Professional Documents

Culture Documents

Toyo - Heat Exchanger-1

Uploaded by

alokbdas100%(1)100% found this document useful (1 vote)

365 views70 pagesHeat Exchanger

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHeat Exchanger

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

365 views70 pagesToyo - Heat Exchanger-1

Uploaded by

alokbdasHeat Exchanger

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 70

QTN No.

SL PART MOC DEN QTY

TK WIDTH LENGTH

1 Shell CS 7.80 12 4400 5600 1

2 Top Bonnet Dished SS 904L 8.00 8 1700 1700 1

3 Top Bonnet Shell SS 904L 8.00 8 1250 4400 1

4 Bottom Bonnet Dished SS 316L 8.00 8 1700 1700 1

5 Bottom Bonnet Shell SS 316L 8.00 8 1250 4400 1

6 Tubesheet SS 316L 8.00 75 1525 1525 2

7 Bottom Bonnet Flange SS 316L 8.00 75 800 1150 1

8 Top Bonnet Flange SS 904L 8.00 75 800 1150 1

9 Nozzle N1, N2 SS 904L 8.00 45 250 650 2

10 Nozzle Neck N1, N2 SS 904L 8.00 8 250 900 2

11 Baffle CS 7.80 8 1000 1000 8

12 Pad for Saddle Supports CS 7.80 12 500 2000 2

13 Ribs for Saddle Supports CS 7.80 12 500 900 10

14 Base Plate for Saddle Supports CS 7.80 12 500 1500 2

15 Support Plate for Saddle Supports CS 7.80 12 900 1500 2

SL PART MOC DEN QTY

OD WT LENGTH

1 Tubes SS 316L 8.00 25.4 1.244 5500 1220

2 Spacer SA 106 Gr.B 8.00 17.14 2.31 5500 10

3 Nozzle Neck N3, N4 SA 106 Gr.B 8.00 273.05 12.7 250 2

SL PART MOC DEN QTY

LENGTH

1 Tie Rod CS 8.00 5500 10

SL PART MOC DEN QTY

1 N3, N4 SA 105 7.80 2

SL PART MOC DEN QTY

1 Gasket PTFE 4

2 Gasket PTFE 2

3 Bolt + Nut SA 193 B5 / H2 48

4 Jack Screw + Dowel Pin

5 Name Plate 1

SL

1

2

3

4

Miscellaenous

SIZE

250 NB

Body Flange and Tubesheet

M24 X 125 Lg

WORKINGS

Drilling

RADIOGRAPHY

DESCRIPTION

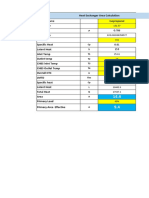

Total Cost of Raw Materials

Testing

Flanges

SIZE

250 NB 150# SORF

SIZE

DIA

13

DRAWING NO.

PLATE

SIZE

PIPES

SIZE

RODS

ITEM

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

CLIENT

5

6

7

8

9

10

Machining

Profit %

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Fabrication %

Over Head %

Others Design

TOTAL

DATE

WEIGHT RATE AMOUNT

2306.30 0.00

184.96 0.00

352.00 0.00

184.96 0.00

352.00 0.00

2790.75 0.00

552.00 0.00

552.00 0.00

117.00 0.00

28.80 0.00

499.20 0.00

187.20 0.00

421.20 0.00

140.40 0.00

252.72 0.00

0.00

WEIGHT RATE AMOUNT

5067.51 0.00

47.35 0.00

41.55 0.00

0.00

WEIGHT RATE AMOUNT

58.30 0.00

0.00

WEIGHT RATE AMOUNT

45.00 0.00

0.00

WEIGHT RATE AMOUNT

0.00

0.00

0.00

0.00

0.00

0.00

0.00

AMOUNT

0.00

0.00

#VALUE!

0.00

TOTAL

Miscellaenous

TOTAL

WORKINGS

Drilling

RADIOGRAPHY

DESCRIPTION

Total Cost of Raw Materials

Testing

Flanges

TOTAL

PLATE

TOTAL

PIPES

TOTAL

RODS

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

18-02-2014

0.00

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

10 #VALUE!

5 #VALUE!

20 #VALUE!

#VALUE!

Machining

Profit %

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Fabrication %

Over Head %

Others Design

TOTAL

Technical

HEAT Exchanger Type: BEM Horizontal

M.O.C: Shell CS 12Thk.

Tube Sheet SS 316L 75Thk.

Baffles CS 8Thk.

Channel SS 904L & SS 316L 8Thk.

Tube SS 316L

Tie Rod CS 13Dia

Shell Side Noz SA 105 250DN

Channel Noz SS 904L 250DN

Tube to Tube Sheet Joint: Expanded & Seal Welded.

Inspection: At our Works by your Engineer.

QTN No.

SL PART MOC DEN QTY

TK WIDTH LENGTH

1 Shell CS 7.80 12 500 3200 1

2 Top Bonnet Dished Zeron 100 8.00 8 280 280 1

3 Top Bonnet Shell Zeron 100 8.00 8 220 500 1

4 Bottom Bonnet Dished Zeron 100 8.00 8 280 280 1

5 Bottom Bonnet Shell Zeron 100 8.00 8 220 500 1

6 Tubesheet Zeron 100 8.00 50 200 200 2

7 Bottom Bonnet Flange Zeron 100 8.00 50 200 200 1

8 Top Bonnet Flange Zeron 100 8.00 50 200 200 1

11 Baffle CS 7.80 4 100 100 4

12 Pad for Saddle Supports CS 7.80 12 150 250 2

13 Ribs for Saddle Supports CS 7.80 12 150 100 10

14 Base Plate for Saddle Supports CS 7.80 12 150 150 2

15 Support Plate for Saddle Supports CS 7.80 12 100 150 2

SL PART MOC DEN QTY

OD WT LENGTH

1 Tubes Zeron 100 8.00 20 1.244 3000 14

2 Spacer SA 106 Gr.B 8.00 15 2.5 3000 4

3 Nozzle Neck N1, N2 Zeron 100 8.00 60.33 5.54 250 2

4 Nozzle Neck N3, N4 SA 106 Gr.B 8.00 60.33 5.54 250 2

SL PART MOC DEN QTY

LENGTH

1 Tie Rod CS 8.00 3000 4

SL PART MOC DEN QTY

1 N1, N2 Zeron 100 8.00 2

1 N3, N4 SA 105 7.80 2

SL PART MOC DEN QTY

1 Gasket PTFE 4

2 Gasket PTFE 2

3 Bolt + Nut SA 193 B5 / H2 16

4 Jack Screw + Dowel Pin

5 Name Plate 1

SL

1

2

3

4

50 NB 150# SORF

DESCRIPTION

Total Cost of Raw Materials

Drilling

RADIOGRAPHY

Testing

WORKINGS

Flanges

SIZE

50 NB 150# SORF

Miscellaenous

SIZE

50 NB

Body Flange and Tubesheet

M16 X 85 Lg

10

DRAWING NO.

PLATE

SIZE

PIPES

SIZE

RODS

SIZE

DIA

ITEM

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

CLIENT

5

6

7

8

9

10

Fabrication %

Over Head %

Profit %

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Machining

DATE

WEIGHT RATE AMOUNT

149.76 0.00

5.02 0.00

7.04 0.00

5.02 0.00

7.04 0.00

32.00 0.00

16.00 0.00

16.00 0.00

1.25 0.00

7.02 0.00

14.04 0.00

4.21 0.00

2.81 0.00

0.00

WEIGHT RATE AMOUNT

24.63 0.00

9.42 0.00

3.81 0.00

3.81 0.00

0.00

WEIGHT RATE AMOUNT

7.53 0.00

0.00

WEIGHT RATE AMOUNT

6.00 0.00

6.00 0.00

0.00

WEIGHT RATE AMOUNT

0.00

0.00

0.00

0.00

0.00

0.00

0.00

AMOUNT

0.00

0.00

#VALUE!

0.00

DESCRIPTION

Total Cost of Raw Materials

Drilling

RADIOGRAPHY

Testing

TOTAL

WORKINGS

TOTAL

Flanges

TOTAL

Miscellaenous

PLATE

TOTAL

PIPES

TOTAL

RODS

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

18-02-2014

0.00

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

10 #VALUE!

5 #VALUE!

20 #VALUE!

#VALUE!

Fabrication %

Over Head %

Profit %

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Machining

Technical

HEAT Exchanger Type: BEM Horizontal

M.O.C: Shell CS 12 Thk.

Tube Sheet Zeron 100

Baffles CS 4 Thk.

Channel

Tube Zeron 100

Tie Rod CS 10 Dia

Shell Side Noz SA 105 50DN

Channel Noz Zeron 100 50DN

Tube to Tube Sheet Joint: Expanded & Seal Welded.

Inspection: At our Works by your Engineer.

Zeron 100 8 Thk.

QTN No.

SL PART MOC DEN QTY

TK WIDTH LENGTH

1 Shell SS 316L 8.00 4 1100 4200 1

2 Bonnet Dished SS 316L 8.00 6 500 500 2

3 Bonnet Shell SS 316L 8.00 6 850 1100 1

4 Tubesheet SS 316L 8.00 60 350 350 1

5 Channel Flange SS 316L 8.00 60 430 430 1

6 Shell Flange SS 316L 8.00 60 430 430 1

7 Baffle SS 316L 8.00 4 250 250 6

7 Support Plate SS 316L 8.00 4 350 350 1

8 Pad for Saddle Supports SS 316L 8.00 12 250 500 2

9 Ribs for Saddle Supports SS 316L 8.00 12 250 200 10

10 Base Plate for Saddle Supports SS 316L 8.00 12 250 400 2

11 Support Plate for Saddle Supports SS 316L 8.00 12 200 350 2

SL PART MOC DEN QTY

OD WT LENGTH

1 Tubes SA 182 8.00 20 1.244 3000 48

2 U-Tubes SA 182 8.00 20 1.244 500 24

3 Spacer SA 182 8.00 15 2.5 3000 4

4 Nozzle Neck N1, N2 SA 182 8.00 114.3 8.58 250 2

5 Nozzle Neck N3, N4 SA 182 8.00 114.3 8.58 250 2

SL PART MOC DEN QTY

LENGTH

1 Tie Rod SS 316L 8.00 3000 4

SL PART MOC DEN QTY

1 N1, N2 SA 182 8.00 2

1 N3, N4 SA 182 8.00 2

SL PART MOC DEN QTY

1 Gasket PTFE 4

2 Gasket PTFE 2

3 Bolt + Nut SA 193 B5 / H2 16

4 Jack Screw + Dowel Pin

5 Name Plate 1

SL

1

2

3

4 Testing

RADIOGRAPHY

M16 X 90 Lg

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

Body Flange and Tubesheet

Flanges

SIZE

100 NB 150# SORF

100 NB 150# SORF

Miscellaenous

SIZE

100 NB

10

DRAWING NO.

PLATE

SIZE

PIPES

SIZE

RODS

SIZE

DIA

ITEM

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

CLIENT

5

6

7

8

9

10

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

DATE

WEIGHT RATE AMOUNT

147.84 0.00

24.00 0.00

44.88 0.00

58.80 0.00

88.75 0.00

88.75 0.00

12.00 0.00

3.92 0.00

24.00 0.00

48.00 0.00

19.20 0.00

13.44 0.00

0.00

WEIGHT RATE AMOUNT

84.44 0.00

7.04 0.00

9.42 0.00

11.40 0.00

11.40 0.00

0.00

WEIGHT RATE AMOUNT

7.53 0.00

0.00

WEIGHT RATE AMOUNT

13.00 0.00

13.00 0.00

0.00

WEIGHT RATE AMOUNT

0.00

0.00

0.00

0.00

0.00

0.00

0.00

AMOUNT

0.00

0.00

#VALUE!

0.00 Testing

RADIOGRAPHY

TOTAL

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

TOTAL

Flanges

TOTAL

Miscellaenous

PLATE

TOTAL

PIPES

TOTAL

RODS

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

18-02-2014

0.00

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

10 #VALUE!

5 #VALUE!

20 #VALUE!

#VALUE!

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

Technical

HEAT Exchanger Type: BEU Horizontal

M.O.C: Shell SS 316L 4 Thk

Tube Sheet SS 316L

Baffles SS 316L 4 Thk

Channel SS 316L 6 Thk

Tube SS 316L

Tie Rod SS 316L 10 Thk

Shell Side Noz SS 316L 100DN

Channel Noz SS 316L 100DN

Tube to Tube Sheet Joint: Expanded & Seal Welded.

Inspection: At our Works by your Engineer.

QTN No.

SL PART MOC DEN QTY

TK WIDTH LENGTH

1 Shell SS 316L 8.00 10 750 2000 1

2 Bonnet Dished SS 316L 8.00 10 360 360 2

3 Bonnet Shell SS 316L 8.00 10 500 750 1

4 Tubesheet SS 316L 8.00 60 250 250 1

5 Channel Flange SS 316L 8.00 60 320 320 1

6 Shell Flange SS 316L 8.00 60 320 320 1

7 Baffle SS 316L 8.00 4 170 170 4

7 Support Plate SS 316L 8.00 4 250 250 1

8 Pad for Saddle Supports SS 316L 8.00 12 200 350 2

9 Ribs for Saddle Supports CS 7.80 12 200 150 10

10 Base Plate for Saddle Supports CS 7.80 12 200 250 2

11 Support Plate for Saddle Supports CS 7.80 12 150 250 2

SL PART MOC DEN QTY

OD WT LENGTH

1 Tubes SA 182 8.00 20 1.244 2000 36

2 U-Tubes SA 182 8.00 20 1.244 350 18

3 Spacer SA 182 8.00 15 2.5 2000 4

4 Nozzle Neck N1, N2 SA 182 8.00 60.33 5.54 250 2

5 Nozzle Neck N3, N4 SA 182 8.00 60.33 5.54 250 2

SL PART MOC DEN QTY

LENGTH

1 Tie Rod SS 316L 8.00 2000 4

SL PART MOC DEN QTY

1 N1, N2 SA 182 8.00 2

1 N3, N4 SA 182 8.00 2

SL PART MOC DEN QTY

1 Gasket PTFE 4

2 Gasket PTFE 2

3 Bolt + Nut SA 193 B5 / H2 16

4 Jack Screw + Dowel Pin

5 Name Plate 1

SL

1

2

3

4 Testing

RADIOGRAPHY

M16 x 85 Lg

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

Body Flange and Tubesheet

Flanges

SIZE

50 NB 150# SORF

50 NB 150# SORF

Miscellaenous

SIZE

50 NB

10

DRAWING NO.

PLATE

SIZE

PIPES

SIZE

RODS

SIZE

DIA

ITEM

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

CLIENT

5

6

7

8

9

10

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

DATE

WEIGHT RATE AMOUNT

120.00 0.00

20.74 0.00

30.00 0.00

30.00 0.00

49.15 0.00

49.15 0.00

3.70 0.00

2.00 0.00

13.44 0.00

28.08 0.00

9.36 0.00

7.02 0.00

0.00

WEIGHT RATE AMOUNT

42.22 0.00

3.69 0.00

6.28 0.00

3.81 0.00

3.81 0.00

0.00

WEIGHT RATE AMOUNT

5.02 0.00

0.00

WEIGHT RATE AMOUNT

5.00 0.00

5.00 0.00

0.00

WEIGHT RATE AMOUNT

0.00

0.00

0.00

0.00

0.00

0.00

0.00

AMOUNT

0.00

0.00

#VALUE!

0.00 Testing

RADIOGRAPHY

TOTAL

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

TOTAL

Flanges

TOTAL

Miscellaenous

PLATE

TOTAL

PIPES

TOTAL

RODS

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

18-02-2014

0.00

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

10 #VALUE!

5 #VALUE!

20 #VALUE!

#VALUE!

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

Technical

HEAT Exchanger Type: BEU Horizontal

M.O.C: Shell SS 316L 10Thk

Tube Sheet SS 316L

Baffles SS 316L 4Thk

Channel SS 316L 10Thk

Tube SS 316L

Tie Rod SS 316L 10Dia

Shell Side Noz SS 316L 50DN

Channel Noz SS 316L 50DN

Tube to Tube Sheet Joint: Expanded & Seal Welded.

Inspection: At our Works by your Engineer.

QTN No.

SL PART MOC DEN QTY

TK WIDTH LENGTH

1 Shell SS 316L 8.00 10 550 2600 1

2 Bonnet Dished SS 316L 8.00 10 300 300 2

3 Bonnet Shell SS 316L 8.00 10 450 550 1

4 Tubesheet SS 316L 8.00 60 180 180 1

5 Channel Flange SS 316L 8.00 60 250 250 1

6 Shell Flange SS 316L 8.00 60 250 250 1

7 Baffle SS 316L 8.00 4 150 150 4

7 Support Plate SS 316L 8.00 4 180 180 1

8 Pad for Saddle Supports SS 316L 8.00 12 200 350 2

9 Ribs for Saddle Supports SS 316L 8.00 12 200 150 10

10 Base Plate for Saddle Supports SS 316L 8.00 12 200 250 2

11 Support Plate for Saddle Supports SS 316L 8.00 12 150 250 2

SL PART MOC DEN QTY

OD WT LENGTH

1 Tubes SA 182 8.00 20 1.244 2500 18

2 U-Tubes SA 182 8.00 20 1.244 280 9

3 Spacer SA 182 8.00 15 2.5 2500 4

4 Nozzle Neck N1, N2 SA 182 8.00 60.33 5.54 250 2

5 Nozzle Neck N3, N4 SA 182 8.00 60.33 5.54 250 2

SL PART MOC DEN QTY

LENGTH

1 Tie Rod SS 316L 8.00 2500 4

SL PART MOC DEN QTY

1 N1, N2 SA 182 8.00 2

1 N3, N4 SA 182 8.00 2

SL PART MOC DEN QTY

1 Gasket PTFE 4

2 Gasket PTFE 2

3 Bolt + Nut SA 193 B5 / H2 16

4 Jack Screw + Dowel Pin

5 Name Plate 1

SL

1

2

3

4

ITEM

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

CLIENT

10

DRAWING NO.

PLATE

SIZE

PIPES

SIZE

RODS

SIZE

DIA

Body Flange and Tubesheet

Flanges

SIZE

50 NB 150# SORF

50 NB 150# SORF

Miscellaenous

SIZE

50 NB

RADIOGRAPHY

M16 x 85 Lg

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

Testing

5

6

7

8

9

10

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

DATE

WEIGHT RATE AMOUNT

114.40 0.00

14.40 0.00

19.80 0.00

15.55 0.00

30.00 0.00

30.00 0.00

2.88 0.00

1.04 0.00

13.44 0.00

28.80 0.00

9.60 0.00

7.20 0.00

0.00

WEIGHT RATE AMOUNT

26.39 0.00

1.48 0.00

7.85 0.00

3.81 0.00

3.81 0.00

0.00

WEIGHT RATE AMOUNT

6.27 0.00

0.00

WEIGHT RATE AMOUNT

5.00 0.00

5.00 0.00

0.00

WEIGHT RATE AMOUNT

0.00

0.00

0.00

0.00

0.00

0.00

0.00

AMOUNT

0.00

0.00

#VALUE!

0.00

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

18-02-2014

PLATE

TOTAL

PIPES

TOTAL

RODS

TOTAL

Flanges

TOTAL

Miscellaenous

RADIOGRAPHY

TOTAL

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

Testing

0.00

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

10 #VALUE!

5 #VALUE!

20 #VALUE!

#VALUE!

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

Technical

HEAT Exchanger Type: BEU Horizontal

M.O.C: Shell SS 316L 10Thk

Tube Sheet SS 316L

Baffles SS 316L 4Thk

Channel SS 316L 10Thk

Tube SS 316L

Tie Rod SS 316L 10Dia

Shell Side Noz SS 316L 50DN

Channel Noz SS 316L 50DN

Tube to Tube Sheet Joint: Expanded & Seal Welded.

Inspection: At our Works by your Engineer.

QTN No.

SL PART MOC DEN QTY

TK WIDTH LENGTH

1 Shell SS 316L 8.00 10 750 2600 1

2 Top Bonnet Dished SS 316L 8.00 4 380 380 1

3 Top Bonnet Shell SS 316L 8.00 4 250 750 1

4 Bottom Bonnet Dished SS 316L 8.00 4 380 380 1

5 Bottom Bonnet Shell SS 316L 8.00 4 250 750 1

6 Tubesheet SS 316L 8.00 50 350 350 2

7 Bottom Bonnet Flange SS 316L 8.00 50 350 350 1

8 Top Bonnet Flange SS 316L 8.00 50 350 350 1

11 Baffle SS 316L 8.00 4 180 180 4

12 Pad for Saddle Supports SS 316L 8.00 12 150 250 2

13 Ribs for Saddle Supports SS 316L 8.00 12 150 100 10

14 Base Plate for Saddle Supports SS 316L 8.00 12 150 150 2

15 Support Plate for Saddle Supports SS 316L 8.00 12 100 150 2

SL PART MOC DEN QTY

OD WT LENGTH

1 Tubes SS 316L 8.00 20 1.244 2500 48

2 Spacer SS 316L 8.00 15 2.5 2500 4

3 Nozzle Neck N1, N2 SS 316L 8.00 60.33 5.54 250 2

4 Nozzle Neck N3, N4 SS 316L 8.00 60.33 5.54 250 2

SL PART MOC DEN QTY

LENGTH

1 Tie Rod SS 316L 8.00 2500 4

SL PART MOC DEN QTY

1 N1, N2 SS 316L 8.00 2

1 N3, N4 SS 316L 8.00 2

SL PART MOC DEN QTY

1 Gasket PTFE 4

2 Gasket PTFE 2

3 Bolt + Nut SA 193 B5 / H2 16

4 Jack Screw + Dowel Pin

5 Name Plate 1

SL

1

2

3

4

ITEM 2 NOS

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

CLIENT

10

DRAWING NO.

PLATE

SIZE

PIPES

SIZE

RODS

SIZE

DIA

Body Flange and Tubesheet

Flanges

SIZE

50 NB 150# SORF

50 NB 150# SORF

Miscellaenous

SIZE

50 NB

RADIOGRAPHY

M16 X 85 Lg

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

Testing

5

6

7

8

9

10

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

DATE

WEIGHT RATE AMOUNT

156.00 0.00

4.62 0.00

6.00 0.00

4.62 0.00

6.00 0.00

98.00 0.00

49.00 0.00

49.00 0.00

4.15 0.00

7.20 0.00

14.40 0.00

4.32 0.00

2.88 0.00

0.00

WEIGHT RATE AMOUNT

70.37 0.00

7.85 0.00

3.81 0.00

3.81 0.00

0.00

WEIGHT RATE AMOUNT

6.27 0.00

0.00

WEIGHT RATE AMOUNT

6.00 0.00

6.00 0.00

0.00

WEIGHT RATE AMOUNT

0.00

0.00

0.00

0.00

0.00

0.00

0.00

AMOUNT

0.00

0.00

#VALUE!

0.00

2 NOS

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

18-02-2014

PLATE

TOTAL

PIPES

TOTAL

RODS

TOTAL

Flanges

TOTAL

Miscellaenous

RADIOGRAPHY

TOTAL

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

Testing

0.00

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

10 #VALUE!

5 #VALUE!

20 #VALUE!

#VALUE!

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

Technical

HEAT Exchanger Type: BEM Horizontal

M.O.C: Shell SS 316L 10Thk

Tube Sheet SS 316L

Baffles SS 316L 4Thk

Channel SS 316L 4Thk

Tube SS 316L

Tie Rod SS 316L 10Dia

Shell Side Noz SS 316L 50DN

Channel Noz SS 316L 50DN

Tube to Tube Sheet Joint: Expanded & Seal Welded.

Inspection: At our Works by your Engineer.

QTN No.

SL PART MOC DEN QTY

TK WIDTH LENGTH

1 Shell CS 7.80 10 900 3100 1

2 Top Bonnet Dished SS 316L 8.00 4 420 420 1

3 Top Bonnet Shell SS 316L 8.00 4 250 900 1

4 Bottom Bonnet Dished SS 316L 8.00 4 420 420 1

5 Bottom Bonnet Shell SS 316L 8.00 4 250 900 1

6 Tubesheet SS 316L 8.00 50 400 400 2

7 Bottom Bonnet Flange CS 7.80 50 400 400 1

8 Top Bonnet Flange CS 7.80 50 400 400 1

11 Baffle CS 7.80 4 220 220 5

12 Pad for Saddle Supports CS 7.80 12 150 250 2

13 Ribs for Saddle Supports CS 7.80 12 150 100 10

14 Base Plate for Saddle Supports CS 7.80 12 150 150 2

15 Support Plate for Saddle Supports CS 7.80 12 100 150 2

SL PART MOC DEN QTY

OD WT LENGTH

1 Tubes SS 316L 8.00 20 1.244 3100 44

2 Spacer SS 316L 8.00 15 2.5 3100 4

3 Nozzle Neck N1, N2 SS 316L 8.00 60.33 5.54 250 2

4 Nozzle Neck N3, N4 CS 7.80 60.33 5.54 250 2

SL PART MOC DEN QTY

LENGTH

1 Tie Rod CS 7.80 3000 4

SL PART MOC DEN QTY

1 N1, N2 SS 316L 8.00 2

1 N3, N4 CS 7.80 2

SL PART MOC DEN QTY

1 Gasket PTFE 4

2 Gasket PTFE 2

3 Bolt + Nut SA 193 B5 / H2 16

4 Jack Screw + Dowel Pin

5 Name Plate 1

SL

1

2

3

4

ITEM

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

CLIENT

10

DRAWING NO.

PLATE

SIZE

PIPES

SIZE

RODS

SIZE

DIA

Body Flange and Tubesheet

Flanges

SIZE

50 NB 150# SORF

50 NB 150# SORF

Miscellaenous

SIZE

50 NB

RADIOGRAPHY

M16 X 85 Lg

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

Testing

5

6

7

8

9

10

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

DATE

WEIGHT RATE AMOUNT

217.62 0.00

5.64 0.00

7.20 0.00

5.64 0.00

7.20 0.00

128.00 0.00

62.40 0.00

62.40 0.00

7.55 0.00

7.02 0.00

14.04 0.00

4.21 0.00

2.81 0.00

0.00

WEIGHT RATE AMOUNT

79.98 0.00

9.74 0.00

3.81 0.00

3.72 0.00

0.00

WEIGHT RATE AMOUNT

7.34 0.00

0.00

WEIGHT RATE AMOUNT

6.00 0.00

6.00 0.00

0.00

WEIGHT RATE AMOUNT

0.00

0.00

0.00

0.00

0.00

0.00

0.00

AMOUNT

0.00

0.00

#VALUE!

0.00

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

18-02-2014

PLATE

TOTAL

PIPES

TOTAL

RODS

TOTAL

Flanges

TOTAL

Miscellaenous

RADIOGRAPHY

TOTAL

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

Testing

0.00

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

10 #VALUE!

5 #VALUE!

20 #VALUE!

#VALUE!

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

Technical

HEAT Exchanger Type: BEM Horizontal

M.O.C: Shell CS 10Thk

Tube Sheet SS 316L

Baffles CS 4Thk

Channel SS 316L 4Thk

Tube SS 316L

Tie Rod CS 10Dia

Shell Side Noz CS 50DN

Channel Noz SS 316L 50DN

Tube to Tube Sheet Joint: Expanded & Seal Welded.

Inspection: At our Works by your Engineer.

QTN No.

SL PART MOC DEN QTY

TK WIDTH LENGTH

1 Shell SS 316L 8.00 10 600 4100 1

2 Top Bonnet Dished D 2205 8.00 4 300 300 1

3 Top Bonnet Shell D 2205 8.00 4 270 550 1

4 Bottom Bonnet Dished D 2205 8.00 4 300 300 1

5 Bottom Bonnet Shell D 2205 8.00 4 270 550 1

6 Tubesheet D 2205 8.00 50 300 300 2

7 Bottom Bonnet Flange SS 316L 8.00 50 300 300 1

8 Top Bonnet Flange SS 316L 8.00 50 300 300 1

11 Baffle SS 316L 8.00 4 150 150 4

12 Pad for Saddle Supports CS 7.80 12 150 250 2

13 Ribs for Saddle Supports CS 7.80 12 150 100 10

14 Base Plate for Saddle Supports CS 7.80 12 150 150 2

15 Support Plate for Saddle Supports CS 7.80 12 100 150 2

SL PART MOC DEN QTY

OD WT LENGTH

1 Tubes D 2205 8.00 20 1.244 4100 26

2 Spacer SS 316L 8.00 15 2.5 4100 4

3 Nozzle Neck N1, N2 D 2205 8.00 60.33 5.54 250 2

4 Nozzle Neck N3, N4 SS 316L 8.00 60.33 5.54 250 2

SL PART MOC DEN QTY

LENGTH

1 Tie Rod SS 316L 8.00 4100 4

SL PART MOC DEN QTY

1 N1, N2 D 2205 8.00 2

1 N3, N4 SS 316L 7.80 2

SL PART MOC DEN QTY

1 Gasket PTFE 4

2 Gasket PTFE 2

3 Bolt + Nut SA 193 B5 / H2 16

4 Jack Screw + Dowel Pin

5 Name Plate 1

SL

1

2

3

4 Testing

RADIOGRAPHY

M16 X 85 Lg

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

Body Flange and Tubesheet

Flanges

SIZE

50 NB 150# SORF

50 NB 150# SORF

Miscellaenous

SIZE

50 NB

10

DRAWING NO.

PLATE

SIZE

PIPES

SIZE

RODS

SIZE

DIA

ITEM 2 Nos

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

CLIENT

5

6

7

8

9

10

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

DATE

WEIGHT RATE AMOUNT

196.80 0.00

2.88 0.00

4.75 0.00

2.88 0.00

4.75 0.00

72.00 0.00

36.00 0.00

36.00 0.00

2.88 0.00

7.02 0.00

14.04 0.00

4.21 0.00

2.81 0.00

0.00

WEIGHT RATE AMOUNT

62.51 0.00

12.88 0.00

3.81 0.00

3.81 0.00

0.00

WEIGHT RATE AMOUNT

10.29 0.00

0.00

WEIGHT RATE AMOUNT

6.00 0.00

6.00 0.00

0.00

WEIGHT RATE AMOUNT

0.00

0.00

0.00

0.00

0.00

0.00

0.00

AMOUNT

0.00

0.00

#VALUE!

0.00 Testing

RADIOGRAPHY

TOTAL

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

TOTAL

Flanges

TOTAL

Miscellaenous

PLATE

TOTAL

PIPES

TOTAL

RODS

2 Nos

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

18-02-2014

0.00

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

10 #VALUE!

5 #VALUE!

20 #VALUE!

#VALUE!

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

Technical

HEAT Exchanger Type: BEM Horizontal

M.O.C: Shell SS 316L 10Thk

Tube Sheet Duplex SS

Baffles SS 316L 4Thk

Channel Duplex SS 4Thk

Tube Duplex SS

Tie Rod SS 316L 10Dia

Shell Side Noz SS 316L 50DN

Channel Noz Duplex SS 50DN

Tube to Tube Sheet Joint: Expanded & Seal Welded.

Inspection: At our Works by your Engineer.

QTN No.

SL PART MOC DEN QTY

TK WIDTH LENGTH

1 Shell CS 7.80 10 600 4100 1

2 Top Bonnet Dished D 2205 8.00 4 300 300 1

3 Top Bonnet Shell D 2205 8.00 4 270 550 1

4 Bottom Bonnet Dished D 2205 8.00 4 300 300 1

5 Bottom Bonnet Shell D 2205 8.00 4 270 550 1

6 Tubesheet D 2205 8.00 50 300 300 2

7 Bottom Bonnet Flange CS 7.80 50 300 300 1

8 Top Bonnet Flange CS 7.80 50 300 300 1

11 Baffle CS 7.80 4 150 150 4

12 Pad for Saddle Supports CS 7.80 12 150 250 2

13 Ribs for Saddle Supports CS 7.80 12 150 100 10

14 Base Plate for Saddle Supports CS 7.80 12 150 150 2

15 Support Plate for Saddle Supports CS 7.80 12 100 150 2

SL PART MOC DEN QTY

OD WT LENGTH

1 Tubes D 2205 8.00 20 1.244 4100 16

2 Spacer CS 7.80 15 2.5 4100 4

3 Nozzle Neck N1, N2 D 2205 8.00 60.33 5.54 250 2

4 Nozzle Neck N3, N4 CS 7.80 60.33 5.54 250 2

SL PART MOC DEN QTY

LENGTH

1 Tie Rod CS 7.80 4100 4

SL PART MOC DEN QTY

1 N1, N2 D 2205 8.00 2

1 N3, N4 CS 7.80 2

SL PART MOC DEN QTY

1 Gasket PTFE 4

2 Gasket PTFE 2

3 Bolt + Nut SA 193 B5 / H2 16

4 Jack Screw + Dowel Pin

5 Name Plate 1

SL

1

2

3

4 Testing

RADIOGRAPHY

M16 X 85 Lg

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

Body Flange and Tubesheet

Flanges

SIZE

50 NB 150# SORF

50 NB 150# SORF

Miscellaenous

SIZE

50 NB

10

DRAWING NO.

PLATE

SIZE

PIPES

SIZE

RODS

SIZE

DIA

ITEM 2 Nos

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

CLIENT

5

6

7

8

9

10

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

DATE

WEIGHT RATE AMOUNT

191.88 0.00

2.88 0.00

4.75 0.00

2.88 0.00

4.75 0.00

72.00 0.00

35.10 0.00

35.10 0.00

2.81 0.00

7.02 0.00

14.04 0.00

4.21 0.00

2.81 0.00

0.00

WEIGHT RATE AMOUNT

38.47 0.00

12.56 0.00

3.81 0.00

3.72 0.00

0.00

WEIGHT RATE AMOUNT

10.03 0.00

0.00

WEIGHT RATE AMOUNT

6.00 0.00

6.00 0.00

0.00

WEIGHT RATE AMOUNT

0.00

0.00

0.00

0.00

0.00

0.00

0.00

AMOUNT

0.00

0.00

#VALUE!

0.00 Testing

RADIOGRAPHY

TOTAL

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

TOTAL

Flanges

TOTAL

Miscellaenous

PLATE

TOTAL

PIPES

TOTAL

RODS

2 Nos

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

18-02-2014

0.00

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

10 #VALUE!

5 #VALUE!

20 #VALUE!

#VALUE!

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

Technical

HEAT Exchanger Type: BEM Horizontal

M.O.C: Shell CS 10Thk.

Tube Sheet Duplex SS

Baffles CS 4Thk.

Channel Duplex SS 4Thk.

Tube Duplex SS

Tie Rod CS 10Dia

Shell Side Noz CS 50DN

Channel Noz Duplex SS 50DN

Tube to Tube Sheet Joint: Expanded & Seal Welded.

Inspection: At our Works by your Engineer.

QTN No.

SL PART MOC DEN QTY

TK WIDTH LENGTH

1 Shell CS 7.80 10 750 2600 1

2 Top Bonnet Dished SS 316L 8.00 4 380 380 1

3 Top Bonnet Shell SS 316L 8.00 4 250 750 1

4 Bottom Bonnet Dished SS 316L 8.00 4 380 380 1

5 Bottom Bonnet Shell SS 316L 8.00 4 250 750 1

6 Tubesheet SS 316L 8.00 50 350 350 2

7 Bottom Bonnet Flange SS 316L 8.00 50 350 350 1

8 Top Bonnet Flange SS 316L 8.00 50 350 350 1

11 Baffle CS 7.80 4 180 180 4

12 Pad for Saddle Supports CS 7.80 12 150 250 2

13 Ribs for Saddle Supports CS 7.80 12 150 100 10

14 Base Plate for Saddle Supports CS 7.80 12 150 150 2

15 Support Plate for Saddle Supports CS 7.80 12 100 150 2

SL PART MOC DEN QTY

OD WT LENGTH

1 Tubes SS 316L 8.00 20 1.244 2600 38

2 Spacer CS 7.80 15 2.5 2600 4

3 Nozzle Neck N1, N2 SS 316L 8.00 60.33 5.54 250 2

4 Nozzle Neck N3, N4 CS 7.80 60.33 5.54 250 2

SL PART MOC DEN QTY

LENGTH

1 Tie Rod CS 7.80 2600 4

SL PART MOC DEN QTY

1 N1, N2 SS 316L 8.00 2

1 N3, N4 CS 7.80 2

SL PART MOC DEN QTY

1 Gasket PTFE 4

2 Gasket PTFE 2

3 Bolt + Nut SA 193 B5 / H2 16

4 Jack Screw + Dowel Pin

5 Name Plate 1

SL

1

2

3

4 Testing

RADIOGRAPHY

M16 X 85 Lg

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

Body Flange and Tubesheet

Flanges

SIZE

50 NB 150# SORF

50 NB 150# SORF

Miscellaenous

SIZE

50 NB

10

DRAWING NO.

PLATE

SIZE

PIPES

SIZE

RODS

SIZE

DIA

ITEM

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

CLIENT

5

6

7

8

9

10

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

DATE

WEIGHT RATE AMOUNT

152.10 0.00

4.62 0.00

6.00 0.00

4.62 0.00

6.00 0.00

98.00 0.00

49.00 0.00

49.00 0.00

4.04 0.00

7.02 0.00

14.04 0.00

4.21 0.00

2.81 0.00

0.00

WEIGHT RATE AMOUNT

57.94 0.00

7.96 0.00

3.81 0.00

3.72 0.00

0.00

WEIGHT RATE AMOUNT

6.36 0.00

0.00

WEIGHT RATE AMOUNT

6.00 0.00

6.00 0.00

0.00

WEIGHT RATE AMOUNT

0.00

0.00

0.00

0.00

0.00

0.00

0.00

AMOUNT

0.00

0.00

#VALUE!

0.00 Testing

RADIOGRAPHY

TOTAL

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

TOTAL

Flanges

TOTAL

Miscellaenous

PLATE

TOTAL

PIPES

TOTAL

RODS

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

18-02-2014

0.00

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

10 #VALUE!

5 #VALUE!

20 #VALUE!

#VALUE!

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

Technical

HEAT Exchanger Type: BEM Horizontal

M.O.C: Shell CS 10Thk

Tube Sheet SS 316L

Baffles CS 4Thk

Channel SS 316L 4Thk

Tube SS 316L

Tie Rod CS 10Dia

Shell Side Noz CS 50DN

Channel Noz SS 316L 50DN

Tube to Tube Sheet Joint: Expanded & Seal Welded.

Inspection: At our Works by your Engineer.

QTN No.

SL PART MOC DEN QTY

TK WIDTH LENGTH

1 Shell CS 7.80 10 750 3800 1

2 Top Bonnet Dished SS 316L 8.00 4 380 380 1

3 Top Bonnet Shell SS 316L 8.00 4 270 750 1

4 Bottom Bonnet Dished SS 316L 8.00 4 380 380 1

5 Bottom Bonnet Shell SS 316L 8.00 4 270 750 1

6 Tubesheet SS 316L 8.00 50 350 350 2

7 Bottom Bonnet Flange SS 316L 8.00 50 350 350 1

8 Top Bonnet Flange SS 316L 8.00 50 350 350 1

11 Baffle CS 7.80 4 180 180 6

12 Pad for Saddle Supports CS 7.80 12 150 250 2

13 Ribs for Saddle Supports CS 7.80 12 150 100 10

14 Base Plate for Saddle Supports CS 7.80 12 150 150 2

15 Support Plate for Saddle Supports CS 7.80 12 100 150 2

SL PART MOC DEN QTY

OD WT LENGTH

1 Tubes SS 316L 8.00 20 1.244 3800 30

2 Spacer CS 7.80 15 2.5 3800 4

3 Nozzle Neck N1, N2 SS 316L 8.00 60.33 5.54 250 2

4 Nozzle Neck N3, N4 CS 7.80 60.33 5.54 250 2

SL PART MOC DEN QTY

LENGTH

1 Tie Rod CS 7.80 3800 4

SL PART MOC DEN QTY

1 N1, N2 SS 316L 8.00 2

1 N3, N4 CS 7.80 2

SL PART MOC DEN QTY

1 Gasket PTFE 4

2 Gasket PTFE 2

3 Bolt + Nut SA 193 B5 / H2 16

4 Jack Screw + Dowel Pin

5 Name Plate 1

SL

1

2

3

4 Testing

RADIOGRAPHY

M16 X 85 Lg

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

Body Flange and Tubesheet

Flanges

SIZE

50 NB 150# SORF

50 NB 150# SORF

Miscellaenous

SIZE

50 NB

10

DRAWING NO.

PLATE

SIZE

PIPES

SIZE

RODS

SIZE

DIA

ITEM

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

CLIENT

5

6

7

8

9

10

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

DATE

WEIGHT RATE AMOUNT

222.30 0.00

4.62 0.00

6.48 0.00

4.62 0.00

6.48 0.00

98.00 0.00

49.00 0.00

49.00 0.00

6.07 0.00

7.02 0.00

14.04 0.00

4.21 0.00

2.81 0.00

0.00

WEIGHT RATE AMOUNT

66.85 0.00

11.64 0.00

3.81 0.00

3.72 0.00

0.00

WEIGHT RATE AMOUNT

9.30 0.00

0.00

WEIGHT RATE AMOUNT

6.00 0.00

6.00 0.00

0.00

WEIGHT RATE AMOUNT

0.00

0.00

0.00

0.00

0.00

0.00

0.00

AMOUNT

0.00

0.00

#VALUE!

0.00 Testing

RADIOGRAPHY

TOTAL

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

TOTAL

Flanges

TOTAL

Miscellaenous

PLATE

TOTAL

PIPES

TOTAL

RODS

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

18-02-2014

0.00

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

10 #VALUE!

5 #VALUE!

20 #VALUE!

#VALUE!

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

Technical

HEAT Exchanger Type: BEM Horizontal

M.O.C: Shell CS 10Thk

Tube Sheet SS 316L

Baffles CS 4Thk

Channel SS 316L 4Thk

Tube SS 316L

Tie Rod CS 10Dia

Shell Side Noz CS 50DN

Channel Noz SS 316L 50DN

Tube to Tube Sheet Joint: Expanded & Seal Welded.

Inspection: At our Works by your Engineer.

QTN No.

SL PART MOC DEN QTY

TK WIDTH LENGTH

1 Shell CS 7.80 10 750 1200 1

2 Top Bonnet Dished SS 316L 8.00 4 380 380 1

3 Top Bonnet Shell SS 316L 8.00 4 300 750 1

4 Bottom Bonnet Dished SS 316L 8.00 4 380 380 1

5 Bottom Bonnet Shell SS 316L 8.00 4 300 750 1

6 Tubesheet CS 7.80 50 350 350 2

7 Bottom Bonnet Flange SS 316L 8.00 50 350 350 1

8 Top Bonnet Flange SS 316L 8.00 50 350 350 1

11 Baffle CS 7.80 4 180 180 6

12 Pad for Saddle Supports CS 7.80 12 150 250 2

13 Ribs for Saddle Supports CS 7.80 12 150 100 10

14 Base Plate for Saddle Supports CS 7.80 12 150 150 2

15 Support Plate for Saddle Supports CS 7.80 12 100 150 2

SL PART MOC DEN QTY

OD WT LENGTH

1 Tubes CS 7.80 20 1.244 1200 42

2 Spacer CS 7.80 15 2.5 1200 4

3 Nozzle Neck N1, N2 SS 316L 8.00 60.33 5.54 250 2

4 Nozzle Neck N3, N4 CS 7.80 60.33 5.54 250 2

SL PART MOC DEN QTY

LENGTH

1 Tie Rod CS 7.80 1200 4

SL PART MOC DEN QTY

1 N1, N2 SS 316L 8.00 2

1 N3, N4 CS 7.80 2

SL PART MOC DEN QTY

1 Gasket PTFE 4

2 Gasket PTFE 2

3 Bolt + Nut SA 193 B5 / H2 16

4 Jack Screw + Dowel Pin

5 Name Plate 1

SL

1

2

3

4 Testing

RADIOGRAPHY

M16 X 85 Lg

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

Body Flange and Tubesheet

Flanges

SIZE

50 NB 150# SORF

50 NB 150# SORF

Miscellaenous

SIZE

50 NB

10

DRAWING NO.

PLATE

SIZE

PIPES

SIZE

RODS

SIZE

DIA

ITEM 2 Nos

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

CLIENT

5

6

7

8

9

10

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

DATE

WEIGHT RATE AMOUNT

70.20 0.00

4.62 0.00

7.20 0.00

4.62 0.00

7.20 0.00

95.55 0.00

49.00 0.00

49.00 0.00

6.07 0.00

7.02 0.00

14.04 0.00

4.21 0.00

2.81 0.00

0.00

WEIGHT RATE AMOUNT

28.82 0.00

3.68 0.00

3.81 0.00

3.72 0.00

0.00

WEIGHT RATE AMOUNT

2.94 0.00

0.00

WEIGHT RATE AMOUNT

6.00 0.00

6.00 0.00

0.00

WEIGHT RATE AMOUNT

0.00

0.00

0.00

0.00

0.00

0.00

0.00

AMOUNT

0.00

0.00

#VALUE!

0.00 Testing

RADIOGRAPHY

TOTAL

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

TOTAL

Flanges

TOTAL

Miscellaenous

PLATE

TOTAL

PIPES

TOTAL

RODS

2 Nos

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

18-02-2014

0.00

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

10 #VALUE!

5 #VALUE!

20 #VALUE!

#VALUE!

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

Technical

HEAT Exchanger Type: BEM Horizontal

M.O.C: Shell CS 10Thk

Tube Sheet CS

Baffles CS 4Thk.

Channel SS 316L 4Thk.

Tube CS

Tie Rod CS 10Dia

Shell Side Noz CS 50DN

Channel Noz SS 316L 50DN

Tube to Tube Sheet Joint: Expanded & Seal Welded.

Inspection: At our Works by your Engineer.

QTN No.

SL PART MOC DEN QTY

TK WIDTH LENGTH

1 Shell CS 7.80 10 900 3600 1

2 Top Bonnet Dished SS 304L 8.00 4 420 420 1

3 Top Bonnet Shell SS 304L 8.00 4 300 900 1

4 Bottom Bonnet Dished SS 304L 8.00 4 420 420 1

5 Bottom Bonnet Shell SS 304L 8.00 4 300 900 1

6 Tubesheet SS 304L 8.00 50 400 400 2

7 Bottom Bonnet Flange SS 304L 8.00 50 400 400 1

8 Top Bonnet Flange SS 304L 8.00 50 400 400 1

11 Baffle CS 7.80 4 220 220 5

12 Pad for Saddle Supports CS 7.80 12 150 250 2

13 Ribs for Saddle Supports CS 7.80 12 150 100 10

14 Base Plate for Saddle Supports CS 7.80 12 150 150 2

15 Support Plate for Saddle Supports CS 7.80 12 100 150 2

SL PART MOC DEN QTY

OD WT LENGTH

1 Tubes SS 304L 8.00 20 1.244 3600 74

2 Spacer SS 304L 8.00 15 2.5 3600 4

3 Nozzle Neck N1, N2 SS 304L 8.00 60.33 5.54 250 2

4 Nozzle Neck N3, N4 CS 7.80 60.33 5.54 250 2

SL PART MOC DEN QTY

LENGTH

1 Tie Rod CS 7.80 3600 4

SL PART MOC DEN QTY

1 N1, N2 SS 304L 8.00 2

1 N3, N4 CS 7.80 2

SL PART MOC DEN QTY

1 Gasket PTFE 4

2 Gasket PTFE 2

3 Bolt + Nut SA 193 B5 / H2 16

4 Jack Screw + Dowel Pin

5 Name Plate 1

SL

1

2

3

4 Testing

RADIOGRAPHY

M16 X 85 Lg

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

Body Flange and Tubesheet

Flanges

SIZE

50 NB 150# SORF

50 NB 150# SORF

Miscellaenous

SIZE

50 NB

10

DRAWING NO.

PLATE

SIZE

PIPES

SIZE

RODS

SIZE

DIA

ITEM

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

CLIENT

5

6

7

8

9

10

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

DATE

WEIGHT RATE AMOUNT

252.72 0.00

5.64 0.00

8.64 0.00

5.64 0.00

8.64 0.00

128.00 0.00

64.00 0.00

64.00 0.00

7.55 0.00

7.02 0.00

14.04 0.00

4.21 0.00

2.81 0.00

0.00

WEIGHT RATE AMOUNT

156.21 0.00

11.31 0.00

3.81 0.00

3.72 0.00

0.00

WEIGHT RATE AMOUNT

8.81 0.00

0.00

WEIGHT RATE AMOUNT

6.00 0.00

6.00 0.00

0.00

WEIGHT RATE AMOUNT

0.00

0.00

0.00

0.00

0.00

0.00

0.00

AMOUNT

0.00

0.00

#VALUE!

0.00 Testing

RADIOGRAPHY

TOTAL

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

TOTAL

Flanges

TOTAL

Miscellaenous

PLATE

TOTAL

PIPES

TOTAL

RODS

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

18-02-2014

0.00

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

10 #VALUE!

5 #VALUE!

20 #VALUE!

#VALUE!

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

Technical

HEAT Exchanger Type: BEM Horizontal

M.O.C: Shell CS 10Thk

Tube Sheet SS 316L

Baffles CS 4Thk

Channel SS 316L 4Thk

Tube SS 316L

Tie Rod CS 10Dia

Shell Side Noz CS 50DN

Channel Noz SS 316L 50DN

Tube to Tube Sheet Joint: Expanded & Seal Welded.

Inspection: At our Works by your Engineer.

QTN No.

SL PART MOC DEN QTY

TK WIDTH LENGTH

1 Shell CS 7.80 12 1050 3100 1

2 Top Bonnet Dished SS 316L 8.00 4 500 500 1

3 Top Bonnet Shell SS 316L 8.00 4 300 1050 1

4 Bottom Bonnet Dished SS 316L 8.00 4 500 500 1

5 Bottom Bonnet Shell SS 316L 8.00 4 300 1050 1

6 Tubesheet SS 316L 8.00 50 450 450 2

7 Bottom Bonnet Flange SS 316L 8.00 50 450 450 1

8 Top Bonnet Flange SS 316L 8.00 50 450 450 1

11 Baffle CS 7.80 4 280 280 5

12 Pad for Saddle Supports CS 7.80 12 150 250 2

13 Ribs for Saddle Supports CS 7.80 12 150 100 10

14 Base Plate for Saddle Supports CS 7.80 12 150 150 2

15 Support Plate for Saddle Supports CS 7.80 12 100 150 2

SL PART MOC DEN QTY

OD WT LENGTH

1 Tubes SS 316L 8.00 20 1.244 3100 88

2 Spacer SS 316L 8.00 15 2.5 3100 4

3 Nozzle Neck N1, N2 SS 316L 8.00 114.3 6.02 250 2

4 Nozzle Neck N3, N4 CS 7.80 114.3 6.02 250 2

SL PART MOC DEN QTY

LENGTH

1 Tie Rod CS 7.80 3100 4

SL PART MOC DEN QTY

1 N1, N2 SS 316L 8.00 2

1 N3, N4 CS 7.80 2

SL PART MOC DEN QTY

1 Gasket PTFE 4

2 Gasket PTFE 2

3 Bolt + Nut SA 193 B5 / H2 16

4 Jack Screw + Dowel Pin

5 Name Plate 1

SL

1

2

3

4 Testing

RADIOGRAPHY

M16 X 85 Lg

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

Body Flange and Tubesheet

Flanges

SIZE

100 NB 150# SORF

100 NB 150# SORF

Miscellaenous

SIZE

100 NB

10

DRAWING NO.

PLATE

SIZE

PIPES

SIZE

RODS

SIZE

DIA

ITEM

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

CLIENT

5

6

7

8

9

10

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

DATE

WEIGHT RATE AMOUNT

304.67 0.00

8.00 0.00

10.08 0.00

8.00 0.00

10.08 0.00

162.00 0.00

81.00 0.00

81.00 0.00

12.23 0.00

7.02 0.00

14.04 0.00

4.21 0.00

2.81 0.00

0.00

WEIGHT RATE AMOUNT

159.97 0.00

9.74 0.00

8.19 0.00

7.99 0.00

0.00

WEIGHT RATE AMOUNT

7.58 0.00

0.00

WEIGHT RATE AMOUNT

13.00 0.00

13.00 0.00

0.00

WEIGHT RATE AMOUNT

0.00

0.00

0.00

0.00

0.00

0.00

0.00

AMOUNT

0.00

0.00

#VALUE!

0.00 Testing

RADIOGRAPHY

TOTAL

WORKINGS

DESCRIPTION

Total Cost of Raw Materials

Drilling

TOTAL

Flanges

TOTAL

Miscellaenous

PLATE

TOTAL

PIPES

TOTAL

RODS

TINITA ENGINEERING (P) LTD.

E S T I M A T I O N

18-02-2014

0.00

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

10 #VALUE!

5 #VALUE!

20 #VALUE!

#VALUE!

Machining

Other Sub-Contracting Dish Pressing

Misce Expansion

Wooden Box

Transportation

Others Design

TOTAL

Fabrication %

Over Head %

Profit %

Technical

HEAT Exchanger Type: BEM Horizontal

M.O.C: Shell CS 12Thk

Tube Sheet SS 316L

Baffles CS 4Thk

Channel SS 316L 4Thk

Tube SS 316L

Tie Rod CS 10Dia

Shell Side Noz CS 100DN

Channel Noz SS 316L 100DN

Tube to Tube Sheet Joint: Expanded & Seal Welded.

Inspection: At our Works by your Engineer.

You might also like

- Ejma7r2 Bellows Worksheet 1Document8 pagesEjma7r2 Bellows Worksheet 1NamıkNo ratings yet

- API2000 Tank CalcsDocument5 pagesAPI2000 Tank CalcsHuzefaFDNo ratings yet

- TBE Inlet Separator V 2100 FLNG2Document6 pagesTBE Inlet Separator V 2100 FLNG2halipzramlyzNo ratings yet

- IBR Thickness CalculationDocument17 pagesIBR Thickness Calculationreach_arindomNo ratings yet

- Ellipsoidal Head Tank - Volume-Height CalculationDocument4 pagesEllipsoidal Head Tank - Volume-Height Calculationdadz mingiNo ratings yet

- Compress Report For Pressure VesselDocument394 pagesCompress Report For Pressure VesselgaurangNo ratings yet

- Pump and Line CalcDocument1 pagePump and Line CalcPRATIK P. BHOIRNo ratings yet

- Fresh HDO Storage TankDocument42 pagesFresh HDO Storage TankHgagselim SelimNo ratings yet

- Calculation of Heat and Mass BalanceDocument16 pagesCalculation of Heat and Mass BalanceHEMANTNo ratings yet

- Calculation Cover SheetDocument6 pagesCalculation Cover SheetAnonymous a4Jwz14WNo ratings yet

- 8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Document42 pages8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Muhamad Amar Hakimmie Suhaimi100% (1)

- Pt. Bahana Karya Mandiri: Data SheetDocument8 pagesPt. Bahana Karya Mandiri: Data SheetBowo Edhi WibowoNo ratings yet

- Design of 5 Tons Capacity Cone Bottom STDocument26 pagesDesign of 5 Tons Capacity Cone Bottom SThgagselim2012No ratings yet

- Heat Ex Changers EstimationDocument46 pagesHeat Ex Changers Estimationshankarbt83No ratings yet

- Template Gas Line SizingDocument11 pagesTemplate Gas Line SizingRindie AuroraNo ratings yet

- Half Pipe Coil AgitatedDocument1 pageHalf Pipe Coil AgitatedNITINNo ratings yet

- Binoy's Engg DatasDocument29 pagesBinoy's Engg DatasSreejith GNo ratings yet

- Heat Exchanger CostingDocument4 pagesHeat Exchanger Costingjrmkum0% (1)

- K1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzleDocument1 pageK1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzlewhngomjNo ratings yet

- Tank Level Calculator Storage Tank: Head Related Size DiagramDocument29 pagesTank Level Calculator Storage Tank: Head Related Size DiagramDHAVALESH AMNo ratings yet

- Vessel Weight CheckDocument8 pagesVessel Weight ChecknileshNo ratings yet

- Maz - Design - Separator Capacity EvaluationDocument5 pagesMaz - Design - Separator Capacity EvaluationNaeem HussainNo ratings yet

- 15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Document4 pages15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Umair A. KhanNo ratings yet

- 1.5D Bend Calculation Per B31.1-2018Document84 pages1.5D Bend Calculation Per B31.1-2018Amit SharmaNo ratings yet

- CS SS - Pipe Weight CalculationDocument1 pageCS SS - Pipe Weight CalculationTashrif Yusuf0% (1)

- Art - 'S TEMA DesignationsDocument4 pagesArt - 'S TEMA Designationsmuhammad_asim_10No ratings yet

- Estimation Software For Presure VesselDocument37 pagesEstimation Software For Presure VesselalexnomitaNo ratings yet

- Flange Closure Design Spreadsheet-11 AmerivenDocument27 pagesFlange Closure Design Spreadsheet-11 AmerivenWilmer FigueraNo ratings yet

- Volume Calculation For Pressure Vessel TankDocument2 pagesVolume Calculation For Pressure Vessel Tanksai srikarNo ratings yet

- Reactor DesignDocument31 pagesReactor DesignMortada OthmanNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolSudjono BroNo ratings yet

- Development of Cone ExcelDocument5 pagesDevelopment of Cone ExcelPratik KarekarNo ratings yet

- Propane Storage TankDocument1 pagePropane Storage TankMarakanaMaheshNo ratings yet

- Data Sheet For Absorber Reflux Drum (GTPT-V-250-003)Document4 pagesData Sheet For Absorber Reflux Drum (GTPT-V-250-003)Mohamed hamza souissiNo ratings yet

- Design Calc S ManualDocument285 pagesDesign Calc S ManualGustavNo ratings yet

- Memoria ASME-Pressure-Vessel-DesignDocument143 pagesMemoria ASME-Pressure-Vessel-DesignJuan MendozaNo ratings yet

- TQ - Air Fin Cooler (CS) - ModificationDocument6 pagesTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaNo ratings yet

- Weight Estimation of Vessels AppsDocument39 pagesWeight Estimation of Vessels Appsmacwan23No ratings yet

- Bectel ASME Process Cal R2Document21 pagesBectel ASME Process Cal R2Sivakumar SelvarajNo ratings yet

- Jacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /HDocument30 pagesJacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /Hmanoj67% (3)

- API 650 Baseplate DesignDocument3 pagesAPI 650 Baseplate DesignmjlazoNo ratings yet

- 7-12-0013 Rev. 6 Nozzle Reinforcement & ProjectionDocument2 pages7-12-0013 Rev. 6 Nozzle Reinforcement & ProjectionJitender Kumar GuptaNo ratings yet

- Nozzle Check Top Head: Input ParametersDocument2 pagesNozzle Check Top Head: Input ParametersRaj Sharma100% (1)

- Erosion Velocity CalculationsDocument9 pagesErosion Velocity CalculationsMANISH GUPTANo ratings yet

- Calculation Sheet: Design CodeDocument1 pageCalculation Sheet: Design CodeCak AndiNo ratings yet

- Superheated Steam Condensate TankDocument4 pagesSuperheated Steam Condensate TankGanesh BhardwajNo ratings yet

- HP Dosing - AgecDocument12 pagesHP Dosing - AgecShameer MajeedNo ratings yet

- TubesheetDocument8 pagesTubesheetVaibhavNo ratings yet

- Dish CalculationDocument2 pagesDish CalculationRyan Goh Chuang HongNo ratings yet

- Heat Exchanger Area & Boilup Rate CalculationDocument19 pagesHeat Exchanger Area & Boilup Rate CalculationNitin KurupNo ratings yet

- Coil Heat CalculationDocument2 pagesCoil Heat CalculationTarmana Antt100% (1)

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Document4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINo ratings yet

- Pipe DataDocument2 pagesPipe DataPawan Kumar Gangwar100% (2)

- Flash Tank Calculation ReportDocument29 pagesFlash Tank Calculation Reporttauqeer100% (1)

- Flange Weight ChartDocument1 pageFlange Weight Chartabhishek198327No ratings yet

- Process Design Support DataDocument53 pagesProcess Design Support DataSuryakant RanderiNo ratings yet

- XSize Pump CALCDocument7 pagesXSize Pump CALCsegunoyesNo ratings yet

- ALL Purspose Excel SheetDocument329 pagesALL Purspose Excel SheetRajput PratiksinghNo ratings yet

- Sample13 DrawingDocument2 pagesSample13 DrawingSourav HaitNo ratings yet

- Example Vessel Re RatingDocument9 pagesExample Vessel Re RatingRBKUMARNo ratings yet

- Spherical Pressure VesselDocument4 pagesSpherical Pressure VesselalokbdasNo ratings yet

- ASME Pressure Vessel Joint EfficienciesDocument5 pagesASME Pressure Vessel Joint EfficienciesalokbdasNo ratings yet

- Vessel Pressure TestingDocument3 pagesVessel Pressure Testingalokbdas100% (1)

- Inspection and Test Plan For Pressure VesselDocument2 pagesInspection and Test Plan For Pressure Vesselalokbdas50% (2)

- Pressure Vessel CertificationDocument4 pagesPressure Vessel CertificationalokbdasNo ratings yet

- Pressure Vessel Dimension InspectionDocument12 pagesPressure Vessel Dimension Inspectionalokbdas100% (3)

- Pressure Vessel RT TestDocument4 pagesPressure Vessel RT TestalokbdasNo ratings yet

- Pressure VesselDocument16 pagesPressure VesselAzhar AliNo ratings yet

- Saddle AnalysisDocument17 pagesSaddle AnalysisAntonio Perez Zornoza100% (1)

- Pressure Vessel DefinitionDocument3 pagesPressure Vessel DefinitionalokbdasNo ratings yet

- Inspection and Test Plan For Shell and Tube Heat ExchangerDocument2 pagesInspection and Test Plan For Shell and Tube Heat Exchangeralokbdas100% (1)

- Inspection and Test Plan For Shell and Tube Heat ExchangerDocument6 pagesInspection and Test Plan For Shell and Tube Heat ExchangertomychalilNo ratings yet

- API 650 Tank Shell Evaluation Rev 3Document31 pagesAPI 650 Tank Shell Evaluation Rev 3alokbdasNo ratings yet

- Calculation Is Based On ASME Section VIII Division 2 Part 4 - 2011 EditionDocument1 pageCalculation Is Based On ASME Section VIII Division 2 Part 4 - 2011 EditionvpjagannaathNo ratings yet

- Heat Exchanger InspectionDocument11 pagesHeat Exchanger InspectionVivek Bhangale100% (1)

- Equipment Design (Week 5) : Dr. H.B. VuthaluruDocument146 pagesEquipment Design (Week 5) : Dr. H.B. Vuthalurualokbdas100% (2)

- Test Ring Calculation (Based On L&T Std. (6249-Lt-Eq-00-Od-0004 - Rev-1) )Document7 pagesTest Ring Calculation (Based On L&T Std. (6249-Lt-Eq-00-Od-0004 - Rev-1) )alokbdasNo ratings yet

- Dimensions of Welded and Seamless Pipe: Nominal Wall ThicknessDocument2 pagesDimensions of Welded and Seamless Pipe: Nominal Wall ThicknessalokbdasNo ratings yet

- Compressor Surge ControlDocument4 pagesCompressor Surge Controlerwan_exeNo ratings yet

- Week 3 - Automation of Steam TurbinesDocument18 pagesWeek 3 - Automation of Steam TurbinesJustin CaliguiaNo ratings yet

- 3-FAMCO Hydraulic System Open CircuitDocument59 pages3-FAMCO Hydraulic System Open CircuitSulyman KemalNo ratings yet

- SprinklersDocument16 pagesSprinklersAdel Suker100% (1)

- Vaillant MAG 1257-8 7.1 MAG 250-4007-8 MAG-sine 250-3257-8Document63 pagesVaillant MAG 1257-8 7.1 MAG 250-4007-8 MAG-sine 250-3257-8liquidus217233% (6)

- Checking and Maint. Schedule A90050-0295Document7 pagesChecking and Maint. Schedule A90050-0295Valeriy DomashenkoNo ratings yet

- B.O.Q Plumbing - Banquet KitchenDocument11 pagesB.O.Q Plumbing - Banquet KitchenparthivNo ratings yet

- Test Procedure of A10VSO28DFLR Macrospec Mac 18 2 PDFDocument1 pageTest Procedure of A10VSO28DFLR Macrospec Mac 18 2 PDFmohamadhakim.19789No ratings yet

- Pipeclass Summary Current RevDocument67 pagesPipeclass Summary Current Rev1985PolytechNo ratings yet

- Job Close Out Report - Oil Flushing - HorizonDocument7 pagesJob Close Out Report - Oil Flushing - HorizonFebilaNo ratings yet

- Progressive Cavity PumpDocument9 pagesProgressive Cavity PumpHasrul RezaNo ratings yet

- Operating and Maintenance Instructions For: Air Valve For Waste Water and Potable WaterDocument3 pagesOperating and Maintenance Instructions For: Air Valve For Waste Water and Potable WaterhoseyliauNo ratings yet

- R4V-R6V Uk-2Document9 pagesR4V-R6V Uk-2Zoran JankovNo ratings yet

- M5M BBDocument22 pagesM5M BBfauzi endraNo ratings yet

- Bit Hydraulics Theory PDFDocument23 pagesBit Hydraulics Theory PDFShakerMahmood100% (1)

- Air ConditionDocument15 pagesAir Conditionarch powerNo ratings yet

- Vacuum Deaerator Operation ManualDocument8 pagesVacuum Deaerator Operation ManualDony IPNo ratings yet

- Compressors: Isothermal - This Model Assumes That TheDocument12 pagesCompressors: Isothermal - This Model Assumes That TheRenneil De PabloNo ratings yet

- AE8404 Propulsion-I QBDocument9 pagesAE8404 Propulsion-I QBMoses DevaprasannaNo ratings yet

- New Kisan June 2021 All India ASTM PricelistDocument4 pagesNew Kisan June 2021 All India ASTM PricelistAmit AgrawalNo ratings yet

- A Filter Is A Screening or Straining Device Used To Clean The Hydraulic FluidDocument3 pagesA Filter Is A Screening or Straining Device Used To Clean The Hydraulic FluidDaniel CantilloNo ratings yet

- LSC Series: Open Drive Large Screw CompressorsDocument8 pagesLSC Series: Open Drive Large Screw CompressorsforuzzNo ratings yet

- P&id Boiler DrawingDocument22 pagesP&id Boiler Drawingmanh hung leNo ratings yet

- Tower A - Pump Head CalcDocument3 pagesTower A - Pump Head CalcceshesolNo ratings yet

- Schematic Symbols Chart (Design Hydraulic and Pneumatic Circits)Document6 pagesSchematic Symbols Chart (Design Hydraulic and Pneumatic Circits)Mahmoud AliNo ratings yet

- دوسة ديناميكا الغازات د.نجدت نشأتDocument73 pagesدوسة ديناميكا الغازات د.نجدت نشأتMSeaiasNo ratings yet

- Thermostatic Expansion Valve: Type TGEDocument28 pagesThermostatic Expansion Valve: Type TGEJorge Villanueva100% (1)

- Side Channel BlowersDocument6 pagesSide Channel Blowerspraveenreddy0027No ratings yet

- 9 Load ControlDocument25 pages9 Load ControlJose Manuel Barroso PantojaNo ratings yet

- User Instructions: Installation Operation Maintenance Serck Audco Pressure Balanced Plug ValveDocument16 pagesUser Instructions: Installation Operation Maintenance Serck Audco Pressure Balanced Plug ValveApoorv GoenkaNo ratings yet