Professional Documents

Culture Documents

VIT154 - DrainageConcept - 2006!01!19

Uploaded by

Huynh Thanh Tam0 ratings0% found this document useful (0 votes)

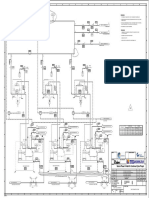

134 views12 pagesThe plant drainage system comprises three subsystems: 1) A storm/surface water drainage system to drain water from building roofs and paved areas via underground pipes to terminal points (TP17); 2) An oily waste water drainage system to drain surface water with oil traces via underground pipes to TP16.1-TP16.8; 3) A waste water drainage system to drain process drains through TP15. Storm water and waste water from individual structures like the power control centre, transformers, and turbine buildings are drained to respective terminal points through underground gravity pipe networks.

Original Description:

Original Title

VIT154- DrainageConcept _2006!01!19.Doc

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe plant drainage system comprises three subsystems: 1) A storm/surface water drainage system to drain water from building roofs and paved areas via underground pipes to terminal points (TP17); 2) An oily waste water drainage system to drain surface water with oil traces via underground pipes to TP16.1-TP16.8; 3) A waste water drainage system to drain process drains through TP15. Storm water and waste water from individual structures like the power control centre, transformers, and turbine buildings are drained to respective terminal points through underground gravity pipe networks.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

134 views12 pagesVIT154 - DrainageConcept - 2006!01!19

Uploaded by

Huynh Thanh TamThe plant drainage system comprises three subsystems: 1) A storm/surface water drainage system to drain water from building roofs and paved areas via underground pipes to terminal points (TP17); 2) An oily waste water drainage system to drain surface water with oil traces via underground pipes to TP16.1-TP16.8; 3) A waste water drainage system to drain process drains through TP15. Storm water and waste water from individual structures like the power control centre, transformers, and turbine buildings are drained to respective terminal points through underground gravity pipe networks.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

DRAWING/DOCUMENT STATUS: FOR APPROVAL

B 2006-01-19 FOR APPROVAL SV RK

A 2006-01-09 FOR APPROVAL PKR RK

Rev. DATE DESCRIPTION

Bearb.

Coord.

Geprft

Checked

APPD.

PROJ ECT :

CAMAU 1 750MW COMBINED CYCLE POWER PLANT

OWNER : OWNERS ENGINEER :

PETRO VIETNAM

CPMB

CONTRACTOR : CONTRACTORS ENGINEER :

LILAMA CORPORATION FICHTNER

SUBCONTRACTORS NAME : SUBCONTRACTORS SUPPLIER :

s

POWER GENERATION

DRAWING TITLE :

PKZ UAS Contents Code Reg. No. UNID

Ursprung/Original Ursprung-Nr./Original-No.

Urspr.-PKZ-Nr.

Orig.-PC

Projekt/Project PKZ/PC

CA MAU 1 CCPP VIT154

Datum

Date

Name Mastab

Scale

N/A A4

UA/DCC

Type

BN00

gezeich.

Drawn

2006-01-09 P.K.RAY Benennung/Title

Inhaltskennzeichen

Contents Code

bearb.

Coord.

2006-01-09 S.VERMA

geprft

Checked

2006-01-09 R. KUMAR

UZ

Abtlg.

Dept.

E-CAM sgd.

Plant Drainage System

Concept LOT 1

Zhl.-Nr.

Reg.-No.

SPEL/P2/200

6/006

Dienstst./Dept. UNID Index/Rev. Version

s AG

POWER GENERATION

SPEL-P2

423179055

B

Blatt-Nr./Page-No.

CM1-L1-C-UZ.05-610095

1/12

Erstellt mit/designed with

Ersatz fr

Supersedes

Siemens Power Engineering Pvt. Ltd.

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration

of a utility model or design, are reserved.

Form SPEL Y:\VIT154\ACAD\Civil\Buildings\Plant drainage concept-2006-01-19\VIT154-PLANT DRAINAGE SYSTEM_19-01-06.doc

Ref. (Department/Year/Serial No.)

Work Report

SPEL/P2/2006/006

Subject/Title Place Date

Plant Drainage System Concept GURGAON 2006/01/19

Author(s) Department Tel. Signature

P.K.Ray SPEL/P2 Sgd.

S.Verma Siemens PG Sgd.

Project

Ca Mau CCPP(Lot1)

Signature for Release by Dept. Concerned

(for Contents, Handling, Distribution)

Signature for External Release by

Sales & Marketing Dept. (Not

Required for Approval Documents)

Handling Instructions

Unrestricted R Kumar sgd

Proj.-Code UA Contents Code Doc. Ident. No.

VIT154 BN00 UZ 423179055

Summary*) Pages of Text: 5 Appendices: 1

This report includes concept of Plant Drainage system of roads and various structures inside the

plant boundary and all buildings within the scope of Siemens.

Appendix-1 consists of data for storm water quantities at different TP17 and oily waste water as

well as locations of TP17 (a to w) and storm water down comers (RWP).

Siemens Concept

The plant drainage system comprises, basically the following subsystems:

1. Storm/Surface water drainage system

Water from roofs of the buildings and paved areas will be drained via underground gravity

flow pipe surface water system to TP17 An exhaustive list of buildings/structures is dis-

cussed in detail further in this report.

2. Oily waste water drainage

Surface Water with traces of oil will be drained via underground gravity flow pipe system to

terminal points TP16.1 to 16.8.

3. Waste water drainage

Waste water from process drains will be drained through TP15. Chemical waste due to

washing will be collected in pits/dykes and will be disposed of manually by owner.

Report No.: SPEL/ P2/2006/006

Page: 2 of 10

Handling: Unrestricted

Siemens Power Engineering Pvt. Ltd.

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration

of a utility model or design, are reserved.

FORM/SPEL Y:\VIT154\ACAD\Civil\Buildings\Plant drainage concept-2006-01-19\VIT154-PLANT DRAINAGE SYSTEM_19-01-06.doc

1. Terms

Systems & Bui ldings

GM Plant drainage system

GQ Domestic waste water collection and drainage system

GU Rainwater system

UBA Structure for power control centre

UBD Structure for LV-auxiliary power transformers

UBE Structure for MV-auxiliary power transformers

UBF Structure for generator transformers

UBN Structure for emergency power generating set

UBS Structure for cable shafts

UBX Structure for generator circuit breaker

UBZ Structure for cable duct

UEN Structure for fuel gas meatering, heating ,filtering

UEY Pipe bridge / sleeperway

UHA Structure for heat recovery steam generator

UHB Structure for auxillary boiler

UHN Structure for bypass stack

UHW Structure for boiler blowdown tank

UHX Structure for sampling container

ULA Structure for feedwater pumps

UMA Steam turbine building

UMB Gas turbine building

UMX Structure for diffuser wall

UMY Structure for Pipe and cable bridge

URB Structure for GT/GT generator fin fan cooler

URC Structure for lube oil fin fan cooler

URX Pipe support

URY Sleeper way

USA Structure for ventilation units

UTX Structure for ignition gas tank

UZA Roads

UZJ Fencing and gates

PAB Main cooling water pipes

GT Gas Turbine

ST Steam Turbine

Report No.: SPEL/ P2/2006/006

Page: 3 of 10

Handling: Unrestricted

Siemens Power Engineering Pvt. Ltd.

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration

of a utility model or design, are reserved.

FORM/SPEL Y:\VIT154\ACAD\Civil\Buildings\Plant drainage concept-2006-01-19\VIT154-PLANT DRAINAGE SYSTEM_19-01-06.doc

The plant drainage system discharges for each structure is handled as follows:

11/12UBA01/02/03, 10UBA21/22, 00UBA91/92: Structure for power control centre

Rain water from roof of the PCC will lead to TP17

11/12UBD 00/10UBD: Structure for LV transformer

No drainage required

11/12 UBE & 10/11/12 UBF: Structure for MV Auxiliary and Generator Transformers

Each transformer area is designed as a containment bunding for 20% collection of discharge of

rainwater, leakage oil and fire fighting water. The sump within the bund will be connected by grav-

ity pipe system to TP16.1.

00UBN : Structure for emergency power generating set

The oily waste water from power generating set will be connected to TP16.5. The container roof

is drained through TP17.

10UBS01- 36 : Cable shafts

No drainage is provided, however a sump will be provided inside each UBS and in case of any

accidental water ingress, it can be pumped out using portable pumps. No permanent pumping will

be provided.

11-12UBX : Structure for generator circuit breaker

Storm water from roof will be drained to surrounding landscape area.

00UBZ: Structure for cable duct

Storm water from surface will be drained into surrounding landscape

11/12UEN : Structure for fuel gas metering, heating and filtering

Storm water from UEN slab surface will be drained into surrounding landscape

11/13UEY,12UEY : Sleeper way, Pipe Bridge

No drainage required.

11-12UHA : Structure for HRSG

Storm water from roof is drained to the storm water pipe to the storm water drainage system.

Waste water from HRSG will be collected and led to the waste water drainage system by gravity

flow through TP16.6

00UHB: Structure for Auxiliary steam generator

Storm water on auxiliary boiler foundation slab and roof is drained to the surrounding landscape.

Waste water collected is routed to TP16.4.

11-12UHN : Structure for bypass stack

Drains from the stacks (in case of washing) are to be connected to TP16.6.

11-12UHW : Structure for boiler blow down tank

Report No.: SPEL/ P2/2006/006

Page: 4 of 10

Handling: Unrestricted

Siemens Power Engineering Pvt. Ltd.

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration

of a utility model or design, are reserved.

FORM/SPEL Y:\VIT154\ACAD\Civil\Buildings\Plant drainage concept-2006-01-19\VIT154-PLANT DRAINAGE SYSTEM_19-01-06.doc

Boiler blow down tank discharge will be directed to TP15 and oily waste water portion of boiler will

be drained to a nearby TP16.4 from the sump pit.

00UHX : Structure for sampling container

A collecting pit will be provided adjacent to the UHX foundation. All drains arising from the sam-

pling container will be connected to this collecting pit. The collecting pits will be connected to

waste water drainage system through nearby TP16.6.

Storm water from roof will be drained into surrounding landscape.

10ULA : Structure for feed water pumps

Rain water from ULA slab will lead to the ground nearby. Accidental oil discharge inside the BFP

enclosure will be collected in sump pits and routed to TP16.4. Discharges from process drains will

also be connected to TP16.4.

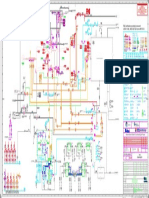

10UMA : Steam turbine building

Floor and equipment drainage from inside the building will be collected in sump pits in UMA slab.

These pits will be connected to a common sump located in CEP pit. The water is than pumped to

nearest outdoor pit which is connected to TP16.3.

Storm water from roof will be led by storm water drainage system toTP17 by gravity.

The lube oil system will be located within a dyke area, any leakage will be stored within the dyke

and removed manually.

11-12UMB : Gas turbine building

Floor and equipment drainage from inside the building will be collected in sump pits in UMB slab.

These pits will be connected to TP16.2.

Storm water from roof will be led by storm water drainage system through TP17.

The lube oil system will be located within a diked area, any leakage will be stored within the diked

and removed manually.

Compressor wash water drains from Diffuser, gas turbine and air inlet duct will be collected in a pit

( TP 16B)outside the UMB building and disposed off it manually by client.

11-12UMX: Structure for diffuser wall

Drains from the diffuser and its enclosure (in case of washing) are to be connected to TP16.6.

10-11-12UMY: Pipe and Cable Bridge

No drainage measure is envisaged. Water will flow to surrounding landscaped areas

11-12 URB : Structure for GT/ GT generator fin fan cooler

No drainage measure is envisaged. Water will flow to surrounding landscaped areas

11-12 URC: Structure for lube oil fin fan cooler

No drainage measure is envisaged. Water will flow to surrounding landscaped areas

10URX 01-02: Pipe Supports

No drainage required.

10URY: Sleeper way

No drainage required.

Report No.: SPEL/ P2/2006/006

Page: 5 of 10

Handling: Unrestricted

Siemens Power Engineering Pvt. Ltd.

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration

of a utility model or design, are reserved.

FORM/SPEL Y:\VIT154\ACAD\Civil\Buildings\Plant drainage concept-2006-01-19\VIT154-PLANT DRAINAGE SYSTEM_19-01-06.doc

11-16USA: Structure for ventilation units

No drainage measure envisaged water will flow to surrounding landscaped areas

10UTX: Structure for ignition gas tank

No drainage measure envisaged, water will flow to surrounding landscaped areas.

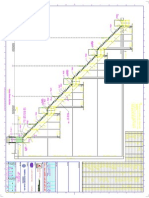

00UZA: Roads

Storm water from road surface is collected by road gullies and led by buried pipe gravity system to

storm water drainage system through TP17.

10UZJ: Fencing and gates

No drainage required

PAB: Main cooling water pipes

No drainage required

Waste water discharge from and during construction shall be connected to TP26.

Report No.: SPEL/ P2/2006/006

Page: 6 of 10

Handling: Unrestricted

Siemens Power Engineering Pvt. Ltd.

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration

of a utility model or design, are reserved.

FORM/SPEL Y:\VIT154\ACAD\Civil\Buildings\Plant drainage concept-2006-01-19\VIT154-PLANT DRAINAGE SYSTEM_19-01-06.doc

APPENDIX-1 VIT154: Camau 720MW CCPP Pl ant Drai nage Concept

Rainfall Data

Maxi maum 20 mi n Rainfall = 49.8 mm (Gi ven value)

Maxi maum 20 mi n Rainfall per hr = 149.4 mm/hr

Maxi mum rainfall in l/s-ha = 415 l/s-ha

Time Coeff. For n=1 and T= 5 min. = 2.07

Design rainfall i ntensity =415 x 2.07 = 859.05 l/s-ha

(Rainfal l i ntensi ty for 5 min duration and a recurrance interval of 1 year)

Table

S.No. Bui lding Description

Plan

Area

(sq.m)

Plan

Area

(ha)

Runoff

coeff.

Rai nfal l

i ntensity

Quantity

of storm

water in

l/sec

1 UMA Steam turbine building 2310 0.231 1 859.05 198.44

2

11 UMB

12UMB Gas turtbine building 2130 0.213 1 859.05 182.99

3

11 UBA01

11 UBA02

11UBA03

Power control centre

(gas turbine) 322 0.032 1 859.05 27.67

4

12 UBA01

12 UBA02

12UBA03

Power control centre

(gas turbine) 322 0.032 1 859.05 27.67

5 00UBN Emergency Diesel 132 0.013 1 859.05 11.32

6

00 UBA92

00 UBA91

10UBA21

10UBA22

Power control centre

(21,22-steam turbine)

(91,92-common part) 355 0.035 1 859.05 30.45

Total quantity of storm water from above buil di ngs = 478.54

Report No.: SPEL/ P2/2006/006

Page: 7 of 10

Handling: Unrestricted

Siemens Power Engineering Pvt. Ltd.

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration

of a utility model or design, are reserved.

FORM/SPEL Y:\VIT154\ACAD\Civil\Buildings\Plant drainage concept-2006-01-19\VIT154-PLANT DRAINAGE SYSTEM_19-01-06.doc

Storm Water Quanti ties at different TP-17

S.No. Bui lding

Strom Water Dis-

charge

Quantity

of storm

water in

l/sec

TP17-a 27.3

TP17-b 27.3

TP17-c 27.3

TP17-d 39.1

TP17-e 39.1

1 UMA

TP17-f 27.6

TP17-g 30.7

TP17-h 19.2

TP17-i 19.2

TP17-j 19.2

TP17-k 6.12

TP17-l 19.2

TP17-m 6.12

TP17-n 19.2

TP17-o 6.43

2 UMB

TP17-q 38.37

3 11 UBA01

11 UBA02

11UBA03 TP17-p 13.84

TP17-r 13.84

4

12 UBA01

12 UBA02

12UBA03 TP17-s 38.37

5 00UBN TP17-t 5.66

Report No.: SPEL/ P2/2006/006

Page: 8 of 10

Handling: Unrestricted

Siemens Power Engineering Pvt. Ltd.

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration

of a utility model or design, are reserved.

FORM/SPEL Y:\VIT154\ACAD\Civil\Buildings\Plant drainage concept-2006-01-19\VIT154-PLANT DRAINAGE SYSTEM_19-01-06.doc

TP17-u 5.66

TP17-v 15.23

6 00 UBA92

00 UBA91

10UBA21

10UBA22 TP17-w 15.23

Report No.: SPEL/ P2/2006/006

Page: 9 of 10

Handling: Unrestricted

Siemens Power Engineering Pvt. Ltd.

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration

of a utility model or design, are reserved.

FORM/SPEL Y:\VIT154\ACAD\Civil\Buildings\Plant drainage concept-2006-01-19\VIT154-PLANT DRAINAGE SYSTEM_19-01-06.doc

Quantity of Oil y water for 10 UBF, 11UBF, 12UBF (trafo oil +fire fighti ng water)

TP-16.1

Quantity of oil water = 99.33 l/sec

Quantity of deluge water = 63 l/sec

Quantity of water for hose pi pe = 31.5 l/sec

Total quantity of water (transfo oil+fire fighting) = 193.83 l/sec

Total quanti ty of water i n the case of emergency as recommended is 170

m

3

i n 10 mi n. = 283 l/sec

(Ref :- MOM items for Kick off meeting 5-9, dec-05)

The total quanti ty of water going in TP-16.1 i s taken as = 283 l/sec

Quantity of Oil y water for UMB

TP-16.2

The quantity of oil y waste water i s taken as =10 l /sec

Quantity of Oil y water for UMA

TP-16.3

The quantity of oil y waste water i s taken as =20 l /sec (emergency case)

(Ref :- MOM items for Kick off meeting 5-9, dec-05)

Quantity of Oil y water for 11UHW, 12UHW

TP-16.4

The quantity of oil y waste water to be pumped out = 10 l/sec

(Ref :- MOM items for Kick off meeting 5-9, dec-05)

Report No.: SPEL/ P2/2006/006

Page: 10 of 10

Handling: Unrestricted

Siemens Power Engineering Pvt. Ltd.

The reproduction, transmission or use of this document or its contents is not

permitted without express written authority. Offenders will be liable for

damages. All rights, including rights created by patent grant or registration

of a utility model or design, are reserved.

FORM/SPEL Y:\VIT154\ACAD\Civil\Buildings\Plant drainage concept-2006-01-19\VIT154-PLANT DRAINAGE SYSTEM_19-01-06.doc

Oily waste water quantiti es

S.No.

Build-

ing

Oi l waste

water

di s-

charge

Quanti ty of

oil y waste in

l/sec

1 10 UBF

11 UBF

12 UBF TP-16.1 283

2 UMB TP-16.2 10

3 UMA TP-16.3 20

4

11 UHW

12 UHW TP-16.4 10

You might also like

- Catalogue2014 PDFDocument158 pagesCatalogue2014 PDFاشرينكيل مسونكيل100% (1)

- InsulationDocument63 pagesInsulationSH1961No ratings yet

- T 2171 - Diesel Storage TankDocument2 pagesT 2171 - Diesel Storage TankHuynh Thanh TamNo ratings yet

- 200MW Volume 1Document350 pages200MW Volume 1api-19984595100% (9)

- HhfyuuDocument4 pagesHhfyuuHiltonNo ratings yet

- Feasibility Report: Proposed Expansion of Cement PlantDocument37 pagesFeasibility Report: Proposed Expansion of Cement PlantAkash DasNo ratings yet

- 14 ACC Air Side PerformanceDocument24 pages14 ACC Air Side PerformanceShivakumarNo ratings yet

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDocument53 pagesPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.Pkkumar_717405No ratings yet

- P&ID CondensationDocument4 pagesP&ID CondensationdnbinhNo ratings yet

- 000-Performance Test Procedure (General)Document10 pages000-Performance Test Procedure (General)K R Kumar RanjanNo ratings yet

- Pltu Process Overview PDFDocument1 pagePltu Process Overview PDFTegar Ardian100% (1)

- 508-CI-CP-02 - R0 - GASchematic DiagramBOM of Relay Based Control PanelDocument17 pages508-CI-CP-02 - R0 - GASchematic DiagramBOM of Relay Based Control Panelpradeep.selvarajanNo ratings yet

- Sewage Lift StationDocument110 pagesSewage Lift Stationmohdnazir100% (1)

- Turbo Generator & Its AuxiliariesDocument89 pagesTurbo Generator & Its AuxiliariesPapun ScribdNo ratings yet

- A. E. Beck (Auth.) - Physical Principles of Exploration Methods - An Introductory Text For Geology and Geophysics Students (1981, Macmillan Education UK)Document240 pagesA. E. Beck (Auth.) - Physical Principles of Exploration Methods - An Introductory Text For Geology and Geophysics Students (1981, Macmillan Education UK)EdilberNo ratings yet

- 234-76-11 Longitudinal & Circumferencial Weld Joints & Seams For Pipes, Drums& VesselsDocument3 pages234-76-11 Longitudinal & Circumferencial Weld Joints & Seams For Pipes, Drums& VesselsJKKNo ratings yet

- Tce Consulting Engineers Limited Design Guide For Auxiliary Steam HeaderDocument12 pagesTce Consulting Engineers Limited Design Guide For Auxiliary Steam HeaderbandithaguruNo ratings yet

- FGD 001Document30 pagesFGD 001tanmaymajhi09_796764No ratings yet

- JO003-10-LA - MDD-IDM-001-4 Feedwater System P&IDDocument3 pagesJO003-10-LA - MDD-IDM-001-4 Feedwater System P&IDHasan MustafaNo ratings yet

- The Future of The Automobile Industry in India - McKinseyDocument13 pagesThe Future of The Automobile Industry in India - McKinseyDhiraj KhotNo ratings yet

- DBR Mechanical REV02Document34 pagesDBR Mechanical REV02abdellah faqdaniNo ratings yet

- 58-75-02 Field Welding Accessibility For Header Butt Weld JointDocument3 pages58-75-02 Field Welding Accessibility For Header Butt Weld JointJKKNo ratings yet

- Session 5. Gas Turbine Related SolutionsDocument30 pagesSession 5. Gas Turbine Related SolutionsMaintenance PTGSNo ratings yet

- 235-76-02 Det. & Assembly For Disk Type Orifice & Butt Welded Tube JointsDocument3 pages235-76-02 Det. & Assembly For Disk Type Orifice & Butt Welded Tube JointsJKKNo ratings yet

- Haryana Power 800mwDocument61 pagesHaryana Power 800mwprakashkumarsinghgkp01No ratings yet

- 2X500 MW Neyveli New Thermal Power Project (NNTPP) Neyveli, Tamilnadu, IndiaDocument28 pages2X500 MW Neyveli New Thermal Power Project (NNTPP) Neyveli, Tamilnadu, IndiaHiltonNo ratings yet

- 20.12 - GEK72281f Steam Purity Recommendations For Steam TurbinesDocument14 pages20.12 - GEK72281f Steam Purity Recommendations For Steam TurbinesLIUNo ratings yet

- 50-83-02 Spec. For Arc & Capacitor Discharge Weldingt of Pr. & Non-Pr. PartsDocument6 pages50-83-02 Spec. For Arc & Capacitor Discharge Weldingt of Pr. & Non-Pr. PartsJKKNo ratings yet

- NPK 000 B1 MR 400136 K RFQ For Condensate Tank R0Document16 pagesNPK 000 B1 MR 400136 K RFQ For Condensate Tank R0DangolNo ratings yet

- 238-76-04 Pulverised Fuel Piping WeldsDocument3 pages238-76-04 Pulverised Fuel Piping WeldsJKKNo ratings yet

- T10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0Document13 pagesT10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0Thắng NguyễnNo ratings yet

- Acb Terasaki ManualDocument114 pagesAcb Terasaki ManualTuấn TrầnNo ratings yet

- 10-87-02 Spec For Ceramic Fibre Blanket InsulationDocument5 pages10-87-02 Spec For Ceramic Fibre Blanket InsulationlightsonsNo ratings yet

- 10-67-02 Field Welding Fusion & Fin Welded WallsDocument3 pages10-67-02 Field Welding Fusion & Fin Welded WallsJKKNo ratings yet

- Hydraulic Calculation FOR Service Water System: I.P.D.C. Project: Shirvan Gas Turbine Power PlantDocument9 pagesHydraulic Calculation FOR Service Water System: I.P.D.C. Project: Shirvan Gas Turbine Power PlantnourfarmajidNo ratings yet

- JO003-10-MA - MDD-DSP-001 P&ID Steam WaterDocument1 pageJO003-10-MA - MDD-DSP-001 P&ID Steam WaterHasan MustafaNo ratings yet

- CCPP Operating BehaviorDocument32 pagesCCPP Operating BehaviorphamquanghieuNo ratings yet

- 13-61-16 Field Welding Data Sheets & Location DrgsDocument17 pages13-61-16 Field Welding Data Sheets & Location DrgsJKKNo ratings yet

- Method Statement For ACC BHELDocument7 pagesMethod Statement For ACC BHELHsebepl NkNo ratings yet

- Circulating Fluidised Bed Boiler Technology Coal Oil Power - PDF (Application PDFDocument16 pagesCirculating Fluidised Bed Boiler Technology Coal Oil Power - PDF (Application PDFGaluh AjengNo ratings yet

- Fuel Oil Dyke Size Calculation-R0Document3 pagesFuel Oil Dyke Size Calculation-R0Amul AmnajeNo ratings yet

- Single Line Flow Diagram of Fly Ash Pressure Conveying SysDocument7 pagesSingle Line Flow Diagram of Fly Ash Pressure Conveying SysHari PrasadNo ratings yet

- SCR AlstomDocument6 pagesSCR Alstomcristi_molinsNo ratings yet

- PDF Created With Pdffactory Pro Trial Version: Pxd-767-Cal-02 23 MMDocument24 pagesPDF Created With Pdffactory Pro Trial Version: Pxd-767-Cal-02 23 MMSISIR KR BARMAN0% (1)

- 1 00 561 U4089 - Rev 04 PDFDocument15 pages1 00 561 U4089 - Rev 04 PDFSandip SurNo ratings yet

- BTG DBRDocument182 pagesBTG DBRParmeshwar Nath Tripathi100% (1)

- BFP Data SheetDocument3 pagesBFP Data Sheetwael zakariaNo ratings yet

- 2-1 Tech Spec Ashuganj R0Document181 pages2-1 Tech Spec Ashuganj R0Anup Mitra100% (1)

- SEC A Bekasi Design SpecDocument20 pagesSEC A Bekasi Design Speccharleselitb92No ratings yet

- T219AB-384A9554 Rev E Deaerating Condenser Functional SpecificationDocument6 pagesT219AB-384A9554 Rev E Deaerating Condenser Functional SpecificationvankayalasuryaNo ratings yet

- Checklist - Stress AnalysisDocument2 pagesChecklist - Stress AnalysisRamalingam PrabhakaranNo ratings yet

- Az - Zour R&M Furnace Dimensions - ADocument1 pageAz - Zour R&M Furnace Dimensions - AShameer MajeedNo ratings yet

- DBR 2x18MWDocument107 pagesDBR 2x18MWErin WardNo ratings yet

- Bi-Drum Vs Single Drum - Research Paper 2Document6 pagesBi-Drum Vs Single Drum - Research Paper 2Parth Merchant100% (1)

- 003-Auxiliary Power Consumption PGT ProcedureDocument9 pages003-Auxiliary Power Consumption PGT ProcedureK R Kumar RanjanNo ratings yet

- Gas Turbine - Partload and Operational Tradeoffs: Michael A. CoccaDocument18 pagesGas Turbine - Partload and Operational Tradeoffs: Michael A. CoccaThanapaet RittirutNo ratings yet

- 05 02Document7 pages05 02arturoncNo ratings yet

- Brochure DoosanSkoda SteamTurbines & GeneratorsDocument13 pagesBrochure DoosanSkoda SteamTurbines & GeneratorsNestramiNo ratings yet

- Design of Incinerator Plant For Vasai-Virar RegionDocument4 pagesDesign of Incinerator Plant For Vasai-Virar RegionVIVA-TECH IJRINo ratings yet

- F06861S-D0602 CONTROL AND PROTECTION SCHEMATIC DIAGRAM OF 11kV SWITCHGEAR OF 500kV SWITCHYARD R0 FADocument20 pagesF06861S-D0602 CONTROL AND PROTECTION SCHEMATIC DIAGRAM OF 11kV SWITCHGEAR OF 500kV SWITCHYARD R0 FASalmanEjazNo ratings yet

- 0314 - 119T8901 - GT Package Connection Pipe TableDocument40 pages0314 - 119T8901 - GT Package Connection Pipe TablefaisalnadimNo ratings yet

- Punch List: 1798-PL-FCB-27 Fabcon Industrial Services FZ LLC ITT-1798 Daelim 19441-1798-2-R0 19441-1798-2-R0Document3 pagesPunch List: 1798-PL-FCB-27 Fabcon Industrial Services FZ LLC ITT-1798 Daelim 19441-1798-2-R0 19441-1798-2-R0Brain AliveNo ratings yet

- Standard SpecificationDocument202 pagesStandard SpecificationksshashidharNo ratings yet

- (FGDS) 250-70P-0002Document104 pages(FGDS) 250-70P-0002Kamal PunnNo ratings yet

- ATT01 UTR01MEK - F21DM001 A Functional DescriptionDocument23 pagesATT01 UTR01MEK - F21DM001 A Functional DescriptionSUNILNo ratings yet

- File - 20220523 - 210015 - Pid FGDDocument11 pagesFile - 20220523 - 210015 - Pid FGDThắng NguyễnNo ratings yet

- HAT Horiz Vessel VolDocument1 pageHAT Horiz Vessel VolJ.SIVIRANo ratings yet

- Revised Agenda Points For VH Meeting 08.02.2023Document5 pagesRevised Agenda Points For VH Meeting 08.02.2023nizamsagar tsgencoNo ratings yet

- Kaneko Sangyo Co.,LtdDocument28 pagesKaneko Sangyo Co.,LtdHuynh Thanh TamNo ratings yet

- Mittal Plate Fabrication GuideDocument101 pagesMittal Plate Fabrication GuideSridharan ChandranNo ratings yet

- Installation and Operation Instructions PDFDocument39 pagesInstallation and Operation Instructions PDFHuynh Thanh TamNo ratings yet

- Effect of Rim Seal On Evaporation Loss From Khark Island Storage Tanks 2157 7463 1 103 PDFDocument7 pagesEffect of Rim Seal On Evaporation Loss From Khark Island Storage Tanks 2157 7463 1 103 PDFHuynh Thanh TamNo ratings yet

- GrothCorporationIndustrialCatalog (TTT)Document194 pagesGrothCorporationIndustrialCatalog (TTT)Huynh Thanh TamNo ratings yet

- CM1-L3-C-10UEJ-55-000006-020 - 0 - 003 Layout1Document1 pageCM1-L3-C-10UEJ-55-000006-020 - 0 - 003 Layout1Huynh Thanh TamNo ratings yet

- CM1-L3-C-10UEJ-55-000006-017 - 0 - 002 Layout1Document1 pageCM1-L3-C-10UEJ-55-000006-017 - 0 - 002 Layout1Huynh Thanh TamNo ratings yet

- CM1-L3-C-10UEJ-55-000006-023 - 0 - 003 Layout1Document1 pageCM1-L3-C-10UEJ-55-000006-023 - 0 - 003 Layout1Huynh Thanh TamNo ratings yet

- CM1-L3-C-10UEJ-55-000006-019 - 0 - 003 Layout1Document1 pageCM1-L3-C-10UEJ-55-000006-019 - 0 - 003 Layout1Huynh Thanh TamNo ratings yet

- CM1-L3-C-10UEJ-55-000006-022 - 0 - 003 Layout1Document1 pageCM1-L3-C-10UEJ-55-000006-022 - 0 - 003 Layout1Huynh Thanh TamNo ratings yet

- CM1-L3-C-10UEJ-55-000006-013 - 0 - 003 Layout1Document1 pageCM1-L3-C-10UEJ-55-000006-013 - 0 - 003 Layout1Huynh Thanh TamNo ratings yet

- CM1-L3-C-10UEJ-55-000006-017 - 0 - 002 Layout1Document1 pageCM1-L3-C-10UEJ-55-000006-017 - 0 - 002 Layout1Huynh Thanh TamNo ratings yet

- CM1-L3-C-10UEJ-55-000006-015 - 0 - 002 Layout1Document1 pageCM1-L3-C-10UEJ-55-000006-015 - 0 - 002 Layout1Huynh Thanh TamNo ratings yet

- CM1 L3 C 10uej 55 000006 010Document1 pageCM1 L3 C 10uej 55 000006 010Huynh Thanh TamNo ratings yet

- CM1-L3-C-10UEJ-55-000006-008 - B - 002 Layout1Document1 pageCM1-L3-C-10UEJ-55-000006-008 - B - 002 Layout1Huynh Thanh TamNo ratings yet

- CM1-L3-C-10UEJ-55-000006-013 - 0 - 003 Layout1Document1 pageCM1-L3-C-10UEJ-55-000006-013 - 0 - 003 Layout1Huynh Thanh TamNo ratings yet

- CM1 L3 C 10uej 55 000006 011Document1 pageCM1 L3 C 10uej 55 000006 011Huynh Thanh TamNo ratings yet

- CM1 L3 C 10uej 55 000006 005Document1 pageCM1 L3 C 10uej 55 000006 005Huynh Thanh TamNo ratings yet

- CM1 L3 C 10uej 55 000006 010Document1 pageCM1 L3 C 10uej 55 000006 010Huynh Thanh TamNo ratings yet

- CM1 L3 C 10uej 55 000006 004Document1 pageCM1 L3 C 10uej 55 000006 004Huynh Thanh TamNo ratings yet

- CM1-L3-C-10UEJ-55-000006-013 - 0 - 003 Layout1Document1 pageCM1-L3-C-10UEJ-55-000006-013 - 0 - 003 Layout1Huynh Thanh TamNo ratings yet

- CM1-L3-C-10UEJ-55-000006-004 - B - 003 Layout1Document1 pageCM1-L3-C-10UEJ-55-000006-004 - B - 003 Layout1Huynh Thanh TamNo ratings yet

- CM1-L3-C-10UEJ-55-000006-006 - B - 003 Layout1Document1 pageCM1-L3-C-10UEJ-55-000006-006 - B - 003 Layout1Huynh Thanh TamNo ratings yet

- CM1-L3-C-10UEJ-55-000006-005 - B - 002 Layout1Document1 pageCM1-L3-C-10UEJ-55-000006-005 - B - 002 Layout1Huynh Thanh TamNo ratings yet

- CM1-L3-C-10UEJ-55-000006-004 - B - 003 Layout1Document1 pageCM1-L3-C-10UEJ-55-000006-004 - B - 003 Layout1Huynh Thanh TamNo ratings yet

- CM1 L3 C 10uej 55 000006 011Document1 pageCM1 L3 C 10uej 55 000006 011Huynh Thanh TamNo ratings yet

- CM1-L3-C-10UEJ-55-000006-004 - B - 003 Layout1Document1 pageCM1-L3-C-10UEJ-55-000006-004 - B - 003 Layout1Huynh Thanh TamNo ratings yet

- FINAL TEST 1 K 2Document4 pagesFINAL TEST 1 K 2Nguyen Cuong100% (1)

- Data Shett Do Atenuador VaristorDocument13 pagesData Shett Do Atenuador VaristorTiagohowpy RamosNo ratings yet

- Inorgchem - D-Block Elements: PropertiesDocument8 pagesInorgchem - D-Block Elements: PropertiesHasantha PereraNo ratings yet

- Lab 3 - Instructions - Wind Energy ModellingDocument2 pagesLab 3 - Instructions - Wind Energy ModellingjohnNo ratings yet

- C1497Document4 pagesC1497BeymerBustamanteMejíaNo ratings yet

- Title: Boom Cylinder Model Number: E32 Serial Number: A94H11001 & Above, AC2N11001 & AboveDocument3 pagesTitle: Boom Cylinder Model Number: E32 Serial Number: A94H11001 & Above, AC2N11001 & AboveMateo Londoño UrreaNo ratings yet

- Man - Maxthermo - Mc49 - EngDocument8 pagesMan - Maxthermo - Mc49 - EngCsaba VargaNo ratings yet

- Connecticut October 2011 Snowstorm Power Restoration Report: Prepared By: Witt Associates December 1, 2011Document50 pagesConnecticut October 2011 Snowstorm Power Restoration Report: Prepared By: Witt Associates December 1, 2011Helen BennettNo ratings yet

- C-SCP360H38B R410aDocument8 pagesC-SCP360H38B R410aRaúl RodríguezNo ratings yet

- Data Sheet Belt Feeder 50 20 02Document6 pagesData Sheet Belt Feeder 50 20 02GIANMARCONo ratings yet

- Data Sheet: PRO ECO 960W 24V 40ADocument5 pagesData Sheet: PRO ECO 960W 24V 40AJoelHernandezGonzalezNo ratings yet

- CDM - English - Formato Traducci N PblicaDocument93 pagesCDM - English - Formato Traducci N PblicaGustavo PreciadoNo ratings yet

- Conduc T: Market Interaction of FirmsDocument10 pagesConduc T: Market Interaction of FirmsChin Yee LooNo ratings yet

- Semester II Shivaji University Kolhapur S. E. Electrical II Power ElectronicsDocument2 pagesSemester II Shivaji University Kolhapur S. E. Electrical II Power ElectronicsAnonymous q6cOT5XgXANo ratings yet

- Energizer 522: Product DatasheetDocument1 pageEnergizer 522: Product DatasheetAli AbdullahNo ratings yet

- Technical Data: @perkinsDocument8 pagesTechnical Data: @perkinsdfheardNo ratings yet

- Bis 15607-2016 PDFDocument7 pagesBis 15607-2016 PDFsatishNo ratings yet

- Automatic Drainage Cleaning Machine Run Through Solar PowerDocument8 pagesAutomatic Drainage Cleaning Machine Run Through Solar Powervikalpsharma96No ratings yet

- Gang SawDocument55 pagesGang SawAstri NgentNo ratings yet

- What Is Geothermal Energy?: Mary H. Dickson and Mario FanelliDocument61 pagesWhat Is Geothermal Energy?: Mary H. Dickson and Mario FanelliVikkiSandyNo ratings yet

- Williams SBDocument4 pagesWilliams SBlong chenNo ratings yet

- Building The Foundation - : On Scene Commander Development ProgramDocument4 pagesBuilding The Foundation - : On Scene Commander Development ProgramSaran rasayaNo ratings yet

- BIO-UV Triogen datasheet-Ozone-PPO3 ENDocument4 pagesBIO-UV Triogen datasheet-Ozone-PPO3 ENTaner BilgiçNo ratings yet

- Nuclear Physics Interview Questions and Answers 830 PDFDocument7 pagesNuclear Physics Interview Questions and Answers 830 PDFpeterjo raveloNo ratings yet