Professional Documents

Culture Documents

Merge 1401507949

Uploaded by

Đăng HảiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Merge 1401507949

Uploaded by

Đăng HảiCopyright:

Available Formats

MOTION OF PARTICLES IN A FLUID 159

Example 3.1

What is the terminal velocity of a spherical steel particle, 0.40 mm in diameter, settling in an oil

of density 820 kg/m

3

and viscosity 10 mN s/m

2

? The density of steel is 7870 kg/m

3

.

Solution

For a sphere:

R

0

u

2

0

Re

2

0

=

2d

3

(

s

)g

3

2

(equation 3.35)

=

2 0.0004

3

820(7870 820)9.81

3(10 10

3

)

2

= 24.2

log

10

24.2 = 1.384

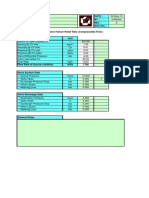

From Table 3.4: log

10

Re

0

= 0.222

Thus: Re

0

= 1.667

and: u

0

=

1.667 10 10

3

820 0.0004

= 0.051 m/s or 51 mm/s

Example 3.2

A nely ground mixture of galena and limestone in the proportion of 1 to 4 by mass is subjected to

elutriation by an upward-owing stream of water owing at a velocity of 5 mm/s. Assuming that

the size distribution for each material is the same, and is as shown in the following table, estimate

the percentage of galena in the material carried away and in the material left behind. The viscosity

of water is 1 mN s/m

2

and Stokes equation (3.1) may be used.

Diameter (m) 20 30 40 50 60 70 80 100

Undersize (per cent by mass) 15 28 48 54 64 72 78 88

The densities of galena and limestone are 7500 and 2700 kg/m

3

, respectively.

Solution

The rst step is to determine the size of a particle which has a settling velocity equal to that of the

upward ow of uid, that is 5 mm/s.

Taking the largest particle, d = (100 10

6

) = 0.0001 m

and: Re

= (5 10

3

0.0001 1000)/(1 10

3

) = 0.5

Thus, for the bulk of particles, the ow will be within region (a) in Figure 3.4 and the settling

velocity is given by Stokes equation:

u

0

= (d

2

g/18)(

s

) (equation 3.24)

160 CHEMICAL ENGINEERING

For a particle of galena settling in water at 5 mm/s:

(5 10

3

) = ((d

2

9.81)/(18 10

3

))(7500 1000) = 3.54 10

6

d

2

and: d = 3.76 10

5

m or 37.6 m

For a particle of limestone settling at 5 nmm/s:

(5 10

3

) = ((d

2

9.81)/(18 10

3

))(2700 1000) = 9.27 10

5

d

2

and: d = 7.35 10

5

m or 73.5 m

Thus particles of galena of less than 37.6 m and particles of limestone of less than 73.5 m

will be removed in the water stream.

Interpolation of the data given shows that 43 per cent of the galena and 74 per cent of the

limestone will be removed in this way.

In 100 kg feed, there is 20 kg galena and 80 kg limestone.

Therefore galena removed = (20 0.43) = 8.6 kg, leaving 11.4 kg, and limestone removed =

(80 0.74) = 59.2 kg, leaving 20.8 kg.

Hence in the material removed:

concentration of galena = (8.6 100)/(8.6 +59.2) = 12.7 per cent by mass

and in the material remaining:

concentration of galena = (11.4 100)/(11.4 +20.8) = 35.4 per cent by mass

As an alternative, the data used for the generation of equation 3.13 for the relation

between drag coefcient and particle Reynolds number may be expressed as an explicit

relation between Re

0

(the value of Re

at the terminal falling condition of the particle)

and the Galileo number Ga. The equation takes the form

(10)

:

Re

0

= (2.33Ga

0.018

1.53Ga

0.016

)

13.3

(3.40)

The Galileo number is readily calculated from the properties of the particle and the uid,

and the corresponding value of Re

0

, from which u

0

can be found, is evaluated from

equation 3.40.

A similar difculty is encountered in calculating the size of a sphere having a given

terminal falling velocity, since Re

0

and R

0

/u

2

are both functions of the diameter d of

the particle. This calculation is similarly facilitated by the use of another combination,

(R

0

/u

2

0

)Re

1

0

, which is independent of diameter. This is given by:

R

0

u

2

0

Re

1

0

=

2g

3

2

u

3

0

(

s

) (3.41)

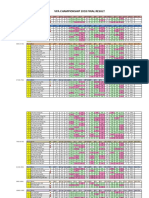

Log Re

is given as a function of log[(R

/u

2

)Re

1

] in Table 3.5 and the functions are

plotted in Figure 3.6. The diameter of a sphere of known terminal falling velocity may

be calculated by evaluating (R

0

/u

2

0

)Re

1

0

, and then nding the corresponding value of

Re

0

, from which the diameter may be calculated.

As an alternative to this procedure, the data used for the generation of equation 3.13

may be expressed to give Re

0

as an explicit function of {(R

/u

2

0

)Re

1

0

}, which from

394 CHEMICAL ENGINEERING

Figure 7.9. Thorough washing

and in no case should the nal ltration pressure be exceeded. After washing, the cake

may be made easier to handle by removing excess liquid with compressed air.

For ease in identication, small buttons are embossed on the sides of the plates and

frames, one on the non-washing plates, two on the frames and three on the washing plates

as shown in Figure 7.10.

Example 7.1

A slurry is ltered in a plate and frame press containing 12 frames, each 0.3 m square and 25 mm

thick. During the rst 180 s the pressure difference for ltration is slowly raised to the nal value

of 400 kN/m

2

and, during this period, the rate of ltration is maintained constant. After the initial

period, ltration is carried out at constant pressure and the cakes are completely formed in a further

900 s. The cakes are then washed with a pressure difference of 275 kN/m

2

for 600 s using thorough

washing (See the plate and frame press in Section 7.4.4). What is the volume of ltrate collected

per cycle and how much wash water is used?

A sample of the slurry had previously been tested with a leaf lter of 0.05 m

2

ltering surface

using a vacuum giving a pressure difference of 71.3 kN/m

2

. The volume of ltrate collected in the

rst 300 s, was 250 cm

3

and, after a further 300 s, an additional 150 cm

3

was collected. It may be

assumed that the cake is incompressible and that the cloth resistance is the same in the leaf as in

the lter press.

LIQUID FILTRATION 395

Figure 7.10. Plates and frames

Solution

In the leaf lter, ltration is at constant pressure from the start.

Thus: V

2

+2

AL

V = 2

(P)A

2

r

t (from equation 7.18)

In the lter press, a volume V

1

of ltrate is obtained under constant rate conditions in time t

1

,

and ltration is then carried out at constant pressure.

Thus: V

2

1

+

AL

V

1

=

(P)A

2

r

t

1

(from equation 7.17)

396 CHEMICAL ENGINEERING

and:

(V

2

V

2

1

) +2

AL

(V V

1

) = 2

(P)A

2

r

(t t

1

) (from equation 7.18)

For the leaf lter

When t = 300 s, V = 250cm

3

= 2.5 10

4

m

3

and when t = 600 s,

V = 400 cm

3

= 4 10

4

m

3

, A = 0.05 m

2

and P = 71.3 kN/m

2

or 7.13 10

4

N/m

2

.

Thus: (2.5 10

4

)

2

+2(0.05L/)2.5 10

4

= 2(7.13 10

4

0.05

2

/r)300

and: (4 10

4

)

2

+2(0.05L/)4 10

4

= 2(7.13 10

4

0.05

2

/r)600

That is: 6.25 10

8

+2.5 10

5

L

=

1.07 10

5

r

and: 16 10

8

+4 10

5

L

=

2.14 10

5

r

Hence: L/ = 3.5 10

3

and r = 7.13 10

11

For the lter press

A = (12 2 0.3

2

) = 2.16 m

2

, P = 400 kN/m

2

= 4 10

5

N/m

2

, t = 180 s. The volume

of ltrate V

1

collected during the constant rate period on the lter press is given by:

V

2

1

+(2.16 3.5 10

3

V

1

) = [(4 10

5

2.16

2

)/(7.13 10

11

)]180

V

2

1

+(7.56 10

3

V

1

) (4.711 10

4

) = 0

or: V

1

= (3.78 10

3

) +

(1.429 10

5

+4.711 10

4

) = 1.825 10

2

m

3

For the constant pressure period:

(t t

1

) = 900 s

The total volume of ltrate collected is therefore given by:

(V

2

3.33 10

4

) +(1.512 10

2

)(V 1.825 10

2

) = 5.235 10

6

900

or: V

2

+(1.512 10

2

V) (4.712 10

3

) = 0

Thus: V = 0.756 10

2

+

(0.572 10

4

+4.712 10

3

)

= 6.15 10

2

or 0.062 m

3

The nal rate of ltration is given by:

PA

2

r(V +AL/)

=

4 10

5

2.16

2

7.13 10

11

(6.15 10

2

+2.16 3.5 10

3

)

= 3.79 10

5

m

3

/s

(from equation 7.16)

If the viscosity of the ltrate is the same as that of the wash-water, then:

Rate of washing at 400 kN/m

2

=

1

4

3.79 10

5

= 9.5 10

6

m

3

/s

Rate of washing at 275 kN/m

2

= 9.5 10

6

(275/400) = 6.5 10

6

m

3

/s

Thus the amount of wash-water passing in 600 s = (600 6.5 10

6

)

= 3.9 10

3

m

3

or 0.004 m

3

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Fluid Mechanics PDFDocument179 pagesFluid Mechanics PDFNishchay Choudhary100% (1)

- Fundamentals of Duct DesignDocument71 pagesFundamentals of Duct Designjmdc100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- AerodynamicsDocument7 pagesAerodynamicsAldrine BanalNo ratings yet

- Fluids Nov2021 Day2Document17 pagesFluids Nov2021 Day2Yedda M Ilagan100% (1)

- Control Valve Failure Relief Rate - Gas ServiceDocument3 pagesControl Valve Failure Relief Rate - Gas ServiceSaeid Rahimi Mofrad100% (1)

- InducerDocument54 pagesInducerYaswanthNo ratings yet

- Drilling HydraulicsDocument78 pagesDrilling HydraulicsKarlos Rdgz100% (1)

- 13 API Power-Law ModelDocument44 pages13 API Power-Law Modeltotos20No ratings yet

- Lecture2 - CFD - Course - Governing Equations (Compatibility Mode) PDFDocument132 pagesLecture2 - CFD - Course - Governing Equations (Compatibility Mode) PDFvibhor28No ratings yet

- NADH Consulting Job Description Lead TSD Specialist PSPDocument2 pagesNADH Consulting Job Description Lead TSD Specialist PSPĐăng HảiNo ratings yet

- VPA Chapionship 2018Document3 pagesVPA Chapionship 2018Đăng HảiNo ratings yet

- Heat Sealing Roll StockDocument13 pagesHeat Sealing Roll StockĐăng HảiNo ratings yet

- 200Document1 page200Đăng HảiNo ratings yet

- InDocument16 pagesInĐăng HảiNo ratings yet

- Part 2 Fundamentals of Fluid FlowDocument3 pagesPart 2 Fundamentals of Fluid FlowJoren Huerno100% (1)

- Fluid Mechanics 1Document32 pagesFluid Mechanics 1essum belaNo ratings yet

- Ce233 PowerpointDocument20 pagesCe233 PowerpointVIDEO HUBNo ratings yet

- MHD Flow of A Non-Newtonian Fluid Through A Circular TubeDocument10 pagesMHD Flow of A Non-Newtonian Fluid Through A Circular TubeIJMERNo ratings yet

- Solidc - Curvas PerformaceDocument8 pagesSolidc - Curvas Performacedouglas alvesNo ratings yet

- IS 2951 (Part 2) - Pressure Drop Calc On Pipe FittingsDocument16 pagesIS 2951 (Part 2) - Pressure Drop Calc On Pipe FittingspritamNo ratings yet

- 7.3 Flow Rate and Viscosity PDFDocument3 pages7.3 Flow Rate and Viscosity PDFAtif KamalNo ratings yet

- K EpsilonDocument39 pagesK EpsilonRahul AroraNo ratings yet

- Super Imposed FlowsDocument4 pagesSuper Imposed FlowssuriyaanaNo ratings yet

- HydraulicsDocument3 pagesHydraulicsIZNo ratings yet

- Viscometers AssignmentDocument5 pagesViscometers AssignmentVissen GoldenEyeNo ratings yet

- CW. Assignment (20 Mark), For 4 MR Due To The Day of The Final ExamDocument3 pagesCW. Assignment (20 Mark), For 4 MR Due To The Day of The Final ExamMohammed KhalidNo ratings yet

- Study of Supersonic Flow in A Constant Rate of Momentum Change PDFDocument11 pagesStudy of Supersonic Flow in A Constant Rate of Momentum Change PDFVirendra KumarNo ratings yet

- Metering PumpsDocument7 pagesMetering PumpsHonesto BautistaNo ratings yet

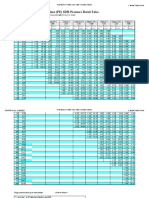

- Polyethylene (PE) SDR-Pressure Rated Tube: Friction Loss CharacteristicsDocument24 pagesPolyethylene (PE) SDR-Pressure Rated Tube: Friction Loss CharacteristicsSaidFerdjallahNo ratings yet

- FM HM Syllabus JnukDocument2 pagesFM HM Syllabus JnukVenkata NarayanaNo ratings yet

- Bellary2015 - RugosidadDocument11 pagesBellary2015 - RugosidadAbraham SilesNo ratings yet

- Rheology of Screen Printing InkDocument85 pagesRheology of Screen Printing InkLearn & EnjoyNo ratings yet

- Automatic and Air Atomizing Spray Nozzles CatalogDocument166 pagesAutomatic and Air Atomizing Spray Nozzles CatalogAsad AhmedNo ratings yet

- Common Control Valve Problems - Basic Principles of Control Valves and Actuators - Automation TextbookDocument34 pagesCommon Control Valve Problems - Basic Principles of Control Valves and Actuators - Automation Textbookvon D' synsNo ratings yet

- Orifice Plate DatasheetDocument29 pagesOrifice Plate DatasheetshayabajNo ratings yet