Professional Documents

Culture Documents

Electrically Heated Systems: Defogger System

Uploaded by

Dalton WiseOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrically Heated Systems: Defogger System

Uploaded by

Dalton WiseCopyright:

Available Formats

ELECTRICALLY HEATED SYSTEMS

CONTENTS

page page

DEFOGGER SYSTEM . . . . . . . . . . . . . . . . . . . . . . . 1 HEATED SEATS . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

DEFOGGER SYSTEM

INDEX

page page

GENERAL INFORMATION

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 1

DESCRIPTION AND OPERATION

BODY CONTROL MODULE . . . . . . . . . . . . . . . . . 2

DEFOGGER RELAY . . . . . . . . . . . . . . . . . . . . . . . 2

DEFOGGER SWITCH . . . . . . . . . . . . . . . . . . . . . . 2

OUTSIDE MIRROR HEATING GRID . . . . . . . . . . . 2

REAR GLASS HEATING GRID . . . . . . . . . . . . . . . 1

DIAGNOSIS AND TESTING

DEFOGGER RELAY . . . . . . . . . . . . . . . . . . . . . . . 4

DEFOGGER SWITCH . . . . . . . . . . . . . . . . . . . . . . 4

REAR GLASS HEATING GRID . . . . . . . . . . . . . . . 3

REAR WINDOW DEFOGGER SYSTEM . . . . . . . . 3

SERVICE PROCEDURES

REAR GLASS HEATING GRID REPAIR . . . . . . . . 5

REMOVAL AND INSTALLATION

DEFOGGER RELAY . . . . . . . . . . . . . . . . . . . . . . . 6

DEFOGGER SWITCH . . . . . . . . . . . . . . . . . . . . . . 6

GENERAL INFORMATION

INTRODUCTION

An el ectri cal l y heated rear wi ndow defogger and

el ectri cal l y heated outsi de rear vi ew mi rrors are

standard factory-i nstal l ed equi pment on thi s model .

The defogger wi l l onl y operate when the i gni ti on

swi tch i s i n the On posi ti on. When the defogger

swi tch i s i n the On posi ti on, el ectri c heater gri ds on

the rear wi ndow gl ass and behi nd the outsi de rear

vi ew mi rror gl ass are energi zed. These gri ds produce

heat to hel p cl ear the rear wi ndow gl ass and outsi de

rear vi ew mi rrors of i ce, snow, or fog.

Thi s defogger system i s control l ed by a swi tch

l ocated i nboard of the steeri ng col umn i n the i nboard

swi tch pod on the i nstrument panel . A Li ght-Emi t-

ti ng Di ode (LED) above the swi tch button i n the

swi tch pod wi l l l i ght to i ndi cate when the defogger

system i s turned on. The Body Control Modul e

(BCM), whi ch contai ns the defogger system ti mer

l ogi c, moni tors the state of the defogger swi tch

through a hard-wi red i nput. The BCM ci rcui try con-

trol s the defogger system through a hard-wi red con-

trol output to the defogger rel ay.

The defogger system wi l l be automati cal l y turned

off after a programmed ti me i nterval of about ten

mi nutes. After the i ni ti al ti med i nterval has expi red,

i f the defogger swi tch i s turned on agai n duri ng the

same i gni ti on cycl e, the defogger system wi l l auto-

mati cal l y turn off after about fi ve mi nutes.

The defogger system wi l l automati cal l y shut off i f

the i gni ti on swi tch i s turned to the Off posi ti on, or i t

can be turned off manual l y by depressi ng the i nstru-

ment panel swi tch. Refer to the owners manual for

more i nformati on on the defogger system control s

and operati on.

Fol l owi ng are general descri pti ons of the major

components i n the defogger system. Refer to 8W-48 -

Rear Wi ndow Defogger and 8W-62 - Power Mi rrors i n

Group 8W - Wi ri ng Di agrams for compl ete ci rcui t

descri pti ons and di agrams.

DESCRIPTION AND OPERATION

REAR GLASS HEATING GRID

The heated rear wi ndow gl ass has two el ectri cal l y

conducti ve verti cal bus bars and a seri es of hori zon-

tal gri d l i nes made of a si l ver-cerami c materi al ,

whi ch i s baked on and bonded to the i nsi de surface of

the gl ass. The gri d l i nes and bus bars compri se a

paral l el el ectri cal ci rcui t.

ZJ ELECTRICALLY HEATED SYSTEMS 8N - 1

When the rear wi ndow defogger swi tch i s pl aced i n

the On posi ti on, el ectri cal current i s di rected to the

rear wi ndow gri d l i nes through the bus bars. The

gri d l i nes heat the rear wi ndow to cl ear the surface

of fog or snow. Protecti on for the heated gri d ci rcui t

i s provi ded by a fuse i n the juncti on bl ock.

The gri d l i nes and bus bars are hi ghl y resi stant to

abrasi on. However, i t i s possi bl e for an open ci rcui t

to occur i n an i ndi vi dual gri d l i ne, resul ti ng i n no

current fl ow through the l i ne.

The gri d l i nes can be damaged or scraped off wi th

sharp i nstruments. Care shoul d be taken when cl ean-

i ng the gl ass or removi ng forei gn materi al s, decal s,

or sti ckers from the gl ass. Normal gl ass cl eani ng sol -

vents or hot water used wi th rags or towel i ng i s rec-

ommended.

A repai r ki t i s avai l abl e to repai r the gri d l i nes and

bus bars, or to rei nstal l the heated gl ass spade ter-

mi nal s.

OUTSIDE MIRROR HEATING GRID

Vehi cl es equi pped wi th the opti onal heated mi rror

package have an el ectri c heati ng gri d l ocated behi nd

the mi rror gl ass of each outsi de rear vi ew mi rror.

The heated mi rrors are control l ed by the rear wi n-

dow defogger swi tch. El ectri cal current i s di rected to

the heati ng gri d i nsi de the mi rror onl y when the rear

wi ndow defogger swi tch i s i n the On posi ti on.

I f the outsi de mi rror heati ng gri ds and rear wi n-

dow heati ng gri d are both i noperati ve, di agnosi s of

the rear wi ndow defogger system shoul d be per-

formed as descri bed i n thi s group. I f the outsi de mi r-

ror heati ng gri ds are i noperati ve, but the rear

wi ndow heati ng gri d i s operati ng as desi gned, refer

to Group 8T - Power Mi rror Systems for the di agno-

si s of the mi rror.

The heati ng gri d behi nd each outsi de mi rror gl ass

cannot be repai red and, i f faul ty or damaged, the

enti re mi rror uni t must be repl aced. Refer to Group

8T - Power Mi rror Systems for the power mi rror ser-

vi ce procedures.

DEFOGGER SWITCH

The rear wi ndow defogger swi tch i s mounted i n the

i nboard i nstrument panel swi tch pod, i nboard of the

steeri ng col umn. The momentary-type swi tch pro-

vi des a hard-wi red ground si gnal to the Body Control

Modul e (BCM) each ti me i t i s depressed. The BCM

rear wi ndow defogger ti mer and l ogi c ci rcui try

responds by energi zi ng or de-energi zi ng the rear wi n-

dow defogger rel ay.

Energi zi ng the rear wi ndow defogger rel ay pro-

vi des el ectri cal current to the rear wi ndow defogger

gri d and the Li ght-Emi tti ng Di ode (LED) i ndi cator i n

the swi tch, whi ch l i ghts to i ndi cate when the defog-

ger system i s turned On. The defogger swi tch and

LED cannot be repai red and, i f faul ty, the i nboard

swi tch pod uni t must be repl aced.

DEFOGGER RELAY

The rear wi ndow defogger rel ay i s a I nternati onal

Standards Organi zati on (I SO)-type rel ay. The rear

wi ndow defogger rel ay i s a el ectromechani cal devi ce

that swi tches fused battery current to the rear gl ass

heati ng gri d and the Li ght-Emi tti ng Di ode (LED)

i ndi cator of the defogger swi tch, when the Body Con-

trol Modul e (BCM) rear wi ndow defogger ti mer and

l ogi c ci rcui try grounds the rel ay coi l . See the Di agno-

si s and Testi ng secti on of thi s group for more i nfor-

mati on on the operati on of the rear wi ndow defogger

rel ay.

The rear wi ndow defogger rel ay i s l ocated i n the

juncti on bl ock, on the ri ght cowl si de i nner panel

bel ow the i nstrument panel i n the passenger com-

partment.

The rear wi ndow defogger rel ay cannot be repai red

and, i f faul ty or damaged, i t must be repl aced.

BODY CONTROL MODULE

A Body Control Modul e (BCM) i s used on thi s

model to control and i ntegrate many of the el ectroni c

functi ons and features i ncl uded on the vehi cl e. The

BCM contai ns a central processi ng uni t and i nter-

faces wi th other modul es i n the vehi cl e on the

Chrysl er Col l i si on Detecti on (CCD) data bus network.

The CCD data bus network al l ows the shari ng of

sensor i nformati on. Thi s hel ps to reduce wi re har-

ness compl exi ty, reduce i nternal control l er hardware,

and reduce component sensor current l oads. At the

same ti me, thi s system provi des i ncreased rel i abi l i ty,

enhanced di agnosti cs, and al l ows the addi ti on of

many new feature capabi l i ti es.

One of the systems that the BCM supports and

control s, i s the rear wi ndow defogger system. I n i ts

rol e as the defogger system ti mer and control l er, the

BCM recei ves hard-wi red i nputs from the defogger

swi tch and the i gni ti on swi tch. The programmi ng i n

the BCM al l ows i t to process the i nformati on from

these i nputs and send a control output to energi ze or

de-energi ze the defogger rel ay. The BCM al so sends a

defogger swi tch status message to the Dri ver Door

Modul e (DDM) and Passenger Door Modul e (PDM)

on the CCD data bus. The DDM and PDM respond

by control l i ng the current feeds to thei r respecti ve

outsi de rear vi ew mi rror heati ng el ements.

The BCM i s mounted under the dri ver si de out-

board end of the i nstrument panel , behi nd the i nstru-

ment panel support armature and bel ow the

outboard swi tch pod. Refer to Group 8E - I nstrument

Panel Systems for the removal and i nstal l ati on pro-

cedures. For di agnosi s of the BCM or the CCD data

bus, the use of a DRB scan tool and the proper Di ag-

8N - 2 ELECTRICALLY HEATED SYSTEMS ZJ

DESCRIPTION AND OPERATION (Continued)

nosti c Procedures manual are recommended. The

BCM can onl y be servi ced by an authori zed el ectroni c

repai r stati on. Refer to the l atest Warranty Pol i ci es

and Procedures manual for a current l i sti ng of autho-

ri zed el ectroni c repai r stati ons.

DIAGNOSIS AND TESTING

REAR WINDOW DEFOGGER SYSTEM

For ci rcui t descri pti ons and di agrams, refer to

8W-48 - Rear Wi ndow Defogger i n Group 8W - Wi r-

i ng Di agrams. The operati on of the el ectri cal l y

heated rear wi ndow defogger system can be con-

fi rmed i n one of the fol l owi ng manners:

1. Turn the i gni ti on swi tch to the On posi ti on.

Whi l e moni tori ng the i nstrument panel vol tmeter, set

the defogger swi tch i n the On posi ti on. When the

defogger swi tch i s turned On, a di sti nct vol tmeter

needl e defl ecti on shoul d be noted.

2. Turn the i gni ti on swi tch to the On posi ti on. Set

the defogger swi tch i n the On posi ti on. The rear wi n-

dow defogger operati on can be checked by feel i ng the

rear wi ndow or outsi de rear vi ew mi rror gl ass. A di s-

ti nct di fference i n temperature between the gri d l i nes

and the adjacent cl ear gl ass or the mi rror gl ass can

be detected wi thi n three to four mi nutes of operati on.

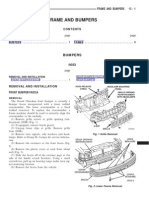

3. Usi ng a 12-vol t DC vol tmeter, contact the rear

gl ass heati ng gri d termi nal A (ri ght si de) wi th the

negati ve l ead, and termi nal B (l eft si de) wi th the pos-

i ti ve l ead (Fi g. 1). The vol tmeter shoul d read battery

vol tage.

The above checks wi l l confi rm system operati on.

I l l umi nati on of the defogger swi tch LED means that

there i s el ectri cal current avai l abl e at the output of

the defogger rel ay, but does not confi rm that the el ec-

tri cal current i s reachi ng the rear gl ass heati ng gri d

l i nes.

I f the defogger system does not operate, the prob-

l em shoul d be i sol ated i n the fol l owi ng manner:

(1) Confi rm that the i gni ti on swi tch i s i n the On

posi ti on.

(2) Ensure that the rear gl ass heati ng gri d feed

and ground wi res are connected to the gl ass. Confi rm

that the ground wi re has conti nui ty to ground.

(3) Check the fuses i n the Power Di stri buti on Cen-

ter (PDC) and i n the juncti on bl ock. The fuses must

be ti ght i n thei r receptacl es and al l el ectri cal connec-

ti ons must be secure.

When the above steps have been compl eted and the

rear gl ass heati ng gri d i s sti l l i noperati ve, one or

more of the fol l owi ng i s faul ty:

Defogger swi tch

Defogger rel ay

Body Control Modul e (BCM)

Rear wi ndow gri d l i nes (al l gri d l i nes woul d

have to be broken or one of the feed wi res di scon-

nected for the enti re system to be i noperati ve).

When the above steps have been compl eted and the

heated mi rror gl ass heati ng el ement i s sti l l i nopera-

ti ve, one or more of the fol l owi ng i s faul ty:

Body Control Modul e (BCM)

Chrysl er Col l i si on Detecti on (CCD) data bus

Dri ver or passenger door modul e

Outsi de rear vi ew mi rror heati ng el ements.

I f setti ng the defogger swi tch to the On posi ti on

produces a severe vol tmeter defl ecti on, check for a

short ci rcui t between the defogger rel ay output and

the rear gl ass heati ng gri d.

REAR GLASS HEATING GRID

For ci rcui t descri pti ons and di agrams, refer to

8W-48 - Rear Wi ndow Defogger i n Group 8W - Wi r-

i ng Di agrams. To detect breaks i n the gri d l i nes, the

fol l owi ng procedure i s requi red:

(1) Turn the i gni ti on swi tch to the On posi ti on. Set

the defogger swi tch i n the On posi ti on. The i ndi cator

l amp shoul d l i ght. I f OK, go to Step 2. I f not OK, see

the Defogger Rel ay di agnosi s i n thi s group.

(2) Usi ng a 12-vol t DC vol tmeter, contact the ver-

ti cal bus bar on the ri ght si de of the vehi cl e wi th the

negati ve l ead. Wi th the posi ti ve l ead, contact the ver-

ti cal bus bar on the l eft si de of the vehi cl e. The vol t-

meter shoul d read battery vol tage. I f OK, go to Step

3. I f not OK, repai r the open ci rcui t to the defogger

rel ay as requi red.

(3) Wi th the negati ve l ead of the vol tmeter, contact

a good body ground poi nt. The vol tage readi ng shoul d

not change. I f OK, go to Step 4. I f not OK, repai r the

ci rcui t to ground as requi red.

(4) Connect the negati ve l ead of the vol tmeter to

the ri ght si de bus bar and touch each gri d l i ne at

mi dpoi nt C wi th the posi ti ve l ead. A readi ng of

approxi matel y si x vol ts i ndi cates a l i ne i s good. A

readi ng of zero vol ts i ndi cates a break i n the gri d

l i ne between mi dpoi nt C and the l eft si de bus bar. A

Fig. 1 Rear Window Glass Grid Test

ZJ ELECTRICALLY HEATED SYSTEMS 8N - 3

DESCRIPTION AND OPERATION (Continued)

readi ng of ten to fourteen vol ts i ndi cates a break

between mi dpoi nt C and the ri ght si de bus bar. Move

the posi ti ve l ead on the gri d l i ne towards the break

and the vol tage readi ng wi l l change as soon as the

break i s crossed.

DEFOGGER SWITCH

For ci rcui t descri pti ons and di agrams, refer to

8W-48 - Rear Wi ndow Defogger i n Group 8W - Wi r-

i ng Di agrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Di sconnect and i sol ate the battery negati ve

cabl e. Remove the i nboard i nstrument panel swi tch

pod and unpl ug the swi tch pod 10-way wi re harness

connector.

(2) Check for conti nui ty between the ground ci r-

cui t cavi ty of the swi tch pod 10-way wi re harness

connector and a good ground. There shoul d be conti -

nui ty. I f OK, go to Step 3. I f not OK, repai r the open

ci rcui t as requi red.

(3) Connect two jumper wi res to the i nboard

swi tch pod. Connect one jumper from the ground ci r-

cui t termi nal i n the 10-way wi re harness connector

receptacl e on the back of the i nboard swi tch pod

housi ng to a good ground. Connect the other jumper

from the fused rear wi ndow defogger rel ay output ci r-

cui t termi nal of the 10-way wi re harness connector

receptacl e to a 12-vol t battery feed. The defogger

swi tch LED i ndi cator shoul d l i ght. I f OK, go to Step

4. I f not OK, repl ace the faul ty i nboard swi tch pod.

(4) Check for conti nui ty between the ground ci r-

cui t and rear wi ndow defogger swi tch sense ci rcui t

termi nal s of the 10-way wi re harness connector

receptacl e on the back of the i nboard swi tch pod

housi ng. There shoul d be momentary conti nui ty as

the defogger swi tch button i s depressed, and then no

conti nui ty. I f OK, go to Step 5. I f not OK, repl ace the

faul ty i nboard swi tch pod.

(5) Unpl ug the whi te 24-way wi re harness connec-

tor from the Body Control Modul e (BCM). Check for

conti nui ty between the rear wi ndow defogger swi tch

sense ci rcui t cavi ty of the i nboard swi tch pod 10-way

wi re harness connector and a good ground. There

shoul d be no conti nui ty. I f OK, go to Step 6. I f not

OK, repai r the short ci rcui t as requi red.

(6) Check for conti nui ty between the rear wi ndow

defogger swi tch sense ci rcui t cavi ti es of the i nboard

swi tch pod 10-way wi re harness connector and the

BCM whi te 24-way wi re harness connector. There

shoul d be conti nui ty. I f OK, see the Defogger Rel ay

di agnosi s i n thi s group. I f not OK, repai r the open

ci rcui t as requi red.

DEFOGGER RELAY

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

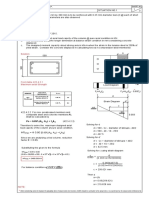

RELAY TEST

The defogger rel ay (Fi g. 2) i s l ocated i n the junc-

ti on bl ock, on the ri ght cowl si de i nner panel bel ow

the i nstrument panel i n the passenger compartment.

Remove the defogger rel ay from the juncti on bl ock to

perform the fol l owi ng tests:

(1) A rel ay i n the de-energi zed posi ti on shoul d

have conti nui ty between termi nal s 87A and 30, and

no conti nui ty between termi nal s 87 and 30. I f OK, go

to Step 2. I f not OK, repl ace the faul ty rel ay.

(2) Resi stance between termi nal s 85 and 86 (el ec-

tromagnet) shoul d be 75 10 ohms. I f OK, go to

Step 3. I f not OK, repl ace the faul ty rel ay.

(3) Connect a battery to termi nal s 85 and 86.

There shoul d now be conti nui ty between termi nal s

30 and 87, and no conti nui ty between termi nal s 87A

and 30. I f OK, see the Rel ay Ci rcui t Test i n thi s

group. I f not OK, repl ace the faul ty rel ay.

Fig. 2 Defogger Relay

8N - 4 ELECTRICALLY HEATED SYSTEMS ZJ

DIAGNOSIS AND TESTING (Continued)

RELAY CIRCUIT TEST

(1) The rel ay common feed termi nal cavi ty (30) i s

connected to battery vol tage and shoul d be hot at al l

ti mes. I f OK, go to Step 2. I f not OK, repai r the open

ci rcui t to the PDC fuse as requi red.

(2) The rel ay normal l y cl osed termi nal (87A) i s

connected to termi nal 30 i n the de-energi zed posi ti on,

but i s not used for thi s appl i cati on. Go to Step 3.

(3) The rel ay normal l y open termi nal (87) i s con-

nected to the common feed termi nal (30) i n the ener-

gi zed posi ti on. Thi s termi nal suppl i es battery vol tage

to the fuse i n the juncti on bl ock that feeds the rear

gl ass heati ng gri d and the defogger swi tch LED i ndi -

cator. There shoul d be conti nui ty between the cavi ty

for rel ay termi nal 87 and the rear gl ass heati ng gri d

and defogger swi tch LED i ndi cator at al l ti mes. I f

OK, go to Step 4. I f not OK, repai r the open ci rcui t

as requi red.

(4) The coi l battery termi nal (86) i s connected to

the el ectromagnet i n the rel ay. I t i s connected to bat-

tery vol tage and shoul d be hot at al l ti mes. Check for

battery vol tage at the cavi ty for rel ay termi nal 86. I f

OK, go to Step 5. I f not OK, repai r the open ci rcui t to

the PDC fuse as requi red.

(5) The coi l ground termi nal (85) i s connected to

the el ectromagnet i n the rel ay. Thi s termi nal i s pro-

vi ded wi th ground by the Body Control Modul e

(BCM) rear wi ndow defogger ti mer and l ogi c ci rcui try

to energi ze the defogger rel ay. There shoul d be conti -

nui ty to the rear wi ndow defogger rel ay control ci r-

cui t cavi ty of the whi te 24-way BCM wi re harness

connector. I f OK, use a DRB scan tool and the proper

Di agnosti c Procedures manual to test the BCM. I f

not OK, repai r the open ci rcui t as requi red.

SERVICE PROCEDURES

REAR GLASS HEATING GRID REPAIR

Repai r of the rear gl ass heati ng gri d l i nes, bus

bars, termi nal s or pi gtai l wi res can be accompl i shed

usi ng a Mopar Rear Wi ndow Defogger Repai r Ki t

(P/N 4267922) or equi val ent.

WARNING: MATERIALS CONTAINED IN THE

REPAIR KIT MAY CAUSE SKIN OR EYE IRRITATION.

THE KIT CONTAINS EPOXY RESIN AND AMINE

TYPE HARDENER, WHICH ARE HARMFUL IF SWAL-

LOWED. AVOID CONTACT WITH THE SKIN AND

EYES. FOR SKIN CONTACT, WASH THE AFFECTED

AREAS WITH SOAP AND WATER. FOR CONTACT

WITH THE EYES, FLUSH WITH PLENTY OF WATER.

DO NOT TAKE INTERNALLY. IF TAKEN INTER-

NALLY, INDUCE VOMITING AND CALL A PHYSICIAN

IMMEDIATELY. USE WITH ADEQUATE VENTILA-

TION. DO NOT USE NEAR FIRE OR FLAME. CON-

TAINS FLAMMABLE SOLVENTS. KEEP OUT OF THE

REACH OF CHILDREN.

(1) Mask the repai r area so that the conducti ve

epoxy can be appl i ed neatl y. Extend the epoxy appl i -

cati on onto the gri d l i ne or the bus bar on each si de

of the break (Fi g. 3).

(2) Fol l ow the i nstructi ons i n the repai r ki t for

prepari ng the damaged area.

(3) Remove the package separator cl amp and mi x

the two conducti ve epoxy components thoroughl y

wi thi n the packagi ng. Fol d the package i n hal f and

cut the center corner to di spense the epoxy.

(4) For gri d l i ne repai rs, mask the area to be

repai red wi th maski ng tape or a templ ate.

(5) Appl y the epoxy through the sl i t i n the mask-

i ng tape or templ ate. Overl ap both ends of the break

by at l east 19 mm (0.75 i n.).

(6) For a termi nal or pi gtai l wi re repl acement,

mask the adjacent areas so the epoxy can be

extended onto the adjacent gri d l i ne as wel l as the

bus bar. Appl y a thi n l ayer of epoxy to the area

where the termi nal or pi gtai l wi re was fastened and

onto the adjacent gri d l i ne.

(7) Appl y a thi n l ayer of conducti ve epoxy to the

termi nal or bare wi re end of the pi gtai l and pl ace i t

i n the proper l ocati on on the bus bar. To prevent the

termi nal or pi gtai l wi re from movi ng whi l e the epoxy

i s curi ng, i t must be wedged or cl amped.

(8) Careful l y remove the maski ng tape or tem-

pl ate.

CAUTION: Do not allow the glass surface to exceed

204 C (400 F) or the glass may fracture.

(9) Al l ow the epoxy to cure 24 hours at room tem-

perature, or use a heat gun wi th a 260 to 371 C

(500 to 700 F) range for fi fteen mi nutes. Hol d the

heat gun approxi matel y 25.4 cm (10 i n.) from the

repai r.

(10) After the conducti ve epoxy i s properl y cured,

remove the wedge or cl amp from the termi nal or pi g-

Fig. 3 Grid Line Repair - Typical

ZJ ELECTRICALLY HEATED SYSTEMS 8N - 5

DIAGNOSIS AND TESTING (Continued)

tai l wi re. Do not attach the wi re harness connectors

unti l the curi ng process i s compl ete.

(11) Check the operati on of the rear wi ndow defog-

ger gl ass heati ng gri d.

REMOVAL AND INSTALLATION

DEFOGGER SWITCH

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Di sconnect and i sol ate the battery negati ve

cabl e.

(2) Usi ng a tri m sti ck or another sui tabl e wi de

fl at-bl aded tool , pry gentl y around the peri meter

edges of the i nboard swi tch pod bezel to rel ease the

snap cl i p retai ners. Remove the bezel from the

i nstrument panel .

(3) Remove the three screws that secure the

i nboard swi tch pod to the i nstrument panel (Fi g. 4).

(4) Pul l the i nboard swi tch pod out from the

i nstrument panel far enough to access and unpl ug

the wi re harness connectors.

(5) Remove the i nboard swi tch pod from the

i nstrument panel .

(6) Reverse the removal procedures to i nstal l .

Ti ghten the swi tch mounti ng screws to 2.2 Nm (20

i n. l bs.).

DEFOGGER RELAY

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Di sconnect and i sol ate the battery negati ve

cabl e.

(2) Remove the fuse access panel by unsnappi ng i t

from the ri ght cowl si de tri m panel .

(3) Remove the push nut that secures the ri ght

cowl si de tri m panel to the juncti on bl ock stud (Fi g.

5).

(4) Remove the two screws that secure the ri ght

cowl si de tri m panel to the ri ght front door openi ng

tri m.

(5) Remove the ri ght cowl si de tri m panel from the

ri ght cowl si de i nner panel .

(6) Unpl ug the defogger rel ay from the juncti on

bl ock.

(7) I nstal l the defogger rel ay by al i gni ng the rel ay

termi nal s wi th the cavi ti es i n the juncti on bl ock and

pushi ng the rel ay fi rml y i nto pl ace.

(8) Connect the battery negati ve cabl e.

(9) Test the rel ay operati on.

(10) I nstal l the ri ght cowl si de tri m panel and the

fuse access panel .

Fig. 4 Inboard Switch Pod Remove/Install

Fig. 5 Right Cowl Side Trim Panel Remove/Install

8N - 6 ELECTRICALLY HEATED SYSTEMS ZJ

SERVICE PROCEDURES (Continued)

HEATED SEATS

INDEX

page page

GENERAL INFORMATION

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 7

DESCRIPTION AND OPERATION

HEATED SEAT CONTROL MODULE . . . . . . . . . . . 7

HEATED SEAT ELEMENT AND SENSOR . . . . . . . 8

HEATED SEAT SWITCH . . . . . . . . . . . . . . . . . . . . 7

DIAGNOSIS AND TESTING

HEATED SEAT CONTROL MODULE . . . . . . . . . . . 9

HEATED SEAT ELEMENT . . . . . . . . . . . . . . . . . . 9

HEATED SEAT SENSOR . . . . . . . . . . . . . . . . . . . 9

HEATED SEAT SWITCH . . . . . . . . . . . . . . . . . . . . 8

HEATED SEAT SYSTEM . . . . . . . . . . . . . . . . . . . 8

REMOVAL AND INSTALLATION

HEATED SEAT CONTROL MODULE . . . . . . . . . . 10

HEATED SEAT SWITCH . . . . . . . . . . . . . . . . . . . . 9

GENERAL INFORMATION

INTRODUCTION

I ndi vi dual l y control l ed el ectri cal l y heated front

seats are avai l abl e factory-i nstal l ed opti onal equi p-

ment on thi s model . The seat heaters wi l l onl y oper-

ate when the i gni ti on swi tch i s i n the On posi ti on,

and the surface temperature at the front seat heati ng

el ement sensors i s bel ow the desi gned temperature

set poi nts of the system. The heated seat system wi l l

not operate i n ambi ent temperatures greater than

about 32 C (90 F).

There are separate three-posi ti on swi tches for each

front seat l ocated i n the i nboard i nstrument panel

swi tch pod, just i nboard of the steeri ng col umn. An

Off, Low, or Hi gh posi ti on can be sel ected wi th each

swi tch, and Li ght-Emi tti ng Di odes (LED) for each

swi tch i l l umi nate to gi ve a vi sual i ndi cati on that the

system i s turned on. The Low heat posi ti on set poi nt

i s about 32 C (90 F), and the Hi gh heat posi ti on set

poi nt i s about 38 C (100 F). Each swi tch control s a

Heated Seat Control Modul e (HSCM) mounted to the

seat cushi on frame under each front seat.

When a seat heater i s turned on, a sensor l ocated

near the seat cushi on el ectri c heater el ement pro-

vi des the HSCM wi th an i nput i ndi cati ng the surface

temperature of the seat cushi on. I f the surface tem-

perature i nput i s bel ow the temperature set poi nt for

the sel ected Low or Hi gh swi tch posi ti on, a rel ay

wi thi n the HSCM energi zes the heati ng el ements i n

the seat cushi on and back. When the sensor i nput

i ndi cates the correct temperature set poi nt has been

achi eved, the HSCM de-energi zes the rel ay. The

HSCM wi l l conti nue to cycl e the rel ay as needed to

mai ntai n the temperature set poi nt.

The HSCM wi l l automati cal l y turn off the heati ng

el ements i f i t detects an open i n the sensor ci rcui t, or

a short i n the heati ng el ement ci rcui t causi ng an

excessi ve current draw. The system i s al so turned off

automati cal l y when the i gni ti on swi tch i s turned to

the Off posi ti on. The control ci rcui t operates on i gni -

ti on swi tched battery feed through a fuse i n the junc-

ti on bl ock. The heati ng el ements operate on battery

feed suppl i ed through the power seat ci rcui t breaker

i n the juncti on bl ock.

Fol l owi ng are general descri pti ons of the major

components i n the heated seat system. Refer to

8W-63 - Power Seat Wi th Heated Seats i n Group 8W

- Wi ri ng Di agrams for compl ete ci rcui t descri pti ons

and di agrams.

DESCRIPTION AND OPERATION

HEATED SEAT SWITCH

The heated seat swi tch i s i ntegral to the i nboard

swi tch pod, whi ch i s mounted i n the i nstrument

panel just i nboard of the steeri ng col umn. The two

three-posi ti on sl i di ng-type swi tches, one swi tch for

each front seat, provi de a resi stor mul ti pl exed si gnal

to thei r respecti ve Heated Seat Control Modul e

(HSCM). Each swi tch has an Off, Low, and Hi gh

posi ti on so that both the dri ver and the front seat

passenger can sel ect a preferred seat heati ng mode.

Each swi tch has a Li ght-Emi tti ng Di ode (LED),

whi ch l i ghts to i ndi cate that the heater for the seat

that the swi tch control s i s turned on. The heated

seat swi tches and thei r LED cannot be repai red. I f

ei ther swi tch or LED i s faul ty, the i nboard swi tch

pod uni t must be repl aced.

HEATED SEAT CONTROL MODULE

The Heated Seat Control Modul e (HSCM) i s an

el ectroni c thermostati c modul e desi gned to operate

the el ectri c seat heater el ements. Two modul es are

used i n the vehi cl e, one for each front seat. The

HSCM for each seat i s i nstal l ed i n a wi re harness

connector that i s l ocated under the seat cushi on

spri ng. The wi re harness connector i s secured by an

ZJ ELECTRICALLY HEATED SYSTEMS 8N - 7

i ntegral cl i p to the i nsi de surface of the outboard seat

cushi on frame.

I nputs to the modul e i ncl ude the i nstrument panel

resi stor mul ti pl exed swi tch si gnal s (whi ch i ncl udes

the seat cushi on temperature sensor ci rcui ts), an

i gni ti on-swi tched battery feed, a non-swi tched bat-

tery feed, and a ground. The onl y HSCM output i s

the feed for the seat heati ng el ements.

The HSCM cannot be repai red and, i f faul ty or

damaged, i t must be repl aced.

HEATED SEAT ELEMENT AND SENSOR

Two heated seat heati ng el ements are used i n each

front seat, one for the seat cushi on and the other for

the seat back. The two el ements for each seat are

connected i n seri es wi th the HSCM.

The temperature sensor i s a Negati ve Temperature

Coeffi ci ent (NTC) thermi stor. One temperature sen-

sor i s used for each seat, and i t i s i ntegrated i nto the

seat cushi on heati ng el ement.

The heati ng el ements are sewn i nto the seat cush-

i on cover and seat back cover assembl i es, whi ch are

servi ced i ndi vi dual l y. The heati ng el ements and tem-

perature sensor cannot be repai red and, i f faul ty or

damaged, the affected seat cover assembl y must be

repl aced. Refer to Group 23 - Body for the seat cush-

i on cover and seat back cover servi ce procedures.

DIAGNOSIS AND TESTING

HEATED SEAT SYSTEM

For ci rcui t descri pti ons and di agrams, refer to

8W-63 - Power Seat Wi th Heated Seats i n Group 8W

- Wi ri ng Di agrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Before testi ng the i ndi vi dual components i n the

heated seat system, check the fol l owi ng:

I f the heated seat swi tch LED doesnt l i ght wi th

the i gni ti on swi tch i n the On posi ti on and the heated

seat swi tch i n the Low or Hi gh posi ti on, check the

fuse i n the juncti on bl ock. I f the fuse i s OK, test the

heated seat swi tch as descri bed i n thi s group. I f not

OK, repai r the shorted ci rcui t or component as

requi red and repl ace the faul ty fuse.

I f the heated seat swi tch LED l i ghts, but the

heati ng el ements dont heat, check the ci rcui t

breaker i n the juncti on bl ock. I f the ci rcui t breaker i s

OK, test the heated seat el ements as descri bed i n

thi s group. I f not OK, repl ace the faul ty ci rcui t

breaker.

HEATED SEAT SWITCH

For ci rcui t descri pti ons and di agrams, refer to

8W-63 - Power Seat Wi th Heated Seats i n Group 8W

- Wi ri ng Di agrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Di sconnect and i sol ate the battery negati ve

cabl e.

(2) Remove the i nboard swi tch pod from the

i nstrument panel . Check for conti nui ty between the

ground ci rcui t cavi ty of the 10-way swi tch pod wi re

harness connector and a good ground. There shoul d

be conti nui ty. I f OK, go to Step 3. I f not OK, repai r

the open ci rcui t as requi red.

(3) Connect the battery negati ve cabl e. Turn the

i gni ti on swi tch to the On posi ti on. Check for battery

vol tage at the fused i gni ti on swi tch output ci rcui t

cavi ty of the 10-way swi tch pod wi re harness connec-

tor. I f OK, turn the i gni ti on swi tch to the Off posi -

ti on, di sconnect and i sol ate the battery negati ve

cabl e, and go to Step 4. I f not OK, repai r the open

ci rcui t as requi red.

(4) Wi th both heated seat swi tches i n the Off posi -

ti on, check for conti nui ty between the fused i gni ti on

swi tch output ci rcui t termi nal and the dri ver heated

seat swi tch output ci rcui t termi nal i n the 10-way

connector receptacl e on the back of the i nboard

swi tch pod. Repeat thi s check between the fused i gni -

ti on swi tch output ci rcui t termi nal and the passenger

heated seat swi tch output ci rcui t termi nal . I n each

case, there shoul d be no conti nui ty. I f OK, go to Step

5. I f not OK, repl ace the faul ty i nboard swi tch pod.

(5) Move both heated seat swi tches to the Low

posi ti on. Usi ng an ohmmeter, check the resi stance

between the fused i gni ti on swi tch output ci rcui t ter-

mi nal and the dri ver heated seat swi tch output ci r-

cui t termi nal i n the 10-way connector receptacl e on

the back of the i nboard swi tch pod. Repeat thi s check

between the fused i gni ti on swi tch output ci rcui t ter-

mi nal and the passenger heated seat swi tch output

ci rcui t termi nal . I n each case, the resi stance readi ng

shoul d be about 11.5 ki l ohms. I f OK, go to Step 6. I f

not OK, repl ace the faul ty i nboard swi tch pod.

8N - 8 ELECTRICALLY HEATED SYSTEMS ZJ

DESCRIPTION AND OPERATION (Continued)

(6) Move both heated seat swi tches to the Hi gh

posi ti on. Usi ng an ohmmeter, check the resi stance

between the fused i gni ti on swi tch output ci rcui t ter-

mi nal and the dri ver heated seat swi tch output ci r-

cui t termi nal i n the 10-way connector receptacl e on

the back of the i nboard swi tch pod. Repeat thi s check

between the fused i gni ti on swi tch output ci rcui t ter-

mi nal and the passenger heated seat swi tch output

ci rcui t termi nal . I n each case, the resi stance readi ng

shoul d be about 6.5 ki l ohms. I f not OK, repl ace the

faul ty i nboard swi tch pod.

HEATED SEAT CONTROL MODULE

Before testi ng the heated seat control modul e, test

the heated seat swi tch, the heated seat el ements, and

the heated seat sensor as descri bed i n thi s group. I f

testi ng of the heated seat swi tch, el ements, and sen-

sor reveal s no probl ems, proceed as fol l ows. For ci r-

cui t descri pti ons and di agrams, refer to 8W-63 -

Power Seat Wi th Heated Seats i n Group 8W - Wi ri ng

Di agrams.

(1) Repl ace the heated seat control modul e wi th a

known good uni t and test the operati on of the heated

seats. I f OK, di scard the faul ty heated seat control

modul e. I f not OK, go to Step 2.

(2) Test each of the ci rcui ts from the heated seat

swi tch, heated seat el ements, and heated seat sensor

to the heated seat control modul e. Repai r any short

or open ci rcui ts as requi red.

HEATED SEAT ELEMENT

The wi re harness connectors for the seat cushi on

and seat back heati ng el ements are l ocated under the

seat, near the rear edge of the seat cushi on frame.

For ci rcui t descri pti ons and di agrams, refer to 8W-63

- Power Seat Wi th Heated Seats i n Group 8W - Wi r-

i ng Di agrams.

SEAT CUSHION

(1) Di sconnect and i sol ate the battery negati ve

cabl e. Unpl ug the 4-way heated seat cushi on wi re

harness connector.

(2) Check for conti nui ty between the two heated

seat dri ver ci rcui t cavi ti es of the seat cushi on cover

hal f of the heated seat cushi on wi re harness connec-

tor. There shoul d be conti nui ty. I f OK, go to Step 3. I f

not OK, repl ace the faul ty seat cushi on cover.

(3) Check for conti nui ty between one of the heated

seat dri ver ci rcui t cavi ti es of the seat cushi on cover

hal f of the heated seat cushi on wi re harness connec-

tor and the seat cushi on frame. There shoul d be no

conti nui ty. I f OK, go to the Seat Back test. I f not OK,

repl ace the faul ty seat cushi on cover.

SEAT BACK

(1) Di sconnect and i sol ate the battery negati ve

cabl e. Unpl ug the 2-way heated seat back wi re har-

ness connector.

(2) Check for conti nui ty between the heated seat

dri ver ci rcui t cavi ty and the ground ci rcui t cavi ty of

the seat back cover hal f of the heated seat back wi re

harness connector. There shoul d be conti nui ty. I f OK,

go to Step 3. I f not OK, repl ace the faul ty seat back

cover.

(3) Check for conti nui ty between the heated seat

dri ver ci rcui t cavi ty of the seat back cover hal f of the

heated seat back wi re harness connector and the seat

back frame. There shoul d be no conti nui ty. I f OK,

test the heated seat sensor as descri bed i n thi s

group. I f not OK, repl ace the faul ty seat back cover.

HEATED SEAT SENSOR

The wi re harness connector for the seat cushi on

heati ng el ement and sensor are l ocated under the

seat, near the rear edge of the seat cushi on frame.

For ci rcui t descri pti ons and di agrams, refer to 8W-63

- Power Seat Wi th Heated Seats i n Group 8W - Wi r-

i ng Di agrams.

(1) Di sconnect and i sol ate the battery negati ve

cabl e. Unpl ug the 4-way heated seat cushi on wi re

harness connector.

(2) Usi ng an ohmmeter, check the resi stance

between the heated seat swi tch output ci rcui t cavi ty

and the ground ci rcui t cavi ty of the seat cushi on

cover hal f of the heated seat cushi on wi re harness

connector. The sensor resi stance shoul d be between 2

ki l ohms and 200 ki l ohms. I f OK, test the heated seat

control modul e as descri bed i n thi s group. I f not OK,

repl ace the faul ty seat cushi on cover.

REMOVAL AND INSTALLATION

HEATED SEAT SWITCH

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Di sconnect and i sol ate the battery negati ve

cabl e.

(2) Usi ng a tri m sti ck or another sui tabl e wi de

fl at-bl aded tool , pry gentl y around the peri meter

edges of the i nboard swi tch pod bezel to rel ease the

ZJ ELECTRICALLY HEATED SYSTEMS 8N - 9

DIAGNOSIS AND TESTING (Continued)

snap cl i p retai ners. Remove the bezel from the

i nstrument panel .

(3) Remove the three screws that secure the

i nboard swi tch pod to the i nstrument panel (Fi g. 1).

(4) Pul l the i nboard swi tch pod out from the

i nstrument panel far enough to access and unpl ug

the wi re harness connectors.

(5) Remove the i nboard swi tch pod from the

i nstrument panel .

(6) Reverse the removal procedures to i nstal l .

Ti ghten the swi tch mounti ng screws to 2.2 Nm (20

i n. l bs.).

HEATED SEAT CONTROL MODULE

(1) Move the power seat adjuster to i ts ful l up and

ful l forward stop posi ti ons.

(2) Di sconnect and i sol ate the battery negati ve

cabl e.

(3) Remove the three screws that secure the seat

si de shi el d to the seat cushi on frame.

(4) Pul l the seat si de shi el d away from the seat far

enough to access and unpl ug the wi re harness con-

nectors from the power seat and power l umbar

swi tches.

(5) Remove the seat si de shi el d from the seat.

(6) Look under the seat to l ocate the heated seat

control modul e and i ts wi re harness connector. These

components are posi ti oned under the seat cushi on

spri ng near the center of the outboard seat cushi on

frame (Fi g. 2). The wi re harness connector has an

i ntegral cl i p that secures i t to the seat cushi on

frame. The heated seat control modul e i s retai ned i n

the wi re harness connector by the tensi on of i ts ter-

mi nal s i n the connector cavi ti es.

WARNING: THERE ARE MANY SHARP METAL

EDGES ON THE SEAT CUSHION FRAME AND SEAT

ADJUSTER RAILS UNDER THE SEAT. WHEN PER-

FORMING THIS SERVICE, A LONG-SLEEVED SHIRT

AND GLOVES SHOULD BE WORN IN ORDER TO

AVOID UNNECESSARY CUTS AND ABRASIONS TO

EXPOSED SKIN.

CAUTION: The heated seat control module wire

harness connector must be stabilized during mod-

ule removal or installation. Failure to properly stabi-

lize the connector will result in damage to the

integral connector mounting clip that secures the

connector to the seat cushion frame.

(7) Kneel i ng outsi de the open front door of the

vehi cl e, use the hand nearest the rear of the seat to

reach between the top and bottom rai l s of the power

seat adjuster to access and stabi l i ze the heated seat

control modul e wi re harness connector.

(8) Whi l e sti l l stabi l i zi ng the wi re harness connec-

tor wi th one hand, use your free hand to reach under

the front of the seat cushi on to grasp the heated seat

control modul e.

(9) Whi l e sti l l stabi l i zi ng the wi re harness connec-

tor wi th one hand, use a gentl e rocki ng and pul l i ng

acti on wi th the other hand to unpl ug the heated seat

control modul e from the wi re harness connector.

(10) Reverse the removal procedures to i nstal l . Be

certai n that the heated seat control modul e termi nal s

are al i gned wi th the cavi ti es i n the wi re harness con-

nector before pushi ng the modul e fi rml y i nto pl ace.

Ti ghten the seat si de shi el d mounti ng screws to 2.2

Nm (20 i n. l bs.).

Fig. 1 Inboard Switch Pod Remove/Install

Fig. 2 Heated Seat Control Module Remove/Install -

Right Side Shown

8N - 10 ELECTRICALLY HEATED SYSTEMS ZJ

REMOVAL AND INSTALLATION (Continued)

You might also like

- Electrically Heated Systems: Defogger SystemDocument10 pagesElectrically Heated Systems: Defogger SystemensmartisNo ratings yet

- ZJ Chime/Buzzer Warning Systems 8U - 1Document4 pagesZJ Chime/Buzzer Warning Systems 8U - 1Dalton WiseNo ratings yet

- Passsive Restraint Systems Guide with Airbag Component DescriptionsDocument12 pagesPasssive Restraint Systems Guide with Airbag Component DescriptionsDalton WiseNo ratings yet

- Chime Buzzer Warning SystemsDocument4 pagesChime Buzzer Warning SystemsArt DoeNo ratings yet

- Horn System Diagnosis and Testing GuideDocument4 pagesHorn System Diagnosis and Testing GuideDalton WiseNo ratings yet

- ZJ Wiper and Washer Systems 8K - 1Document16 pagesZJ Wiper and Washer Systems 8K - 1Dalton WiseNo ratings yet

- ZJ Power Window Systems 8S - 1Document8 pagesZJ Power Window Systems 8S - 1Dalton WiseNo ratings yet

- ZJ Power Seat Systems 8R - 1Document8 pagesZJ Power Seat Systems 8R - 1Dalton WiseNo ratings yet

- ZJ Ignition System 8D - 1Document26 pagesZJ Ignition System 8D - 1Dalton WiseNo ratings yet

- 5 CVM and Convertible TopDocument41 pages5 CVM and Convertible TopVictor SilvNo ratings yet

- 08T - Power Mirror SystemsDocument6 pages08T - Power Mirror SystemsjohnqevilNo ratings yet

- Power Mirror SystemsDocument8 pagesPower Mirror SystemsDalton WiseNo ratings yet

- 08G - Horn SystemsDocument6 pages08G - Horn SystemsEinar OftebroNo ratings yet

- 08T - Power Mirror Systems - Jeep ZJ_96 - Service ManualDocument6 pages08T - Power Mirror Systems - Jeep ZJ_96 - Service ManualThiago CulauNo ratings yet

- 08S - Power Window SystemsDocument4 pages08S - Power Window SystemsjohnqevilNo ratings yet

- Passsive Restraint Systems GuideDocument12 pagesPasssive Restraint Systems GuideDane WallaceNo ratings yet

- ZJ Starting Systems 8B - 1Document10 pagesZJ Starting Systems 8B - 1Dalton WiseNo ratings yet

- ZG Charging System 8C - 1Document8 pagesZG Charging System 8C - 1Dalton WiseNo ratings yet

- Ice & Rain: S76 Maintenance Training Manual CHC Training Centre (Global)Document33 pagesIce & Rain: S76 Maintenance Training Manual CHC Training Centre (Global)FilipeDaumasNo ratings yet

- Mx150 ManualDocument28 pagesMx150 ManualThiago BertiNo ratings yet

- ZJ Power Lock Systems 8P - 1Document8 pagesZJ Power Lock Systems 8P - 1Dalton WiseNo ratings yet

- ZG Power Window Systems 8S - 1Document8 pagesZG Power Window Systems 8S - 1ensmartisNo ratings yet

- ZJ Charging System 8C - 1Document8 pagesZJ Charging System 8C - 1Dalton WiseNo ratings yet

- Intelli SW 250 TransferenciaDocument32 pagesIntelli SW 250 Transferenciajuanka209No ratings yet

- XJ Wiper and Washer Systems 8K - 1Document14 pagesXJ Wiper and Washer Systems 8K - 1hottubdocNo ratings yet

- Turn Signal and Hazard Warning SystemsDocument8 pagesTurn Signal and Hazard Warning SystemsDalton WiseNo ratings yet

- Lighting System: SectionDocument48 pagesLighting System: Sectiontomallor101No ratings yet

- Yamaha Training Electrical Systems 2 IgnitionDocument22 pagesYamaha Training Electrical Systems 2 Ignitionbhu15bhoNo ratings yet

- Starting & Charging System GuideDocument32 pagesStarting & Charging System Guideghar_dashNo ratings yet

- Color Monitor: Service ManualDocument35 pagesColor Monitor: Service ManualReparatii Calculatoare TimisoaraNo ratings yet

- ZG Chime/Buzzer Warning Systems 8U - 1Document4 pagesZG Chime/Buzzer Warning Systems 8U - 1ensmartisNo ratings yet

- Easily Clear Rear Window Fog with Defogger RepairsDocument4 pagesEasily Clear Rear Window Fog with Defogger RepairsLilisbethBasantaNo ratings yet

- GE MKII SCR Drive Training PDFDocument56 pagesGE MKII SCR Drive Training PDFbetobebetoNo ratings yet

- EXJ - 8M99 Jeep XJ Service ManualDocument10 pagesEXJ - 8M99 Jeep XJ Service ManualhottubdocNo ratings yet

- Controls, Start-Up, Operation, Service and Troubleshooting: 30XA080-500 Air-Cooled Liquid Chillers 60 HZDocument126 pagesControls, Start-Up, Operation, Service and Troubleshooting: 30XA080-500 Air-Cooled Liquid Chillers 60 HZHasib Khan100% (1)

- GE MX-150 ManualDocument28 pagesGE MX-150 ManualCristian Munoz60% (5)

- Cryomatic' Console Service ManualDocument25 pagesCryomatic' Console Service ManualJovanović DunjaNo ratings yet

- SSP213 New Technology 99 PDFDocument72 pagesSSP213 New Technology 99 PDFjuanma1358No ratings yet

- AE1311Document12 pagesAE1311Maria DazaNo ratings yet

- Manual Ats ZenithDocument18 pagesManual Ats ZenithGILBERTOPERDOMONo ratings yet

- CH 24 Electrical Power: Training Manual B767-3S2F Ata 24-00Document73 pagesCH 24 Electrical Power: Training Manual B767-3S2F Ata 24-00David Owen100% (1)

- MAINTENANCE TITLEDocument51 pagesMAINTENANCE TITLEtomallor101No ratings yet

- Descrições Do Sistema R22Document34 pagesDescrições Do Sistema R22Victor MiguelNo ratings yet

- Diagnosis and Testing - Power WindowsDocument22 pagesDiagnosis and Testing - Power WindowsMuhammad ZamanNo ratings yet

- Rolls-Royce Engine De-Icing GuideDocument10 pagesRolls-Royce Engine De-Icing GuideJimyToasaNo ratings yet

- GS-1930 GS-1530 Service Manual: Technical PublicationsDocument137 pagesGS-1930 GS-1530 Service Manual: Technical PublicationsFelipe Savieto AcorsiNo ratings yet

- Hybrid02 SYS OPERATION-dikonversiDocument22 pagesHybrid02 SYS OPERATION-dikonversiJajankAbdullohNo ratings yet

- XJ Instrument Panel Systems 8E - 1Document28 pagesXJ Instrument Panel Systems 8E - 1Carlos Gabriel EstergaardNo ratings yet

- Shutdown Solenoid For UG Governor: Installation and Operation ManualDocument28 pagesShutdown Solenoid For UG Governor: Installation and Operation Manualbmsolaris100% (1)

- m90 Manual PDFDocument30 pagesm90 Manual PDFRigoberto RodriguezNo ratings yet

- Speed Control SystemDocument8 pagesSpeed Control SystemDalton WiseNo ratings yet

- SD70ACe IGBT Safety ManualDocument18 pagesSD70ACe IGBT Safety ManualAlberto Alejandro Sanchez100% (1)

- Ezg 8TDocument8 pagesEzg 8TensmartisNo ratings yet

- FINAL HG 11 02 08 enDocument64 pagesFINAL HG 11 02 08 enDarko MiticNo ratings yet

- Service Manual Book NISSAN GRAND LIVINADocument22 pagesService Manual Book NISSAN GRAND LIVINAogyrisky92% (12)

- ZG Starting Systems 8B - 1Document14 pagesZG Starting Systems 8B - 1ensmartisNo ratings yet

- 31-9072 Arctica Profile GE Side-By-Side Refrigerator Service ManualDocument76 pages31-9072 Arctica Profile GE Side-By-Side Refrigerator Service Manualfnsilva2No ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Chrysler Corporation: Service Manual Supplement 1998 Grand CherokeeDocument4 pagesChrysler Corporation: Service Manual Supplement 1998 Grand CherokeeDalton WiseNo ratings yet

- Ezg InaDocument2 pagesEzg InaDalton WiseNo ratings yet

- Ezg inDocument8 pagesEzg inDalton WiseNo ratings yet

- Ezg 23Document54 pagesEzg 23Dalton WiseNo ratings yet

- Ezg 25Document20 pagesEzg 25Dalton WiseNo ratings yet

- Transmission and Transfer Case Guide for 42/44RE Automatic and NV242/249 Transfer CasesDocument296 pagesTransmission and Transfer Case Guide for 42/44RE Automatic and NV242/249 Transfer CasesDalton WiseNo ratings yet

- Ezg 24Document54 pagesEzg 24Dalton WiseNo ratings yet

- Ezg 25aDocument8 pagesEzg 25aDalton WiseNo ratings yet

- Speed Proportional Steering System GuideDocument6 pagesSpeed Proportional Steering System GuideDalton WiseNo ratings yet

- Ezg 24aDocument12 pagesEzg 24aDalton WiseNo ratings yet

- Ezg 19Document26 pagesEzg 19Dalton WiseNo ratings yet

- Ezg 8vDocument10 pagesEzg 8vDalton WiseNo ratings yet

- Ezg 14aDocument40 pagesEzg 14aDalton WiseNo ratings yet

- Ezg 22Document10 pagesEzg 22Dalton WiseNo ratings yet

- Ezg 21aDocument14 pagesEzg 21aDalton WiseNo ratings yet

- Ezg 13Document12 pagesEzg 13Dalton WiseNo ratings yet

- Ezg 14Document66 pagesEzg 14Dalton WiseNo ratings yet

- Ezg 8wDocument488 pagesEzg 8wDalton WiseNo ratings yet

- Ezg 9aDocument48 pagesEzg 9aDalton WiseNo ratings yet

- ZJ Exhaust System and Intake Manifold 11 - 1Document10 pagesZJ Exhaust System and Intake Manifold 11 - 1Dalton WiseNo ratings yet

- ZJ Power Seat Systems 8R - 1Document8 pagesZJ Power Seat Systems 8R - 1Dalton WiseNo ratings yet

- Ezg 9Document120 pagesEzg 9Dalton WiseNo ratings yet

- ZG Exhaust System and Intake Manifold 11 - 1Document4 pagesZG Exhaust System and Intake Manifold 11 - 1Dalton WiseNo ratings yet

- Power Mirror SystemsDocument8 pagesPower Mirror SystemsDalton WiseNo ratings yet

- Ezg 8qaDocument12 pagesEzg 8qaDalton WiseNo ratings yet

- ZJ Vehicle Theft/Security Systems 8Q - 1Document10 pagesZJ Vehicle Theft/Security Systems 8Q - 1Dalton WiseNo ratings yet

- ZJ Power Lock Systems 8P - 1Document8 pagesZJ Power Lock Systems 8P - 1Dalton WiseNo ratings yet

- ZJ Power Window Systems 8S - 1Document8 pagesZJ Power Window Systems 8S - 1Dalton WiseNo ratings yet

- Intermittent Fasting Facts and Myths: Metabolic Benefits of Intermittent FastingDocument4 pagesIntermittent Fasting Facts and Myths: Metabolic Benefits of Intermittent FastingIJAR JOURNALNo ratings yet

- UntitledDocument2 pagesUntitledbassky_368970698No ratings yet

- Storm Water Drainage GuidelinesDocument16 pagesStorm Water Drainage GuidelinesSeeni GovindNo ratings yet

- Fmea PC ProcessDocument2 pagesFmea PC Processsudeep_singh1No ratings yet

- Hepatitis - Seminary WorkDocument15 pagesHepatitis - Seminary WorkDraganaNo ratings yet

- HeavyMetalLimits For Leachability PROP 65 PB and CDDocument3 pagesHeavyMetalLimits For Leachability PROP 65 PB and CDspades24kNo ratings yet

- Christopher Pelling (Ed.) - Greek Tragedy and The Historian - Oxford University Press, USA (1997)Document278 pagesChristopher Pelling (Ed.) - Greek Tragedy and The Historian - Oxford University Press, USA (1997)rmvicentin100% (1)

- Guidelines For Dengue Surveillance Edition2.PDF WHODocument115 pagesGuidelines For Dengue Surveillance Edition2.PDF WHOFebyan Kuan Lu Hap100% (1)

- Mater BiDocument10 pagesMater BihanjunyieeNo ratings yet

- Biosystems Engineering BS CurriculumDocument2 pagesBiosystems Engineering BS CurriculumAsiiimweNo ratings yet

- MRCP EthicsDocument33 pagesMRCP EthicstaherNo ratings yet

- Sample Final OutputDocument3 pagesSample Final OutputRey Dominique VillarNo ratings yet

- Overview of Metal Forming ProcessesDocument19 pagesOverview of Metal Forming ProcessesAnonymous 7yN43wjlNo ratings yet

- Guillaume Apollinaire-Alcools (Athlone French Poets) (French Edition) (2001)Document195 pagesGuillaume Apollinaire-Alcools (Athlone French Poets) (French Edition) (2001)Antonio Scalia100% (5)

- String TheoryDocument12 pagesString TheoryYashvinder SinghNo ratings yet

- Behavior of Connected and Unconnected Back-to-Back Walls For Bridge ApproachesDocument10 pagesBehavior of Connected and Unconnected Back-to-Back Walls For Bridge Approachessalar salarNo ratings yet

- KFS Ut U3Document5 pagesKFS Ut U3Ana DuarteNo ratings yet

- Table Napkin Folding TechniquesDocument6 pagesTable Napkin Folding TechniquesMiguel BaricuatroNo ratings yet

- Implant Dentistry - The Most Promising Discipline of Dentistry PDFDocument488 pagesImplant Dentistry - The Most Promising Discipline of Dentistry PDFnaresh sharmaNo ratings yet

- Toyota Forklift 42 6fgcu15!42!6fgcu18 Parts CatalogDocument22 pagesToyota Forklift 42 6fgcu15!42!6fgcu18 Parts Catalogjosephrichards120800wpq100% (110)

- Company & Project Information for Electrical, Instrumentation ServicesDocument28 pagesCompany & Project Information for Electrical, Instrumentation ServicesMrudul PatilNo ratings yet

- Evaluation of Plant Extracts Against Two Spotted Spider MiteDocument7 pagesEvaluation of Plant Extracts Against Two Spotted Spider MiteAnkaranaRenvaNo ratings yet

- Bone MarrowDocument6 pagesBone Marrow:)No ratings yet

- Panasonic Conduit CatalogDocument8 pagesPanasonic Conduit CatalogAhmed Said100% (2)

- Cambridge English Pre A1 Starters Classroom Activities PDFDocument16 pagesCambridge English Pre A1 Starters Classroom Activities PDFFrank Guevara100% (2)

- Asme Section II A Sa-435 Sa-435mDocument4 pagesAsme Section II A Sa-435 Sa-435mAnonymous GhPzn1xNo ratings yet

- 1,2,4-Triazoles: A Review of Synthetic Approaches and The Biological ActivityDocument22 pages1,2,4-Triazoles: A Review of Synthetic Approaches and The Biological Activitymf720383270No ratings yet

- Variac MFG Business Plan Annexure - 1Document6 pagesVariac MFG Business Plan Annexure - 1Manav MatetiNo ratings yet

- Measuring: TranslateDocument5 pagesMeasuring: Translatechelsea romaidaNo ratings yet

- McMahan Transpositions of Metaphor and Imagery in The Ga Avyūha and Tantric Buddhist PracticeDocument14 pagesMcMahan Transpositions of Metaphor and Imagery in The Ga Avyūha and Tantric Buddhist PracticeAnthony TribeNo ratings yet