Professional Documents

Culture Documents

01 Company Present

Uploaded by

txagusOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01 Company Present

Uploaded by

txagusCopyright:

Available Formats

...

Over the years DIESSE has succesfully developed its know how in the liquid measuring instrument sector and has

registered own patents.

Today, the company is one of the most well-known level gauge manufacturers in the business.

The DIESSE product range covers:

GLASS LEVEL GAUGES

MAGNETIC LEVEL GAUGES

CYLINDRICAL PLUG COCKS

BLOW DOWN VALVES

NEEDLE VALVES

FLOW INDICATORS

COILS

VALVES

Our products are suitable for most industrial process applications and general boiler applications as well.

MISSION:

Repay the company investment by ensuring our customer a high quality product and service while focusing

strongly on reasearch into innovative and personalised solutions

CERTIFICATIONS / COMPLIANCE:

DIESSE

accordance with major international standards such as

UNI EN ISO 9001,

PED 97/23/EC Pressure Equipment Directive

ATEX 94/9/EC

Additional examples of product compliance and certifications

can be found in the relevant sections, along with a list of Diesse

patents.

level gauges are manufactured and certified in

DIESSE S.r.l. Fluid Control

Head office and production

Via dellArtigianato, 10/12

21040 Origgio (VA) - Italia

Tel +39 02 96731337

Fax +39 02 96731683

info@dssrl.it

website

www.dssrl.it

VAT number

01922650120

Fluid Control

STRENGHTS:

Wide skills base and teamwork

help us achieve our business objectives

High product quality

thanks to our careful selection of Italian and European-only materials and through supplier assessment/qualification

process

Strong customer loyalty

For years now we can count on the satisfaction and loyalty of many customers

COMPANY PROCESSES

Offers

Suppliers evaluation

and qualification

Customer order

Project / design

Production

Planning

Production

Marketing

Deliveries

Purchases

Incoming material

controls

External

communication

Instruments

and equipment

maintenance

Customer care:

- Customer special projects development

- Immediate response to customer requests

- Extreme flexibility in terms of production processes and deadlines

- Attention to details and professionalism in identifying the most suitable technical solution for particular applications

or customer need

CUSTOMERS LOYALTY MARKET SHARE

Italy

Europe

Extra Europe

>10 years

from 3 to 9 years

others

33%

21%

47%

35%

18%

46%

GLASS LEVEL GAUGES

1WITH REFLEX GLASSES

1WITH TRANSPARENT GLASSES

1WELD-ON TYPE

1WITH GLASS TUBE

1WITH MICROWAVE TRANSMITTER

Reflex level gauge

type DS LG - RDR GR18

Reflex level gauge

type DS LG - RBR GR18

Reflex level gauge

type DS LG - RBF GR18

Reflex level gauge

with monolithic shut-off cocks

type DS LG - RTR MT18

Tube and protection type

DS LG - TVR GR18

Reflex level gauge

with ball valves

type DS LG - RTF SBB

Transparent level gauge

with illumination lamp EEx d

type DS LG - TPF GR18

essential data

TYPE OF CONNECTIONS (flanged-threaded-weld-on) and related STANDARDS (UNI-ANSI-DIN)

REQUIRED MATERIAL (wetted and non-wetted parts)

TYPE OF FLUID

DESIGN AND MAXIMUM OPERATING PRESSURES

DESIGN AND MAXIMUM OPERATING TEMPERATURES

MINIMUM VISIBLE LENGTH REQUIRED

POSITION OF PROCESS CONNECTIONS

POSITION OF THE VALVE HANDLING

ANY ADDITIONAL ACCESSORIES

CENTRE-TO-CENTRE DISTANCE (distance between process connections)

READING TYPE

Glass level gauges give very accurate level readings, making them

the ideal product for calibrating other instruments as well.

They play a crucial role during system start-up.

The required visible length depends on the type

of fluid and the shape of the tank.

The visible length with a single glass varies from

95 mm to 320 mm. If the required visible length

exceeds these measurements, additional glasses

of the same length are joined together and

mounted on a single bar.

To ensure continuous reading along a housing

consisting of numerous glasses, one or more

housings can be placed on the side at the points

where the reading is interrupted.

Single

housing

Multiple

housing

with continuous

reading

Multiple

housing

TO RECOMMEND THE MOST SUITABLE LEVEL GAUGE, PLEASE PROVIDE

THE FOLLOWING ESSENTIAL DATA WHEN ASKING FOR ADVICE OR

QUOTATION.

You might also like

- Norsok: Instrument Stand 316 SST 50mm NB Pipe StandDocument1 pageNorsok: Instrument Stand 316 SST 50mm NB Pipe StandtxagusNo ratings yet

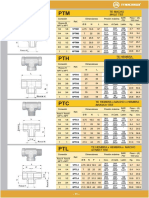

- Figuras PTM-PTH-PTC-PTLDocument1 pageFiguras PTM-PTH-PTC-PTLtxagusNo ratings yet

- Gauge May Be Configured Vert. or Horz. by Position of Blank PlugDocument1 pageGauge May Be Configured Vert. or Horz. by Position of Blank PlugtxagusNo ratings yet

- Norsok: Instrument Stand 316 SST 50mm NB Pipe StandDocument1 pageNorsok: Instrument Stand 316 SST 50mm NB Pipe StandtxagusNo ratings yet

- Norsok: Diaphragm SealDocument1 pageNorsok: Diaphragm SealtxagusNo ratings yet

- Norsok: Product ListDocument1 pageNorsok: Product ListtxagusNo ratings yet

- 1/2" NPT OR 1/4" NPT Note 2: NorsokDocument1 page1/2" NPT OR 1/4" NPT Note 2: NorsoktxagusNo ratings yet

- Norsok I-001-105Document1 pageNorsok I-001-105txagusNo ratings yet

- Norsok: Instr. PipingDocument1 pageNorsok: Instr. PipingtxagusNo ratings yet

- I 001 104Document1 pageI 001 104txagusNo ratings yet

- Norsok: by PipingDocument1 pageNorsok: by PipingtxagusNo ratings yet

- Norsok: Product ListDocument1 pageNorsok: Product ListtxagusNo ratings yet

- A Brief Discussion Over Safety Costs in New Enterprises (SIS, SIL) PDFDocument13 pagesA Brief Discussion Over Safety Costs in New Enterprises (SIS, SIL) PDFtxagusNo ratings yet

- Junction Box Product ListDocument1 pageJunction Box Product ListtxagusNo ratings yet

- Junction Box Product ListDocument1 pageJunction Box Product ListtxagusNo ratings yet

- 1.10 K Controls e Training - Pneumatic Actuator Equipment Interfaces PDFDocument6 pages1.10 K Controls e Training - Pneumatic Actuator Equipment Interfaces PDFtxagusNo ratings yet

- I 001 104Document1 pageI 001 104txagusNo ratings yet

- 1.10 K Controls e Training - Pneumatic Actuator Equipment Interfaces PDFDocument6 pages1.10 K Controls e Training - Pneumatic Actuator Equipment Interfaces PDFtxagusNo ratings yet

- Norsok: NotesDocument1 pageNorsok: NotestxagusNo ratings yet

- Field Equipment Field Junction Box Panel: NorsokDocument1 pageField Equipment Field Junction Box Panel: NorsoktxagusNo ratings yet

- Actuators Selection Procedures (Bettis)Document4 pagesActuators Selection Procedures (Bettis)txagusNo ratings yet

- Installation & Grounding of MagmetersDocument8 pagesInstallation & Grounding of MagmeterstxagusNo ratings yet

- Norsok M CR 501r1Document19 pagesNorsok M CR 501r1Peter AllisonNo ratings yet

- 17 Sil EvlauationDocument14 pages17 Sil EvlauationtxagusNo ratings yet

- Centrifugal PumpDocument12 pagesCentrifugal PumpPrashant DhakateNo ratings yet

- RTD, Life CostsDocument4 pagesRTD, Life CoststxagusNo ratings yet

- Standards & Certification For Hazardous Area Instrumentation (2015)Document6 pagesStandards & Certification For Hazardous Area Instrumentation (2015)txagusNo ratings yet

- Space Heating Handbook (Reznor)Document76 pagesSpace Heating Handbook (Reznor)txagusNo ratings yet

- NFPA 87 RP For Fluid Heaters (Presentation) PDFDocument56 pagesNFPA 87 RP For Fluid Heaters (Presentation) PDFtxagus100% (2)

- Noise Control Manual (Masoneilan) PDFDocument24 pagesNoise Control Manual (Masoneilan) PDFtxagusNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ME080 Section 8 - Other Hydraulic ComponentsDocument101 pagesME080 Section 8 - Other Hydraulic ComponentsAhmed FaragNo ratings yet

- TMC 54-8 EWNA - Water Cooled - F011262Document135 pagesTMC 54-8 EWNA - Water Cooled - F011262Zeevenhooven EquipmentNo ratings yet

- Helping Children and Youth With Self-Harm BehavioursDocument7 pagesHelping Children and Youth With Self-Harm BehavioursjanachidambaramNo ratings yet

- Seriola-1510 MSDS v181205Document12 pagesSeriola-1510 MSDS v181205waqasasad408No ratings yet

- Back To TopSkip To Main ContentDocument60 pagesBack To TopSkip To Main ContentandrewNo ratings yet

- SIEMENS Acuson X150Document6 pagesSIEMENS Acuson X150Pablo RamirezNo ratings yet

- Smart Materials: SS 2008 by Taylor & Francis Group, LLCDocument20 pagesSmart Materials: SS 2008 by Taylor & Francis Group, LLCIonescu CristianNo ratings yet

- Protocol Starting Procedure PDFDocument3 pagesProtocol Starting Procedure PDFAlina100% (2)

- PTK MateriDocument101 pagesPTK MateriAnnisah MardiyyahNo ratings yet

- Cadet Colleg Fateh Jang - A Detailed OverviewDocument10 pagesCadet Colleg Fateh Jang - A Detailed OverviewCadet College Fateh JangNo ratings yet

- Annotated BibliographyDocument2 pagesAnnotated Bibliographyapi-663816171No ratings yet

- Research ReportDocument62 pagesResearch Reportboniphace100% (1)

- Homoeopathic Management of Oral Mucocele: A Case: Dr. Arunava Nath and Dr. Deb Kumar PalitDocument5 pagesHomoeopathic Management of Oral Mucocele: A Case: Dr. Arunava Nath and Dr. Deb Kumar PalitVidhi JobanputraNo ratings yet

- Basic Clinical Lab Competencies For Respiratory Care 5th Edition White Test BankDocument9 pagesBasic Clinical Lab Competencies For Respiratory Care 5th Edition White Test Bankjamesdavismfdgbnjyir100% (9)

- Is7 Eng 101201Document305 pagesIs7 Eng 101201محمدحمادNo ratings yet

- Prediction of Adverse Outcomes in Preeclampsia Using Risk ModelDocument8 pagesPrediction of Adverse Outcomes in Preeclampsia Using Risk ModelEriekafebriayana RNo ratings yet

- SBM Level of Practice: Daraetan Integrated SchoolDocument18 pagesSBM Level of Practice: Daraetan Integrated SchoolRose AquinoNo ratings yet

- Fundamental Nursing LabDocument15 pagesFundamental Nursing LabDev0% (1)

- Kimbely-Clark - CaseDocument2 pagesKimbely-Clark - CaseSHREYA UNNIKRISHNAN PGP 2019-21 BatchNo ratings yet

- Phaseolus VulgarisDocument25 pagesPhaseolus VulgarisMueen mohsinNo ratings yet

- SCDL Organizational Behaviour Paper - 1Document6 pagesSCDL Organizational Behaviour Paper - 1Kattey Spares100% (4)

- WEG CWM Contactors 50070163 enDocument52 pagesWEG CWM Contactors 50070163 enBelo traderNo ratings yet

- Paracentesis PDFDocument3 pagesParacentesis PDFAcitta Raras WimalaNo ratings yet

- Compounding With PhlojelDocument29 pagesCompounding With PhlojelMichael SchreiberNo ratings yet

- Inguillo V First Phil ScalesDocument2 pagesInguillo V First Phil ScalesRein GallardoNo ratings yet

- APG InternalAudit2015 PDFDocument4 pagesAPG InternalAudit2015 PDFBulmaro SanchezNo ratings yet

- 7 Stars Doctor Standards by WHO and FMUIDocument3 pages7 Stars Doctor Standards by WHO and FMUIVito Filbert Jayalie100% (2)

- Secretary, NSW HealthDocument30 pagesSecretary, NSW HealthRiku KusanagiNo ratings yet

- Nitrogen Blanketing Fig 2 - Page 9 PDFDocument16 pagesNitrogen Blanketing Fig 2 - Page 9 PDFzoran cukovicNo ratings yet

- Programs That Work 3.1Document460 pagesPrograms That Work 3.1watchabc100% (10)