Professional Documents

Culture Documents

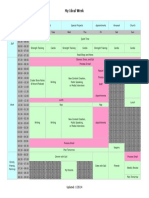

Eloqua Layout E Scan 2014 Jan

Uploaded by

MikQuinlyn SpellerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eloqua Layout E Scan 2014 Jan

Uploaded by

MikQuinlyn SpellerCopyright:

Available Formats

Can e scan increase my

profitability?

How much resource will I need to commit? How long before payback begins? Will my staff adopt this in the process?

Do I consider this for new lines or

existing lines only?

Does this technology work for my process and meet

my specification requirements?

Where is this being used successfully?

How does price match with

competition?

What aftermarket and service

support can I access?

Will the equipment last and

be reliable?

What other applications can

this be used for?

Response message CORP

yes. E scan clients typicall reduce their sampling vs

inline variation by 1 to 2 %. We supply you with a

comprehensive ROI calculation that even provides

months (or weeks) to positive cash flow if purchased

outright or leased

your team of QA and line management will require approximatyely

one month

immediately after instrument validation Real-time information vs sampled lab results gives your

staff a powerful tool to 'see inside the pipe' and

understand what your process is doing- in time to make

adjustments that reduce waste

Whether a new line or an existing line, e scan can

be fit to your needs

We do a comprehensive application analysis for your process at the start. This

may include sample testing in our lab. We perpare a comprehensive report to

support your decision to proceed.

In plants in countries in Europe, Pac rim, The americas,

and afriica.

We meet the competition and believe we

are lower cost in total cost of ownership

over the 10 yearp product life.

We offer service contracts, including

remote support via interernet

Some of our earlier generation product s

have been in successful operation for up to

200 years.

constituents such as fat, protein, moisture,

solids, and product flowability in pumpable

food slurries such as meats, veretable,

fruits, confectionaary, doughs, and dairy.

Up to 3 constituents per calibration with no

limit to the number of calibrations.

Response message SITE

Application dependent

MEAT

Meat fat giveaway reduced from 3% to 2%

Dairy

Reduce milkfat giveaway in cheesemilk, retail milk,

and butter. Standardize protein and solids in retail

milk. Control protein in yogurts. Monitor inclusins in

ice cream. More

Dough

Reduce flour giveaway in corn doughs by up to %.

Veg/fruit slurry

Standardize fat in peanut butters. Maintain solids and

bostwick in tomato paste. Standardize protein in soy

beverages. Measure pulp in orange juices.

Confection

measure moisture for control in taffies and wafer

batters for control. Measure fat in chocolate streams.

Lead yield

1st 2nd 3rd 4th 5th

Can e scan increase my

profitability?

How much resource will I need to commit? How long before payback begins? Will my staff adopt this in the process?

Do I consider this for new lines or

existing lines only?

Can e scan increase my

profitability?

How much resource will I need to commit? How long before payback begins? Will my staff adopt this in the process?

Do I consider this for new lines or

existing lines only?

Engineering (Corp/Site process/site

maintenance) CORP

Does this technology work for my

process and meet my specification

requirements?

Where is this being used successfully?

How does price match with

competition?

How long before payback begins?

How much resource will I need to

commit?

Engineering (Corp/Site process/site

maintenance) SITE MAINTENANCE

Does this technology work for my

process and meet my specification

requirements?

How much resource will I need to commit?

What aftermarket and service

support can I access?

Will our (line) staff adopt this in the

process?

Ongoing support costs?

QA/Lab (corp/site) CORP

Does this technology work for my

process and meet my specification

requirements?

How much resource will plants need to

commit?

Will their staff adopt this in the

process?

What ongoing calibration will be

required?

Will the equipment last and be

reliable?

QA/Lab (corp/site) SITE

Does this technology work for my

process and meet my specification

requirements?

How much resource will plants need to

commit?

Will their staff adopt this in the

process?

What ongoing calibration will be

required?

Will the equipment last and be

reliable?

Line Supervisor

Will the equipment last and be

reliable?

Does this technology work for my process and

meet my specification requirements?

What ongoing calibration will be

required?

Will our (line) staff adopt this in the

process?

Ongoing support costs?

Integrator

Does this technology work for my

clients process and meet their

specification requirements?

Where is this being used successfully?

Can e scan increase my clients

profitability?

What aftermarket and service support

is available, and how much will I have

to supply?

How much resource will I need to

commit to sell?

R&D (CORP)

Does this technology work for my

clients process and meet their

specification requirements?

Where is this being used successfully?

Can e scan increase my clients

profitability?

What other applications can this be

used for?

Ongoing support costs?

Academic

Does this technology work for my

clients process and meet their

specification requirements?

Where is this being used successfully?

Can e scan increase my clients

profitability?

What other applications can this be

used for?

Do I consider this for new lines or

existing lines only?

Plant Management (Corp/Site)

Campaign Objective: Increase e scan sales by nurturing campaign with Eloqua Business Unit / Division: BW & Product Inspection

Positioning Statement: Latest Advance for inline food measurement saves labor, raw materials, and increases production capacity, all with brand protection Subject line

What do milk, meat, candy bars, and tortillas have in common? The answer is simple. Each has a product stream that can be controlled from measurements made with the Thermo Scientific e scan Inline Food analyzer. With no moving parts, the e scan uses revolutionary guided microwave technology to see inside the pipe of pump-able food. The results are dramatic: reliable real-time measurements that can be used to mix these food streams to

specification, eliminating give away in meats, vegetable slurry, confectionary streams. Operators are happy with the simple to use, easy to read display. Plant managers are able to save profits: less re-work and more throughput in their factory. And customers get a continuous flow of consistent product quality- giving the companies brand a continuous boost.

1st or 2nd Level Influencer

Barriers or Questions Key Initial Message Timing Sequence

A-D)

Status

(% complete)

Responsibility

(Who)

Review by product category

Q1 2011 Q1 2010 Change Q4 2010 Change

Checkweighers 1,372,484 $ 1,850,353 $ -26% 1,684,439 $ -19%

Metal Detectors 1,503,715 $ 2,054,871 $ -27% 1,874,923 $ -20%

X-Ray 461,820 $ 586,334 $ -21% 878,369 $ -47%

Detection - $ - $

Moisture - $ 171,200 $

Packaging Misc 346,438 $ 157,204 $ 120% (34,966) $

Coding 19,932 $ - $ (548) $

Total 3,704,389 $ 4,648,762 $ -20% 4,573,417 $ -19%

Review by Region

Q1 2011 Q1 2010 Change Change $ Q4 2010 Change

China 428,832 $ 564,705 $ -24% 135,873 $ 524,638 $ -18%

Argentina 119,229 $ (21,583) $ (140,812) $ (9,001) $

Chile 24,410 $ (89,738) $ (114,148) $ (8,356) $

Italy 1,013,842 $ 1,496,328 $ -32% 482,486 $ 1,461,027 $ -31%

Minneapolis 1,848,674 $ 2,246,107 $ -18% 397,433 $ 2,175,809 $ -15%

Rugby 98,332 $ 205,992 $ -52% 107,660 $ 107,181 $ -8%

South Africa 53,139 $ 246,951 $ -78% 193,812 $ 68,352 $ -22%

Mexico - PI 110,509 $ - $ (110,509) $ 253,767 $ -56%

Total 3,704,389 $ 4,648,762 $ -20% 944,373 $ 4,573,417 $ -19%

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Greddy E-Manage Installation ManualDocument6 pagesGreddy E-Manage Installation ManualTHMotorsports.net100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Aggregate Crushing Value Test Lab ReportDocument2 pagesAggregate Crushing Value Test Lab ReportComr A Y ZarginaNo ratings yet

- Hospital Building Civil ProjectDocument128 pagesHospital Building Civil ProjectArun Ragu100% (6)

- National Programs List of Accessible Program For Q4 2014Document2 pagesNational Programs List of Accessible Program For Q4 2014MikQuinlyn SpellerNo ratings yet

- MikQuinlyn Speller Marketing Specialist - Travelers National Programs AE&S Campaign 2014-15Document27 pagesMikQuinlyn Speller Marketing Specialist - Travelers National Programs AE&S Campaign 2014-15MikQuinlyn SpellerNo ratings yet

- Marketing Opportunities 2013Document63 pagesMarketing Opportunities 2013MikQuinlyn SpellerNo ratings yet

- 2014 PI MarCom Budget Proposal SpellerRev 6Document17 pages2014 PI MarCom Budget Proposal SpellerRev 6MikQuinlyn SpellerNo ratings yet

- MikQuinlyn Speller Marketing Specialist - Travelers National Programs Refresh and Rebrand 2014-15Document27 pagesMikQuinlyn Speller Marketing Specialist - Travelers National Programs Refresh and Rebrand 2014-15MikQuinlyn SpellerNo ratings yet

- Website Redesign PresentationDocument15 pagesWebsite Redesign PresentationMikQuinlyn SpellerNo ratings yet

- MikQuinlyn Speller Marketing Specialist - Travelers National Programs AE&S Campaign 2014-15Document27 pagesMikQuinlyn Speller Marketing Specialist - Travelers National Programs AE&S Campaign 2014-15MikQuinlyn SpellerNo ratings yet

- MikQuinlyn Speller Marketing Specialist - Travelers Environmental Practice Campaign Re-Energizer 2014-15Document20 pagesMikQuinlyn Speller Marketing Specialist - Travelers Environmental Practice Campaign Re-Energizer 2014-15MikQuinlyn SpellerNo ratings yet

- Wash N Play MikQuinlyn SpellerDocument8 pagesWash N Play MikQuinlyn SpellerMikQuinlyn SpellerNo ratings yet

- Food Trade AssociationseditedDocument2 pagesFood Trade AssociationseditedMikQuinlyn SpellerNo ratings yet

- Thermo PI Ad 2Document12 pagesThermo PI Ad 2MikQuinlyn SpellerNo ratings yet

- Marketing Opportunities 2013Document63 pagesMarketing Opportunities 2013MikQuinlyn SpellerNo ratings yet

- Thermo Fisher 2014 MediaDocument2 pagesThermo Fisher 2014 MediaMikQuinlyn SpellerNo ratings yet

- Marketing PR and Product Launch Schedule2014rev2Document12 pagesMarketing PR and Product Launch Schedule2014rev2MikQuinlyn SpellerNo ratings yet

- Metal Detection3Document1 pageMetal Detection3MikQuinlyn SpellerNo ratings yet

- 2014 PI MarCom Budget Proposal SpellerRev 6Document17 pages2014 PI MarCom Budget Proposal SpellerRev 6MikQuinlyn SpellerNo ratings yet

- Thermo PI Ad AnalyticsPigDocument1 pageThermo PI Ad AnalyticsPigMikQuinlyn SpellerNo ratings yet

- Thermo Fisher 2014 MediaDocument2 pagesThermo Fisher 2014 MediaMikQuinlyn SpellerNo ratings yet

- 4 Largest Magazine in ItalyDocument6 pages4 Largest Magazine in ItalyMikQuinlyn SpellerNo ratings yet

- MikQuinlyn Speller's Resume 2013Document4 pagesMikQuinlyn Speller's Resume 2013MikQuinlyn SpellerNo ratings yet

- AccountAbility Minnesota Newsletter 12/06Document4 pagesAccountAbility Minnesota Newsletter 12/06MikQuinlyn SpellerNo ratings yet

- MikQuinlyn Speller Traditional Resume - Spring 2013Document5 pagesMikQuinlyn Speller Traditional Resume - Spring 2013MikQuinlyn SpellerNo ratings yet

- Marketing Communications Training BKGuideDocument29 pagesMarketing Communications Training BKGuideMikQuinlyn SpellerNo ratings yet

- MikQuinlyn Speller References Spring 2013Document2 pagesMikQuinlyn Speller References Spring 2013MikQuinlyn SpellerNo ratings yet

- Internal Architecture of Intel 8086, FinalDocument24 pagesInternal Architecture of Intel 8086, FinalAshek E Elahi SohanNo ratings yet

- Service Manual Sony MHC-V5Document122 pagesService Manual Sony MHC-V5Enya Andrea Ribba HernandezNo ratings yet

- Imageclass Lbp611cn 613cdw 2Document2 pagesImageclass Lbp611cn 613cdw 2Maulana Ikhwan SadikinNo ratings yet

- Konica Bizhub 7272 - User ManualDocument436 pagesKonica Bizhub 7272 - User Manualfaco1723No ratings yet

- SR.11.10961 - Sour Well Design GuideDocument52 pagesSR.11.10961 - Sour Well Design GuideMahmoud Ahmed Ali Abdelrazik100% (1)

- KSSR - MatematikDocument6 pagesKSSR - MatematikFaris FarhanNo ratings yet

- Occupant Manikin Introduction: 95th Percentile Male Driver ModelDocument9 pagesOccupant Manikin Introduction: 95th Percentile Male Driver ModelarstjunkNo ratings yet

- Envea Dusty Manual enDocument26 pagesEnvea Dusty Manual enmikiNo ratings yet

- The Contemporary WorldDocument9 pagesThe Contemporary WorldDennis RaymundoNo ratings yet

- Gas LiftDocument35 pagesGas LiftHìnhxămNơigóckhuấtTimAnh100% (1)

- Crisis Management PlanDocument8 pagesCrisis Management PlanNfareeNo ratings yet

- Differences Between Routers, Switches and HubsDocument2 pagesDifferences Between Routers, Switches and HubsPappu KhanNo ratings yet

- .Anber Globe!Document20 pages.Anber Globe!Cristina GabaroiNo ratings yet

- Manual em Portugues DGX230Document120 pagesManual em Portugues DGX230Agosthis0% (1)

- My Ideal Week PDFDocument1 pageMy Ideal Week PDFAnonymous QE45TVC9e3No ratings yet

- BS Basics Boundary Scan PDFDocument2 pagesBS Basics Boundary Scan PDFShankar ArunmozhiNo ratings yet

- Range and Angle Tracking Techniques for Moving Target EstimationDocument34 pagesRange and Angle Tracking Techniques for Moving Target Estimationmykingboody2156No ratings yet

- Multipoint Socket Profile VW 010 43: KonzernnormDocument4 pagesMultipoint Socket Profile VW 010 43: KonzernnormRicardo Vitoriano100% (1)

- Is 15560 - 2005Document12 pagesIs 15560 - 2005kalpanaadhiNo ratings yet

- Managing Information for Better DecisionsDocument12 pagesManaging Information for Better DecisionsTosin WilliamsNo ratings yet

- Text Programming Guide For iOSDocument106 pagesText Programming Guide For iOSPetr MánekNo ratings yet

- Fiedler's Contingency Model of Leadership Effectiveness: Background and Recent DevelopmentsDocument24 pagesFiedler's Contingency Model of Leadership Effectiveness: Background and Recent DevelopmentsEdielyn Gonzalvo GutierrezNo ratings yet

- June 2014 Draft for Public ReviewDocument59 pagesJune 2014 Draft for Public ReviewRomel Vargas Sánchez0% (1)

- PDF 7758Document2 pagesPDF 7758José Antônio CardosoNo ratings yet

- Mara Vatz, "Knowing When To Stop: The Investigation of Flight 191"Document30 pagesMara Vatz, "Knowing When To Stop: The Investigation of Flight 191"MIT Comparative Media Studies/WritingNo ratings yet

- Aritco Home Lifts 2014 DEC en LDocument52 pagesAritco Home Lifts 2014 DEC en LBuzaareNo ratings yet

- Manual, contact info and schematic for GSM moduleDocument10 pagesManual, contact info and schematic for GSM modulethaiNo ratings yet