Professional Documents

Culture Documents

LM6 Aluminium

Uploaded by

RajaSekarsajjaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LM6 Aluminium

Uploaded by

RajaSekarsajjaCopyright:

Available Formats

LM6 Aluminium Casting Alloy

LM6

Aluminium Casting Alloy

(Al Sil2)

This alloy conforms to British Standards 1490 LM6

CHEMICAL COMPOSITION

%

Copper 0.1 max.

Manesi!m 0.10 max.

Silicon 10.0"1#.0

$ron 0.6 max.

Mananese 0.% max.

&ic'el 0.1 max.

(inc 0.1 max.

Lead 0.1 max.

Tin 0.0% max.

Titani!m 0.) max.

*l!mini!m +emainder

MECHANICAL PROPERTIES

SAND CAST CHILL CAST

0.)% ,roof Stress -&.mm

)

/0 6!" "!#

Tensile Stress -&.mm

)

/ 0 $6!$% $%!2&

1lonation -%/0 '!$ "!$'

$mpact +esistance. $2od -&m/ 6( %(

Brinell 3ardness &!m4er '!'' ''!6

1nd!rance Limit -% 5 106 cycles7 8 &.mm

)

/ '$ 6#

Mod!l!s 9f 1lasticity -5 10# &.mm

)

/ "$ "$

Shear Strenth &.mm

)

/ $2 !!!

0 The :al!es sho;n are typical ranes for sand and chill cast test 4ars prod!ced to the

re<!irements of B.S.1490 and for 6 mm diameter die cast 4ars7 those in hea:ier type are

minim!m specification :al!es.

STREN)TH AT ELE*ATED TEMPERAT+RES

Tensile strenth and hardness decrease fairly re!larly ;ith increasin temperat!re and 4ecome

relati:ely poor at temperat!res of the order of )%0 =C.

PH,SICAL PROPERTIES

Coefficient of Thermal 1xpansion -per =C at )0"100=C/ 0.0000)0

Thermal Cond!cti:ity -cal.cm

)

.cm.=C. at )%=C/ 0 0.#4

1lectrical Cond!cti:ity -% copper standard at )0=C 0 #6

Solidification Shrin'ae -approx. %/ #.6

Specific >ra:ity ).6%

?ree2in +ane -=C/ approx. %6%"%6%

0 *pplies to sand castins7 :al!es are approximate and ;ill :ary ;ith condition.

MACHINA-ILIT,

*lloys of this and similar compositions are rather diffic!lt to machine. This is d!e firstly to their

tendency to dra and secondly to the rapid tool ;ear ca!sed 4y the hih silicon content.

Car4ide tipped tools ;ith lare ra'e anles and relati:ely lo; c!ttin speeds i:e comparati:ely

ood res!lts. * c!ttin l!4ricant and coolant sho!ld 4e employed.

CORROSION RESISTANCE

LM6 exhi4its excellent resistance to corrosion !nder 4oth ordinary atmospheric and marine

conditions. ?or the se:erest conditions this property can 4e f!rther enhanced 4y anodic

treatment.

ANODISIN)

LM6 can 4e anodised 4y any of the common processes@ the res!ltin protecti:e film ranin in

colo!r from rey to dar' 4ro;n.

CASTIN) CHARACTERISTICS

.lui/ity

Can 4e cast into thinner and more intricate sections than any of the other types of castin alloys.

P01ssu01 Tig2tn1ss

1specially s!ita4le for lea' tiht castins.

Hot T1a0ing

Castins in sand or chill mo!lds exhi4it complete freedom for hot tearin.

Ty3i4al Pou0ing T1m310atu01

* typical temperat!re for sand and chill castins is 6)%=C 4!t in practice $t may rane

considera4ly a4o:e or 4elo; this :al!e accordin to the dimensions of the castin. ,o!rin

Temperat!res for die castins depend :ery larely on the partic!lar castin and the machine and

:ary too ;idely for a typical temperat!re to pro:ide !sef!l !idance. The melt sho!ld not@

ho;e:er@ 4e allo;ed to stand at temperat!res only a little a4o:e the free2in rane or the 4ottom

of the melt may 4ecome enriched in s!ch elements as iron and mananese.

Not1s ! ?or sand castins and medi!m and hea:y section chill castins the alloy m!st 4e

modified 4efore po!rin -4y treatment ;ith sodi!m or sodi!m salts . $f the maxim!m mechanical

properties are to 4e realised. *n alternati:e modifyin process is the treatment of the melt ;ith

stronti!m as an al!mini!m"silicon"stronti!m hardener. * more persistant state of modification is

achie:ed 4y this method.

HEAT TREATMENT

A!ctility can 4e impro:ed slihtly 4y heatin at )%0"#00=C@ 4!t apart from stress relie:in@ the

heat treatment of LM6 is of little ind!strial interest.

APPLICATION AND )ENERAL NOTES

S!ita4le for Marine Bon dec'B castins@ ;ater"cooled manifolds and Cac'ets@ motor car and road

transport fittins7 thin section and intricate castins s!ch as ho!sin@ meter cases and

s;itch4oxes7 for :ery lare castins@ e. cast doors and panels ;here ease of castin is essential7

for chemical and dye ind!stry castins@ e. p!mp parts7 for paint ind!stry and food and domestic

castins. The eneral !se ;here marine atmospheres or ser:ice conditions ma'e corrosion

resistance a matter of maCor importance. 1specially s!ita4le for castins that are to 4e ;elded.

The d!ctility of LM6 alloy ena4le castins easily to 4e rectified or e:en modified in shape@ e.

simple components may 4e cast straiht and later 4ent to the re<!ired conto!r.

1<!ally adapta4le for sand and permanent mo!ld castins.

The al!mini!m silicon alloys possess exceptional castin characteristics@ ;hich ena4le them to

4e !sed to prod!ce intricate castins of thic' and thin sections. ?l!idity and freedom from hot

tearin increase ;ith silicon content and are excellent thro!ho!t the rane. Their resistance to

corrosion is :ery ood@ 4!t special care is re<!ired in machinin. $n eneral@ the 4inary alloys are

not heat treated7 at ele:ated temperat!res their strenth falls rapidly. *ltho!h of medi!m

strenth their hardness and elastic limit are lo; 4!t they possess excellent d!ctility.

HADLEIGH CASTINGS LIMITED

Pond Hall Road

Hadleigh

Ipsi!h

Su""ol#

IP$ %P&

England

Tele' (( )*+ ,($- ./$/.,

0a1' (( )*+ ,($- ./$.$2

You might also like

- 24 Copper AlloysDocument29 pages24 Copper Alloysniceweather157No ratings yet

- Steel Casting Handbook Supplement 8 - High Alloy Data Sheets - Corrosion SeriesDocument93 pagesSteel Casting Handbook Supplement 8 - High Alloy Data Sheets - Corrosion SeriesjosemiguelzuNo ratings yet

- Cast Steel HandBookDocument93 pagesCast Steel HandBookAlexa Harper100% (1)

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Aluminum Foundry TechniqueDocument51 pagesAluminum Foundry Techniqueazadsingh1No ratings yet

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- SOMCHE-Low PH Underdeposit CorrosionDocument6 pagesSOMCHE-Low PH Underdeposit CorrosionpscheahNo ratings yet

- LM6 Alloy Detail PDFDocument4 pagesLM6 Alloy Detail PDFramashishNo ratings yet

- LM6 Alloy DetailDocument4 pagesLM6 Alloy DetaildsoNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Evaluation of Al-5Ti-1B and Al-10Sr in LM6 Sand CastingsDocument8 pagesEvaluation of Al-5Ti-1B and Al-10Sr in LM6 Sand CastingscrazynupNo ratings yet

- The Foseco Foundryman's Handbook: Facts, Figures and FormulaeFrom EverandThe Foseco Foundryman's Handbook: Facts, Figures and FormulaeT.A. BurnsRating: 3 out of 5 stars3/5 (2)

- Specification Sheet: Alloy 410: (UNS S41000) / W.Nr. 1.4006Document2 pagesSpecification Sheet: Alloy 410: (UNS S41000) / W.Nr. 1.4006Rahul KhoslaNo ratings yet

- Lead Smelting and Refining, With Some Notes on Lead MiningFrom EverandLead Smelting and Refining, With Some Notes on Lead MiningNo ratings yet

- High Temperature Crude Oil Corrosivity: Where Sulfur & Naphthenic Acid Chemistry & Metallurgy MeetDocument20 pagesHigh Temperature Crude Oil Corrosivity: Where Sulfur & Naphthenic Acid Chemistry & Metallurgy MeetsendelkrNo ratings yet

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenFrom EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenRating: 4 out of 5 stars4/5 (2)

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Anshuman RoyNo ratings yet

- Steel and Its Heat Treatment: Bofors HandbookFrom EverandSteel and Its Heat Treatment: Bofors HandbookRating: 2.5 out of 5 stars2.5/5 (3)

- Corrosion Resistance TableDocument20 pagesCorrosion Resistance TableThitipong Rukkhot100% (1)

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryFrom EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNo ratings yet

- LM4 Alloy DetailDocument5 pagesLM4 Alloy Detailcharles_boyle_3No ratings yet

- Blacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithFrom EverandBlacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithNo ratings yet

- Total X 8%: High-Alloy SteelsDocument19 pagesTotal X 8%: High-Alloy SteelsmohammedetaNo ratings yet

- Jurnal SMA (1) RajeshDocument6 pagesJurnal SMA (1) RajeshMuhammad Falqi YusufNo ratings yet

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- FEB09SSIDocument24 pagesFEB09SSILouHew100% (2)

- Carbide Roll MaterialDocument10 pagesCarbide Roll MaterialziadNo ratings yet

- Corrosion Resistance Table: Conversion FactorsDocument21 pagesCorrosion Resistance Table: Conversion FactorsMutiara PrimasterNo ratings yet

- 4 - 6 % Silicon Ductile IronsDocument2 pages4 - 6 % Silicon Ductile IronsmedoksNo ratings yet

- LM6 Aluminium Casting Alloyhb11Document4 pagesLM6 Aluminium Casting Alloyhb11Nader MohamedNo ratings yet

- Al en Ab 42000 DatasheetDocument2 pagesAl en Ab 42000 Datasheetc4pp3ll410_m4tt0No ratings yet

- Cu Ni FabricationDocument28 pagesCu Ni FabricationAli Varmazyar100% (1)

- Etching Specialty AlloysDocument6 pagesEtching Specialty AlloysNitin100% (1)

- LM29Document6 pagesLM29Thangapandian NNo ratings yet

- Sm13crs 95 enDocument6 pagesSm13crs 95 enhorstiillingNo ratings yet

- 904LDocument5 pages904LManish542No ratings yet

- 11-14%Cr IIW Document - Part 2 PDFDocument21 pages11-14%Cr IIW Document - Part 2 PDFManuel CarreñoNo ratings yet

- Mds SM13CRM 110 en PDFDocument6 pagesMds SM13CRM 110 en PDFPedroSoucasauxNo ratings yet

- Specification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Document2 pagesSpecification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Felipe A. Gutiérrez M.No ratings yet

- Shape Memory AlloysDocument14 pagesShape Memory AlloysRohith MenonNo ratings yet

- Chrome PlatingDocument11 pagesChrome PlatingMahesh Babu100% (1)

- Corrosion Guide - Stainless Internation NickelDocument20 pagesCorrosion Guide - Stainless Internation NickelJohn BurkeNo ratings yet

- Refractory For EAF-GuideDocument4 pagesRefractory For EAF-GuideJayasimha TammineniNo ratings yet

- 410 Spec SheetDocument2 pages410 Spec SheetThomasJolyNo ratings yet

- Maraging SteelsDocument14 pagesMaraging SteelsJoseph JoelNo ratings yet

- And To Milling: L 2090 2091 Aluminum IumDocument2 pagesAnd To Milling: L 2090 2091 Aluminum IumJOENo ratings yet

- Study of Microstructure of Steels at Different Cooling Rates and Further Check Hardness of The SamplesDocument43 pagesStudy of Microstructure of Steels at Different Cooling Rates and Further Check Hardness of The SamplesDeepu ChoudharyNo ratings yet

- Aluminium Casting Alloy (AL - Si12) : Home About Us Processes Design Quality Products Technical ContactDocument3 pagesAluminium Casting Alloy (AL - Si12) : Home About Us Processes Design Quality Products Technical Contactrafdinal.sNo ratings yet

- Columbus Stainless Pocket GuideDocument29 pagesColumbus Stainless Pocket Guidebruteforce2000No ratings yet

- Silica Ramming MassDocument17 pagesSilica Ramming Masssagar kashinath kodle100% (1)

- Soldering: / JoiningDocument5 pagesSoldering: / JoiningKasia MazurNo ratings yet

- All About SKV Welding: (A Complete Guide On AT Welding For P.Way Engineers / Officers)Document132 pagesAll About SKV Welding: (A Complete Guide On AT Welding For P.Way Engineers / Officers)radhakrishnangNo ratings yet

- Ferrous Alloys Stainless Steels.: U.P.Madangeri SO-E (NP) Piping SectionDocument33 pagesFerrous Alloys Stainless Steels.: U.P.Madangeri SO-E (NP) Piping Sectionramverma163999No ratings yet

- Cardona 2011Document15 pagesCardona 2011Macarena BlancoNo ratings yet

- Hydro Pneumatic DamperDocument6 pagesHydro Pneumatic DamperRajaSekarsajjaNo ratings yet

- Carbon It RidingDocument3 pagesCarbon It RidingRajaSekarsajjaNo ratings yet

- Nitro - CarburizingDocument9 pagesNitro - CarburizingRajaSekarsajjaNo ratings yet

- Heavy Vehicle Dynamics Comparison Between Leaf Spring HydropneumaticDocument7 pagesHeavy Vehicle Dynamics Comparison Between Leaf Spring HydropneumaticRajaSekarsajjaNo ratings yet

- Raw 4x4 BrochureDocument1 pageRaw 4x4 BrochureRajaSekarsajjaNo ratings yet

- Evaluation of Coating PerformanceDocument14 pagesEvaluation of Coating PerformanceRajaSekarsajjaNo ratings yet

- Disc Spring SheetDocument2 pagesDisc Spring SheetRajaSekarsajjaNo ratings yet

- 3-D Measurements On PistonsDocument4 pages3-D Measurements On PistonsRajaSekarsajjaNo ratings yet

- Leaf Spring CatalogueDocument1 pageLeaf Spring CatalogueRajaSekarsajjaNo ratings yet

- Tubular Piston RodsDocument1 pageTubular Piston RodsRajaSekarsajjaNo ratings yet

- PTFE Piston RingsDocument21 pagesPTFE Piston RingsRajaSekarsajjaNo ratings yet

- PTFE Piston RingsDocument21 pagesPTFE Piston RingsRajaSekarsajjaNo ratings yet

- Shock Absorber Performance Test Rig: Ubique SystemsDocument1 pageShock Absorber Performance Test Rig: Ubique SystemsRajaSekarsajjaNo ratings yet

- Damping Force at Zero Velocity ExplainedDocument6 pagesDamping Force at Zero Velocity ExplainedRajaSekarsajjaNo ratings yet

- Where The Graphs Come FromDocument7 pagesWhere The Graphs Come FromRajaSekarsajjaNo ratings yet

- Guide To Dyno GraphsDocument10 pagesGuide To Dyno GraphsRajaSekarsajjaNo ratings yet

- JRZ Suspension EngineeringDocument25 pagesJRZ Suspension EngineeringRajaSekarsajja100% (1)

- Automobile Industry in PPT Ankit KumarDocument60 pagesAutomobile Industry in PPT Ankit Kumarkumaripm33% (3)

- Cyclic WeatheringDocument8 pagesCyclic WeatheringRajaSekarsajjaNo ratings yet

- Supergas SpringsDocument2 pagesSupergas SpringsRajaSekarsajjaNo ratings yet

- Suspension Design Rajeev - MokashiDocument16 pagesSuspension Design Rajeev - MokashiJatin351100% (1)

- Mistakes in AuditDocument4 pagesMistakes in AuditRajaSekarsajjaNo ratings yet

- Safe T Ryders Newsletter - Nov 2011Document2 pagesSafe T Ryders Newsletter - Nov 2011Maribelle AlbaNo ratings yet

- 106 - 1piping Data HandbookDocument1 page106 - 1piping Data HandbookramchandNo ratings yet

- Method Statement - Structural ConcreteDocument7 pagesMethod Statement - Structural Concretearif_rubinNo ratings yet

- Heat Treatment of Gauge MaterialsDocument16 pagesHeat Treatment of Gauge MaterialsshdblikhnNo ratings yet

- Chapter 14Document2 pagesChapter 14Anam Shoaib0% (1)

- L1011 DirectLiftControlDocument7 pagesL1011 DirectLiftControlDarek CzarneckiNo ratings yet

- Project Final Report On Distribution Channel Vizag Steel PlantDocument100 pagesProject Final Report On Distribution Channel Vizag Steel PlantOm PrakashNo ratings yet

- Introduction To Supply Chain Management: Mcgraw-Hill/IrwinDocument60 pagesIntroduction To Supply Chain Management: Mcgraw-Hill/Irwintariq_jamil99No ratings yet

- Piping StopplerDocument3 pagesPiping Stoppleranusaan2007No ratings yet

- Pune PWD DSR 2016-17Document448 pagesPune PWD DSR 2016-17GaneshZombade96% (95)

- Cassiopeia AKTF5 - SMAT Tengku Ampuan JemaahDocument5 pagesCassiopeia AKTF5 - SMAT Tengku Ampuan JemaahLiey Azim IINo ratings yet

- Rice Trade Policy and Rice Tariffication LawDocument5 pagesRice Trade Policy and Rice Tariffication LawJan Marinel A. SerinoNo ratings yet

- Project Panorama Editable 091013Document80 pagesProject Panorama Editable 091013ganeshram2305No ratings yet

- 80 Marketing - QC-HSE Installtion Procedure Q-051-07-YMN Betara Rev ADocument9 pages80 Marketing - QC-HSE Installtion Procedure Q-051-07-YMN Betara Rev Agstketut100% (1)

- Advanced Full Range Engine (AFRE) Program Envisions Hybrid Propulsion System Paving The Way To Routine, Reusable Hypersonic FlightDocument3 pagesAdvanced Full Range Engine (AFRE) Program Envisions Hybrid Propulsion System Paving The Way To Routine, Reusable Hypersonic FlightStephen TrimbleNo ratings yet

- MivanDocument19 pagesMivanshamkumavatNo ratings yet

- AssignmentDocument4 pagesAssignmentAyush BhardwajNo ratings yet

- Stainless Steel Structure Design HandbookDocument20 pagesStainless Steel Structure Design Handbookgnino2No ratings yet

- Example GR Thessaloniki 20795 DB 2018-02-06 Filtered En-UsDocument10 pagesExample GR Thessaloniki 20795 DB 2018-02-06 Filtered En-UsChris AnokwuruNo ratings yet

- LombardDocument8 pagesLombardMehtabhavesh19No ratings yet

- Professional Qualification in Commercial Ship Marine Surveying Prospectus PDFDocument28 pagesProfessional Qualification in Commercial Ship Marine Surveying Prospectus PDFViliame D RoqicaNo ratings yet

- Sika MonoTop 610 PDS (CE)Document4 pagesSika MonoTop 610 PDS (CE)Virah Sammy ChandraNo ratings yet

- Milk Production Trend - Dairy Development - Outlook PDFDocument10 pagesMilk Production Trend - Dairy Development - Outlook PDFrubel_nsuNo ratings yet

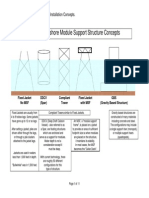

- 6.offshore ConceptsDocument0 pages6.offshore Conceptshaidar1992No ratings yet

- APH PresentationDocument36 pagesAPH PresentationBhargav Chaudhari100% (1)

- Series 2000 Specification SheetDocument2 pagesSeries 2000 Specification SheetWattsNo ratings yet

- Aircraft Fire CategoryDocument1 pageAircraft Fire CategoryRusshzel PauleNo ratings yet

- Metal-Cutting Saws: Unit 5Document44 pagesMetal-Cutting Saws: Unit 5Krunal GandhiNo ratings yet

- Legrand Cable Lighting & Data Trunking TechnicalDocument35 pagesLegrand Cable Lighting & Data Trunking TechnicalboltgingerkoppyNo ratings yet

- 3 (3) MSA - Drug and Device in S Korea - 20171Document34 pages3 (3) MSA - Drug and Device in S Korea - 20171seraNo ratings yet

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EFrom EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70ERating: 3 out of 5 stars3/5 (6)

- Fire Protection Engineering in Building DesignFrom EverandFire Protection Engineering in Building DesignRating: 4.5 out of 5 stars4.5/5 (5)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesFrom EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNo ratings yet

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Fundamentals of Risk Management for Process Industry EngineersFrom EverandFundamentals of Risk Management for Process Industry EngineersNo ratings yet

- Fire Fighting Pumping Systems at Industrial FacilitiesFrom EverandFire Fighting Pumping Systems at Industrial FacilitiesRating: 4.5 out of 5 stars4.5/5 (3)

- Culture, Health and Illness: An Introduction for Health ProfessionalsFrom EverandCulture, Health and Illness: An Introduction for Health ProfessionalsNo ratings yet

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- What Went Wrong?: Case Histories of Process Plant Disasters and How They Could Have Been AvoidedFrom EverandWhat Went Wrong?: Case Histories of Process Plant Disasters and How They Could Have Been AvoidedRating: 5 out of 5 stars5/5 (2)

- Healthy Buildings: How Indoor Spaces Drive Performance and ProductivityFrom EverandHealthy Buildings: How Indoor Spaces Drive Performance and ProductivityRating: 5 out of 5 stars5/5 (2)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Tensor Technology Guide: Tensor Ring Benefits and UsesFrom EverandTensor Technology Guide: Tensor Ring Benefits and UsesRating: 5 out of 5 stars5/5 (2)

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet