Professional Documents

Culture Documents

OHS Hazard Assessment Case Study

Uploaded by

ABCMARCH0%(3)0% found this document useful (3 votes)

713 views28 pagesASSESSMENT

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentASSESSMENT

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0%(3)0% found this document useful (3 votes)

713 views28 pagesOHS Hazard Assessment Case Study

Uploaded by

ABCMARCHASSESSMENT

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 28

Managing workplace hazards, and

consultation in the workplace

Aim

This unit of work aims to provide students with an understanding of:

o how to identify a workplace hazard

o how to assess the risk of the hazard occurring

o how to implement measures for controlling hazards

o the role and responsibilities of health and safety representatives and committees

o the importance of consultation in the workplace.

Outcomes

On completion of this unit of work, students will be able to:

o define what a hazard is and be able to identify a workplace hazard

o explain what risk management is and conduct a risk assessment activity

o understand the measures that can be implemented to control the risks in a

workplace

o explain the role and responsibilities of health and safety representatives and

OHS committees.

o understand the importance of consultation in the workplace

Unit outline

Topic Content Related Activities

Workplace hazards and risk

management

o What is a hazard?

o Hazard identification and

risk assessment

o Risk management

o Hazard control in the

workplace

o The working environment

o Activity 1: Identifying

hazards and risk

management

o Activity 3: Case studies

o Safety First or Expect

the Worst: Activities 10

and 11

The role and responsibilities

of health and safety

committees and

representatives

o Consultation in the

workplace

o The role of the health and

safety representative

o The role of the health and

safety committee

o Activity 2: The OHS Act

2000 (Worksheet 1, 2)

UNIT

2

Unit 2: Managing workplace hazards, and consultation in the workplace Page 2 of 28

What is a hazard?

The Occupational Health and Safety Regulation 2001 defines a hazard as anything

(including work practices or procedures) that has the potential to harm the health or safety

of a person.

Hazards can be grouped into five broad areas:

o physical eg. noise, radiation, light, vibration

o chemical eg. poisons, dusts

o biological eg. viruses, plants, parasites

o mechanical/electrical eg. slips, trips and falls, tools, electrical equipment

o psychological eg. fatigue, violence, bullying.

Hazards can arise from:

o the work environment

o the use of machinery and substances

o poor work design

o inappropriate systems and procedures

Examples of workplace hazards include:

o manual handling e.g pushing, pulling, carrying, lifting

o work environment e.g. floor surfaces, noise, temperature

o machinery

o heat e.g. burns and scalds

o electricity e.g. electrocution

o harassment e.g. bullying and/or violence

o hazardous substances e.g. chemicals, fumes

o biological waste

o skin penetrating injuries e.g. knife or syringe injuries

o noise

o confined space

Recognising the hazards in a workplace and taking steps to eliminate or control the hazard

ensures the safety and well being of all employees. It is easier and more effective to

eliminate or control the hazard before serious injuries result.

The Occupational Health and Safety Regulation 2001 states that an employer must

eliminate any reasonably foreseeable risk to the health and safety of employees and

others in the workplace and if this is not practicable must control the risk.

Hazards can be dealt with by:

o eliminating the hazard

o changing the equipment or materials

o changing work methods

o using personal protection equipment (PPE) (as a last resort)

(Source: WorkCover, NSW)

Unit 2: Managing workplace hazards, and consultation in the workplace Page 3 of 28

Hazard identification and risk assessment

There are a number of ways hazards can be identified in the workplace. These include:

o workplace inspections

o consultation between employees and employers

o monitoring injury and illness records

o health and environment monitoring

o recording complaints

o observation

Once a hazard has been identified, you can then assess how dangerous it is by asking:

o How likely is it that the hazard may cause an injury or illness to someone?

o How severe will the injury or illness be?

The answers to these questions will help in assessing, controlling or eliminating the

hazard. The level of risk will determine the priority assigned to its elimination or control.

Risk is the probability that harm might come to a person. It is a measure of how likely an

injury or illness is when a hazard exists.

Risk assessment is the process used to determine the likelihood that people may be

exposed to injury, illness or disease in the workplace arising from any situation identified

during the hazard identification process.

How likely is it to happen?

o It could happen any time - very likely

o It could happen sometime - likely

o It could happen but very rarely unlikely

o It could happen but probably never happen very unlikely

How bad is it likely to be?

o Kill or cause permanent injury

o Cause long term illness or serious injury

o Cause someone to need medical attention

o Cause someone to need first aid

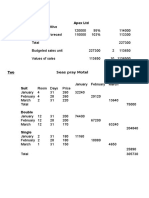

WorkCover provides a Risk Assessment Matrix to assist in the assessment of hazards in

the workplace. (Over page)

Hazards can be rated on a scale of 1 to 6 using the risk assessment matrix.

o 1 is high risk

o 6 is low risk

Once a hazard has been identified and the risk assessed, suitable control measures

should be put in place to eliminate the risk to employees health and safety.

(Source: Hazpak: Making Your Workplace Safer, WorkCover NSW)

Unit 2: Managing workplace hazards, and consultation in the workplace Page 4 of 28

The risk assessment matrix

1. How severely

could it hurt

someone?

OR

How ill could

it make

someone?

2. How likely is it to be that bad?

++

Very likely

Could happen

any time

+

Likely

Could happen

some time

-

Unlikely

Could happen,

but very rarely

- -

Very unlikely

Could happen,

but probably

never will

!!!! Kill or cause

permanent

disability or

ill health

1 1

2

3

!!! Long term

illness or

serious

injury

1

2

3 4

!! Medical

attention

and several

days off

work

2

3 4 5

! First aid

needed

3

4 5

6

(Source: Hazpak: Making Your Workplace Safer, WorkCover NSW )

Unit 2: Managing workplace hazards, and consultation in the workplace Page 5 of 28

What is risk management?

Risk management is introduced to control workplace hazards and

so reduce the risk of an injury or illness occurring. Employers need

to develop a risk management policy so risks in the workplace can

be controlled or eliminated.

Risk management involves:

o Identifying the hazard

Know what the dangers are in the workplace.

Keep records of accidents and injuries, conduct

safety inspections of the workplace and list all plant and hazardous

substances.

o Assessing the risk

Determine what the risk is that someone may be injured. Assess how

likely it is that a hazardous event will occur and what the consequences

are likely to be.

o Controlling the risk

Implement measures to prevent injury or illness. First try to eliminate the

risk. If this is not possible, the risk should be minimised using substitution,

modifications, isolation or engineering controls. Back-up controls such as

personal protective equipment should only be used as a last resort.

o Monitoring and improving the workplace

Control measures should be reviewed to maintain their effectiveness and

further refine the process.

If elimination of the hazard is not possible, then the risk still exists and should be

minimised by using the most effective method, using the following, in order:

o substituting the system of work or machinery with

something safer

o isolating the hazard

o minimising the risk by introducing engineering

controls eg. guard rail, scaffolding

o minimising the risk by adopting administrative

controls eg. warning signs, safe work practices, job

rotation, training

o using personal protective equipment eg. safety glasses, ear muffs.

If no single control is sufficient, a combination of the above controls needs to be put in

place to minimise the risk to the lowest level that is reasonably practical.

The measures at the fourth and fifth levels are less effective, and require more frequent

reviews of the hazards and systems of work.

(Source: Risk Management at Work: Guide 2001, WorkCover NSW)

Unit 2: Managing workplace hazards, and consultation in the workplace Page 6 of 28

Hazard control in the workplace

Hierarchy of hazard controls

To ensure a safe workplace, hazards must be controlled using a range

of methods.

The hierarchy of hazard controls is a list, in order of preference, which

can be considered in hazard control. It emphasises controlling a hazard

at the source. This is done by giving preference to the use of the

'engineering controls' as listed below.

Where possible, the ideas listed below should be used because they

are less likely to be affected by human failure and because they are less disruptive and

uncomfortable for people working in the area. Whichever method is used, the

effectiveness of the control measure used should be monitored regularly.

Engineering Controls

o Design. Try to ensure that hazards are 'designed out' when new materials, equipment

and work systems are being planned for the workplace.

o Remove the hazard or Substitute less hazardous materials, equipment or substances.

o Adopt a safer process. Alterations to tools, equipment or work systems can often

make them much safer.

o Enclose or isolate the hazard through the use of guards or remote handling

techniques.

o Provide effective ventilation through local or general exhaust ventilation systems.

Administrative Controls

o Establish appropriate Administrative Procedures such as:

job rotation to reduce exposure or boredom, or timing the

job so that fewer workers are exposed

routine maintenance and housekeeping procedures

training on hazards and correct work procedures.

Personal Protective Equipment

o Provide suitable and properly maintained Personal Protective Equipment (PPE) and

training in its use.

(Source: http://www.workcover.nsw.gov.au/Publications/OHS/Hazards/hazardhierarchy.htm)

Unit 2: Managing workplace hazards, and consultation in the workplace Page 7 of 28

Examples of common hazards

The table below shows examples of typical problems created by workplace hazards and

some injuries and illnesses that can result. Individual workplaces may have hazards other

than those listed below.

HAZARD TYPICAL PROBLEMS

TYPICAL INJURY/ILLNESS

REQUIRING FIRST AID

Manual handling Overexertion/Repetitive

movement

Sprains, strains, fractures

Falls

Falls from heights, slips and

trips on uneven surfaces

Fractures, bruises, cuts,

dislocations, concussion

Electricity Contact with electrical

current

Shock, burns, loss of

consciousness, cardiac

arrest

Plant Being hit by projectiles,

striking objects, being

caught in machinery,

overturning vehicles

Cuts, bruises, dislocations,

fractures, amputation, eye

damage

Hazardous substances Exposure to chemicals, e.g.

solvents, acids,

hydrocarbons

Dizziness, vomiting,

dermatitis, respiratory

problems, burns to skin or

eyes

Temperature, UV radiation Effects of heat or cold from

weather or work

environment

Sunburn, frostbite, heat

stress, heat stroke,

hypothermia

Biological Allergens, needle stick,

exposure to infectious

agents

Severe allergic reaction,

injuries, skin rash, infection

Occupational violence Intimidation, conflict,

physical assault

Nausea, shock, collapse,

physical injuries

(Source: First Aid in the Workplace: Guide 2001, WorkCover, NSW)

Unit 2: Managing workplace hazards, and consultation in the workplace Page 8 of 28

The working environment

Employers also have obligations in relation to the working environment. The requirements

relate to:

o Working space

provide sufficient working space to allow people to work safely

ensure that floors and surfaces are constructed and maintained to minimise the

possibility of slips, trips and falls

ensure that people are able to move about a place of work safely and

unhindered.

o Lighting

provide adequate lighting to allow workers to work safely, move safely, and

enter and exit the workplace safely (including from emergency exits)

ensure that there is not excessive glare or reflection

ensure that lighting allows persons who are not workers to move safely within

the place of work.

o Hot and cold working environments

provide adequate ventilation and air movement in indoor environments that may

become hot

provide adequate access to heated or sheltered areas and warm clothing or

other personal protective equipment if employees are exposed to cold

provide appropriate work and rest regimes relative to physical fitness, general

health, medication taken and body weight appropriate for both hot and cold

working environments.

o Noise management

not allow exposure to noise levels that exceed an eight-hour noise equivalent of

85 dB(A) or peak at more than 140 dB(C).

o Other obligations

fire prevention, electricity, confined spaces, manual handling, atmosphere

ventilation, working at heights.

(Source: WorkCover, NSW)

Unit 2: Managing workplace hazards, and consultation in the workplace Page 9 of 28

Consultation with workers in workplace health and safety

Consultation is defined in the Occupational Health and Safety Act 2000 as the sharing of

relevant information on occupational health and safety where employees are given the

opportunity to express their views and contribute in a timely fashion to resolution of

occupational health and safety issues (Sec 14).

Consultation means that employees views are valued and taken into account by the

business. Consultation needs to be a two-way communication that allows for employees to

contribute to the decision-making which affects their health, safety and welfare.

Consultation is not the same as negotiation.

Employers must consult with their employees in the following situations:

o when determining how the consultation process will take place

o in the assessment of risks and the review of risk assessments previously conducted

o when making decisions on the control of OHS risks in the workplace

o during the introduction or change of procedures used for monitoring risks, for

example health surveillance

o when making decisions about the

adequacy of welfare facilities

o when proposed changes are made to

premises, work methods, plant or

substances which may affect the

health, safety or welfare of employees

at work

o when making decisions about consultation procedures

o as prescribed by the Regulations from time to time.

Training

Under the OHS Regulation 2001, employers are required to provide specified induction

training to each new employee (Clause 13(1)) as well as ensure that any person who may

be exposed to a risk to health and safety at the workplace is

informed of the risk, and is provided with any information,

instruction and training necessary to ensure their health and

safety (Clause 13(2)).

Work experience and work placement students should receive

information and any training necessary from the host employer

to ensure their safety.

The employer must also provide persons in its organisation who have training and

information responsibilities with all available information necessary to enable them to fulfil

those responsibilities (Clause 13(3)).

Unit 2: Managing workplace hazards, and consultation in the workplace Page 10 of 28

Types of consultation arrangements

The OHS Act 2000 requires employers to adopt an OHS consultation arrangement to

assist with meeting their duty to consult. The OHS Act provides three options:

o an OHS Committee comprised of employer and employee representatives

o OHS Representatives elected by employees

o other Agreed Arrangements agreed to between the employer and their employees

Through consultation, employers can become more aware of hazards and OHS issues

experienced by employees. Employees can provide suggestions about how to solve health

and safety problems.

Employee participation enables the employee to contribute to determining how the work

can be undertaken safely.

Training must be provided to committee members or representatives, and records of

training must be kept for three years after the end of their employment.

Regardless of the type of consultation arrangement introduced in an organisation, it must

be agreed upon by both the employees and management.

Occupational health and safety committees

An OHS Committee can be formed where:

o there are 20 or more employees and the

majority request it

o a WorkCover inspector directs it

o where the business decides it would be

useful to have one.

The Committee membership must contain a

balance of employers and employees and the

number of employers must not exceed the number

of employees.

The term for a committee is two years.

Occupational health and safety representatives

OHS Representative/s could be useful for small businesses, or where there are several

work locations, and can be formed when:

o at least one employee requests it

o WorkCover directs it

o the business believes it would be appropriate

A representatives term is for two years.

Unit 2: Managing workplace hazards, and consultation in the workplace Page 11 of 28

OHS committees and representatives have the following responsibilities:

1. Keep under review the measures taken to ensure the health, safety and welfare of

persons at the place of work

2. Investigate any matter that poses a risk

3. Attempt to resolve a matter

4. Request an investigation by an inspector

5. Consult with a WorkCover inspector and accompany them on an inspection if

required

In addition to the functions set out in the OHS Act, the OHS Regulation provides that

OHS Representatives have the following functions:

o To assist in the development of arrangements for

recording hazards and accidents to promote improved

health and safety

o To make recommendations on their training needs as

an OHS Representative

o To make recommendations on the OHS training of

employees

(Source: OHS Consultation: Code of Practice 2001 - WorkCover, Occupational Health

and Safety Act 2000, Occupational Health and Safety Regulation 2001)

Unit 2: Managing workplace hazards, and consultation in the workplace Page 12 of 28

Young workers guide to a safe work place OHT

Tips for young workers

o Take responsibility for your own safety

o Keep yourself and others safe

o Listen to advice, instruction and act on it

o Know what to look for when entering a new or

different workplace

o Know what questions to ask about the job

o No fooling around you are not immortal!

ASK your supervisor

o What are the dangers of my job?

o What are the hazards?

o Should I have any job safety training?

o Do I need any personal protective equipment?

o What training is needed on how to use my PPE?

o Where are the first aid facilities?

o Who is the first aid person?

o What do I do if I get injured?

o Where are the fire extinguishers?

o Where are the emergency exits?

o How will I know if there is an emergency?

o What should I do in an emergency?

o Who do I go to in the workplace if I have a health or

safety question?

Unit 2: Managing workplace hazards, and consultation in the workplace Page 13 of 28

Managing workplace hazards

Student Activity 1: Identifying hazards and risk management

Answer the following questions.

1) List 3 hazards that you may find in each of the following workplaces:

a) Office

b) Hotel

c) Factory

d) Farm

e) Building site

2) List injuries that may result from each of the following hazards:

a) Manual handling

b) Noise

c) Hazardous substances

3) Complete the attached worksheet on hazards in your school.

Unit 2: Managing workplace hazards, and consultation in the workplace Page 14 of 28

Hazards, Risks and Controls Worksheet

Complete the following worksheet using your school as an example.

List hazards you have observed in different areas of the school.

Describe the risks associated with each hazard.

Suggest ways that the risks associated with the hazard may be controlled.

Places to observe may include computer rooms, the kitchens, industrial arts rooms, the library, the front office, classrooms, the

playground

Hazard (problem)

anything that can lead to someone

developing an illness or being injured

Risk (harm)

the potential to cause harm to people or

property

Controls (solution)

Eliminate, change the equipment or

materials, change work methods, use

personal protection

Example: Manual Handling

Muscle strain

Back injuries

Change work practice to ensure correct

procedures are followed.

Unit 2: Managing workplace hazards, and consultation in the workplace Page 15 of 28

Consultation in the workplace

Student Activity 2: The Occupational Health and Safety Act 2000 -

Worksheet 1

Go to the website: http://www.austlii.edu.au/au/legis/nsw/consol_act/ohasa2000273/

Click on Item 13 Duty of employer to consult in Part 2 - Duties Relating To Health, Safety

And Welfare At Work, Division 2 Duty to consult.

Section 13 deals with the requirement for the employer to consult or discuss with employees

any issues related to health and safety, allowing employees the chance to contribute to any

decisions that are made on health, safety and welfare.

Read the information and answer the following:

1. Why must an employer consult with or discuss health and safety issues with

employees?

2. What are the maximum penalties for those employers who fail to consult with

employees?

3. How does an employer consult with employees on health and safety issues? (Note:

You will need to refer to Item 16 to help you answer this).

Unit 2: Managing workplace hazards, and consultation in the workplace Page 16 of 28

The Occupational Health and Safety Act 2000 - Worksheet 2

Go to the website: http://www.austlii.edu.au/au/legis/nsw/consol_act/ohasa2000273/

Click on Item 18 - Functions of OHS committees and OHS representatives in Part 2 - Duties

Relating To Health, Safety And Welfare At Work, Division 2 Duty to consult.

Occupational Health and Safety Committee.

If an employer employs twenty or more people and the majority of employees request the

establishment of a Occupational Health and Safety Committee then a committee must be

established.

Occupational Health and Safety Representatives

An Occupational Health and Safety Representative must be elected for the purpose of

consultation if at least one employee makes this request.

Read through the details on this web page and list the three main functions of Occupational

Health and Safety Committees.

Unit 2: Managing workplace hazards, and consultation in the workplace Page 17 of 28

Case Studies workplace hazards

Student Activity 3

Read the case studies provided and answer the questions that follow each case study.

Case Study 1: Demolition company fined $75,000 following accident

The lack of clear instructions and proper supervision in the dangerous business of demolition

lay at the core of a breach of the Occupational Health and Safety Act that resulted in a

$75,000 fine being imposed on Delta Pty Ltd in the Industrial Relations Commission.

This conclusion by Justice Boland in the case that led to two workers sustaining serious

injuries after a building collapsed sent a clear safety message to all demolition operators, the

Acting General Manager of WorkCover NSW said today.

In 1997 the defendant was contracted to demolish a number of buildings on the Fox Studio

premises in Sydney.

On 30 May one of the buildings was being demolished in a method known as controlled

collapse.

Two employees of the defendant were on a scissor lift cutting timber purlins inside the building

when the structure collapsed, toppling the lift.

One worker sustained a compound fracture to one arm, injuries to the liver, fractured ribs and

a fractured pelvis.

The other employee suffered a fractured pelvis, loss of several teeth, and injuries to his

tendon, cheek and mouth.

The court heard that hinge cuts and rust in several of the buildings steel supports had

weakened the structure and contributed to its collapse.

Justice Boland said that the absence of the demolition supervisor as approved by the

defendants state manager, and his replacement with someone who was not experienced

enough for such a dangerous operation, was a serious error of judgement in respect of the

defendants responsibilities under the Occupational Health and Safety Act.

(Source: WorkCover Authority of NSW)

Unit 2: Managing workplace hazards, and consultation in the workplace Page 18 of 28

Case Study 1 Questions

1. How many employees were injured in the accident?

2. Identify the hazard in the article above.

3. List the factors that contributed to the accident.

4. List some control measures that could have been used to prevent the accident.

5. Why was the employer held responsible for the accident?

Unit 2: Managing workplace hazards, and consultation in the workplace Page 19 of 28

Case Study 2: WorkCover protects young employees 12 January 2001

WorkCover NSW today launched a $1.7million public education campaign targeted specifically

at the health and safety of young workers. "Young people are particularly vulnerable to

workplace injury because of their inexperience," said the Chairperson of the Board of

WorkCover, the Hon Joe Riordan, AO.

Mr. Riordan launched the campaign at the Newcastle Workers Club accompanied by local

Paralympian Heath Francis, who is sponsored by WorkCover. Heath was injured in a

workplace accident at the age of seven.

"Employers must be aware of their legal obligation to provide a safe workplace for all their

employees, but we are reminding them to pay special attention to the needs of young

workers," said Mr. Riordan.

"Over 8,400 workers under the age of 25 were injured at their place of employment in New

South Wales in the 1998/99 period," he said.

"In this same period, nine young workers were tragically killed at work, in accidents that could

have been prevented.

"Some of these people were on their first day at work.

"Its simply unacceptable," Mr. Riordan said.

The public education campaign, consisting of television and radio commercials, has been

designed to graphically illustrate that there is no substitute for proper training and supervision

to ensure safety in the workplace.

"From the very first day a young person begins a job, they must be trained to do that job with

safety as the prime consideration," Mr. Riordan said.

"The Occupational Health and Safety Act provides penalties of up to $875,000 for employers

who fail to maintain a safe working environment.

"Too often we see employers taking steps to operate safely after an accident occurs.

"The State Government and WorkCover are committed to ensuring this changes. Education is

one of the most powerful forms of intervention in the area of work safety," Mr. Riordan said.

As well as the television and radio campaign, WorkCover NSW has already distributed free to

all high schools and TAFE colleges, multi-media kits informing young people of occupational

health and safety issues before they start work.

"Our young people deserve no less than to work in a culture of safety," Mr. Riordan said.

(Source: WorkCover Authority of NSW 2000)

Unit 2: Managing workplace hazards, and consultation in the workplace Page 20 of 28

Case Study 2 Questions

1. Why are young people vulnerable to workplace injuries?

2. What must an employer provide to young workers?

3. How many young workers were injured in NSW in the period 1998/1999?

4. How many young people were killed in the same period?

5. What does the education campaign launched by WorkCover NSW consist of?

6. What penalty applies to employers who fail to provide a safe workplace?

Unit 2: Managing workplace hazards, and consultation in the workplace Page 21 of 28

Laws that protect workplace health and safety

Student Activity 4: Roles and Responsibilities in the Workplace

Outcomes: Students will be able to:

o demonstrate an awareness that each section of the workplace has

legal responsibilities in regard to Occupational Health and Safety

o recognise and distinguish between the duties and responsibilities of

the employer

the employee

the OHS committee and OHS representative

the WorkCover inspector

Resources:

o Overhead transparencies:

Instructions to students

Suggested answers

o Activity cards set of 40 cards with each card having a role or responsibility of one of

the various groups. One set for each group. Teachers will need to prepare these cards.

A master card sheet is supplied for photocopying.

o 4 boards one for each group:

employer

employee

health and safety representative

WorkCover inspector

Activity Outline:

o Divide the class into groups of 3 or 4.

o Each group should have a set of 40 cards and a set of 4 boards with headings of

employer, employee, heath and safety representative, WorkCover inspector.

o Students in each group are to discuss the role or responsibility printed on each card.

Students decide which group has the responsibility printed on the card.

o Students place the card on the board that matches the responsibility with the workplace

group responsible.

Unit 2: Managing workplace hazards, and consultation in the workplace Page 22 of 28

You are to work in groups of 3 to 4.

Make sure you have a set of 40 cards and a set of 4 boards.

Take each card and discuss with the other members in your

group who you think has responsibility for that role, i.e is it the

employer, the employee, the health and safety representative

or the WorkCover inspector?

Place the card on the appropriate board so that the

role/responsibility matches the workplace group responsible.

Questions for you to answer:

1. What do you notice about the number of cards on each

board?

2. Who has the greater number of responsibilities in

occupational health and safety issues?

3. What are the three most important factors you have learned,

about your role and responsibility in the workplace?

ACTIVITY 4

INSTRUCTIONS TO STUDENTS

Unit 2: Managing workplace hazards, and consultation in the workplace Page 23 of 28

Card set roles and responsibilities

Provide a safe

working

environment

Investigate any

matter that may

be a risk

Provide

supervision so

employees can

work safely

Tidy or remove

any tripping

hazards in your

workplace.

Provide and

maintain safe

plant (machinery,

equipment)

Attempt to

resolve any

workplace safety

issues.

Establish a health

and safety

committee

Must not prevent

aid to an injured

worker

Identify, access

and eliminate

risks

Investigate any

suspected breach

of OHS

legislation

Provide first aid

facilities

Provide amenities

(drinking

water,

washrooms etc)

Provide

information on

workplace

hazards

Carry out medical

examinations with

the

employees

consent

Provide protective

equipment and

clothing

Regulate the

speed and

frequency of work

Take care of the

health and safety

of yourself and

others

Restrict access to

or dismantle

things on the

premises

Provide guards

on dangerous

machines

Ensure a safe

system of work

Talk to employer

about health or

safety hazards

Require any

person to answer

questions

Provide storage

areas for

equipment

Request a

Workcover

Inspector

investigation

Co-operate with

employer on

safety and health

matters

Provide clean and

tidy work areas

Use equipment

for its intended

use

Accompany a

Workcover

Inspector during

an inspection

Report any

incident, accident

or near miss

Provide

ventilation

systems for dust

removal

Correctly use

protective

equipment/

clothing

Accompany an

employee, if

requested, during

an interview on

an OHS matter

Be paid time to

attend OH&S

courses approved

by WorkCover

Provide

appropriate

training and

instruction

Read safety

information and

follow safety rules

Be consulted

about any

proposed

changes to the

workplace

Provide

information and

training on

chemicals

Take care to use

equipment safely

Unit 2: Managing workplace hazards, and consultation in the workplace Page 24 of 28

What is a hazard? OHT

o Anything (including work practices or

procedures) that has the potential to harm the

health or safety of a person.

Types of hazards:

o physical eg. noise, radiation, light, vibration

o chemical eg. poisons, dusts

o biological eg. viruses, plants, parasites

o mechanical/electrical eg. slips, trips and falls,

tools, electrical equipment

o psychological eg. fatigue, violence, bullying

Hazards can arise from:

o the work environment

o the use of machinery and substances

o poor work design

o inappropriate systems and procedures

Control hazards by:

o Workplace inspections

o Consultation

o Monitoring injury and illness records

o Recording complaints

o Observation

Dealing with hazards:

o Eliminate the hazard

o Change the equipment or materials

o Change work methods

o Use personal protection equipment (PPE)

Unit 2: Managing workplace hazards, and consultation in the workplace Page 25 of 28

Risk management OHT

o Identify the hazard

Know what the dangers are in the workplace.

Keep records of accidents and injuries,

conduct safety inspections of the workplace

and list all plant and hazardous substances.

o Assess the risk

Determine what the risk is that someone may

be injured. Assess how likely it is that a

hazardous event will occur and what the

consequences are likely to be.

o Control the risk

Implement measures to prevent injury or

illness. First try to eliminate the risk. If this is

not possible, the risk should be minimised

using substitution, modifications, isolation or

engineering controls. Back-up controls such

as personal protective equipment should only

be used as a last resort.

o Monitor and improve the workplace

Control measures should be reviewed to

maintain their effectiveness and further refine

the process.

Unit 2: Managing workplace hazards, and consultation in the workplace Page 26 of 28

Hierarchy of Control OHT

If eliminating a hazard is not possible, then:

o Substitute

o Isolate

o Minimise Engineering

o Minimise Administrative

o PPE

Unit 2: Managing workplace hazards, and consultation in the workplace Page 27 of 28

Roles and Responsibilities OHT

WORKCOVER INSPECTORS

Investigate any suspected breach of the

occupational health and safety legislation.

OCCUPATIONAL HEALTH AND SAFETY

COMMITTEES AND REPRESENTATIVES

o Keep under review the measures

taken to ensure health and safety

o Investigate any matter that poses a

risk

o Attempt to resolve a health and safety

issue

o Request an investigation by a

WorkCover inspector

o Consult with a WorkCover inspector

and accompany them on an

investigation, if required

Unit 2: Managing workplace hazards, and consultation in the workplace Page 28 of 28

EMPLOYER

Must

o Provide a safe working environment

o Provide a safe system of work

o Provide proper training and information

o Identify hazards, assess the risks and eliminate or

control the risks

o Provide supervision

o Supply personal protective equipment and clothing

o Consult with employees

o Provide amenities

o Provide first aid facilities and personnel

o Provide for emergencies

o Ensure OHS committee members and representatives

are trained

o Not victimise or unlawfully dismiss an employee

o Not charge employees for things done

EMPLOYEE

o Must take reasonable care for the health and safety of

people who are at their place of work

o Must co-operate with their employer or other person

o Must notify the employer or supervisor of any risk to

health and safety

o Must not deliberately create a risk to health and safety

o Must not interfere with or misuse things provided for

health, safety and welfare

o Must not hinder aid to an injured worker

o Must not refuse assistance in either receiving aid or giving

aid

o Must not disrupt the workplace by creating health or safety

fears

Note: Students in the workplace should also follow these guidelines

to ensure the safety of themselves and others.

You might also like

- OOL OX EetingDocument23 pagesOOL OX EetingmjfprgcNo ratings yet

- Environmental Management System and Iso 14000 SeriesDocument8 pagesEnvironmental Management System and Iso 14000 SeriesAkanksha SrivastavaNo ratings yet

- Risk AssessmentDocument36 pagesRisk AssessmentBala muruganNo ratings yet

- PP Assignment 2Document3 pagesPP Assignment 2Huda GulNo ratings yet

- Module 2-B Emergency PreparednessDocument16 pagesModule 2-B Emergency PreparednessRobin RubinaNo ratings yet

- Occupational Health and Safety Policy Guidelines For The Health Sector in Kenya PDFDocument80 pagesOccupational Health and Safety Policy Guidelines For The Health Sector in Kenya PDFaponojecy100% (2)

- Topic 4 Hazard Identification PDFDocument15 pagesTopic 4 Hazard Identification PDFDiyana OsmanNo ratings yet

- COSH Assignment 3Document9 pagesCOSH Assignment 3Platoon Nicart BejerNo ratings yet

- Occupational Safety, Health & Environment ManagementDocument50 pagesOccupational Safety, Health & Environment ManagementAna Bella RosarioNo ratings yet

- Risk Management/ Emergency Preparedness PlanDocument39 pagesRisk Management/ Emergency Preparedness PlanIra MejiaNo ratings yet

- Safety & Health Program 1Document20 pagesSafety & Health Program 1BuicheNo ratings yet

- Crisis Management GuidelinesDocument2 pagesCrisis Management GuidelinesKeith Marcel MenezesNo ratings yet

- Chapter 10 - Environmental Management PlanDocument13 pagesChapter 10 - Environmental Management PlanMelanieNo ratings yet

- PM 215 - Module 3 - 23-24Document18 pagesPM 215 - Module 3 - 23-24Louray JeanNo ratings yet

- OHS Hazard Assessment Case StudyDocument28 pagesOHS Hazard Assessment Case StudyABCMARCH100% (1)

- Safety and Health ProgramDocument20 pagesSafety and Health ProgramSanjana GaneshNo ratings yet

- Occupational Health Hazards and Safety Practices: ErgonomicsDocument56 pagesOccupational Health Hazards and Safety Practices: ErgonomicsPhilemon MsangiNo ratings yet

- Workplace Environmental Hazards: Ykk Zipper Philippines, IncDocument39 pagesWorkplace Environmental Hazards: Ykk Zipper Philippines, IncBriggs Tiglao100% (1)

- 2 (MPH) Hazard Identification Risk Assessment and Control ProcedureDocument9 pages2 (MPH) Hazard Identification Risk Assessment and Control ProcedureLwandziso DlaminiNo ratings yet

- How to Empower Children in the World: Earth Leaders for Environmental MonitoringFrom EverandHow to Empower Children in the World: Earth Leaders for Environmental MonitoringNo ratings yet

- Environmental Management SystemDocument18 pagesEnvironmental Management SystemksbbsNo ratings yet

- Emergency Action Plan TEMP1 - 16Document17 pagesEmergency Action Plan TEMP1 - 16Kim ClaresseNo ratings yet

- Unit 1 - Introduction To Occupational Health and SafetyDocument30 pagesUnit 1 - Introduction To Occupational Health and Safetyvidya chakitwarNo ratings yet

- Occupational Health and Safety Management A Practical Approach PDFDocument2 pagesOccupational Health and Safety Management A Practical Approach PDFLogan0% (1)

- Prepare For IELTS PDFDocument169 pagesPrepare For IELTS PDFABCMARCHNo ratings yet

- Hazard Identification, Risk Assessment and Risk ControlDocument4 pagesHazard Identification, Risk Assessment and Risk ControlNarayanasami Kannan0% (1)

- Chapter 4. Ergonomics Hazards and Risks ManagementDocument46 pagesChapter 4. Ergonomics Hazards and Risks Managementmich abi100% (1)

- MEE5022 OSH Assignment 1Document3 pagesMEE5022 OSH Assignment 1Muhammad Syahir BadruddinNo ratings yet

- OHS Lecture DraftDocument16 pagesOHS Lecture DraftPhilcas LiNo ratings yet

- Summative Assessments 244383Document9 pagesSummative Assessments 244383Nomsa ZunguNo ratings yet

- Module 1-C Emergency PreparednessDocument9 pagesModule 1-C Emergency PreparednessRobin RubinaNo ratings yet

- Matrix Data Analysis ChartDocument6 pagesMatrix Data Analysis ChartMeng Arnold100% (1)

- A Comparative Study of Performance Appraisal in Manufacturing and Service SectorDocument5 pagesA Comparative Study of Performance Appraisal in Manufacturing and Service Sectorajayajay83100% (3)

- 6 Hazard AvoidanceDocument22 pages6 Hazard AvoidancefirahliyanaNo ratings yet

- Ppe ChecklistDocument1 pagePpe ChecklistIvan BaraćNo ratings yet

- Elements of An Effective Safety and Health ProgramDocument20 pagesElements of An Effective Safety and Health ProgramJojo Betanio AkajoknoNo ratings yet

- OHS Policies and ProceduresDocument9 pagesOHS Policies and Proceduresjuvan05No ratings yet

- BOHS Prelim Hand OutsDocument12 pagesBOHS Prelim Hand OutsAmlid AmarNo ratings yet

- Literature ReviewDocument10 pagesLiterature ReviewZay NahNo ratings yet

- CMDocument38 pagesCMAnn AlvarezNo ratings yet

- 1 Environmental Management Notes: 1.1 Environmental Planning and SustainabilityDocument12 pages1 Environmental Management Notes: 1.1 Environmental Planning and SustainabilityJaishikha DawahooNo ratings yet

- Assignment 3 GuideDocument1 pageAssignment 3 GuideMapaseka MpopoNo ratings yet

- OHS BrochureDocument2 pagesOHS Brochureprassna_kamat1573No ratings yet

- 4.2 Unit GC2: Controlling Workplace Hazards: Learning OutcomesDocument18 pages4.2 Unit GC2: Controlling Workplace Hazards: Learning Outcomesnavin100% (2)

- 6.4 Learner Entry GuidanceDocument13 pages6.4 Learner Entry GuidancePierre WepenerNo ratings yet

- Ohsms Awareness & Implementation For ContractorsDocument24 pagesOhsms Awareness & Implementation For ContractorsFadzlli AminNo ratings yet

- Environmental Health and SafetyDocument3 pagesEnvironmental Health and Safetyapi-79130528No ratings yet

- CHAPTER 1 and 2Document37 pagesCHAPTER 1 and 2Jaimie Del MundoNo ratings yet

- Basic Occupational Safety & Health: Bachelor of Engineering Technology-Major in Construction TechnologyDocument9 pagesBasic Occupational Safety & Health: Bachelor of Engineering Technology-Major in Construction TechnologyRoss Arvin CremaNo ratings yet

- Matrix DiagramDocument8 pagesMatrix DiagramGaneshkumar RamasubbuNo ratings yet

- Fs ST 1-ILO 4 enDocument5 pagesFs ST 1-ILO 4 enSalman ShahzadNo ratings yet

- Principles of OSH. 1Document33 pagesPrinciples of OSH. 1Vadem Janus LactaotaoNo ratings yet

- Health and Safety NotesDocument3 pagesHealth and Safety Notesapi-247871582100% (1)

- Key Elements of Health and Safety Management SystemDocument6 pagesKey Elements of Health and Safety Management SystemGabbar 98No ratings yet

- Topic 6 Relevant Notes Part 1 - HIRACDocument6 pagesTopic 6 Relevant Notes Part 1 - HIRACNazrina RinaNo ratings yet

- Chapter 2Document15 pagesChapter 2Kamal JazlanNo ratings yet

- Organizing Safety Health and EnvironmentDocument8 pagesOrganizing Safety Health and EnvironmentpriyanshuNo ratings yet

- National Disaster Management StructureDocument22 pagesNational Disaster Management StructureBojan NeskovicNo ratings yet

- Sample IA GUIDEDocument7 pagesSample IA GUIDEAmalNo ratings yet

- 1 Class 2018Document6 pages1 Class 2018ahmadgamal070No ratings yet

- Zastita Na Radu, BrosuricaDocument31 pagesZastita Na Radu, BrosuricaSifi1989No ratings yet

- Unit 2 OHSDocument30 pagesUnit 2 OHSsir_criscapiliNo ratings yet

- Week 12 Questions For QuizDocument1 pageWeek 12 Questions For QuizABCMARCHNo ratings yet

- Distance Learning Activity 2 AnswerDocument2 pagesDistance Learning Activity 2 AnswerABCMARCHNo ratings yet

- Chapter 4 - Market Research PDFDocument7 pagesChapter 4 - Market Research PDFABCMARCHNo ratings yet

- READINGDocument1 pageREADINGABCMARCHNo ratings yet

- Wordlist Ielts Use This Word and U Score 8 in Essay (Anirudhshumi)Document106 pagesWordlist Ielts Use This Word and U Score 8 in Essay (Anirudhshumi)2mohan7No ratings yet

- Process of CommunicationDocument32 pagesProcess of CommunicationABCMARCHNo ratings yet

- Flow ChartDocument3 pagesFlow Chartnitin235No ratings yet

- General Training Reading Sample Task - Matching InformationDocument3 pagesGeneral Training Reading Sample Task - Matching InformationMarisha JuckoNo ratings yet

- Week 7Document29 pagesWeek 7ABCMARCHNo ratings yet

- 2631264678799Document14 pages2631264678799ABCMARCHNo ratings yet

- Presentation T12013Document3 pagesPresentation T12013ABCMARCHNo ratings yet

- Lecture 5 OHS LegalsDocument52 pagesLecture 5 OHS LegalsABCMARCHNo ratings yet

- Hilda Corrected ProjectDocument28 pagesHilda Corrected ProjectABCMARCH100% (1)

- Class Activity Week 1Document6 pagesClass Activity Week 1ABCMARCHNo ratings yet

- Dis Learning 1Document4 pagesDis Learning 1ABCMARCHNo ratings yet

- Purchase Ditribution LedgerDocument3 pagesPurchase Ditribution LedgerABCMARCHNo ratings yet

- Dis Learning 1Document4 pagesDis Learning 1ABCMARCHNo ratings yet

- 10 Australian SlangDocument2 pages10 Australian SlangABCMARCHNo ratings yet