Professional Documents

Culture Documents

Gear Pump Start Up

Uploaded by

César A. ChacónOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gear Pump Start Up

Uploaded by

César A. ChacónCopyright:

Available Formats

ENGINEERING

SPECIFICATION

A6-829-102873

Patent liability is supplier's responsibility. All information hereon is confidential property of Grove Worldwide and its affiliates.

Disclosure of information from this specification to others for any purpose other than that for which it was loaned is prohibited

CURRENT REVISION

#

DATE

11-May-03

ORIGINAL ECO

107408

APPROVED BY

T. Elliott

SPECIFICATION #

A6-829-102873

Indicates change PAGE 1

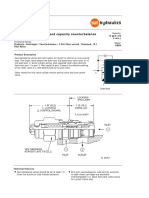

Title: Hydraulic Gear Pump Start-Up Procedure.

Objective:

To assist assembly personnel in proper gear pump start-up as recommended by the manufacturer.

Procedure:

1. Fill the reservoir with the proper hydraulic fluid to the high level mark on the reservoir sight gage.

2. Gear pumps are very good at self priming; the biggest concern is to make sure we are not sucking air

into the pump inlet or allowing the pump suction or inlet fluid to bleed-back to the reservoir when the

engine is stopped. Therefore, assure that all suction or inlet lines are air tight.

3. Remove all pump outlet hoses. Fill pump outlet port on each pump section with as much hydraulic oil

as it will take. Re-connect hoses.

Note: This step can be done before the pump is installed. Simply remove the plastic cap on the outlet of

the pump and fill with as much oil as possible, re-install the cap and then install the pump.

4. Start engine.

A. Idle engine for two to three minutes with no functions actuated. Check for leaks and repair if re-

quired. Lay your hand on the pump to check for excessive heat build-up. If the pump section is

too hot to keep your hand on, stop the engine immediately. All pumps should be about the same

temperature, but it depends on the pressure drop across the circuits upstream, which will vary

from one to another.

If the pump makes excessive noise it is probably sucking air into the inlet keeping the pump

from priming. If this occurs, stop engine, and inspect all connections of the suction hose/tube for

a lose connection, or for a missing or damaged o-ring.

Caution! Pay special attention to the service brake charge pump on units with the dual accumu-

lator charging valve for hydraulic service brakes. If the dual accumulator charge is set to high,

the pump will continually push all its flow across an integral relief valve that dumps the heated

flow back into the inlet of the pump. This causes a hot-loop situation that will very quickly

heat the pump section above hydraulic reservoir temperature. If this does occur, stop the engine

immediately. Adjust the dual accumulator charging valve socket head screw, located in its tank

port, out or CCW to lower the pressure (see pressure setting procedure to perform this adjust-

ment). Re-start the engine listening for the dual accumulator charge valve to cycle on and off (a

one to two second charge cycle). Repeat the checks in step 4A, and if OK proceed to step 4B.

ENGINEERING

SPECIFICATION

A6-829-102873

Patent liability is supplier's responsibility. All information hereon is confidential property of Grove Worldwide and its affiliates.

Disclosure of information from this specification to others for any purpose other than that for which it was loaned is prohibited

CURRENT REVISION

#

DATE

11-May-03

ORIGINAL ECO

107408

APPROVED BY

T. Elliott

SPECIFICATION #

A6-829-102873

Indicates change PAGE 2

B. Increase RPM to 1500-1800 for 1-2 minutes with no functions actuated and again, make checks

outlined in step A. Incrementally increase throttle to full RPM and then cycle the functions that

each section supplies to verify proper speed (verify pump flow).

5. Proceed to pressure setting procedure.

ENGINEERING

SPECIFICATION

A6-829-102873

Patent liability is supplier's responsibility. All information hereon is confidential property of Grove Worldwide and its affiliates.

Disclosure of information from this specification to others for any purpose other than that for which it was loaned is prohibited

CURRENT REVISION

#

DATE

11-May-03

ORIGINAL ECO

107408

APPROVED BY

T. Elliott

SPECIFICATION #

A6-829-102873

Indicates change PAGE 3

REVISION RECORD

REV ECO DESCRIPTION BY DATE APPROVED

You might also like

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- ZF As Tronic DescriptionDocument24 pagesZF As Tronic Descriptionahmedkhl97% (35)

- Roots Blower Operating ManualDocument15 pagesRoots Blower Operating Manualanup_nairNo ratings yet

- Emd Mi259Document20 pagesEmd Mi259Mike Finazzi100% (3)

- API Plan 53-Accumulator Bladder ChargingDocument11 pagesAPI Plan 53-Accumulator Bladder Chargingsumantabal_uceNo ratings yet

- Motor NTA 855Document252 pagesMotor NTA 855luisdeangeli88% (26)

- Injection Actuation Pressure - TestDocument18 pagesInjection Actuation Pressure - TestDanielly GersonNo ratings yet

- Types and Working Principle of ElevatorDocument17 pagesTypes and Working Principle of ElevatorPankaj Mahata83% (6)

- Tenant Protection Plan Notes Per 2014 Code 28-104.8.4 As Modified by Nyc Ll154 of 2017Document8 pagesTenant Protection Plan Notes Per 2014 Code 28-104.8.4 As Modified by Nyc Ll154 of 2017Leonardo Jr. SasingNo ratings yet

- HPLC Troubleshooting Guide-Gilson PDFDocument27 pagesHPLC Troubleshooting Guide-Gilson PDFMohammad Kazi Monsur0% (1)

- Tanque Presurizado de Acero Pro-Source Plus - Manual Del Propietario - 1000000173 - 2010 - PENTAIR WATER PDFDocument24 pagesTanque Presurizado de Acero Pro-Source Plus - Manual Del Propietario - 1000000173 - 2010 - PENTAIR WATER PDFpevareNo ratings yet

- EPF Glycol Pump Instruction Manual-GS2200 Series-2014Document19 pagesEPF Glycol Pump Instruction Manual-GS2200 Series-2014arasNo ratings yet

- IM Series7000 Neptune Mechanical Dia PumpDocument21 pagesIM Series7000 Neptune Mechanical Dia Pumptabman59No ratings yet

- dp7490 Pump ManualDocument16 pagesdp7490 Pump Manualvipequi50No ratings yet

- CAT Pumps Service ManualDocument8 pagesCAT Pumps Service ManualAnonymous alQXB11EgQNo ratings yet

- Prueva PresionDocument7 pagesPrueva PresionAlonso PachecoNo ratings yet

- Electronic Management SystemsDocument12 pagesElectronic Management SystemsTri KinartoNo ratings yet

- Pump-Elite - Operating InstructionsDocument12 pagesPump-Elite - Operating Instructionsbookslover1No ratings yet

- BA PM19478-19658 e 002Document5 pagesBA PM19478-19658 e 002AleksxxNo ratings yet

- Installation and Operating InstructionsDocument20 pagesInstallation and Operating InstructionsArtūrs CeimersNo ratings yet

- Hydroconstant-VariableSpeedDrivesDocument16 pagesHydroconstant-VariableSpeedDrivesJohn Jairo HoNo ratings yet

- CT Ecn 71.0 - EngDocument29 pagesCT Ecn 71.0 - Englucian.voinicaNo ratings yet

- CONTRACT No.14023 DATE 20.03.2014 Sirajganj 225Mw Combined Cycle Power Plant Project (2 Unit-Dual Fuel)Document11 pagesCONTRACT No.14023 DATE 20.03.2014 Sirajganj 225Mw Combined Cycle Power Plant Project (2 Unit-Dual Fuel)VictorNo ratings yet

- REXROTH Service Manual PVC PSSFDocument6 pagesREXROTH Service Manual PVC PSSFRaghavendra DeshpandeNo ratings yet

- V40232 Clark C270 Torque ConverterDocument44 pagesV40232 Clark C270 Torque ConverterRemHenry100% (4)

- Motor C6.6 Caterpillar Prueba de AireDocument4 pagesMotor C6.6 Caterpillar Prueba de AiremanuelNo ratings yet

- Choke Maintnance PDFDocument42 pagesChoke Maintnance PDFbtrasla9023No ratings yet

- Portable Cargo Pump TK80 Simillar To Marflex Portable PPDocument18 pagesPortable Cargo Pump TK80 Simillar To Marflex Portable PPSubramoniam MarineNo ratings yet

- Hybrid P3130Document6 pagesHybrid P3130sajid_boyNo ratings yet

- Pro-Source Plus Steel Pressure Tanks: Owner'S ManualDocument10 pagesPro-Source Plus Steel Pressure Tanks: Owner'S ManualJhon QuiñonesNo ratings yet

- Instruction - Flushing Gas Turbine Lubricant Oil SystemDocument5 pagesInstruction - Flushing Gas Turbine Lubricant Oil SystemRicky Hendra Silalahi100% (1)

- 3Pfr Plunger Pump Service Manual: 3 Frame Split Manifold: 230, 240, 270, 231, 241, 271, 237, 247, 277, 279Document8 pages3Pfr Plunger Pump Service Manual: 3 Frame Split Manifold: 230, 240, 270, 231, 241, 271, 237, 247, 277, 279yorgo7002No ratings yet

- LC HDP 1100 D2数显喷油器13版说明书Document22 pagesLC HDP 1100 D2数显喷油器13版说明书DariusNo ratings yet

- 199R7948 5rev5 PDFDocument16 pages199R7948 5rev5 PDFbatman2054No ratings yet

- Mud Pumps Manual PDFDocument48 pagesMud Pumps Manual PDFMohamed Benlarbi100% (5)

- MEGA Operating InstructionsDocument14 pagesMEGA Operating InstructionsSumit SinghaNo ratings yet

- Bte-Bta10k Pump ManualDocument19 pagesBte-Bta10k Pump ManualAlexsandro CordeiroNo ratings yet

- 35391B RevaDocument234 pages35391B RevaFelipe FloresNo ratings yet

- Fluid Power Intensifiers Series PC, PD and PS: The Easier, Less Costly Way To Provide High Pressure Hydraulic PowerDocument8 pagesFluid Power Intensifiers Series PC, PD and PS: The Easier, Less Costly Way To Provide High Pressure Hydraulic PowernvkjayanthNo ratings yet

- 2214Document8 pages2214Ken ArokNo ratings yet

- Bristol Changing All Compressors PDFDocument18 pagesBristol Changing All Compressors PDFfelix alfredo sorianoNo ratings yet

- Manual Vacuum CoolairDocument8 pagesManual Vacuum CoolairasedayuNo ratings yet

- 35 FR2 SVCDocument10 pages35 FR2 SVCneider machucaNo ratings yet

- Rotor Tech IncDocument18 pagesRotor Tech IncDaniel Jurcich100% (1)

- Toyota - Paseo - Workshop Manual - 1990 - 1991Document3,179 pagesToyota - Paseo - Workshop Manual - 1990 - 1991cginternet.ofcNo ratings yet

- 3545 Manual de ServicioDocument8 pages3545 Manual de Servicioneider machucaNo ratings yet

- Catalogo de Compresores BristolDocument31 pagesCatalogo de Compresores BristolsalvatoreNo ratings yet

- Function of Diesel EngineDocument16 pagesFunction of Diesel EngineShienna MañiboNo ratings yet

- Caterpillar 236B-246B-252B Y 262BDocument22 pagesCaterpillar 236B-246B-252B Y 262BVictor Montesdeoca100% (1)

- Fuel System Pressure TestDocument6 pagesFuel System Pressure TestADIMITRA100% (2)

- Brands Vilter Manual VMC 400 SeriesDocument234 pagesBrands Vilter Manual VMC 400 SeriesJose Ricardo Prado SandovalNo ratings yet

- All About Marine Enginnering OralsDocument76 pagesAll About Marine Enginnering OralsUdana Hettiarachchi100% (3)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)From EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)No ratings yet

- Maintenance Inspection Manual - NationalDocument59 pagesMaintenance Inspection Manual - NationalCésar A. ChacónNo ratings yet

- Prop 65 WarningsDocument1 pageProp 65 WarningsCésar A. ChacónNo ratings yet

- Notice To Users of This ManualDocument2 pagesNotice To Users of This ManualCésar A. ChacónNo ratings yet

- P.A.T. / L.M.I. DS 160 Service Manual: Americas TrainingDocument48 pagesP.A.T. / L.M.I. DS 160 Service Manual: Americas TrainingCésar A. ChacónNo ratings yet

- 1400a Om CTRL103-02Document88 pages1400a Om CTRL103-02César A. ChacónNo ratings yet

- The Principles For Responsible Investment Podcast TranscriptDocument9 pagesThe Principles For Responsible Investment Podcast TranscriptCésar A. ChacónNo ratings yet

- PCSD Health Safety Plan NOV 2021Document5 pagesPCSD Health Safety Plan NOV 2021César A. ChacónNo ratings yet

- Patriot PressDocument2 pagesPatriot PressCésar A. ChacónNo ratings yet

- Service Manual: Crane Model NumberDocument2 pagesService Manual: Crane Model NumberCésar A. ChacónNo ratings yet

- Patriot PressDocument2 pagesPatriot PressCésar A. ChacónNo ratings yet

- PCSD Health Safety Plan NOV 2021Document5 pagesPCSD Health Safety Plan NOV 2021César A. ChacónNo ratings yet

- Dodig 2022 013 - RedactedDocument46 pagesDodig 2022 013 - RedactedCésar A. ChacónNo ratings yet

- ZF Esquematicos y Datos TecnicosDocument2 pagesZF Esquematicos y Datos TecnicosCésar A. ChacónNo ratings yet

- E7 Hydraulic Diagram-ESDocument2 pagesE7 Hydraulic Diagram-ESCésar A. Chacón100% (1)

- E7 Hydraulic Diagram-ESDocument2 pagesE7 Hydraulic Diagram-ESCésar A. Chacón100% (1)

- 5600F-5700F 100% Port Eccentric Plug Valve Val-Matic® SpecificationDocument2 pages5600F-5700F 100% Port Eccentric Plug Valve Val-Matic® Specificationnourhan abdelazimNo ratings yet

- Xq114-6yx Manual PDFDocument55 pagesXq114-6yx Manual PDFFredy NavasNo ratings yet

- Catalog Advanced RocksDocument81 pagesCatalog Advanced RocksDarya Khan BhuttoNo ratings yet

- 20 RT-flex MechanicalDocument60 pages20 RT-flex MechanicalKesavan Vimal KumarNo ratings yet

- Manual Trident Klasik 200Document12 pagesManual Trident Klasik 200DanielMachadopovoa100% (1)

- Deluge ValveDocument10 pagesDeluge ValvevpnrrajaNo ratings yet

- P 2010 MX tcm325 6752Document65 pagesP 2010 MX tcm325 6752josebernal_mza100% (2)

- International StandardsDocument93 pagesInternational StandardsakashdadNo ratings yet

- ITP For Manual ValveDocument7 pagesITP For Manual ValveHamid Taghipour ArmakiNo ratings yet

- Model BFV-300/BFV-300C Butterfly Valve Grooved End General DescriptionDocument8 pagesModel BFV-300/BFV-300C Butterfly Valve Grooved End General DescriptionMERCURE GARINDOLPGNo ratings yet

- Pump Protection ValveDocument16 pagesPump Protection ValveRadient MushfikNo ratings yet

- Hand Test Pumps: Operating InstructionsDocument12 pagesHand Test Pumps: Operating InstructionssaratchandranbNo ratings yet

- 2010 Cameron Barton Tecnova HTDocument23 pages2010 Cameron Barton Tecnova HTDeji AdesiyanNo ratings yet

- 5 - Counter Balance Valve TSCA 70-10 - CBCHDocument4 pages5 - Counter Balance Valve TSCA 70-10 - CBCHIvan MaltsevNo ratings yet

- BS en 13547-2013Document30 pagesBS en 13547-2013Ahmed HassanNo ratings yet

- Kennedy - Modelo 2945A - Poste IndicadorDocument14 pagesKennedy - Modelo 2945A - Poste Indicadorcchristt2584No ratings yet

- Belgen150 & 200 - MAY 2006 - 65084-1BDocument42 pagesBelgen150 & 200 - MAY 2006 - 65084-1BdavidNo ratings yet

- ParkerStore Catalogue 2012 - ENDocument620 pagesParkerStore Catalogue 2012 - ENsajay_suryaNo ratings yet

- 18 Ac79d1 8 enDocument28 pages18 Ac79d1 8 enHoàngViệtAnhNo ratings yet

- Atlas Copco Stationary Air Compressors Ga 30-Instruction BookDocument49 pagesAtlas Copco Stationary Air Compressors Ga 30-Instruction Bookphoenix a703100% (1)

- Sirri Island Gas Gathering & NGL Recovery Project: Active Fire Fighting Safety Equipment SpecificationDocument12 pagesSirri Island Gas Gathering & NGL Recovery Project: Active Fire Fighting Safety Equipment SpecificationRIMEL ASMANo ratings yet

- PL PC200-7 0209 3434Document11 pagesPL PC200-7 0209 3434Jamyansuren TseveendorjNo ratings yet

- 1000LPH RO System Quotation - HinadaDocument5 pages1000LPH RO System Quotation - HinadaramzibtrNo ratings yet

- MasterSeries 856 Specification SheetDocument2 pagesMasterSeries 856 Specification SheetFEBCONo ratings yet

- 5090b-Excavator Hydraulic SystemDocument2 pages5090b-Excavator Hydraulic SystemAlex Franklin Camaña JiménezNo ratings yet

- JIS F Standards List 2012Document15 pagesJIS F Standards List 2012Mathan KumarNo ratings yet

- Genuine Metaris MHP/M Series Gear PumpsDocument4 pagesGenuine Metaris MHP/M Series Gear PumpsTravisReign Dicang02No ratings yet