Professional Documents

Culture Documents

LPG Air Mixing 2 A3

Uploaded by

ambientinstal instal0 ratings0% found this document useful (0 votes)

286 views1 pageThe document discusses natural gas replacement systems that use liquefied petroleum gas (LPG) mixed with air. These LPG/air systems can be used as backup equipment during natural gas supply issues or for peak shaving. When LPG is mixed with air at the proper ratio, the mixture burns the same as natural gas. There are different types of LPG/air systems depending on how the LPG is vaporized before mixing. These systems allow areas without natural gas pipelines to still access fuel.

Original Description:

lpg-air-mixing-2-a3

Original Title

lpg-air-mixing-2-a3

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses natural gas replacement systems that use liquefied petroleum gas (LPG) mixed with air. These LPG/air systems can be used as backup equipment during natural gas supply issues or for peak shaving. When LPG is mixed with air at the proper ratio, the mixture burns the same as natural gas. There are different types of LPG/air systems depending on how the LPG is vaporized before mixing. These systems allow areas without natural gas pipelines to still access fuel.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

286 views1 pageLPG Air Mixing 2 A3

Uploaded by

ambientinstal instalThe document discusses natural gas replacement systems that use liquefied petroleum gas (LPG) mixed with air. These LPG/air systems can be used as backup equipment during natural gas supply issues or for peak shaving. When LPG is mixed with air at the proper ratio, the mixture burns the same as natural gas. There are different types of LPG/air systems depending on how the LPG is vaporized before mixing. These systems allow areas without natural gas pipelines to still access fuel.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

The mixing technology can be used as Back-up equipment or Gas costs Peak shaving.

Technology is also economic alternative.

ADVANTAGES:

Economic reasons (back-up system): uninterruptible gas service rates, better position to negotiate fuel cost

with Natural Gas supplier.

Alternative solution: pipelines maintenance and servicing, global cut-off of gas (emergency back-up), standby

solution for accidents at pipelines.

Supply a remote community with Natural Gas permanent or temporary until extension of Natural Gas

main.

LPG/AIR IS 100% INTERCHANGEABLE WITH NATURAL GAS:

Combustion characteristics of LPG/air are identical to Natural Gas.

NO modifications of Natural Gas equipment: no burner modifications, no orifice changes, no regulator or

line adjustments.

You can switch to LPG/air immediately - NO pre-purging or post purging of the line.

LPG/air mixture can directly replace the natural gas in combustion applications.

When LPG is mixed with Air to the correct ratio, the resulting mixture will burn with the same

characteristics as Natural Gas.

LPG/AIR MIXED RATIO:

DIFFERENT USES OF LPG/AIR SYSTEM:

LPG/Air bridges

the gap between

off-system

development and

extension of

natural gas mains.

Extensive

distribution

network for

propane-butane

is the condition.

Peak-shaving

with LPG/air

systems can

offset costly

charges.

Injections at

selected points

can expand

system capacity

more

economically

than adding pipe.

Interruptible gas

service rates

encourage

LPG/air systems

at end user sites.

55% propane / 45% air | 47% butane / 53% air

Natural Gas-Problems

-Variation in Demand

-Pipeline Maintenance

-Recent experience of

gas cut-off

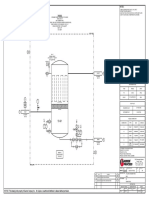

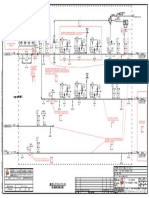

OPERATION

In the basis of the system there are mixer and LPG

vaporizer.

Depending on its type the vaporizer uses electric or gas

energy for transformation of LPG liquid to vapor. LPG

vapor enters then the venturi mixer. As pressurized

vapor passes through the mixer, the kinetic energy of the

gas draws in air from the atmosphere through a check

valve. The mixture is then re-pressurized through the

diffuser before it enters the surge tank.

For bigger capacities and higher discharge pressures the

air is supplied through compressor and mixing process is

digitally controlled.

Unlike diesel, fuel oil or propane, synthetic natural gas

does not require additional gas trains, piping, regulators,

or special fuel delivery systems inside the factory. The

propane air mixture is simply connected to the natural

gas piping just after the metering station (and pressure

reducing station) but before entering the building.

TYPES OF NG REPLACEMENT SYSTEMS

There are 3 types of system depending on mode of LPG vaporizing:

DFM (with Direct Fired vaporizer) XPM (with XP electric vaporizer) QM (with waterbath vaporizer)

Combination of Algas Direct Fired

vaporizer, venturi mixer and LPG pump.

Combination of Algas XP electric

vaporizer, venturi mixer and LPG pump.

Combination of gas fired waterbath

vaporizer, venturi mixer and LPG pump.

Capacity range: 2.5 to 28 MM Btu/h at

delivery pressures from 5 to 12 psig for

propane and 5 to 8 psig for butane

atmospherically (with no compressor).

100% turndown means these units

are perfect for variable or steady

loads.

The most economical solution to

lower gas bills.

Available in 110V/50-60Hz or

220V/50-60Hz. Electrical

consumption less than 1 amp.

Air inlet silencer (80dB at 10 feet).

Capacity range: 2.5 to 21 MM Btu/h at

delivery pressures from 5 to 12 psig for

propane and 5 to 8 psig for butane

atmospherically (with no compressor).

100% turndown capability

Able to make natural gas in less

than one minute!

Venturi silencer

Explosion proof (Class I, Division 1,

Group D)

Capacity range: 2.5 to 21 MM Btu/h at

delivery pressures from 5 to 12 psig for

propane and 5 to 8 psig for butane

atmospherically (with no compressor).

Integrated PLC controlled operating

system with user interface and

on/off/standby modes.

Component cycle and runtime

display

Air intake header with silencer

The 300mbar systems may require and underground tank. Higher pressure systems require a small liquid pump.

OPERATING SCHEME

You might also like

- IR HL Heatless DryerDocument1 pageIR HL Heatless DryerYing Kei ChanNo ratings yet

- P-I Transducer - P200-P290 PDFDocument4 pagesP-I Transducer - P200-P290 PDFman_y2kNo ratings yet

- CT Blowdown PhilosophyDocument6 pagesCT Blowdown PhilosophyzamijakaNo ratings yet

- Control Valve SizingDocument4 pagesControl Valve SizingAmolNo ratings yet

- Condensate Line SizingDocument23 pagesCondensate Line SizingNirnay Patil100% (2)

- 503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDFDocument8 pages503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDFsvnaik14No ratings yet

- Hydrocarbon Dewpoint Control and Liquid Recovery and FractionationDocument68 pagesHydrocarbon Dewpoint Control and Liquid Recovery and Fractionationlili aboudNo ratings yet

- Svrcek S 3 Phase Separator ArticleDocument12 pagesSvrcek S 3 Phase Separator ArticleRobert MontoyaNo ratings yet

- Cone Design ToolDocument1 pageCone Design ToolPramod KumarNo ratings yet

- Safety Valve Technical DetailsDocument5 pagesSafety Valve Technical DetailsvineethvskkdNo ratings yet

- AX5 Vaporizer Electric Water Bath Type LPG VaporizerDocument2 pagesAX5 Vaporizer Electric Water Bath Type LPG VaporizerRicky DermawanNo ratings yet

- Float Board Level GaugeDocument6 pagesFloat Board Level GaugeanaismariaNo ratings yet

- DP Calc 1Document3 pagesDP Calc 1Manjunath HardcheeseNo ratings yet

- Ref Pipe Sizing Ver 02 21 11Document12 pagesRef Pipe Sizing Ver 02 21 11Ahmef100% (1)

- Flare Gas Recovery Data Sheet PDFDocument1 pageFlare Gas Recovery Data Sheet PDFMohamed AdelNo ratings yet

- Boilermate Boiler BookDocument6 pagesBoilermate Boiler Bookhamidrezaee008No ratings yet

- Steam Tracing AppendixDocument13 pagesSteam Tracing AppendixAmin BagheriNo ratings yet

- DPH 503 ManualDocument35 pagesDPH 503 ManualKrishnaraj DhavalaNo ratings yet

- Steam Separator and Steam Trap Are Almost Same in FunctionDocument7 pagesSteam Separator and Steam Trap Are Almost Same in FunctionTHEOPHILUS ATO FLETCHERNo ratings yet

- UFC-85 Plants For Urea Fertilizer Projects: Recommended DosageDocument8 pagesUFC-85 Plants For Urea Fertilizer Projects: Recommended Dosagevaratharajan g rNo ratings yet

- Seprasol Plus: Liquid/Gas CoalescersDocument4 pagesSeprasol Plus: Liquid/Gas CoalescersSiavash YarahmadiNo ratings yet

- LMF-GP LX15-8 - 10 - 13Document2 pagesLMF-GP LX15-8 - 10 - 13MAZEN0% (1)

- FD Fan Sizing CalculationDocument3 pagesFD Fan Sizing CalculationkumarananyarupeshNo ratings yet

- E07 QDocument20 pagesE07 QSoledad Fernández SantosNo ratings yet

- Tube Rupture (Two Phase-Omega Method) PDFDocument1 pageTube Rupture (Two Phase-Omega Method) PDFAmin RoisNo ratings yet

- Yazd-System Description For Clean Drain System PDFDocument7 pagesYazd-System Description For Clean Drain System PDFace-winnieNo ratings yet

- Ekoplastik PPR Catalogue of Products PDFDocument36 pagesEkoplastik PPR Catalogue of Products PDFnamNo ratings yet

- CV - Orifice Diameter PDFDocument8 pagesCV - Orifice Diameter PDFManuelNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Best Practices For Steam Control Valve InstallationDocument4 pagesBest Practices For Steam Control Valve InstallationBen MusimaneNo ratings yet

- Two Phase Flow RegimeDocument8 pagesTwo Phase Flow RegimeNoman Abu-FarhaNo ratings yet

- Flash Steam SystemDocument4 pagesFlash Steam SystemAnonymous CX51waINo ratings yet

- CLKMC 0109 UsDocument4 pagesCLKMC 0109 UsRioga RiogaNo ratings yet

- LORENTZ Pressure Switch 1-5 Bar: Instruction Sheet For Wiring and AdjustingDocument1 pageLORENTZ Pressure Switch 1-5 Bar: Instruction Sheet For Wiring and AdjustingLuis RolaNo ratings yet

- NGL1 V1 Sec 7Document203 pagesNGL1 V1 Sec 7varatharajan g rNo ratings yet

- Psychrometric ProcessesDocument9 pagesPsychrometric ProcessesArt JamesNo ratings yet

- Ozone Solubility ChartDocument0 pagesOzone Solubility ChartWONG TSNo ratings yet

- C29732-01-Pid-02.0 - P&id Scrubber TT-006Document1 pageC29732-01-Pid-02.0 - P&id Scrubber TT-006omarNo ratings yet

- Pressure Gauge DatasheetDocument2 pagesPressure Gauge DatasheetazlanNo ratings yet

- Jockey PumpDocument5 pagesJockey PumpBrandon LeonardNo ratings yet

- Principles of Hydrocarbon Dew PointDocument4 pagesPrinciples of Hydrocarbon Dew PointRowan BalajiNo ratings yet

- FL1627Document2 pagesFL1627Isaac Montero BarreraNo ratings yet

- Liquid Valve CV CalcDocument4 pagesLiquid Valve CV Calcamit_kt1973No ratings yet

- Fuel Gas Skid Train PDFDocument1 pageFuel Gas Skid Train PDFhadNo ratings yet

- PSV NoiseDocument7 pagesPSV NoiseJomer J SimpsonNo ratings yet

- Is 14164 2008Document45 pagesIs 14164 2008Pukhraj DagaNo ratings yet

- VAD Variable Area Desuperheaters: Desuperheater OverviewDocument6 pagesVAD Variable Area Desuperheaters: Desuperheater OverviewLucasZanaNo ratings yet

- New CalculationDocument9 pagesNew CalculationDeepak Shakya100% (1)

- CPA 50E Type A RF Dimensional Specifications - May 2013Document1 pageCPA 50E Type A RF Dimensional Specifications - May 2013Karthick RamasubramanianNo ratings yet

- Orifice Plate CalculationDocument30 pagesOrifice Plate CalculationSatish SohaniNo ratings yet

- EGC2 - EGC4 Electronic Gas CarburetorDocument6 pagesEGC2 - EGC4 Electronic Gas CarburetorSathish Kumar CNo ratings yet

- Pom Blending SystemsDocument8 pagesPom Blending Systemspablo292No ratings yet

- Technical Description BVG 2014 (En) LightDocument12 pagesTechnical Description BVG 2014 (En) LightarieprachmanNo ratings yet

- Jjmie: Comparative Performance and Emission Properties of Spark-Ignition Outboard Engine Powered by Gasoline and LPGDocument6 pagesJjmie: Comparative Performance and Emission Properties of Spark-Ignition Outboard Engine Powered by Gasoline and LPGShaun MendozaNo ratings yet

- Oil and Gas Automation Solutions Issue #16Document5 pagesOil and Gas Automation Solutions Issue #16FabricioVNo ratings yet

- Technical - Sales Catalogue - 0001101120 - 1.0Document44 pagesTechnical - Sales Catalogue - 0001101120 - 1.0alejovelNo ratings yet

- Operate Your Diesel Engine On Natural GasDocument4 pagesOperate Your Diesel Engine On Natural GasJa JahNo ratings yet

- 3550Document3 pages3550பிரசன்னகுமார் ஆனந்தன்No ratings yet

- Cogeneration Gas TurbineDocument7 pagesCogeneration Gas TurbineAlexzander AdisakNo ratings yet

- 4 ME467-RetrofittingDocument17 pages4 ME467-Retrofittingnoman88407No ratings yet

- Boiler Tank in Tank ACV Smart Line Multi Energy - 400 Litri - Fisa - Tehnica PDFDocument2 pagesBoiler Tank in Tank ACV Smart Line Multi Energy - 400 Litri - Fisa - Tehnica PDFambientinstal instalNo ratings yet

- CH2 - Energy FundamentalsDocument41 pagesCH2 - Energy Fundamentalsambientinstal instalNo ratings yet

- Healthcare Buildings Equipment GuideDocument48 pagesHealthcare Buildings Equipment Guideambientinstal instalNo ratings yet

- TBH424Document1 pageTBH424ambientinstal instalNo ratings yet

- MOTOR Brushless ss2814 Xiii 1000kvDocument1 pageMOTOR Brushless ss2814 Xiii 1000kvsalah eddineNo ratings yet

- Bomba FlightDocument2 pagesBomba FlightGustavo HRNo ratings yet

- Porting Relations 2 StrokesDocument10 pagesPorting Relations 2 Strokespistonbreaker100% (8)

- Electrical 02Document10 pagesElectrical 02Hary Kriz33% (3)

- Samsung CodesDocument14 pagesSamsung Codesapi-3738581100% (2)

- Black Invention MythsDocument16 pagesBlack Invention MythsjoetylorNo ratings yet

- Oracle E-Business Suite Release 12.2.6 Readme (Doc ID 2114016.1)Document18 pagesOracle E-Business Suite Release 12.2.6 Readme (Doc ID 2114016.1)KingNo ratings yet

- Longitudinal Section Cross Section of AbutmentDocument1 pageLongitudinal Section Cross Section of AbutmentMATHANNo ratings yet

- ARMY TM 9-1804 Power Train Body Frame .25ton 4X4 Truck M38 Jul52Document206 pagesARMY TM 9-1804 Power Train Body Frame .25ton 4X4 Truck M38 Jul52RockWagon100% (2)

- Activation and Deactivation of CatalystsDocument16 pagesActivation and Deactivation of Catalystsshan0214No ratings yet

- Operate A Personal Computer PDFDocument56 pagesOperate A Personal Computer PDFBirhanu Girmay100% (8)

- ZXComputingDocument100 pagesZXComputingozzy75No ratings yet

- An Analysis of The Ejector-Ram-Rocket EngineDocument9 pagesAn Analysis of The Ejector-Ram-Rocket Enginefundamental_aeroNo ratings yet

- Knowledge Area Quiz-Project Integration ManagementDocument4 pagesKnowledge Area Quiz-Project Integration Managementcrown212No ratings yet

- d9 VolvoDocument57 pagesd9 Volvofranklin972100% (2)

- GIT CloudDocument20 pagesGIT CloudGyanbitt KarNo ratings yet

- Particle Swarm Optimization - WikipediaDocument9 pagesParticle Swarm Optimization - WikipediaRicardo VillalongaNo ratings yet

- MMD 74 XX DR PS 0020 - C03Document1 pageMMD 74 XX DR PS 0020 - C03bramexNo ratings yet

- Owners Manuel SupplementDocument6 pagesOwners Manuel SupplementJohn HansenNo ratings yet

- Stainless Steel: Presented By, Dr. Pragati Jain 1 YearDocument68 pagesStainless Steel: Presented By, Dr. Pragati Jain 1 YearSneha JoshiNo ratings yet

- Meitrack Gprs Protocol v1.6Document45 pagesMeitrack Gprs Protocol v1.6monillo123No ratings yet

- NanoDocument10 pagesNanoRavi TejaNo ratings yet

- 1450 01 Air Hoists and Trolleys Atlas CopcoDocument12 pages1450 01 Air Hoists and Trolleys Atlas Copcomohammed shammiNo ratings yet

- TabulationDocument13 pagesTabulationWildan PushNo ratings yet

- CS 303e, Assignment #10: Practice Reading and Fixing Code Due: Sunday, April 14, 2019 Points: 20Document2 pagesCS 303e, Assignment #10: Practice Reading and Fixing Code Due: Sunday, April 14, 2019 Points: 20Anonymous pZ2FXUycNo ratings yet

- Bombas Pentax SADocument48 pagesBombas Pentax SAAgustin CahuanaNo ratings yet

- Eps Atc 0017 PDFDocument3 pagesEps Atc 0017 PDFSdreamworksNo ratings yet

- 165T-5 Parts ListDocument26 pages165T-5 Parts ListJorge Luis Galezo MuñozNo ratings yet

- 2015 Audi q5 sq5 71153 PDFDocument302 pages2015 Audi q5 sq5 71153 PDFPraveen100% (1)

- Splunk 7 Essentials Third EditionDocument388 pagesSplunk 7 Essentials Third EditionHaripriya100% (1)