Professional Documents

Culture Documents

Wps p91 - Bhel

Uploaded by

Ashish Gupta100%(4)100% found this document useful (4 votes)

2K views2 pageswps p91- bhel

Original Title

wps p91- bhel

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentwps p91- bhel

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(4)100% found this document useful (4 votes)

2K views2 pagesWps p91 - Bhel

Uploaded by

Ashish Guptawps p91- bhel

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

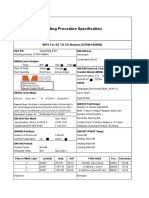

BHARAT HEAVY ELECTRI CALS LI MI TED

WELDING TECHNOLOGY CENTRE

Tiruchirappalli-620014

WELDING PROCEDURE SPECIFICATION

Form No. 101-401 Page 1 of 2

WPS No.: 1050 Date: 30.11.06 Supporting PQR No.: 1181

Rev. :01 Date: 07.12.06

Welding Process: GTAW +SMAW Type: Manual

(Auto,Semi-Auto,Manual,Machine)

Application: Groove welding of 9Cr 1 Mo 0.25 V (T91/P91) steel Tubes/ Pipes for

thickness up to 20.00 mm with pre heat & PWHT.

JOINTS (QW-402)

J oint Design : As per production Drg.

Backing (Yes/No) : GTAW: No; SMAW: Yes.

Backing Material (type) : GATW: Nil; SMAW: Metal.

Metal/Non fusing metal/ :

Non metallic/Others

BASE METAL (QW-403)

P. No.: 5B Group No.: 2 to P. No.: 5B Group No.: 2

Spec. Type & Grade : SA 213 T91 or equivalent.

Chem. Analysis & Mech. Prop :

Thickness Range

Groove: 5.0 to 20.0mm Fillet: N.A.

Pipe Dia. range: Unlimited

Others: Nil

FILLER METALS (QW-404)

GATW SMAW

AWS No. (Class): E 90S-B9 E9018-B9/E9015-B9 Size of filler metal: Refer table

Specn. No. (SFA): 5.28 5.5 Flux Trade Names: N.A

F. No.: 5 5 Consumable insert: N.A.

A. No.: 6 4 Electrode |Flux (Class): N.A.

Deposited weld metal thickness range

Groove: 5-20 mm max. GTAW: 4.0 mm max. (Max.2 mm per pass) SMAW: Balance (Max.5 mm /

pass)

Fillet: Nil.

POSITION (QW-405)

Position of Groove: All

Position of fillet: N.A.

Weld Progression: Vertical up.

(Up / Down)

Others: Nil

PREHEAT (QW-406)

Preheat temp (min). : 220

O

c

Inter pass temp. (Max.): 350

o

C

Pre heat maintenance: 220

O

c (Min)

Other: Insulate while cooling to 80-100degc

and keep the job dry. Maintain at 80-100deg

c for 1 hr. and conduct PWHT immediately.

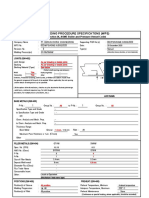

BHARAT HEAVY ELECTRI CALS LI MI TED

WELDING TECHNOLOGY CENTRE

Tiruchirappalli-620014

WELDING PROCEDURE SPECIFICATION

Form No. 101-401 WPS No.: 1050 Rev 01 Page 2 of 2

PWHT (QW-408)

Temp. Range: 760 10

o

C

Time Range 2.5-mts/ mm (Thickness of weld)

(Min.120 Minutes.)

Others: Rate of heating / cooling above 350

o

C

110

O

C/Hr maximum

GAS (QW-408)

Gases Purity% Flow Rt.

Shielding Argon 99.99 6-14 LPM

Trailing N.A. ---- ----

Backing Argon 99.99 10-20 LPM

(For root welding)

ELECTRICAL CHARACTERISTICS (QW-409)

Current (AC/DC): See table Polarity: See table

Amps. (Range): See table Volts: See table

Tungsten Electrode type and size: EWTh-2/EWCe-2, 2.4 mm.

Mode of metal transfer for (GMAW): N.A.

Electrode wire feed speed range: N.A.

Pulsing current (GTAW): Nil.

TECHNIQUES (QW-410)

String or Weave Bead: String

Orifice or Gas cup size: 6/9

Initial and inter pass cleaning: Brushing/Chipping/Grinding

Method of back Gouging: Nil.

Oscillation: N.A

Contact tube to work distance: N.A

Multiple or single pass (per side): Multiple

Multiple or single electrode: Single

Electrode spacing: N.A.

Peening: Nil.

Others: Nil

Filler Current

Weld

Layer

Process

Class

Dia.

mm

Type Amps.

Volt

Range

Travel

speed

range

Others

(hot wire,

torch

angle

etc.)

Root GTAW ER 90S-B9 2.4 DCEN 70-100 N.A. N.A. Nil

Others

Layers

SMAW

E9018-B9

Or

E9015-B9

2.5 DCEP 70-100 N.A. N.A. Nil

-Do- SMAW -Do- 3.2 DCEP 90-130 N.A. N.A. Nil

-Do- SMAW -Do- 4.0 DCEP 140-160 N.A. N.A. Nil

Prepared by: Reviewed by: Approved by:

(Kankar Narzary) (Dr K.P.Dhandapani) (B.Natarajan)

Welding Engineer / WTC DGM/ WTC & WCMC SDGM/ WTC & WCMC

You might also like

- GTAW Welding Procedure SpecificationDocument3 pagesGTAW Welding Procedure SpecificationVimin Prakash100% (1)

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- WPS for Welding SA-335 P11 to SA-234 WP11Document3 pagesWPS for Welding SA-335 P11 to SA-234 WP11Ganesh rohitNo ratings yet

- Super Duplex Stainless SteelDocument1 pageSuper Duplex Stainless SteelUma Shankar100% (1)

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinNo ratings yet

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- WPS for SS to CS WeldingDocument1 pageWPS for SS to CS WeldingLipika GayenNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- 6GR RequirementsDocument1 page6GR Requirementswalitedison100% (1)

- WPS PQR ProcedureDocument31 pagesWPS PQR Proceduresudeesh kumarNo ratings yet

- Wps Gmaw SawDocument2 pagesWps Gmaw Sawupedro26No ratings yet

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- QW-451 Procedure Qualification Thickness Limits and Test SpecimensDocument2 pagesQW-451 Procedure Qualification Thickness Limits and Test SpecimensmiteshNo ratings yet

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- SURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPSDocument2 pagesSURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPSsuria qaqcNo ratings yet

- Method Statement For Titanium PipeworkDocument3 pagesMethod Statement For Titanium Pipeworkprem nautiyalNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- PQRDocument2 pagesPQRalokbdasNo ratings yet

- Madina Trading WPS No. 017Document12 pagesMadina Trading WPS No. 017MAT-LIONNo ratings yet

- WELDING PROCEDURE SPECIFICATION FOR SOUTH PARS GAS FIELD DEVELOPMENTDocument1 pageWELDING PROCEDURE SPECIFICATION FOR SOUTH PARS GAS FIELD DEVELOPMENTAhmed LepdaNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Multiple PQR QualificationDocument4 pagesMultiple PQR QualificationKarthikeyan ShanmugavelNo ratings yet

- WPS PQR 12Document9 pagesWPS PQR 12Ranjan KumarNo ratings yet

- Welding Procedure Specification for SMAW of Carbon Steel Butt JointsDocument2 pagesWelding Procedure Specification for SMAW of Carbon Steel Butt JointstayyabNo ratings yet

- API Welding Procedure Specification PDFDocument3 pagesAPI Welding Procedure Specification PDFBob LeeNo ratings yet

- ASME P NumbersDocument1 pageASME P NumbersFahri Risfa ZulfiNo ratings yet

- WPS Sa 335 P91 PipeDocument3 pagesWPS Sa 335 P91 Pipecsankarananth50% (2)

- WPS - EngineerDocument20 pagesWPS - Engineerhunghoanglong100% (1)

- (Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Document2 pages(Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Quality LaveenaNo ratings yet

- Shell Rolling ProcedureDocument26 pagesShell Rolling ProcedureKingston Rivington100% (1)

- Ayari Maher: Qualified Welder I.D.CardDocument10 pagesAyari Maher: Qualified Welder I.D.CardZouhair BenmabroukNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationGodwin A.udo-akanNo ratings yet

- P91 Profile WpsDocument6 pagesP91 Profile WpsManzar KhanNo ratings yet

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (2)

- Wps For Smaw06-001 (Pipe 6g CS)Document10 pagesWps For Smaw06-001 (Pipe 6g CS)walitedisonNo ratings yet

- WPSDocument3 pagesWPSKhurram Burjees100% (1)

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- 03 WPS PQR For FCAWDocument3 pages03 WPS PQR For FCAWBrijesh Yadav100% (1)

- WPS, PQR 041Document21 pagesWPS, PQR 041swamykommula100% (1)

- Welding of P91Document37 pagesWelding of P91nishant361100% (4)

- PART 66 ASME IX - Part 2 Essential Variable For Welder QualificationDocument13 pagesPART 66 ASME IX - Part 2 Essential Variable For Welder Qualificationravindra_jivaniNo ratings yet

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNo ratings yet

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- P91 Profile WpsDocument6 pagesP91 Profile WpsZead Ali Adal100% (2)

- Welding Procedure Specification and Procedure Qualification RecordDocument2 pagesWelding Procedure Specification and Procedure Qualification RecordNatdanai NorawanNo ratings yet

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- Form No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2Document10 pagesForm No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2JithinAbrahamNo ratings yet

- WPS Gtaw+smawDocument2 pagesWPS Gtaw+smawAnand GNo ratings yet

- WPS TITLEDocument2 pagesWPS TITLERichard Periyanayagam86% (14)

- WPS GTAW Stainless SteelDocument2 pagesWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- Welding Procedure Specification: Bharat Heavy Electricals LimitedDocument2 pagesWelding Procedure Specification: Bharat Heavy Electricals LimitedMakhdum Muhardiana PutraNo ratings yet

- MPI GuideDocument17 pagesMPI Guidejaga67No ratings yet

- PV Elite WebinarDocument24 pagesPV Elite WebinarAndrea Hank LattanzioNo ratings yet

- Very Important TopicDocument10 pagesVery Important TopicAshish GuptaNo ratings yet

- Attendance FormatDocument1 pageAttendance FormatAshish GuptaNo ratings yet

- Attendance FormatDocument1 pageAttendance FormatAshish GuptaNo ratings yet

- ASTM e 186Document4 pagesASTM e 186Ashish GuptaNo ratings yet

- API-510-Closed-1-AnswersDocument5 pagesAPI-510-Closed-1-AnswersEinsteinw2No ratings yet

- Note On HumidityDocument19 pagesNote On HumidityCharles Bailey100% (1)

- Acknowledgement: Ravneet KaurDocument1 pageAcknowledgement: Ravneet KaurAshish GuptaNo ratings yet

- Post Weld Heat TreatmentDocument2 pagesPost Weld Heat TreatmentgullenariNo ratings yet

- Ultrasonic Testing FormulasDocument4 pagesUltrasonic Testing FormulasNavneet Singh100% (1)

- SSC-394 Strength Assessment of Pitted Plate Panels PDFDocument91 pagesSSC-394 Strength Assessment of Pitted Plate Panels PDFBruno Avila Paulo100% (1)

- Ik Kone Mein Tha BaithaDocument1 pageIk Kone Mein Tha BaithaAshish GuptaNo ratings yet

- Gnana Prakash. R - New2Document5 pagesGnana Prakash. R - New2Ashish GuptaNo ratings yet

- ESAB Mmaw ProcessDocument19 pagesESAB Mmaw ProcessBurag HamparyanNo ratings yet

- FCI Advt 2015 PDFDocument24 pagesFCI Advt 2015 PDFAnkit GhildiyalNo ratings yet

- Guest House ListDocument5 pagesGuest House ListAshish GuptaNo ratings yet

- RRB Junior Engineer Mechanical Model Question Paper Solved 16Document31 pagesRRB Junior Engineer Mechanical Model Question Paper Solved 16Ashish Gupta100% (1)

- Quality ToolsDocument10 pagesQuality Toolsjypy100% (1)

- Delhi Metro Route MapDocument1 pageDelhi Metro Route Mapnakulyadav7No ratings yet

- Industrial Radiography Image Forming TechniquesDocument99 pagesIndustrial Radiography Image Forming TechniquesAshish GuptaNo ratings yet

- MR & QMD Audit FindingsDocument1 pageMR & QMD Audit FindingsAshish GuptaNo ratings yet

- 1997 Jones ThermoDocument29 pages1997 Jones ThermoAshish GuptaNo ratings yet

- Advt 25feb2015 01Document1 pageAdvt 25feb2015 01Sree BloggersNo ratings yet

- ITP Tank Nozzle ModificationDocument1 pageITP Tank Nozzle ModificationAshish GuptaNo ratings yet

- SSPC Surface Preparation StandardsDocument7 pagesSSPC Surface Preparation StandardsAshish GuptaNo ratings yet

- WWW - Hssc.gov - In: Closing Date For Deposit of Fee 31.03.2014Document22 pagesWWW - Hssc.gov - In: Closing Date For Deposit of Fee 31.03.2014Ashish GuptaNo ratings yet

- Power Plant Project ReportDocument3 pagesPower Plant Project ReportAshish GuptaNo ratings yet

- Form 10 CDocument4 pagesForm 10 CAshish GuptaNo ratings yet

- Weld Set Reference: Z194539 Power Wave® S350 (Imperial Units)Document4 pagesWeld Set Reference: Z194539 Power Wave® S350 (Imperial Units)Cristhian De La BarraNo ratings yet

- Top Gun Mig-Mag 350i SWFDocument15 pagesTop Gun Mig-Mag 350i SWFTom PleysierNo ratings yet

- BIWDocument8 pagesBIWSreenath Krishnachar100% (2)

- Welding InspectionDocument19 pagesWelding InspectionMaricrisMendozaNo ratings yet

- CSWIP Module Re-ExamDocument2 pagesCSWIP Module Re-ExamAhmad Khalimi Ilmawan100% (1)

- An Overview of Indian Welding Industry - ReportDocument16 pagesAn Overview of Indian Welding Industry - ReportBinoy ShahNo ratings yet

- تكنلوجيا اللحام بالميج ماجDocument30 pagesتكنلوجيا اللحام بالميج ماجSamerNo ratings yet

- IcfrrpDocument8 pagesIcfrrpmohammed noorullahNo ratings yet

- Guideline For Welding P91Document44 pagesGuideline For Welding P91Howo4DieNo ratings yet

- Electrode Dan Welding Wires 1646204294Document7 pagesElectrode Dan Welding Wires 1646204294Gibran RamadhanNo ratings yet

- A Review Porosity in Aluminum WeldingDocument10 pagesA Review Porosity in Aluminum WeldingBenny TavlovichNo ratings yet

- Welding efficiency and benchmarking key performance indicatorsDocument5 pagesWelding efficiency and benchmarking key performance indicatorsjohndupNo ratings yet

- Catalogue of Xtlaser Handheld Fiber Laser Welding Machine-Xtlaser-ElizaDocument17 pagesCatalogue of Xtlaser Handheld Fiber Laser Welding Machine-Xtlaser-Elizacentaury2013No ratings yet

- RL 350 PDFDocument150 pagesRL 350 PDFBhumika100% (8)

- Welding Heat Input & Interpass GuideDocument6 pagesWelding Heat Input & Interpass GuideVishal Sparkle QE3No ratings yet

- 254smo (Uns 31254)Document8 pages254smo (Uns 31254)Yang Gul LeeNo ratings yet

- 1 - Machines Fronius and Other Welding Power SourceDocument27 pages1 - Machines Fronius and Other Welding Power Sourcef_allahdadNo ratings yet

- Reference Cement HolcimDocument11 pagesReference Cement Holcimkamals55No ratings yet

- EsabDocument108 pagesEsabEmilio BonnetNo ratings yet

- Inspection and Welding Repairs of Pressure VesselsDocument8 pagesInspection and Welding Repairs of Pressure VesselsAlper Çakıroğlu100% (1)

- Welding of Ni SteelDocument4 pagesWelding of Ni SteelVikas Kumar PathakNo ratings yet

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- Weld Metal Cost Worksheet Instructions: Covered ElectrodesDocument1 pageWeld Metal Cost Worksheet Instructions: Covered ElectrodesSmith SivaNo ratings yet

- H 3159Document58 pagesH 3159Alex GigenaNo ratings yet

- Arc Welding: (Soldadura Por Arco) Profesor: Dr. Jorge Álvarez Díaz Materia: Procesos de ManufacturaDocument19 pagesArc Welding: (Soldadura Por Arco) Profesor: Dr. Jorge Álvarez Díaz Materia: Procesos de ManufacturaRicky VillalobosNo ratings yet

- A133 A137Document5 pagesA133 A137Madirley PimentaNo ratings yet

- Copper AlloysDocument4 pagesCopper AlloysMuhammed SulfeekNo ratings yet

- Compendium of Policies & Guidelines SC 2011Document30 pagesCompendium of Policies & Guidelines SC 2011tesdaro12No ratings yet

- SP-1174 - 2004 EditionDocument47 pagesSP-1174 - 2004 EditionSatish Kulkarni100% (2)