDocument34 pagesFull Test Bank For Health Economics and Policy 7Th Edition Henderson PDF Docx Full Chapter Chapterpeeepochaq15d100% (9)

- Recommended Standards For Newborn ICU DesignDocument39 pagesRecommended Standards For Newborn ICU DesignAlbert SekarNo ratings yet

- Практичне 25. Щодений раціонDocument3 pagesПрактичне 25. Щодений раціонAnnaAnnaNo ratings yet

- Ecological Imbalance in IndiaDocument4 pagesEcological Imbalance in IndiaabhywaNo ratings yet

- Marketing Study of Mango JuiceDocument18 pagesMarketing Study of Mango JuiceVijay ArapathNo ratings yet

- Metabolism of Carbohydrates and LipidsDocument7 pagesMetabolism of Carbohydrates and LipidsKhazel CasimiroNo ratings yet