Professional Documents

Culture Documents

Injection Molding Control

Uploaded by

Nalin T BandaraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Injection Molding Control

Uploaded by

Nalin T BandaraCopyright:

Available Formats

Pro-Set 200

Injection Molding Control

(Catalog Number 1747-L542P)

Product Data

Pro-Set 200 Software

for Injection Molding Control

Before you purchase or retrofit another injection molding machine, investigate the Allen-Bradley

Pro-Set 200 Injection Molding Control. Based on our widely used SLC Small Logic Controller,

this system provides complete control of the molding machine.

The Right Control

For You

As a high-volume injection molder of tight-tolerance parts, you know

that to remain competitive you must find ways to leverage your two

greatest assets, your molding machinery and personnel.

If you can improve machine performance with advanced technologies

without staffing your operation with computer specialists, you can

realize a competitive advantage. If you can automate your processes

and allow your people to focus on quality, process improvement, and

new product innovation, you can grow your revenues and profits.

We want to help you put modern technologies to work so you can:

improve your processes

simplify machine operations

increase safety

reduce the cycle time and lower the scrap rate

reduce machine downtime through automation

The Pro-Set 200 Injection Molding Control System offers you these

features and more.

Pro-Set 200 Injection Molding Control System

Advanced Process Control

with ERC2 Expert

Response Compensation

ERC2 is the second generation of Allen-Bradleys patented Expert

Response Compensation closed-loop control technology. It is an

advanced control algorithm which provides automatic tuning of the

pressure and velocity loops associated with clamp, injection, and

ejector motion. It:

eliminates the need to manually tune pressure and velocity loops,

resulting in simplified machine setups in less time

measures machine performance during each cycle and compares it

with desired molding parameters. Based on profile configuration,

ERC2 provides the control outputs to achieve desired setpoints

informs an operator if machine performance appears to fall outside

of calculated machine capabilities

ERC2 is a one-button automatic tuning feature that frees you from the

tedious and complex process of tuning control systems and lets you

concentrate on the quality of parts being produced. As a result, you

will experience:

Profiled Action for

Better Injection and

Faster Cycles

greater process stability

increased production yields

lower scrap rates

simplified machine operation

Profiling lets you configure the operation of screw, clamp, and ejectors

for faster, smoother, molding cycles. We provide profiling screens

where you subdivide machine action into position segments, each

having a pressure or velocity setpoint. This lets you manipulate

hydraulic pressure and/or velocity of the injection ram, allowing you to

mold even the most complex parts with the most difficult of materials.

For example, you can divide the injection phase into 5 segments and

tailor the speed of the injection shot to the characteristics of your mold

and/or material.

Injection Profile

There is a corresponding velocity

setpoint and pressure setpoint

associated with each position setpoint.

You use the corresponding velocity

and pressure setpoints to go from one

positionentire profile(and to the next velocity (Vel) or

The to the next controls either

profile). Transfer is a transition to the velocity or

pressure (psi) with a corresponding

next selected profile. associated with each position

pressure setpoint

(Pos) setpoint.

segment 4

segment 3

segment 2

segment 1

segment 5

Ram (screw)

Pos 4

Vel 5

xx.xx

Pos 3

Vel 4

xx.xx

Pos 2

Vel 3

xx.xx

Pos 1

Vel 2

xx.xx

Vel 1

xx.xx

xx.xx

xx.xx

xx.xx

xx.xx

psi 5

psi 4

psi 3

psi 2

psi 1

xxxx

xxxx

xxxx

xxxx

xxxx

Transfer to the pack profile can occur during

any part of the injection phase. Transfer criteria

is based on: xx.xx position

xxxx pressure

xx.xx position mask

xx.xx time

Publication 6500-2.9 February 1998

Pro-Set 200 Injection Molding Control System

Profiles Used in

the Molding Process

Any profile in the inject, clamp, and ejector phases can be controlled

by pressure or velocity to suit you molding machine. Here are the

default (pressure or velocity) control modes and number of segments

for all of the profiles that Pro-Set 200 uses in the molding process:

Control of Inject Phase

Profile:

Injection

Pack

Hold

Pre-Decompress

Plastication

Post-Decompress

Segments:

5

2

2

1

5

1

Default Mode:

Velocity

Pressure

Pressure

Velocity

Pressure

Velocity

Control of Clamp Phase

Profile:

Close

Clamp LPMP

Tonnage

Low Hold

Decompress

Clamp Open

Segments:

3

1

1

1

1

4

Default Mode:

Velocity

Pressure

Pressure

Pressure

Pressure

Velocity

Control of Ejector Phase

Profile:

Ejector Forward

Ejector Reverse

Tip Stroke

We Do the Engineering

For You

Segments:

2

1

1

Default Mode:

Velocity

Velocity

Velocity

Pro-Set 200 provides machine-tested ladder logic programs and

operator-interface screens for these functions:

set up and configure the machine

detect and display high and low limits and deviation alarms

store and retrieve mold/part setups

display production data

change the machine mode (manual, semi-automatic, automatic)

sequence the clamp, injection, and ejector phases

set and pull cores

interface to the temperature control module (1746-BTM)

The software is designed to run a typical injection molding machine

with minimal modification. Of course you can customize these machine

logic programs and operator-interface screens to support your unique

requirements. This might include the integration of robots, conveyors,

parts counters, material handling equipment or other devices which are

involved in your plastics processing operations.

Decreasing the system engineering time translates directly to reduced

costs in control system retrofits and new system commissioning.

Publication 6500-2.9 February 1998

Pro-Set 200 Injection Molding Control System

System Expansion to

Match Your Machine

Pro-Set 200 software runs on an SLC 5/04P processor, part of

Allen-Bradleys standard SLC architecture This architecture offers

expansion and configuration flexibility. System I/O can range from

as few as 7 I/O slots in an SLC chassis to multiple chassis with up to

30 slots. This means that Pro-Set 200 can be used in applications

requiring extremely high I/O counts or unique I/O configurations.

All standard SLC I/O and specialty modules can be integrated into

your Pro-Set 200 system.

Precise Temperature

Control

The Allen-Bradley Barrel Temperature Module (1746-BTM) is

specifically designed for the thermal characteristics of temperature

zones associated with plastics molding machines and extruders. A

patented cold- startup routine is designed to bring machine temperature

zones up to setpoint faster than traditional tuning methods with less

overshoot or temperature oscillation.

The BTMs autotuning functions ensure that temperatures are controlled

even when process conditions change or environmental conditions

would otherwise cause an undesired variance from setpoint. The BTM,

when used in a Pro-Set 200 system, provides one-touch automatic

temperature control and tuning. Machine operators need only turn on

the temperature zones and BTM takes care of the rest. The BTM:

is easy to use

has resolution of "0.1 degree C / F

is optimized for your process

You would set up and monitor temperature control loops with this

PanelView screen, included in the set of Pro-Set 200 operator screens.

Publication 6500-2.9 February 1998

Pro-Set 200 Injection Molding Control System

An Easy-to-use

Control System

Menu-driven screens step operators and setup personnel through a

logical sequence of the displays necessary to configure a machine,

set up a new mold, or diagnose processing problems. Pro-Set 200

offers mold/part storage making mold changes quick and easy.

Communication Networks

and Software to Gather

Process Data

Whether you need to gather information for process analysis,

production monitoring, or integration into plant-wide information

networks, Allen-Bradley networking strategies offer a variety of

physical connection schemes and data transfer protocols. Since

information processing requirements vary, it is extremely valuable to

have choices. Allen-Bradley offers solutions including DeviceNet,

ControlNet, Ethernet, Data Highway, and others which give you

options when networking your injection molding operation. We also

recommend Rockwell Software products such as RSTrend and

RSView for production monitoring and process analysis.

Lower Cost

In addition to being a cost effective system at time of purchase, our

SLC-based system offers lower life-cycle costs than most other control

choices since it relies on the same modules and technologies employed

in thousands of applications throughout the industry. You get the

benefit of worldwide availability of replacement parts and support

services from engineers who are experienced with Allen-Bradley /

Rockwell Automation products.

Training and Support

At Allen-Bradley, we back everything we sell with training and support.

We have plastics experts available to support your individual needs from

initial system concepts throughout the life of the product. For more

information, contact your local Allen-Bradley sales office or distributor.

Publication 6500-2.9 February 1998

Pro-Set 200 Injection Molding Control System

The Components of Our

Molding Control System

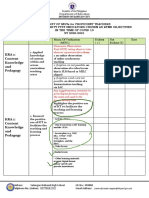

The components of our molding control system are shown below:

Pro-Set 200

PanelView Screens

Reserved

I/O Slot

PanelView 550 or 900

SLC 5/04P

Processor

Fast Analog

I/O Modules

Temperature

Control

Modules

Optional Modules

for other purposes

(ac, dc, relay)

Pro-Set 200

Ladder Logic

|

|

|

|

|

|

|

|

|

|

| |

|/|

| |

|/|

|/|

(

(

(

(

(

)

)

)

)

)

Power

Supply

from position and pressure sensors

type J and K T/C

to proportional pressure and flow valves

This Hardware or Software:

Does the Following:

SLC 5/04P Processor

(1747-L542P)

executes the sequence logic which controls the injection molding machine. Embedded within this

processor are the ERC2 algorithms which control the pressure and flow valves for the injection,

clamp, and ejector phases.

Fast analog I/O module

(1746-FIO4V or 1746-FIO4I)

accepts position and pressure inputs and provide analog output signals to the proportional valves

which control velocity and pressure. You need a least one FIO4V or FIO4I module for each controlled

phase (pressure and position inputs and pressure and velocity outputs). To select these modules:

If your valves require and/or your sensors produce"10V dc signals, use FIO4V

if your valves require and/or your sensors produce 4-20mA signals, use FIO4I

To control all three phases (inject, clamp, eject) with pressure/position inputs and pressure/flow

outputs, you need at least three modules. More may be required for other I/O combinations.

Temperature control module

(1746-BTM)

provides temperature control for the barrel of the injection molding machine. These modules contain

specialized start-up and auto-tuning algorithms which have been optimized for barrel temperature

control. Each module controls four temperature loops using either J or K thermocouples (grounded or

ungrounded). The ladder logic and PanelView screens accommodate eight temperature loops.

Important: Separate output modules provide the time-proportioned (on/off) or analog outputs for the

temperature loops. BTM modules do not have outputs.

PanelView 550 or 900 operator interface

lets you enter and modify profile and temperature setpoints, see alarms, view production data, etc.

Pro-Set 200 software (6500-PS210)

which contains:

ladder logic

PV550 or PV900 screen display

Miscellaneous input and output modules

Publication 6500-2.9 February 1998

works with the ERC2 algorithms to control closed-loop hydraulic pressure and flow circuits of the

inject, clamp, and eject phases of machine operation. Also controls the machines sequential

operations. You may modify this logic to accommodate your specific machine.

lets you operate the machine (configure profiles, modify/monitor temperatures, save/restore recipes),

calibrate, and troubleshoot. You may modify or add screens for additional machine features.

accept limit-switch and pushbutton inputs; control heaters, directional valves, pilot lights, and manual

functions. You can use any of the 1746-type I/O modules in the SLC 500 product line.

Pro-Set 200 Injection Molding Control System

How Pro-Set 200 Works

The following diagram illustrates how Pro-Set 200 works.

Important: The processor uses selectable-timed-interrupt (STI)

files to provide fast I/O updates from/to fast analog I/O modules.

The processor interrupts the main program scan at timed intervals

and goes to the STI file to read inputs and process outputs. This

ensures a fast, repeatable response for STI functions.

2. Ladder logic scales position

and pressure inputs and stores

scaled values in the data table.

1. The processor scans

position and pressure

inputs in the STI file.

Fast Analog

I/O Module

Machine

Setpoints

Position Inputs

Production

Data

SLC 5/04P Processor

Raw

Position

DH

Communications

Data

Table

Pressure Inputs

Raw

Pressure

STI

File

ERC2

Algorithms

scaled

position

Pressure

Valve

Fast Analog

I/O Module

scaled

pressure

Pressure

Output

scaled

position

3. ERC2 algorithms

use scaled position

and pressure inputs

to compute velocity

and pressure outputs.

scaled

pressure

Data

Table

Output to

Pressure Valve

Flow

Valve

Velocity

Output

velocity, pressure

output values

velocity, pressure

output values

Direct

Outputs

Output to

Flow Valve

Main

Ladder Logic

File

Directional

Valves

Pilot Lights

Data

Table

I/O

Update

Pumps

Heaters

Direct

Inputs

5. The processor sends velocity and

pressure outputs from the STI file to the fast

analog I/O modules to actuate the valves.

User Program

and Data

4. Ladder logic transfers velocity

and pressure output values from

the data table into the STI file.

Operating

System

Pushbuttons

Limit

Switches

Publication 6500-2.9 February 1998

Pro-Set 200 Injection Molding Control System

Pro-Set 200

Inputs and Outputs

Ladder logic for Pro-Set 200 software includes the following inputs

and outputs:

Inputs

Outputs

Manual Mode Switch

Manual Mode Lamp

Semi-automatic Mode Switch

Semi-automatic Mode Lamp

Automatic Mode Switch

Automatic Mode Lamp

Clamp Open Pushbutton or Selector Switch

Motors Running Lamp

Clamp Close Pushbutton or Selector Switch

Malfunction Lamp

Ejector Retract Pushbutton or Selector Switch

Malfunction Audible Alarm

Ejector Forward Pushbutton or Selector Switch

Clamp Solenoid Valve

Core Set Pushbutton or Selector Switch

Clamp-close Solenoid Valve

Core Pull Pushbutton or Selector Switch

Clamp-open Solenoid Valve

Inject Forward Pushbutton or Selector Switch

Clamp Proportional Valve

Screw Rotate Pushbutton or Selector Switch

Inject Forward Solenoid Valve

Inject Forward Pushbutton or Selector Switch

Inject Retract Solenoid Valve

Inject Retract Pushbutton or Selector Switch

Inject Proportional Valve

Malfunction Reset Pushbutton Switch

Pack Solenoid Valve

Motors Running Switch

Hold Solenoid Valve

Safety Ratchet-up/down Switches

Screw Rotate Solenoid Valve

Front/Rear Safety Gates Closed/Open Switches

Backpressure Solenoid Valve

Barrel Heat-on Switch

Ejector Solenoid Valve

Mold Set Switch

Ejector Forward Solenoid Valve

Core Set/Pull Limit Switches

Ejector Retract Solenoid Valve

Inject/Screw Off/On (Dry Cycle) Switch

Ejector Proportional Valve

Inject Forward/Retract Limit Switches

Additional Pump Solenoid Valve

Clamp Open Overstroke Switch

Barrel Master Heat Contactor

Clamp Decompress Switch

Clamp at Tonnage Pressure Switch

Clamp Locked Limit Switch (Toggle Clamp)

Purge Guard Closed Switch

Typical System Hardware

A typical Pro-Set 200 system consists of this Allen-Bradley equipment:

Equipment:

Qty:

Catalog Number:

SLC 5/04P Processor

1747-L542P

Barrel Temperature Control Module

1-3

1746-BTM

Fast Analog I/O Modules

1-3

1746-FIO4I or 1746-FIO4V

Auxiliary Power Supply

1746-P4

I/O Chassis

1746-A10

Operator Interface Terminal

PanelView 550 or 900

Injection Molding Labels for PanelView

6500-PS2LBL

Pro-Set 200 Software

6500-PS210

I/O Modules as required, such as 1746-IB16, 1746-OB16

Publication 6500-2.9 February 1998

Pro-Set 200 Injection Molding Control System

Feature Specifications:

program memory size 32K

high-speed performance 0.90 ms/K typical

control of up to 960 local I/O

online programming (includes runtime editing)

built-in DH+ channel, supporting:

high-speed SLC 5/04P to SLC 5/04P communication

messaging capability between PLCsR and SLCs

built-in RS-232 channel, supporting:

DF1 Full-Duplex for remote or point-to-point communication,

or direct connection to IBM compatible programming devices

DF1 Half-Duplex Master/Slave for SCADA

type communication

DH-485 (serves as a second DH-485 channel using a

1747-PIC or direct connection to IBM compatible

programming devices)

ASCII for connection to other ASCII devices, such as bar

code readers, printers, and weigh scales

passthru capability to PanelView 550 and PanelView 900

remote I/O passthru

built-in real-time clock/calendar

1 ms Selectable Timed Interrupt (STI)

0.50 ms Discrete Input Interrupt (DII)

advanced math features trigonometric, PID, exponential,

floating point, and the compute instruction

indirect addressing

flash PROM provides firmware upgrades without physically

changing EPROMS

keyswitch RUN, REMote, PROGram (clear faults)

General Specifications

Power Supply Loading at 5V dc

1.0A for the SLC 5/04P processor

Power Supply Loading at 24V dc

200 mA for the SLC 5/04P processor

Program Scan Hold-up Time after Power Loss

20-3000 ms (dependent on power supply loading)

Clock/Calendar Accuracy

" 54 sec/month @ 25 C (77 F)

" 81 sec/month @ 60 C (140 F)

Noise Immunity

Vibration

ba

NEMA Standard ICS 2230

Shock (operating)

Displacement: 0.015 inch, pk-to-pk at 557 Hz

Acceleration: 2.5Gs at 572000 Hz

30Gs

Ambient Temperature Rating

Operating: 0 to + 60 C (32 F to 140 F)

Storage: 40C to 85 C (40 F to 185 F)

Humidity

5 to 95% without condensation

Agency Certification

(when product or packaging is marked)

Class I Div 2 Hazardous

marked for all applicable directives

Specifications for the

SLC 5/04P Processor

(Cat. No. 1747-L542P)

Publication 6500-2.9 February 1998

10

Pro-Set 200 Injection Molding Control System

Communication Options

The processor supports the following types of communication options.

Data Highway Plus (DH+) channel offers:

communication rates of 57.6K, 115.2K, and 230K baud

maximum network length of 3,048 m (10,000 ft.)

Belden 9463 (blue hose) cable connection between nodes

(daisy chain connection)

built-in isolation

DH-485 channel offers:

configurable communication rates up to 19.2K baud

electrical isolation via the 1746-AIC

maximum network length of 1219 m (4,000 ft.)

RS-485 electrical specifications

Belden 9842 cable connection between nodes

(daisy chain connection)

RS-232 channel offers:

Specifications of the Barrel

Temperature Module

(Cat. No. 1746-BTM)

communication rates up to 19.2K baud

maximum distance between devices is 15.24 m (50 ft.)

RS-232C electrical specifications

modem support

built-in isolation

Electrical Specifications

Backplane current consumption

Backplane power consumption

110 mA at 5V dc

85 mA at 24V dc

0.6W maximum (0.55W @ 5V dc, 2W @ 24V dc)

Number of channels

4 (backplane and channel-to-channel isolated)

I/O chassis location

any I/O module slot except slot 0

A/D conversion method

sigma-delta modulation

Input filtering

analog filter with low pass digital filter

Normal mode rejection

(between [+] input and [] input)

Common mode rejection

(between inputs and chassis ground)

Channel bandwidth (3db)

greater than 50 dB at 50 Hz

greater than 60 dB at 60 Hz

greater than 120 dB at 50/60 Hz

(with 1K ohm imbalance)

8 Hz

Calibration

once every six months

Isolation

1000 V transient or 150 VAC continuous

channel-to-channel or channel-to-backplane

Environmental Specifications

Operating temperature

0C to 60C (32F to 140F)

Storage temperature

40C to +85C (40F to +185F)

Relative humidity

5% to 95% (without condensation)

Agency Certification

(when product or packaging is marked)

Class I Div 2 Hazardous

marked for all applicable directives

Publication 6500-2.9 February 1998

Pro-Set 200 Injection Molding Control System

11

Physical Specifications

LED indicators

5 green status indicators

one for each of 4 channels

one for module status

Module ID code

10223

Recommended cable:

for thermocouple inputs

for mV inputs

Maximum wire size

shielded twisted pair thermocouple extension wire

alpha 5121 or equivalent

two 14 AWG wires per terminal

Maximum cable impedance

150 W maximum loop impedance, for <1LSB error

Terminal strip

removable, Allen-Bradley spare part

catalog number 1746RT32

Refer to the thermocouple manufacturer for the correct extension wire.

Overall accuracy

Overall accuracy includes variances in cold-junction compensation,

calibration, non-linearity, and resolution.

Input

Type

Maximum Error

@ 25C

Maximum Error

@ 77F

Temperature Drift

(0C60C)

1.06C

1.91F

0.0193C/C, F/F

1.72C

3.10F

0.0328C/C, F/F

50 mV

30 mV

30 mV

1.0 mV/C, 1.8 mV/F

100 mV

30 mV

30 mV

4.0 mV/C, 2.7 mV/F

Assumes the module terminal block temperature is stable.

Input Specifications

Thermocouple linearization

TC Type J 210C to 760C (346F to 1400F)

TC Type K 270C to 1370C (454F to 2498F)

Millivolt (50 mV dc to +50 mV dc)

Millivolt (100 mV dc to +100 mV dc)

IPTS68 standard, NBS MN125, NBS MN161

Cold junction compensation

accuracy 1.5C, 0C to 70C (32F to 158F)

Input impedance

greater than 10MW

Temperature scale

0.1C or 0.1F

DC millivolt scale

0.01 mV

Open circuit detection

leakage current

Open circuit detection

20 nA typical

Time to detect open circuit

0.5 seconds, typical

Input step response

0 to 99.9% (less 1 LSB) in 600 ms (worst case)

Display resolution

0.1C/step or 0.1F/step

Module update time

less than 500 ms

Channel turn-off time

up to one module update time

Type of input (selectable)

upscale

Publication 6500-2.9 February 1998

12

Pro-Set 200 Injection Molding Control System

Specifications for

Fast Analog Modules

(Cat. No. 1746-FIO4I or

1746-FIO4V)

General Specifications

Catalog

1746-

ID

Code

Input Channels

per Module

Output Channels

per Module

Backplane Current

5V

24V

FIO4I

3224

2 current output

55 mA

150 mA

FIO4V

3218

2 differential,

select V or I per channel

2 differential,

select V or I per channel

2 voltage outputs

55 mA

120 mA

Input and output channels are isolated from the backplane but not from each other.

SLC Communication Format

16-bit twos compliment binary

Location of LSB in I/O Image Word

0000 0000 0000 0001

Impedance to ANL COM

500K ohms

Impedance, Channel-to-channel

1M ohms

Field Wiring to Backplane Isolation

500V dc (continuous)

Cable

shielded, Belden #8761 (recommended)

Wire Size

#14 AWG (max)

Grounding Wire (optional)

1/4 wide (min) braid

Terminal Block, 1746-RT28

removable

Installation

single slot in the 1746 I/O Rack

Calibration

factory calibrated

Noise Immunity

NEMA standard ICS 2230

Environmental Conditions

Operating Temperature

Storage Temperature

Relative Humidity

0-60C (32-140F)

40 to 85C (40 to 185F)

5-95% (noncondensing)

General Input Specifications

Step Response (5-95%)

Class I Div 2 Hazardous

marked for all applicable directives

Agency Certification

(when product or packaging is marked)

100 sec

Converter Resolution

12-bit

Conversion Method

successive approximation

Nonlinearity

0.073% of full scale (max)

Common Mode Voltage Range

0-20V dc (max)

Common Mode Rejection Ratio at 10 Hz

n/a

Common Mode Rejection Ratio at 60 Hz

50 db (min), 1K ohm imbalance

Normal Mode Rejection at 60 Hz (min.)

n/a

Channel Bandwidth

7.0K Hz (min) @ 3 db point

Image Format (HEX)

0FFF

Track/hold Time to Get Signal before Conversion

1.5 s (nominal)

Signal Convert From Hold

6.0 sec (nominal)

Conversion Time

Module Throughput Delay

7.5 sec every 512 sec (nominal)

) 512 sec (typ)

1.10 ms (max

Worst case throughput occurs when the module just misses seeing an event occur.

Publication 6500-2.9 February 1998

Pro-Set 200 Injection Molding Control System

13

Current-loop Input Specifications

Full Scale

20 mA

Input Range

0-20 mA (nom) 0-30 mA (max)

Current Input Coding

0-2047 counts for 0-20 mA

Absolute Maximum Input Voltage

7.5V dc or 7.5V ac RMS

Input Impedance

250 ohms (nominal)

Resolution

9.7656 A per bit

Overall Accuracy at 25C (77F)

0.510% of full scale

0.850% of full scale

98 ppm/C of full scale (max)

0.400% of full scale

0.707% of full scale

89 ppm/C (max)

Overall Accuracy, 0-60C (32-140F)

Overall Accuracy Drift

Gain Error at 25C (77F)

Gain Error, 0-60C (32-140F)

Gain Error Drift

Offset Error at 25C (77F)

Offset Error, 0-60C (32-140F)

Offset Error Drift

2 LSB (typical)

4 LSB

0.14 LSB/C (max )

Overvoltage Protection

7.5V ac RMS (max)

Computed by box method:

2 [max offset error] / 60C

Voltage Input Specifications

Full Scale

10V dc

Input Range

0-10V dc 1 LSB

Input Impedance

1M ohms (nominal)

Overvoltage Protection (IN+ to IN)

220V dc or ac RMS, continuously

Resolution

2.4414 mV per LSB (nominal)

Voltage Input Coding

0-4095 counts for 0-10V dc

Overall Accuracy at 25C (77F)

0.440% of full scale

0.750% of full scale

88 ppm/C (max)

0.323% of full scale

0.530% of full scale

79 ppm/C (max)

4 LSB (max)

2 LSB (typical)

0.14 LSB/C (max )

Overall Accuracy, 0-60C (32-140F)

Overall Accuracy Drift

Gain Error at 25C (77F)

Gain Error, 0-60C (32-140F)

Gain Error Drift

Offset Error, 0-60C (32-140F)

Offset Error at 25C (77F)

Offset Error Drift

Computed by box method:

2 [max offset error] / 60C

Publication 6500-2.9 February 1998

14

Pro-Set 200 Injection Molding Control System

Output Specifications

Full Scale

Output Range

Output Coding

Output Resolution

Converter Resolution

Location of LSB in I/O Image Word

Nonlinearity

Conversion Method

Step Response

Load Range

Load Current

Load Reactance

Over-range Capability

10V dc

10 to +10V 1 LSB (normal)

32,768 to +32,764 for -10 to +10V dc

1.22070 mV per LSB

14-bit

0000 0000 0000 01XX

0.05% of full scale

R2R ladder

2.5 ms (normal)

Overall Accuracy at 25C (77F)

0.208% of full scale

0.384% of full scale

54 ppm/C of full scale (max)

0.208% of full scale

0.374% of full scale

47 ppm/C (max)

9 LSB (typical)

11 LSB

0.05 LSB/C (max)

Overall Accuracy, 0-60C (32-140F)

Overall Accuracy Drift

Gain Error at 25C (77F)

Gain Error, 0-60C (32-140 F)

Gain Error Drift

Offset Error at 25C (77F)

Offset Error, 0-60C (32-140 F)

Offset Error Drift

1K to ohms

10 mA (max)

1 F (max)

n/a

Pro-Set 200, ERC2, PanelView, and SLC are trademarks of Allen-Bradley Company, Inc.

Publication 6500-2.9 February 1998

16

Pro-Set 200 Injection Molding Control System

Allen-Bradley, a Rockwell Automation Business, has been helping its customers improve

productivity and quality for more than 90 years. We design, manufacture and support a broad

range of automation products worldwide. They include logic processors, power and motion

control devices, Operator Interfaces, sensors and a variety of software. Rockwell is one of the

worlds leading technology companies.

Worldwide representation.

Allen-Bradley Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel: (1) 414 382-2000 Fax: (1) 414 382-4444

Publication 6500-2.9 February 1998

Supersedes Publication 6500-2.9 July 1997

Publication 6500-2.9 February 1998

Copyright 1998 Allen-Bradley Company, Inc. Printed in USA

You might also like

- IMM BR IR enDocument13 pagesIMM BR IR enwatnaNo ratings yet

- eSW-1200 eSW-1200s: Mechanical Edition For RobotDocument44 pageseSW-1200 eSW-1200s: Mechanical Edition For Robothung nguyenNo ratings yet

- Advanced Thermoforming: Methods, Machines and Materials, Applications and AutomationFrom EverandAdvanced Thermoforming: Methods, Machines and Materials, Applications and AutomationRating: 5 out of 5 stars5/5 (1)

- 70D Manual BookDocument43 pages70D Manual BookgeorgioNo ratings yet

- Cy 600 800gii PDFDocument92 pagesCy 600 800gii PDFArmando Rivera100% (1)

- TSTA User ManualDocument218 pagesTSTA User ManualHieu NguyenNo ratings yet

- Molding Machine & MoldingDocument24 pagesMolding Machine & MoldingJyoti KaleNo ratings yet

- Huski - MM - H-RS - ENG - 4-11-1 - 200703Document518 pagesHuski - MM - H-RS - ENG - 4-11-1 - 200703Андрей ШарыйNo ratings yet

- XWZ-120A Operation Manual: Full Automatic Cartoning MachineDocument35 pagesXWZ-120A Operation Manual: Full Automatic Cartoning MachinealexjoelNo ratings yet

- TD El-Exis SP EnglischDocument60 pagesTD El-Exis SP EnglischJuan Angel CamposNo ratings yet

- 5092@feedmax BS6@ENDocument40 pages5092@feedmax BS6@ENALFONSO TORRESNo ratings yet

- SZ-600H Operation ManualDocument106 pagesSZ-600H Operation ManualAndreia BeatriceNo ratings yet

- Mar 2017Document76 pagesMar 2017deshmukhdpraveenNo ratings yet

- SYW SidelDocument42 pagesSYW Sidelgodganesha100% (1)

- (20210426 HUILI) 75 Injection Blow Moulding MachineDocument11 pages(20210426 HUILI) 75 Injection Blow Moulding MachineEsteban Juan Sejas AlanocaNo ratings yet

- Hydac Plastic Injection Molding MachinesDocument12 pagesHydac Plastic Injection Molding MachinespeterNo ratings yet

- Molded Parts DefectsDocument9 pagesMolded Parts DefectsPadmanava DasguptaNo ratings yet

- Ketop c100 t2 1384364 72700 0648630 Panel Operatorski Keba ManualDocument151 pagesKetop c100 t2 1384364 72700 0648630 Panel Operatorski Keba ManualJavier Del Pozo GarciaNo ratings yet

- Mold Machining Methods, Part 1Document22 pagesMold Machining Methods, Part 1Edenilson FadekNo ratings yet

- Manual de Operacion OGB-3 英文说明书Document68 pagesManual de Operacion OGB-3 英文说明书Gabriel Cab PaatNo ratings yet

- Arburg370&420C PDFDocument8 pagesArburg370&420C PDFMatoa PapedaNo ratings yet

- User Guide : CC300 Operator PanelDocument49 pagesUser Guide : CC300 Operator PanelilijaNo ratings yet

- Fully Automatic Blow Molding Machine DMK-L8Document67 pagesFully Automatic Blow Molding Machine DMK-L8MANPASANDMANGOSIPNo ratings yet

- Microinjection Molding of Thermoplastic Polymers: A ReviewDocument14 pagesMicroinjection Molding of Thermoplastic Polymers: A ReviewMario Allesina JuniorNo ratings yet

- Frank Fischer - Injection MoldingDocument12 pagesFrank Fischer - Injection MoldingStarchyLittleOleMeNo ratings yet

- 2014 AMCO CatalogDocument19 pages2014 AMCO CatalogAhmet MetinNo ratings yet

- KraussMaffei MC4 EthernetDocument18 pagesKraussMaffei MC4 Ethernetjohnny79No ratings yet

- 1 BlowMolding Documentation(英文)倍福Document31 pages1 BlowMolding Documentation(英文)倍福Aymane QariohNo ratings yet

- Drymax E Battery en V1 4Document59 pagesDrymax E Battery en V1 4bschmaltzy1No ratings yet

- CV Cipet Production NewDocument4 pagesCV Cipet Production NewKamlesh KumarNo ratings yet

- Two-Component Adhesive Mixer Technical DescriptionDocument4 pagesTwo-Component Adhesive Mixer Technical DescriptionCengiz Bay100% (2)

- Cartoning C2024Document70 pagesCartoning C2024Imam RidwanNo ratings yet

- Setting Process ConditionsDocument10 pagesSetting Process ConditionszaldsonNo ratings yet

- Product Details CD Programs: Basic Injection Molding Machine OperationsDocument25 pagesProduct Details CD Programs: Basic Injection Molding Machine OperationsOmar A. Hernandez100% (1)

- Manual 120726 Blow Moulding PDFDocument31 pagesManual 120726 Blow Moulding PDFrize1159No ratings yet

- Instruction and Spare Part Manual: Type: Evolution Model: 1R.9.36.126 - Neck Handling YEAR: 2013 Ref.: BielorussiaDocument524 pagesInstruction and Spare Part Manual: Type: Evolution Model: 1R.9.36.126 - Neck Handling YEAR: 2013 Ref.: BielorussiaVasiliyNo ratings yet

- 23 3 16 Delcos XL L Serie en UkDocument80 pages23 3 16 Delcos XL L Serie en UkChris MurrayNo ratings yet

- Smart Power User Manual PDFDocument1,030 pagesSmart Power User Manual PDFAntonio Lucas100% (4)

- UHLMANN Blister Machine B 1240Document3 pagesUHLMANN Blister Machine B 1240Mahendra Putrianti Sasongko0% (1)

- Automatic Pet Stretch Blow MoldingDocument3 pagesAutomatic Pet Stretch Blow MoldingdivineengineeringNo ratings yet

- Lean Manufacturing Injection MoldingDocument0 pagesLean Manufacturing Injection MoldingPuneet KhatriNo ratings yet

- Sumitomo Global Network and All-Electric Injection Molding MachinesDocument8 pagesSumitomo Global Network and All-Electric Injection Molding MachinesRusmana Syamil0% (1)

- Arburg Hydraulic Allrounders 680472 en GBDocument16 pagesArburg Hydraulic Allrounders 680472 en GBPurece EugenNo ratings yet

- Operating Instructions: MCD 3000 Soft StarterDocument44 pagesOperating Instructions: MCD 3000 Soft StarterDragoslav DzolicNo ratings yet

- JSW Large Electric Injection Molding Machines Promote Higher Productivity & Energy SavingsDocument6 pagesJSW Large Electric Injection Molding Machines Promote Higher Productivity & Energy SavingsAlexi JuniorNo ratings yet

- Solanum Mexico Blister Packaging MachineDocument7 pagesSolanum Mexico Blister Packaging MachineHumberto GonzálezNo ratings yet

- Demag en PDFDocument36 pagesDemag en PDFaleskytronNo ratings yet

- Jetmaster c2 Series (268-408)Document140 pagesJetmaster c2 Series (268-408)EdgarNo ratings yet

- 45 1014 01Document31 pages45 1014 01Adam C. VeresNo ratings yet

- C2000 For Injection Molding MachineDocument11 pagesC2000 For Injection Molding Machineadilson_No ratings yet

- Blow MouldingDocument18 pagesBlow MouldingShaheen ArihaNo ratings yet

- SELOGICADocument16 pagesSELOGICAziroin van100% (1)

- Arburg Selogica 522776 en GB PDFDocument16 pagesArburg Selogica 522776 en GB PDFMohamed Mamdouh100% (1)

- Engel Service Manual - Machine: Serial No.: 167521 VC 750/150 TECHDocument164 pagesEngel Service Manual - Machine: Serial No.: 167521 VC 750/150 TECHЖеня Драчук100% (3)

- Plastic Vacuum Conveying AccessoriesDocument24 pagesPlastic Vacuum Conveying AccessoriesTony Cresicbene100% (1)

- Common Capper ProblemDocument8 pagesCommon Capper Problembebas PratomoNo ratings yet

- NC 5 Prezentare EngDocument33 pagesNC 5 Prezentare EngSolomon Bogdan-DanielNo ratings yet

- Arburg Thermoset 522948 en Gb-1Document12 pagesArburg Thermoset 522948 en Gb-1retnadiah354No ratings yet

- Aerospec 100Document3 pagesAerospec 100Nalin T BandaraNo ratings yet

- Starting Method of MotorsDocument9 pagesStarting Method of MotorsRanil FernandoNo ratings yet

- PEM-DD Manual 1.01 enDocument42 pagesPEM-DD Manual 1.01 enNalin T BandaraNo ratings yet

- Relative Turbidity Meter ITM-51: Food Product Information ITM-51 - ITM-51RDocument8 pagesRelative Turbidity Meter ITM-51: Food Product Information ITM-51 - ITM-51RNalin T BandaraNo ratings yet

- Peterson CoilDocument6 pagesPeterson CoilNalin T BandaraNo ratings yet

- Synchronous Generator Transient AnalysisDocument12 pagesSynchronous Generator Transient AnalysisRiyah_Rae100% (9)

- Brochure Topworx Discrete Valve Controllers Product Topworx en 82560Document32 pagesBrochure Topworx Discrete Valve Controllers Product Topworx en 82560Nalin T BandaraNo ratings yet

- Peterson CoilDocument6 pagesPeterson CoilNalin T BandaraNo ratings yet

- Peterson CoilDocument6 pagesPeterson CoilNalin T BandaraNo ratings yet

- Microwave Link DesignDocument69 pagesMicrowave Link DesignHell RiderNo ratings yet

- Macbeth SoliloquysDocument4 pagesMacbeth SoliloquysGavin RobinsonNo ratings yet

- Stochastic Calculus For Discontinuous ProcessesDocument20 pagesStochastic Calculus For Discontinuous Processesjulianli0220No ratings yet

- Complete List of Connectives and Discourse Markers For IELTS SpeakingDocument8 pagesComplete List of Connectives and Discourse Markers For IELTS SpeakingDanial Daghianoosi100% (1)

- Chemistry - Superscripts, Subscripts and Other Symbols For Use in Google DocsDocument2 pagesChemistry - Superscripts, Subscripts and Other Symbols For Use in Google DocsSandra Aparecida Martins E SilvaNo ratings yet

- The Relationship Between Psychology and LiteratureDocument4 pagesThe Relationship Between Psychology and LiteratureWiem Belkhiria0% (2)

- The Tales Themselves - An Overview by Dr. Anna ChallengerDocument15 pagesThe Tales Themselves - An Overview by Dr. Anna Challengerhimkeraditya100% (2)

- The Babylonian Lunar Three in CalendricaDocument17 pagesThe Babylonian Lunar Three in CalendricaJen AnyiNo ratings yet

- IJECE-Paper FormatDocument3 pagesIJECE-Paper FormatHeaven varghese C S C SNo ratings yet

- 4 Best Ways To Find Blocking Sessions in Oracle 11gDocument5 pages4 Best Ways To Find Blocking Sessions in Oracle 11gMa GodfreyNo ratings yet

- Question Forms Auxiliary VerbsDocument10 pagesQuestion Forms Auxiliary VerbsMer-maidNo ratings yet

- Ms Word: 1. Creating and Editing DocumentsDocument12 pagesMs Word: 1. Creating and Editing DocumentsTehreem FatimaNo ratings yet

- Handel's Early Experiences Shaped His Later Interest in JudaismDocument13 pagesHandel's Early Experiences Shaped His Later Interest in JudaismAlexandra WilsonNo ratings yet

- Red Hat Enterprise Virtualization 3.1 Administration Guide en USDocument374 pagesRed Hat Enterprise Virtualization 3.1 Administration Guide en USbangbus77No ratings yet

- Developing Macro Skills in Acompetence Based Curriculum Handout PDFDocument47 pagesDeveloping Macro Skills in Acompetence Based Curriculum Handout PDFHanieline EmanaNo ratings yet

- Job ApplicationDocument15 pagesJob ApplicationЮлияNo ratings yet

- Hazrat Shaikh Shah Kareem Allah Chisti Known As Ashiq Khaja Barkas HyderabadDocument53 pagesHazrat Shaikh Shah Kareem Allah Chisti Known As Ashiq Khaja Barkas HyderabadMohammed Abdul Hafeez, B.Com., Hyderabad, IndiaNo ratings yet

- Syllabus For Fundamentals of The Embedded Systems: Programming ExamplesDocument3 pagesSyllabus For Fundamentals of The Embedded Systems: Programming ExamplesvarshaNo ratings yet

- X++ RDP ReportDocument18 pagesX++ RDP ReportosamaanjumNo ratings yet

- Jove Empire and Caldari State Sov DataDocument97 pagesJove Empire and Caldari State Sov DatakrushnievaNo ratings yet

- Balkh and the Sasanians: Insights from Bactrian Economic DocumentsDocument21 pagesBalkh and the Sasanians: Insights from Bactrian Economic DocumentsDonna HallNo ratings yet

- Standard Form Categorical Propositions - Quantity, Quality, and DistributionDocument8 pagesStandard Form Categorical Propositions - Quantity, Quality, and DistributionMelese AbabayNo ratings yet

- CS302P - Sample PaperDocument10 pagesCS302P - Sample PaperMian GNo ratings yet

- Book The Kingdom Has ComeDocument70 pagesBook The Kingdom Has ComeAdeleke Babatunde100% (1)

- Logical Unit Number (LUN)Document1 pageLogical Unit Number (LUN)Shishir YadavNo ratings yet

- Advanced Excel Formulas and Functions GuideDocument12 pagesAdvanced Excel Formulas and Functions GuideVasanthKumar BudarpuNo ratings yet

- LaserCAD ManualDocument65 pagesLaserCAD ManualOlger NavarroNo ratings yet

- Panchanguli Devi Mantra To Forecast FutureDocument1 pagePanchanguli Devi Mantra To Forecast FutureHAREESHNo ratings yet

- Online Principal Transfer List 2021Document2 pagesOnline Principal Transfer List 2021PriyeshNo ratings yet

- Checklist of MOVs for Proficient TeachersDocument8 pagesChecklist of MOVs for Proficient TeachersEvelyn Esperanza AcaylarNo ratings yet

- Cambridge Assessment International Education: Food and Nutrition 0648/02 May/June 2019Document4 pagesCambridge Assessment International Education: Food and Nutrition 0648/02 May/June 2019Zoe NyaberekaNo ratings yet

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsFrom EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Perfume Engineering: Design, Performance and ClassificationFrom EverandPerfume Engineering: Design, Performance and ClassificationRating: 4 out of 5 stars4/5 (5)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Guidelines for Siting and Layout of FacilitiesFrom EverandGuidelines for Siting and Layout of FacilitiesNo ratings yet

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisFrom EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Guidelines for Developing Quantitative Safety Risk CriteriaFrom EverandGuidelines for Developing Quantitative Safety Risk CriteriaNo ratings yet

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Bow Ties in Risk Management: A Concept Book for Process SafetyFrom EverandBow Ties in Risk Management: A Concept Book for Process SafetyNo ratings yet

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet