Professional Documents

Culture Documents

BIA - Efflorescence Prevention and Control 2009-08

Uploaded by

RONALD MUELLEROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BIA - Efflorescence Prevention and Control 2009-08

Uploaded by

RONALD MUELLERCopyright:

Available Formats

Brick Brief

August 2009

www.gobrick.com | 1850 Centennial Park Drive, Reston, Virginia 20191 | 703-620-0010

Introduction

Efflorescence is a white, crystalline deposit on the

surface of concrete or clay masonry that is comprised of

water-soluble salts. Efflorescence begins when soluble

salts and other compounds are dissolved in water, which

becomes a salt solution. This salt solution migrates to

the surface of masonry through the masonry units or the

mortar. The water evaporates and leaves the salts on the

surface of the masonry as efflorescence.

Since efflorescence appears on the face of the brickwork,

it is often erroneously assumed to originate from the brick

itself. Fired clay brick is rarely the source of efflorescing

salts. Instead, it is much more common for efflorescence

to be caused by the transfer of soluble salt from cement-

based mortar, grout or concrete masonry that is in direct

contact with the clay brick used in the wall. This is known

because clay brick, unlike other building materials,

can be tested to determine its potential to contribute to

efflorescence. This test, found in ASTM C67, rates a

clay brick as non-effloresced when it does not exhibit

efflorescence after partial immersion in distilled water

for seven days. When similar testing is conducted on a

material containing cement, the material typically fails.

Non-efflorescing brick are readily available throughout the

United States.

Efflorescence that occurs on brickwork less than a

year old is often attributed to new building bloom, as

shown in Photo 1. In most cases, new building bloom

will dissipate over time if the brickwork is allowed to

dry after completion and if environmental factors such

as wind and rain are given sufficient time to naturally

clean the brickwork. Efflorescence that occurs a year

or more after construction is complete is generally

attributed to excessive water penetration or poor

drainage.

While more information on how to deal with efflorescence

can be found in Technical Note 23A, Efflorescence

Causes and Prevention, this Brick Brief furnishes

suggestions on how proper material selection, design and

detailing and construction practices can help minimize its

occurrence.

Material Selection

Architects and specifiers can refer to ASTM C1400,

Standard Guide for Reduction of Efflorescence Potential

in New Masonry Walls, which provides guidance to

reduce the possibility of efflorescence in new buildings.

More importantly, it should be kept in mind that all mortar,

grout and concrete masonry units contain cement with

varying degrees of water-soluble alkalis (water-soluble

compounds) usually the principal contributors to

efflorescence.

Cements high in alkaline content are more prone to

produce efflorescence than cements of lower alkaline

content. Consequently, low-alkali cement should be

specified when available to minimize the potential of

efflorescence and new building bloom as well.

Careful selection of other products can also help reduce

efflorescence potential. Specifying potable water and

clean, washed sand for mortar or grout is recommended.

It is also recommended to choose building trim, such as

caps, coping and sills, that are not made of materials that

contain soluble salts, which can increase efflorescence

potential over prolonged exposure to water washing over

its surface.

Design and Detailing

While rainwater can penetrate all masonry walls to some

degree, proper design can limit available moisture,

which in turn helps to suppress the development of

Photo 1: New Building Bloom. This type of

eforescence may begin before construction is completed.

EFFLORESCENCE PREVENTION AND CONTROL

www.gobrick.com | Brick Brief | Efflorescence Prevention and Control | Page 2

efflorescence. Design measures that help improve the

resistance of brickwork to efflorescence include the

following:

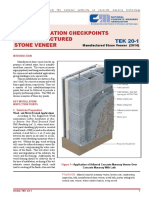

Ai r space. For more than 40 years, BIA has

recommended drainage walls that incorporate an air

space because they separate the exterior brickwork

from other elements in a wall assembly (see Figure 1).

The air space allows the water to drain down the back

of the brick wythe and prevents the migration of salts

from backing materials by isolating the brick wythe

from the materials containing soluble compounds.

The air space must be kept clean during construction

to allow drainage and to prevent water from bridging

the air space and transferring soluble salts from other

sources.

Flashing on trim. Trim materials are frequently used in

locations most vulnerable to water penetration, such as

caps, coping and sills under windows. These materials

also may contain salts that contribute to efflorescence.

To minimize efflorescence, buildings should include

flashing or other materials to act as a capillary break, as

well as a prevention of contact, between trim materials

and the brickwork. Since moisture may still wash over

trim material and collect water-soluble materials, the use

of low-alkali materials can minimize efflorescence even

more.

Waterproof below-grade masonry. Most groundwater

contains a high concentration of soluble salts, which can

accumulate in the masonry. To eliminate these salts as

sources of efflorescence, BIA recommends waterproofing

the masonry below grade and placing base flashing such

that it drains water out of the wall a few courses above

grade. Mortar or grout should be used to support the

base flashing below the air space, as shown in Figure 1.

Construction Practices

Several steps can be taken to reduce the amount of

water that accumulates in masonry materials during the

construction process, including the following:

Storage of materials. All masonry units should be

stored off the ground to avoid contact with rain or snow,

groundwater or contamination by dirt and plant life.

These materials should also be covered by a waterproof

membrane to keep them dry.

Water. Clean, potable water free of salts and other

materials should always be used.

Proper filling of mortar joints. Attention to both the

complete filling of mortar joints intended to receive mortar,

as well as keeping all cavities and air spaces clean and

free of mortar droppings, is absolutely critical.

Covering unfinished brickwork. Unfinished brickwork

should be covered with water-resistant membranes or

tarps held in place by weights or ropes at the end of

each workday. Otherwise, partially completed masonry

walls exposed to rain and other elements can become

saturated with water that can take weeks if not months

to dry after the completion of the building.

Sealant joints. J oints between masonry and door and

window frames, expansion joints and other locations

where sealants are required should be treated with

care since they are the most frequent sources of rain

penetration into masonry.

Moving Forward

While the above-mentioned measures are helpful

today, it should be noted the National Brick Research

Center (NBRC), headquartered at Clemson University,

has been developing a test method that consistently

evaluates materials that potentially contribute to

efflorescence by measuring soluble salts with ion

chromatography. Ultimately, a set of guidelines can

be used to select masonry materials, which will be

very significant in helping to curtail the potential for

efflorescence.

Brick Briefs are short discussions of a particular topic. The

information contained herein must be used with good technical

judgment. Final decisions on the use of this information must

rest with the project designer and owner. 2009 Brick Industry

Association.

Flashing

Water Exits

at Base Flashing

through Weep

Water Drains

Down Back

of Brickwork

Some Water

May Enter

Brickwork

Air Space

Mortar or Grout

to Support

Base Flashing

Figure 1: Drainage Wall Systems. BIA recommends the

use of drainage wall systems, as shown above. BIA does

not recommend the barrier strategy of lling a collar joint

between masonry wythes because it places a source of

salts in direct contact with the brickwork.

You might also like

- Water Proofing-Residential BuildingsDocument26 pagesWater Proofing-Residential BuildingsRichard WalkerNo ratings yet

- Damp Proofing: Presented by Ahsan Rabbani Civil Engineering DepartmentDocument27 pagesDamp Proofing: Presented by Ahsan Rabbani Civil Engineering DepartmentMichael Matshona100% (1)

- Informguide Brick PDFDocument8 pagesInformguide Brick PDFmoni_john_1No ratings yet

- Damp Proof Paper 101019Document13 pagesDamp Proof Paper 101019Tamilchelvam MurogayahNo ratings yet

- Building Consrucion: Submitted byDocument15 pagesBuilding Consrucion: Submitted byAmit BharatiNo ratings yet

- To Avoid Rot in The Floor - ABC NewsDocument2 pagesTo Avoid Rot in The Floor - ABC NewsturbobrikNo ratings yet

- Durability of ConcreteDocument74 pagesDurability of ConcreteSalman KhanNo ratings yet

- From ExperienceDocument3 pagesFrom ExperiencetcwlingleungNo ratings yet

- Bulding Construction (CE3G) - CracksDocument46 pagesBulding Construction (CE3G) - CracksLalitha Krishna MoorthyNo ratings yet

- Carbonation NBB Good ArticleDocument10 pagesCarbonation NBB Good ArticleDian PageNo ratings yet

- Failures in A BuildingDocument3 pagesFailures in A Buildingkhushi jainNo ratings yet

- Unit - V Approach To Repairs, Part - 1Document29 pagesUnit - V Approach To Repairs, Part - 1Imaad UddinNo ratings yet

- Curing Cement PlasterDocument3 pagesCuring Cement PlasterChristian LlagasNo ratings yet

- The Basics of Deteriorating Concrete at Wastwater Plants-Tips On Causes Repair and ResourcesDocument9 pagesThe Basics of Deteriorating Concrete at Wastwater Plants-Tips On Causes Repair and ResourcesPrakash100% (1)

- 2.2 Concrete FailureDocument64 pages2.2 Concrete Failuremuhammad harrisNo ratings yet

- Concrete Defects & DeteriorationDocument5 pagesConcrete Defects & DeteriorationhgfbNo ratings yet

- Sample Report: Building Survey OnDocument24 pagesSample Report: Building Survey OnDoraMariNo ratings yet

- Cracks in Public Buildings and Their RemediesDocument6 pagesCracks in Public Buildings and Their RemediesScholah NgeiNo ratings yet

- W.P.T. - Penetron ChemicalsDocument30 pagesW.P.T. - Penetron ChemicalsguptasonsonNo ratings yet

- Leaching L0333 AGG079 003 BREDocument45 pagesLeaching L0333 AGG079 003 BREjuli_radNo ratings yet

- WaterproofingDocument23 pagesWaterproofingtoncalderon100% (1)

- Chapter 5 MortarDocument6 pagesChapter 5 MortarSabrina AlyaNo ratings yet

- Customizing GRC DesignsDocument24 pagesCustomizing GRC DesignsSynaxis ReadymixNo ratings yet

- Damp Prevention in BuildingsDocument43 pagesDamp Prevention in Buildingswaterproofing_best100% (3)

- Water Proofing MethodsDocument18 pagesWater Proofing MethodsreetNo ratings yet

- DefectsDocument16 pagesDefectsSemNo ratings yet

- Defects Due To DampnessDocument7 pagesDefects Due To DampnessDevendra KumarNo ratings yet

- Causes and Prevention of Cracks in BuildingDocument35 pagesCauses and Prevention of Cracks in BuildingharNo ratings yet

- Cracks in BuildingsDocument21 pagesCracks in BuildingsCharan TejaNo ratings yet

- Building Defects Ali 03Document26 pagesBuilding Defects Ali 03Ali Azhar RajputNo ratings yet

- Common Defects in PlasterDocument2 pagesCommon Defects in PlasterRm1262No ratings yet

- Construction DefectDocument28 pagesConstruction Defectsonali100% (1)

- Characteristics of Concrete With Admixtures PDFDocument6 pagesCharacteristics of Concrete With Admixtures PDFTran Huynh NamNo ratings yet

- Defects in Buildings Construction - Structural & Non Structural Defects in ConstructionDocument5 pagesDefects in Buildings Construction - Structural & Non Structural Defects in ConstructionPrajakta RahateNo ratings yet

- URBAN DESIGN unit-IVDocument16 pagesURBAN DESIGN unit-IVmrunalini KolaNo ratings yet

- ABC Tile Adhesive Heavy DutyDocument1 pageABC Tile Adhesive Heavy DutyMark GoducoNo ratings yet

- Civil Engineering Cracks Types and CausesDocument8 pagesCivil Engineering Cracks Types and Causeskatia diaNo ratings yet

- Waterproofing Admixture PDFDocument2 pagesWaterproofing Admixture PDFSegun100% (1)

- Technical Note TN 38 Cracks in Concrete PDFDocument4 pagesTechnical Note TN 38 Cracks in Concrete PDFJohnNo ratings yet

- Repairing The Surface of Concrete 01102010Document6 pagesRepairing The Surface of Concrete 01102010dingwen1974No ratings yet

- Modern WaterproofingDocument17 pagesModern WaterproofingDileepa DissanayakeNo ratings yet

- Categorization of General Problems and Defects in Historical BuildingDocument10 pagesCategorization of General Problems and Defects in Historical BuildingRafiq FitriNo ratings yet

- Method Statement For Repaire External PaintingDocument1 pageMethod Statement For Repaire External PaintingYASIRNo ratings yet

- ARDEX Guide To Waterproofing Liquid Applied MembranesDocument88 pagesARDEX Guide To Waterproofing Liquid Applied MembranesMoataz MedhatNo ratings yet

- Types of CracksDocument3 pagesTypes of CracksShativel ViswanathanNo ratings yet

- Civil Engineering Drawing & Graphics (Theory) : 10/27/2014 Pepared by Engr Fazal-E-JalalDocument33 pagesCivil Engineering Drawing & Graphics (Theory) : 10/27/2014 Pepared by Engr Fazal-E-JalalKousalya MkNo ratings yet

- Understanding Dampness: About The AuthorsDocument10 pagesUnderstanding Dampness: About The AuthorsPANKAJ TAMBAKHE0% (1)

- Concrete SolutionDocument6 pagesConcrete SolutionMohamed KhanNo ratings yet

- AdmixtureDocument6 pagesAdmixtureDunvillNo ratings yet

- Formulation Techniques Using Feve Resins in Waterborne and HighDocument10 pagesFormulation Techniques Using Feve Resins in Waterborne and HighManuel ChireNo ratings yet

- Report - Building Defects Submitted by - Group 2 Submitted To - V.K. Bakde SirDocument7 pagesReport - Building Defects Submitted by - Group 2 Submitted To - V.K. Bakde SirVaishnavi SikchiNo ratings yet

- Deterioration of Concrete Materials: Prof. Ravindra Gettu and Dr. Radhakrishna G. PillaiDocument73 pagesDeterioration of Concrete Materials: Prof. Ravindra Gettu and Dr. Radhakrishna G. PillaiPiyush SinghNo ratings yet

- Concrete: Various Terms Used / Steps For Concreting Operation A) BatchingDocument5 pagesConcrete: Various Terms Used / Steps For Concreting Operation A) BatchingDARK KnightNo ratings yet

- Hydrated LimeDocument1 pageHydrated Limeavmurugan87100% (1)

- Types of AdmixturesDocument3 pagesTypes of AdmixturesvanamgouthamNo ratings yet

- Tiling Over Movement JointsDocument14 pagesTiling Over Movement JointspankajNo ratings yet

- BB Efflorescence Prevention and ControlDocument2 pagesBB Efflorescence Prevention and ControlIndra Jeet YadavNo ratings yet

- Advanced Concrete Durability (Assignment-02)Document3 pagesAdvanced Concrete Durability (Assignment-02)Suzon IkramNo ratings yet

- Construction Engineering: Start With The Name of Allah Who Is Most Rehman and RaheemDocument9 pagesConstruction Engineering: Start With The Name of Allah Who Is Most Rehman and RaheemUmair Masood Memon100% (2)

- CastStone - Vs - AdheredVeneer 2008-09-16 PDFDocument6 pagesCastStone - Vs - AdheredVeneer 2008-09-16 PDFRONALD MUELLERNo ratings yet

- Roofing and Waterproofing: Standard Terminology Relating ToDocument9 pagesRoofing and Waterproofing: Standard Terminology Relating ToRONALD MUELLERNo ratings yet

- D5361Document20 pagesD5361RONALD MUELLERNo ratings yet

- TEK 20-01 Key Installation Checkpoints For MSV 2014Document4 pagesTEK 20-01 Key Installation Checkpoints For MSV 2014RONALD MUELLERNo ratings yet

- DTX - 400 Drum Score Practice GroovesDocument12 pagesDTX - 400 Drum Score Practice GroovesRONALD MUELLERNo ratings yet

- Percussive Arts Society International Drum Rudiments PDFDocument2 pagesPercussive Arts Society International Drum Rudiments PDFgalaxi20No ratings yet

- Yamaha DD65 YDD60 Owner's ManualDocument59 pagesYamaha DD65 YDD60 Owner's ManualRONALD MUELLERNo ratings yet

- EM 1110-2-2002 Chapter 2-Evalution of Concrete 1995-06-30Document23 pagesEM 1110-2-2002 Chapter 2-Evalution of Concrete 1995-06-30RONALD MUELLERNo ratings yet

- Causes of Distress and Deterioration of Concrete, EM 1110-2-2002 1995-06-30Document14 pagesCauses of Distress and Deterioration of Concrete, EM 1110-2-2002 1995-06-30RONALD MUELLERNo ratings yet

- Wire Rope Rigging & Supply: RIGGERS' Forming VisesDocument2 pagesWire Rope Rigging & Supply: RIGGERS' Forming VisesVictor Manuel Garcia RamirezNo ratings yet

- JSEC 12.a-R LGDDocument208 pagesJSEC 12.a-R LGDTucsi2000No ratings yet

- Userguide PDFDocument164 pagesUserguide PDFajdCruiseNo ratings yet

- Swissotel KolkataDocument2 pagesSwissotel KolkataaddykoolNo ratings yet

- Passive Design in Tropical ClimatesDocument8 pagesPassive Design in Tropical ClimatesCham LedesmaNo ratings yet

- HSDPA Throughput Optimization Case StudyDocument18 pagesHSDPA Throughput Optimization Case StudySandeepNo ratings yet

- 10-Unit Commercial BuildingDocument5 pages10-Unit Commercial BuildingJeremy BuelbaNo ratings yet

- A Study of Selection of Structural SystemDocument9 pagesA Study of Selection of Structural SystemEmal Khan HandNo ratings yet

- Intro. 2 Command Line Interfaces: Data Link University CollegeDocument23 pagesIntro. 2 Command Line Interfaces: Data Link University CollegeSefakor AwuramaNo ratings yet

- Testing of Concrete Masonry: Laboratory Experiment NoDocument10 pagesTesting of Concrete Masonry: Laboratory Experiment NokeishasantiagoNo ratings yet

- CLOUD - Implementing Accounting Hub PDFDocument490 pagesCLOUD - Implementing Accounting Hub PDFDaniel KirubakarNo ratings yet

- App12 - ACI Meshed Slab and Wall DesignDocument51 pagesApp12 - ACI Meshed Slab and Wall DesignDario Manrique GamarraNo ratings yet

- AdventNet ME OpUtilsDocument180 pagesAdventNet ME OpUtilsSSRK CREATION100% (1)

- My Home and My FamilyDocument3 pagesMy Home and My Familyanitza22No ratings yet

- Qlikview 10 Accesspoint SSODocument21 pagesQlikview 10 Accesspoint SSOAlberto AlavezNo ratings yet

- Reference Guide: TMS320C6000 DSP External Memory Interface (EMIF)Document146 pagesReference Guide: TMS320C6000 DSP External Memory Interface (EMIF)Ahmed AyyubNo ratings yet

- Netvertex Use CasesDocument66 pagesNetvertex Use CasesAniket UmekarNo ratings yet

- EPIC Architecture ILPDocument81 pagesEPIC Architecture ILPrkritsada6805No ratings yet

- 21 Linear Slot DiffusrDocument20 pages21 Linear Slot Diffusrraphael vazhappillyNo ratings yet

- Floor Truss GuideDocument4 pagesFloor Truss GuideSamia H. BhuiyanNo ratings yet

- Thetford Marine Catalog North America 2021 Low Res PDFDocument84 pagesThetford Marine Catalog North America 2021 Low Res PDFJulio LemosNo ratings yet

- 1.1 General Overview of Surface StructuresDocument23 pages1.1 General Overview of Surface StructuresCivilEngClub100% (6)

- Vicidial Multi-Server Manual by Poundteam v1 1Document25 pagesVicidial Multi-Server Manual by Poundteam v1 1Elyin Martinez0% (1)

- Software Development ReportDocument28 pagesSoftware Development ReportPaul Oladimeji100% (1)

- RV School of Architecture Case StudyDocument10 pagesRV School of Architecture Case StudytejasNo ratings yet

- Kamakshi Amman Temple KanchipuramDocument6 pagesKamakshi Amman Temple KanchipuramKomalah Purusothman100% (1)

- Mitsubishi Lift Guide PDFDocument17 pagesMitsubishi Lift Guide PDFAri Dwi SetiawanNo ratings yet

- Sadlerstone Technical BulletinDocument21 pagesSadlerstone Technical BulletinParashuram ChauhanNo ratings yet

- RavenaDocument14 pagesRavenaLi_Sa4No ratings yet

- ReportDocument16 pagesReportJohn Louie GonzalesNo ratings yet