Professional Documents

Culture Documents

Estrategias de Operaciones en El Mundo

Uploaded by

Kimberly Holcomb0 ratings0% found this document useful (0 votes)

11 views2 pagesEstrategias de operaciones para la administracion de la cadena de valor

Original Title

Estrategias de operaciones en el mundo

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentEstrategias de operaciones para la administracion de la cadena de valor

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views2 pagesEstrategias de Operaciones en El Mundo

Uploaded by

Kimberly HolcombEstrategias de operaciones para la administracion de la cadena de valor

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

24 Industrial Engineer

Business leaders are only begin-

ning to understand the potential to create

value in a companys supply chain. Supply

chain management is growing more popu-

lar in executive suites, leading to questions

about how it creates protable growth.

The importance of supply chains and

their effectiveness, or lack thereof, never

has been more apparent than it is today.

Supply chains drive value, which ultimately

reaches shareholders and investors. Todays

CEOs and boards no longer can ignore the

end-to-end business impacts of the supply

chain.

New understandings have surfaced

about supply chains. The supply chain

megaprocesses plan, buy, make, move,

store, sell, return comprise the operations

of the business. And the four flows mate-

rials/products, information, cash and work

flow determine the effectiveness and effi-

ciency of the operations.

Traditionally, each megaprocess was

treated as a functional silo. Little infor-

mation crossed boundaries. Now, supply

chains likely have many interrelated trad-

ing partners spanning geographies, time

zones and cultures. Using what we call the

supply chain value framework which

encompasses the goals, objectives, actions

and value drivers for creating value is an

excellent way to engage these areas and

partners to create shareholder value.

As companies examine opportunities

for profitable growth, margin improve-

ment and capital efficiency, this framework

keeps process leaders focused on results.

Ensuring that key value drivers are identi-

fied and prioritized is vital. Benchmarking

and adapting best practices are essential to

ensure the right actions are taken. Compa-

nies can leverage their megaprocesses to

increase or create value by analyzing the

following 10 areas:

Procurement: Accept procurement as

a much broader responsibility, beginning

with strategic sourcing, to include all mega-

processes and encompass responsibility of

supplier relationship management.

Outsourcing: Focus on core compe-

tencies and outsource all other tasks.

Inventory: Increase inventory turns

and fill rates simultaneously. Put advanced

sales and operations planning processes in

place to unleash working capital and drive

customer service.

Transportation: Establish efforts to

develop core carrier programs, implement

transportation management systems,

decouple inbound freight and enhance

shipment planning and execution oppor-

tunities.

Network: Changes such as globaliza-

tion, mergers and acquisitions, and the

evolution of your marketplace all demand

an annual review of your network. Evalu-

ate the number of and justification for your

locations, along with the operation strate-

gies, to establish the lowest cost/highest

customer service network.

Service supply chain: View this as a

profit center. Assess reverse logistics and

end-of-life product opportunities with an

eye toward enhancing profitable growth.

Speed, agility and productivity:

Successful organizations will boost speed,

agility and productivity across the mega-

processes.

Tax-effective supply chain: Supply

chain managers need to understand the

effective tax rate, and tax managers need to

understand the supply chain.

Cash-to-cash cycle (C2C) manage-

ment: The C2C cycle is the length of time

a companys cash is tied up in working

capital before it is returned in the form of

collections of receivables. Consider the

C2C cycle in all supply chain improve-

ments.

Technology: Move forward with tech-

nology upgrades that provide a strong

business case.

For more details about achieving profit-

able growth through supply chain strategy,

download the white paper Leveraging the

Supply Chain for Increased Shareholder

Value from www.tompkinsinc.com/

publications. d

James A. Tompkins is president and CEO of

Tompkins Associates and Tompkins International.

He has written or contributed to more than 30

books, hosts the Global Supply Chain Podcast

series and writes the GoGoGo! blog. Contact him

at jtompkins@tompkinsinc.com.

Creating value

New understandings

have surfaced.

supply chain BY JAMES A. TOMPKINS

Copyright of Industrial Engineer: IE is the property of Institute of Industrial Engineers and its content may not

be copied or emailed to multiple sites or posted to a listserv without the copyright holder's express written

permission. However, users may print, download, or email articles for individual use.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 7 Keys To Facility LocationDocument5 pages7 Keys To Facility LocationKimberly HolcombNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Art of Military LogisticsDocument6 pagesThe Art of Military LogisticsKimberly HolcombNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Ford Motor Company and Firestone Tyre RecallDocument13 pagesFord Motor Company and Firestone Tyre RecallKimberly HolcombNo ratings yet

- Two Sides For Every Story: Bridgestone/ FordDocument6 pagesTwo Sides For Every Story: Bridgestone/ FordKimberly HolcombNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Measurement (Ques - Ch2 - Electromechanical Instruments) PDFDocument56 pagesMeasurement (Ques - Ch2 - Electromechanical Instruments) PDFmadivala nagarajaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- LDS Conference Report 1930 Semi AnnualDocument148 pagesLDS Conference Report 1930 Semi AnnualrjjburrowsNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- CNS Drugs Pharmaceutical Form Therapeutic Group: 6mg, 8mgDocument7 pagesCNS Drugs Pharmaceutical Form Therapeutic Group: 6mg, 8mgCha GabrielNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Landow - The Rhetoric of HypermediaDocument26 pagesLandow - The Rhetoric of HypermediaMario RossiNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Simple Linear Equations A Through HDocument20 pagesSimple Linear Equations A Through HFresgNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- CSL - Reflection Essay 1Document7 pagesCSL - Reflection Essay 1api-314849412No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Customer AnalysisDocument6 pagesCustomer AnalysisLina LambotNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Ghosh, D. P., 1971, Inverse Filter Coefficients For The Computation of Apparent Resistivity Standard Curves For A Horizontally Stratified EarthDocument7 pagesGhosh, D. P., 1971, Inverse Filter Coefficients For The Computation of Apparent Resistivity Standard Curves For A Horizontally Stratified EarthCinthia MtzNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Exam3 Buscom T F MC Problems FinalDocument23 pagesExam3 Buscom T F MC Problems FinalErico PaderesNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- What Does The Scripture Say - ' - Studies in The Function of Scripture in Early Judaism and Christianity, Volume 1 - The Synoptic GospelsDocument149 pagesWhat Does The Scripture Say - ' - Studies in The Function of Scripture in Early Judaism and Christianity, Volume 1 - The Synoptic GospelsCometa Halley100% (1)

- 10 Fonts For A Better WebsiteDocument3 pages10 Fonts For A Better WebsiteAlyzza Kara AcabalNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Personal Development: Quarter 2 - Module 2: Identifying Ways To Become Responsible in A RelationshipDocument21 pagesPersonal Development: Quarter 2 - Module 2: Identifying Ways To Become Responsible in A RelationshipTabada Nicky100% (2)

- The Students Ovid Selections From The Metamorphoses by Ovid, Margaret Worsham MusgroveDocument425 pagesThe Students Ovid Selections From The Metamorphoses by Ovid, Margaret Worsham MusgroveMiriaam AguirreNo ratings yet

- Ped Xi Chapter - 3Document15 pagesPed Xi Chapter - 3DebmalyaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Bahasa Inggris XIIDocument1 pageBahasa Inggris XIIclaudiaomega.pNo ratings yet

- Acc 106 Ebook Answer Topic 4Document13 pagesAcc 106 Ebook Answer Topic 4syifa azhari 3BaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Read Chapter 4 Minicase: Fondren Publishing, Inc. From The Sales Force Management Textbook by Mark W. Johnston & Greg W. MarshallDocument1 pageRead Chapter 4 Minicase: Fondren Publishing, Inc. From The Sales Force Management Textbook by Mark W. Johnston & Greg W. MarshallKJRNo ratings yet

- BrookfieldDocument8 pagesBrookfieldFariha Naseer Haral - 28336/TCHR/JVAITNo ratings yet

- Episode 5 The Global TeacherDocument8 pagesEpisode 5 The Global TeacherEllieza Bauto SantosNo ratings yet

- Sample File: A of TheDocument6 pagesSample File: A of TheMegan KennedyNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Breast Cancer ChemotherapyDocument7 pagesBreast Cancer Chemotherapydini kusmaharaniNo ratings yet

- Percy JacksonDocument13 pagesPercy JacksonDawn Marco0% (2)

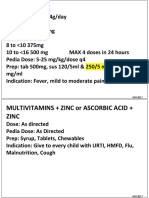

- Common RHU DrugsDocument56 pagesCommon RHU DrugsAlna Shelah IbañezNo ratings yet

- Counter-Example NLPDocument8 pagesCounter-Example NLPRafaelBluskyNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Effective Communication Chapter11Document9 pagesEffective Communication Chapter11kamaljeet70No ratings yet

- Abstraction and Empathy - ReviewDocument7 pagesAbstraction and Empathy - ReviewXXXXNo ratings yet

- The Acceptability of Indian Mango Leaves Powdered As A Tea: (Mangifera Indica Linn.)Document22 pagesThe Acceptability of Indian Mango Leaves Powdered As A Tea: (Mangifera Indica Linn.)Marissa M. DoriaNo ratings yet

- Business Environment Analysis (Porter's 5 Forces Model)Document9 pagesBusiness Environment Analysis (Porter's 5 Forces Model)FarihaNo ratings yet

- Deeg Palace Write-UpDocument7 pagesDeeg Palace Write-UpMuhammed Sayyaf AcNo ratings yet

- Cambridge English First Fce From 2015 Reading and Use of English Part 7Document5 pagesCambridge English First Fce From 2015 Reading and Use of English Part 7JunanNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)