Professional Documents

Culture Documents

CNC Lathe Machine Project

Uploaded by

Nisar HussainOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CNC Lathe Machine Project

Uploaded by

Nisar HussainCopyright:

Available Formats

CNC LATHE MACHINE

INTRODUCTION TO CNC MACHINE: CNC stands for computer numeric controlled. It refers

to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically

control the motion of one or more axis on the machine.

The development of NC machine tools started from a task supported by the US Air Force in the

early 1950s, involving MIT and several machine-tool manufacturing companies. The need was

recognized for machines to be able to manufacture complex jet aircraft parts.

As computer technology evolved, computers replaced the more inflexible controllers found on

the NC machines; hence the dawn of the CNC era.

CNC machine tools use software programs to provide the instructions

necessary to control the axis motions, spindle speeds, tool changes and so on.

CNC machine tools allow multiple axes of motion simultaneously,

resulting in 2D and 3D contouring ability.

CNC technology also increases productivity and quality control by

allowing multiple parts to be produced using the same program and tooling.

TYPES OF CNC MACHINES: There are many types of CNC machines used in the industries,

such as,

Mills and Machining Centers

Lathes and Turning Centers

Drilling Machines

EDM Sinker and wire cut Machines

Flame and Laser-Cutting Machines

Water Jet Profilers

ELEMENTS OF A

CNC MACHINE

ELEMENTS OF A CNC MACHINE: The various units are as follows:

INPUT UINIT: It receives all the commands from the operator interface (operation station

containing all switches, push buttons, displays required to operate and monitor machine

activities) and feedback or status of machine in the form of a.c, d.c, analog signals, or by

digitally.

Different ways of data input are:

MDI: Manual Data Input

PROGRAM PREPARATION WITH CAD CAM

PROGRAM DATA TRANSFER FROM PC TO CNC M/C

PROGRAM DATA TRANSFER FROM PC TO DNC OPERATIONS

CONTROL UNIT: It takes instructions from the memory unit and interprets them one at a time.

It processes information received from the operator and machine interface. These informations

are then interpreted and manipulated with hardware logic and computer programmes. It sends

appropriate instructions to other units to cause instruction execution. It turns on and off

machine outputs and controls motion via machine interface.

TYPES OF CNC MACHINE CONTROL UNITS:

FANUC CONTROLL

SIEMENS

GSK

MECH3

MEMORY UNIT: It stores instructions and data received from the input. It also stores the results

of arithmetic operations and supply information to output unit. Part programs are usually

stored in a Random Access Memory, which provide immediate access to any storage location

point in memory.

ARITHMATIC UNIT: It performs calculations and makes decisions. Its results are stored in memory

unit.

OUTPUT UNIT: it receives data from the memory at the command of control unit. The signals

are made compatible with output devices so that commands issued by output unit can be

obeyed by them.

OPERATOR AND MACHINE INTERFACE: operator stations forms a major operator interface. It is

used to initiate automatic operation, to input data, and to monitor activities using display

devices. A host computer also serves as operator interface, when a part is made on this

machine the host computer modifies the part programme, while it is running by making

corrections based on the error table, to obtain improved accuracy on the part.

OPERATIONAL FEATURES of CNC MACHINES:

CNC OPEN LOOP AND CLOSE LOOP SYSTEM: The open and closed loop system describes the two

primary types of CNC control systems. Open and closed loop describes the control process of a

system. Open loop refers to a system where the communication between the controller system

and the motor is one way.

OPEN LOOP SYSTEM: Refers to a system using a stepper motor, where the communication

between the controller system and motor is one way. The process is fairly simple. The machinist

will decide what he/she wants to accomplish and will generate the G-code and the software will

create the necessary steps and direction signals to perform the desired task. The computer will

relay this information to the controller which then energizes the motor. What distinguishes open

looped from a close looped system is after the motor moves to the desired position; there is no

feedback to the controller system to verify the action.

CLOSE LOOP SYSTEM:

The closed-loop system has a feedback subsystem to monitor the actual output and correct

any discrepancy from the programmed input. The feedback system could be either analog or

digital. The analog systems measure the variation of physical variables such as position and

velocity in terms of voltage levels. Digital systems monitor output variations by means of

electrical pulses.

Closed-loop systems are very powerful and accurate because they are capable of monitoring

operating conditions through feedback subsystems and automatically compensating for any

variations in real-time.

Most modern closed-loop CNC systems are able to provide very close resolution of 0.0001 of

an inch. Closed-looped systems would, naturally, require more control devices and circuitry in

order for them to implement both position and velocity control. This, obviously, makes them

more complex and more expensive than the open-loop system.

CNC COORDINATE SYSTEM: In order to shape metal by machine tools, the cutting tool

should move in contact with the work piece at certain specific points, while the work piece or

cutting tool is rotating.

Coordinate system is required to define the movement on the machine.

Basically there are two common Coordinate systems:

CARTESIAN COORDINATE SYSTEM

POLAR COORDINATE SYSTEM

If the motor does not operate as instructed

there is no way for the system to know that

this is occurring. The controller system will

continue performing the next task or step as

if there is no problem until a limit switch is

tripped or the operator resets the machine.

Open loop systems run the risk overloading

the machine and losing steps which can ruin

the work piece or cause harm to the

machine. These are the drawbacks of open

loop system.

2D Cartesian coordinate system: When dealing with 2 dimensions (2D), the two-

dimensional coordinate system is used.

3D CARTESIAN COORDINATE SYSTEM: When dealing with three dimensions (3D), the

three dimensional coordinates system is used;

Three Axis Milling machine: In a Three Axis Vertical Milling Machine:

X is the direction of the Table travel

Y is the direction of the Cross travel

Z the Spindle travel up down

6 AXIS MILLING MACHINE

Polar Coordinate System: The point is located by its distance (radius r) to the point of

origin and its angle (alpha ) to a specified axis.

The angle is positive if it is measured in counterclockwise direction starting from positive X-axis

CNC Lathe (turning) Machines coordinate system:

Machine Zero Point (M): The origin of the coordinate system. It is defined by the manufacturer

and cannot be changed. In general, the machine zero point M is located in the center of the work

spindle nose for cnc lathe.

The work pieces zero point (W) it is the origin of the work part-based coordinate system.

Its location is specified by the programmer.

CNC PROGRAMMING:

Offline programming linked to CAD programs.

Conversational programming by the operator.

MDI ~ Manual Data Input.

Manual Control using jog buttons or `electronic hand wheel'.

Word-Address Coding using standard G-codes and M-codes.

Basics of NC Part Programming: During secondary motion, either the tool moves relative

to the work piece or the work piece moves relative to the tool. In NC programming, it is always

assumed that the tool moves relative to the work piece no matter what the real situation is.

The position of the tool is described by using a Cartesian coordinate system. If (0, 0, 0) position can

be described by the operator, then it is called floating zero.

In defining the motion of the tool from one point to another, either absolute positioning mode or

incremental positioning mode can be used.

Absolute positioning: In this mode, the desired target position of the tool for a particular

move is given relative to the origin point of the program.

Incremental positioning: In this mode, the next target position for the tool is given

relative to the current tool position.

Structure of an NC Part Program: Commands are input into the controller in units called

blocks or statements.

Fixed sequential format

Tab sequential format

Word address format-----sample block N135 G01 X1.0 Y1.0 Z0.125 F5

Programming Key Letters:

O- Program number (Used for program identification)

N - Sequence number (Used for line identification)

G - Preparatory function

X - X axis designation

Y - Y axis designation

Z - Z axis designation

R - Radius designation

F - Feed rate designation

S - Spindle speed designation

H - Tool length offset designation

D - Tool radius offset designation

T - Tool Designation

M - Miscellaneous function

Table of Important G codes:

G44 Tool length compensation

(minus)

G49 Tool length compensation

cancel

G80 Cancel canned cycles

G81 Drilling cycle

G82 Counter boring cycle

G83 Deep hole drilling cycle

G90 Absolute positioning

G91 Incremental positioning

G00 Rapid Transverse

G01 Linear Interpolation

G02 Circular Interpolation, CW

G03 Circular Interpolation, CCW

G17 XY Plane

G18 XZ Plane

G19 YZ Plane

G20/G70 Inch units

G21/G71 Metric Units

G42 Cutter compensation right

G43 Tool length compensation(plus)

LIST OF IMPORTANT M CODES:

M06 Tool change

M08 Coolant on

M09 Coolant off

M10 Clamps on

M11 Clamps off

M30 Program stop, reset to start

PROGRAMMING EXAMPLE:

M00 Program stop.

M01 Optional program stop

M02 Program end

M03 Spindle on clockwise

M04 Spindle on counterclockwise

M05 Spindle stops.

M06 TOOL CHANGE

M08 COOLANT ON

M09 COOLANT OFF

M10 CLAMPS ON

M11 CLAMPS OFF

M30 PROGRAM STOP.

You might also like

- NC, CNC, DNCDocument38 pagesNC, CNC, DNCVijayKumar100% (2)

- Machining 2 ReportDocument11 pagesMachining 2 ReportTan Jun ZheNo ratings yet

- Lab Report OnshaperDocument10 pagesLab Report OnshaperSanatan Choudhury100% (3)

- Fyp Report Dpe 080001k Liang YueDocument90 pagesFyp Report Dpe 080001k Liang YueYue Lee100% (1)

- Surface GrindingDocument14 pagesSurface GrindingariefNo ratings yet

- Ipe Lab Report 4Document11 pagesIpe Lab Report 4Sourav Sutradhar0% (1)

- Part Manufacturing On CNC Milling: Manufacturing Process Lab Lab Report Experiment # 04Document7 pagesPart Manufacturing On CNC Milling: Manufacturing Process Lab Lab Report Experiment # 04yushi100% (2)

- Lab Report CNC LatheDocument6 pagesLab Report CNC LathePeter Van der Put0% (1)

- CNC Lab ReportDocument3 pagesCNC Lab ReportPei Shan ChoongNo ratings yet

- Report CNC TurningDocument23 pagesReport CNC Turningdkeaumani57% (7)

- Lab Report CNC Milling Manufacturing ProcessDocument15 pagesLab Report CNC Milling Manufacturing ProcessDevani HerastNo ratings yet

- Lathe ReportDocument11 pagesLathe ReportWan Syafiq Wan Syamsulbahri100% (2)

- Milling Report (Indexing)Document23 pagesMilling Report (Indexing)Aiman AlifNo ratings yet

- CIM LAB Manual-1 PDFDocument40 pagesCIM LAB Manual-1 PDFgagan100% (1)

- Report Writing On Milling MachineDocument11 pagesReport Writing On Milling MachineSailesh Pathak100% (1)

- Experiment No. 5 Centrifugal Casting ProcessDocument6 pagesExperiment No. 5 Centrifugal Casting ProcessDhananjay ShimpiNo ratings yet

- Experiment No 3Document3 pagesExperiment No 3pomar026100% (1)

- CAD AdvantagesandDisadvantagesDocument1 pageCAD AdvantagesandDisadvantagesManikanta NaiduNo ratings yet

- CNC Report1Document55 pagesCNC Report1coolguy02088775% (4)

- Exercise Industrial RobotsDocument2 pagesExercise Industrial RobotsMohd SapeqNo ratings yet

- DJJ 10033-Chapter 6 NewDocument43 pagesDJJ 10033-Chapter 6 NewAbbas SeuNo ratings yet

- Conclusion What We Can Conclude From This Report Is We Able To Study The Meaning of CNC WhichDocument1 pageConclusion What We Can Conclude From This Report Is We Able To Study The Meaning of CNC WhichMuhd Qayyum Mohd Fuad80% (5)

- Mini Project ReportDocument9 pagesMini Project ReportJayanth Gowda Virat100% (1)

- CNC Lab ReportDocument5 pagesCNC Lab ReportMuhammad SanaNo ratings yet

- Report Cad Cam.Document12 pagesReport Cad Cam.Wan Azlizan Zakaria33% (3)

- Machine ShopDocument6 pagesMachine ShopZain MirzaNo ratings yet

- Lab 2 TurningDocument12 pagesLab 2 TurningLuqman HakimNo ratings yet

- Lab Sheet MillingDocument5 pagesLab Sheet MillingLalang Laut BestNo ratings yet

- CNC Machining Report - Wheel BaseDocument25 pagesCNC Machining Report - Wheel BaseMichael M. W. de SilvaNo ratings yet

- Clamping & Clamping DevicesDocument52 pagesClamping & Clamping DevicesTousif RezaNo ratings yet

- Cad-Cam Lab Manual (F)Document90 pagesCad-Cam Lab Manual (F)muthuvasans880% (2)

- Six Weeks Industrial Training ReportDocument27 pagesSix Weeks Industrial Training ReportGagan Deep100% (2)

- Mini Project Report Industrial Automation SreekuDocument38 pagesMini Project Report Industrial Automation Sreekusreekumar456No ratings yet

- Mit Portfolio Correction TapeDocument28 pagesMit Portfolio Correction Tapeapi-532214657No ratings yet

- Hydraulic and Pneumatic ReportDocument1 pageHydraulic and Pneumatic ReportJus Hemanth HemanNo ratings yet

- Grinding Lab 2Document9 pagesGrinding Lab 2Ming QuanNo ratings yet

- Safety Measures - Mech - CAD CAM LABDocument1 pageSafety Measures - Mech - CAD CAM LABmaran2326No ratings yet

- Angle Measurement Using Sine BarDocument4 pagesAngle Measurement Using Sine Barsameerkhan_mhsscoe0% (1)

- Methods of Adjusting Clearance in GuidewaysDocument8 pagesMethods of Adjusting Clearance in GuidewaysVivek Bure67% (3)

- Numerical Control PDFDocument23 pagesNumerical Control PDFmishari67% (3)

- CNC Milling Machine - FYP Final Report - V1Document57 pagesCNC Milling Machine - FYP Final Report - V1Anas Asif64% (11)

- Report MIG WeldingDocument12 pagesReport MIG Weldingyuwaraja0% (2)

- Construction of CNC Machine-3 UnitDocument32 pagesConstruction of CNC Machine-3 UnitMariappan Arumugam50% (2)

- Lab Session Introduction To Lathe MachineDocument5 pagesLab Session Introduction To Lathe MachineAqib ZamanNo ratings yet

- Presentation ON: ComparatorsDocument25 pagesPresentation ON: Comparatorsaneesh19inNo ratings yet

- Double Acting Hacksaw Using Scotch Yoke MechanismDocument38 pagesDouble Acting Hacksaw Using Scotch Yoke MechanismDevendra Thakur78% (37)

- Lab Report On CNC MachineDocument5 pagesLab Report On CNC MachineAhmad Syamil100% (1)

- Non Conventional Machining PDFDocument55 pagesNon Conventional Machining PDFMarthande100% (1)

- Locating Principle and LocatorsDocument35 pagesLocating Principle and LocatorsPes Mobile100% (1)

- Fabrication of Pneumatic Punching and Riveting MachineDocument45 pagesFabrication of Pneumatic Punching and Riveting MachineElakkiya Karthic100% (7)

- CNC Milling Machine REPORTDocument11 pagesCNC Milling Machine REPORTMazlin Azura100% (2)

- Project Report - FinalDocument67 pagesProject Report - FinalCharlesNo ratings yet

- Training ReportDocument48 pagesTraining ReportVishnu Kamal67% (3)

- CNC Lathe MachineDocument8 pagesCNC Lathe MachineParameshwara MeenaNo ratings yet

- Unit - Iv Introduction and Concepts of NC/ CNC MachineDocument15 pagesUnit - Iv Introduction and Concepts of NC/ CNC MachineAbhi RamNo ratings yet

- Unit - 1 FinalDocument59 pagesUnit - 1 FinalGokulraju RangasamyNo ratings yet

- CNC MachineDocument4 pagesCNC Machinejawad khalidNo ratings yet

- CNC MachineDocument4 pagesCNC Machinejawad khalidNo ratings yet

- Cim Lab ManualDocument51 pagesCim Lab ManualYashas0% (1)

- CNC 5TH SemDocument8 pagesCNC 5TH SemdibyenindusNo ratings yet

- Chapter V and VIDocument27 pagesChapter V and VINisar HussainNo ratings yet

- Page 1 of 20: TH TH THDocument20 pagesPage 1 of 20: TH TH THtripathymanjulNo ratings yet

- 11072019Document1 page11072019Nisar HussainNo ratings yet

- Revised Training Module For Assistant Loco PilotsDocument3 pagesRevised Training Module For Assistant Loco PilotsNisar HussainNo ratings yet

- Important Dates PDFDocument1 pageImportant Dates PDFNisar HussainNo ratings yet

- Curriculum MTech Mechanical Manufacturing PDFDocument84 pagesCurriculum MTech Mechanical Manufacturing PDFG. RajeshNo ratings yet

- Syllabus of Inspector of Legal Metrology - 13052016 PDFDocument1 pageSyllabus of Inspector of Legal Metrology - 13052016 PDFNisar HussainNo ratings yet

- HW Solutions For Period 3Document10 pagesHW Solutions For Period 3dellibabu509No ratings yet

- Acad 2D FCPDocument17 pagesAcad 2D FCPNisar HussainNo ratings yet

- Bivek FCPDocument23 pagesBivek FCPNisar HussainNo ratings yet

- Revision Question Bank ME 2204Document11 pagesRevision Question Bank ME 2204Rajendra Kumar YadavNo ratings yet

- Us 1776444Document5 pagesUs 1776444Nisar HussainNo ratings yet

- Revision Question Bank ME 2204Document5 pagesRevision Question Bank ME 2204Nisar HussainNo ratings yet

- Engineering CompositesDocument193 pagesEngineering CompositesMelih AltıntaşNo ratings yet

- TRG Cal All Institues 2016 17 v1 2 PDFDocument10 pagesTRG Cal All Institues 2016 17 v1 2 PDFNisar HussainNo ratings yet

- SSC - Candidate's Application Details (Registration-Id - 51101321462)Document3 pagesSSC - Candidate's Application Details (Registration-Id - 51101321462)Nisar HussainNo ratings yet

- Westbengal Notification 22.01.16 PDFDocument18 pagesWestbengal Notification 22.01.16 PDFNisar HussainNo ratings yet

- West Bengal Staff Selection Commission: Transport/ Computer Supervisor RecruitmentDocument8 pagesWest Bengal Staff Selection Commission: Transport/ Computer Supervisor RecruitmentNisar HussainNo ratings yet

- Notification 14 FAD CO 99 APO Tradesman Mate Material Asst Other PostsDocument8 pagesNotification 14 FAD CO 99 APO Tradesman Mate Material Asst Other PostsAnkit SharmaNo ratings yet

- WBPDCL INDIA 2016 Advertisement PDFDocument10 pagesWBPDCL INDIA 2016 Advertisement PDFNisar HussainNo ratings yet

- KPS16 Detailed AdvDocument9 pagesKPS16 Detailed AdvAnonymous D792jOOENo ratings yet

- Feb Capsule Eng PDFDocument48 pagesFeb Capsule Eng PDFdassreerenjiniNo ratings yet

- Legal Metro 2 PDFDocument1 pageLegal Metro 2 PDFNisar HussainNo ratings yet

- 101 Math Short Cuts-Mental Ability PDFDocument20 pages101 Math Short Cuts-Mental Ability PDFsanits591100% (1)

- Wk1 - Introduction To CNCDocument34 pagesWk1 - Introduction To CNCNisar HussainNo ratings yet

- OngcDocument1 pageOngcNisar HussainNo ratings yet

- YouthCentral Resume VCE WorkExpDocument6 pagesYouthCentral Resume VCE WorkExpRick MercadoNo ratings yet

- Uggestion Arts PDFDocument3 pagesUggestion Arts PDFNisar HussainNo ratings yet

- HS 2018 History SuggestionDocument3 pagesHS 2018 History SuggestionNisar HussainNo ratings yet

- Easy In, Easy Out: Partner Connection Related LinkDocument2 pagesEasy In, Easy Out: Partner Connection Related LinkNisar HussainNo ratings yet

- Progress Test 2 (Units 4-6) : Name - ClassDocument6 pagesProgress Test 2 (Units 4-6) : Name - ClassРусланNo ratings yet

- Guide To Computer Forensics and Investigations 5th Edition Bill Test BankDocument11 pagesGuide To Computer Forensics and Investigations 5th Edition Bill Test Bankshelleyrandolphikeaxjqwcr100% (30)

- First Order Logic: Artificial Intelligence COSC-3112 Ms. Humaira AnwerDocument24 pagesFirst Order Logic: Artificial Intelligence COSC-3112 Ms. Humaira AnwerKhizrah RafiqueNo ratings yet

- Problem Tutorial: "Erase Nodes": 1 CNT (U, V)Document6 pagesProblem Tutorial: "Erase Nodes": 1 CNT (U, V)Roberto FrancoNo ratings yet

- Coursera XQVQSBQSPQA5 - 2 PDFDocument1 pageCoursera XQVQSBQSPQA5 - 2 PDFAlexar89No ratings yet

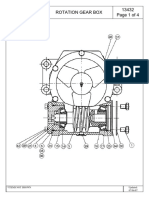

- Caja de Engranes para Pluma DunbarRotationGearBoxDocument4 pagesCaja de Engranes para Pluma DunbarRotationGearBoxMartin CalderonNo ratings yet

- Emeter MDM White PaperDocument9 pagesEmeter MDM White PapernittecatNo ratings yet

- Business Statistics Communicating With Numbers 4E 4Th Edition Sanjiv Jaggia Full ChapterDocument67 pagesBusiness Statistics Communicating With Numbers 4E 4Th Edition Sanjiv Jaggia Full Chapterdoris.heck867100% (3)

- Outreach in FIRST LEGO LeagueDocument10 pagesOutreach in FIRST LEGO LeagueΑνδρέας ΜήταλαςNo ratings yet

- Excel NotesDocument9 pagesExcel NotesAhnNo ratings yet

- Accelerating IceCubes Photon Propagation Code WitDocument11 pagesAccelerating IceCubes Photon Propagation Code WitNEed for workNo ratings yet

- SAP Single Sign-On 3.0 Product OverviewDocument39 pagesSAP Single Sign-On 3.0 Product OverviewAde PutrianaNo ratings yet

- M2 Pre-Task: Application Software - System Software Driver Software Programming SoftwareDocument2 pagesM2 Pre-Task: Application Software - System Software Driver Software Programming SoftwareBee Anne BiñasNo ratings yet

- Account Statement From 3 Jan 2021 To 3 Jul 2021: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDocument8 pagesAccount Statement From 3 Jan 2021 To 3 Jul 2021: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceSanatan ThakurNo ratings yet

- Module 6: Flow Control Valves: Basic PneumaticsDocument18 pagesModule 6: Flow Control Valves: Basic PneumaticsJohn Fernand RacelisNo ratings yet

- تقارير مختبر محركات احتراق داخليDocument19 pagesتقارير مختبر محركات احتراق داخليwesamNo ratings yet

- 4150 70-37-3 Requirement AnalysisDocument71 pages4150 70-37-3 Requirement AnalysisSreenath SreeNo ratings yet

- SM ATF400G-6 - EN - Intern Use OnlyDocument1,767 pagesSM ATF400G-6 - EN - Intern Use OnlyReinaldo Zorrilla88% (8)

- 2023 It SbaDocument8 pages2023 It SbaCarl ThomasNo ratings yet

- Sanam MathDocument13 pagesSanam MathAbrar Ahmed KhanNo ratings yet

- T100-V Service ManualDocument22 pagesT100-V Service ManualSergey KutsNo ratings yet

- Biochips: Submitted byDocument17 pagesBiochips: Submitted byCharina Marie CaduaNo ratings yet

- Lecture-13 Indexing and Its Types: Subject: DBMS Subject Code: BCA-S301T Faculty: Saurabh JhaDocument16 pagesLecture-13 Indexing and Its Types: Subject: DBMS Subject Code: BCA-S301T Faculty: Saurabh JhaShivam KushwahaNo ratings yet

- Dynapac Mini Roller - CC125Document14 pagesDynapac Mini Roller - CC125Iftequar Rizwan KhanNo ratings yet

- Erbe Service Manual Icc200 Icc300h-E Icc350Document266 pagesErbe Service Manual Icc200 Icc300h-E Icc350tonybimbo73% (15)

- The Environment and Corporate Culture: True/False QuestionsDocument21 pagesThe Environment and Corporate Culture: True/False QuestionsĐỗ Hiếu ThuậnNo ratings yet

- HDM Method PDFDocument117 pagesHDM Method PDFBonagiri DheerajNo ratings yet

- Meridium Enterprise APM ModulesAndFeaturesDeploymentDocument517 pagesMeridium Enterprise APM ModulesAndFeaturesDeploymenthellypurwantoNo ratings yet

- NetworksDocument6 pagesNetworksscribdNo ratings yet

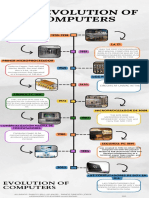

- Infografia Línea Del Tiempo Historia de La Computadoras en InglesDocument1 pageInfografia Línea Del Tiempo Historia de La Computadoras en InglesGEORGEGAMER MCNo ratings yet

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsFrom EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsRating: 5 out of 5 stars5/5 (1)

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!From EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!No ratings yet

- A Pathway to Decarbonise the Shipping Sector by 2050From EverandA Pathway to Decarbonise the Shipping Sector by 2050No ratings yet

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceFrom EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceNo ratings yet

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsFrom EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsRating: 4.5 out of 5 stars4.5/5 (2)

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerFrom EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerNo ratings yet

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Carbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersFrom EverandCarbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersRating: 4.5 out of 5 stars4.5/5 (2)

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977From EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977No ratings yet

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsFrom EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsNo ratings yet

- Global Landscape of Renewable Energy FinanceFrom EverandGlobal Landscape of Renewable Energy FinanceNo ratings yet

- SketchUp Success for Woodworkers: Four Simple Rules to Create 3D Drawings Quickly and AccuratelyFrom EverandSketchUp Success for Woodworkers: Four Simple Rules to Create 3D Drawings Quickly and AccuratelyRating: 1.5 out of 5 stars1.5/5 (2)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)