Professional Documents

Culture Documents

DAT Centrifugal Pump

Uploaded by

EDUARDOCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DAT Centrifugal Pump

Uploaded by

EDUARDOCopyright:

Available Formats

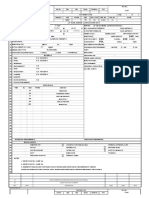

Rev: 0

1 Rev DESCRIPTION

2 Code/standard: API 610, Latest Edition Service:

3 Qty. required: Pump type: Centrifugal

4 Pump size: No. stages:

5 GENERAL

6 Pumps to operate in parallel with: Gear provided by:

7 Pumps to operate in series with: Gear mounted by:

8 Motor driven: Turbine driven:

9 Motor provided by: Turbine provided by:

10 Motor mounted by: Turbine mounted by:

11 DESIGN DATA/OPERATING CONDITIONS (per pump) SITE AND UTILITY DATA

12 Capacity: Normal (USgpm) Location:

13 Rated (USgpm)

14 Other (USgpm)

15 Suction pressure Max (psig) Rated (psig) Electrical class.: CL Gr Div

16 Discharge pressure (psig) Winterization required:

17 Differential pressure (psig) Tropicalization required:

18 Differential head (ft) NPSHA (ft) Site data:

19 Service, Continuous Intermittent(start/day) Altitude (ft) Barometer (psia)

20 LIQUID: Ambient temperature Min Max (F)

21 Type/name of liquid Relative humidity Min Max (%)

22 Pumping temperature Normal (F)

23 Max (F) Other

24 Min (F) Utilities:

25 Vapour pressure (psia) @ (F) Steam

26 Specific Gravity Norm Max Min Min (psig) (F)

27 Specific heat (c

p

) (Btu/lbF) Max (psig) (F)

28 Viscosity (cP) @ (F) Electricity: Volt/phase/Hz

29 Max viscosity (cP) Cooling water:

30 Corrosive/erosive agent Temp inlet (F) Max return (F)

31 Chlorine concentration (ppm) Press normal (psig) Design (psig)

32 H

2

S concentration (ppm) Min return (psig) Max allow PD (psi)

33 Liquid Hazardous Flammable Water source

34 Other: Chloride concentration (ppm)

35 Avail. Instrument air pressure: Max Min (psig)

36 PERFORMANCE (By Vendor) MATERIAL (By vendor)

37 Curve No. RPM Appendix H class

38 Impeller diameter: Rated Max Min (in) Min design metal temp (F)

39 Rated power (Bhp) Efficiency (%) Barrel/case

40 Minimum continuous flow: (USgpm) Impeller

41 Max Head @ rated impeller (ft) Case/Impeller wear rings

42 Max Power @ rated impeller (Bhp) Shaft

43 NPSH required at rated capacity (ft) Diffusers

44 Suction specific speed Coupling spacer/hubs

45 Max sound pressure level required 85 @ 3.28 ft (dBA) Coupling diaphragms (disks)

46 Estimated max sound press level (dBA) Remarks:

47 Remarks:

48

49

DATE BY CHK'D APP'D

WO #: Equip. Name:

Client:

DATA SHEET

Project: CENTRIFUGAL PUMP - API 610

REVISION LOG

REV: DESCRIPTION

Plant/Area: Equip. No:

ADL Doc. No: ENG-DAT-000089

Pump Vendor

Pump Vendor

Other

Other

Pump Vendor

Pump Vendor

Other

Other

Indoor Outdoor Grade

Heated Under roof Mezzanine

Dust Fumes

Source Doc: DS.131.0001US.CAL.R00 Page 1 of 5

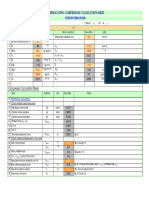

Rev: 0

WO #: Equip. Name:

Client:

DATA SHEET

Project: CENTRIFUGAL PUMP - API 610

Plant/Area: Equip. No:

ADL Doc. No: ENG-DAT-000089

1 Rev CONSTRUCTION (By vendor)

2 Pump type (see API 610 fig 1-1):

3 Nozzle connections:

4 Description No Size (NPS) Rating Facing Position Type

5 (in) FX FY FZ MX MY MZ

6 Suction

7 Discharge

8 Drain N/A N/A

9 Vent N/A N/A

10 Press gauge N/A N/A

11 Temp gauge N/A N/A

12 Warm-up N/A N/A

13

14 Casing: Couplings:

15 Mounting Make

16 Model

17 Rating (hp/100rpm)

18 Split Lubrication

19 Type Limited end float required

20 Spacer length (in)

21 Service factor

22 Press rating MAWP (psig) @ (F) Drive half coupling mounted by:

23 Hydro test press (psig) Couplings per API 671

24 Rotation: Baseplates:

25 Shaft: Dia at coupling (in) API baseplate number (see API 610 APP M)

26 Dia. between bearings (in) Non grout

27 Span between bearings (in) Remarks:

28 Span between bearing & impeller (in)

29 MECHANICAL SEAL (By vendor)

30 Seal data API 682 Y/N Barrier/buffer fluid

31 Appendix H seal code Supply temp Max Min (F)

32 Seal manufacturer Specific gravity @ (F)

33 Size and type Fluid description

34 Seal chamber Temp (F) Press (psig) Vapour pressure (psia) @ (F)

35 Flow (USgpm) Size Hazardous Flammable

36 Length Total Clear (in) Flow rate Max Min (USgpm)

37 Seal construction Sleeve mat. Gland mat. Pressure required Max Min (psig)

38 Temperature required Max Min (F)

39 Gland taps Quench fluid Fluid description

40 Flow rate (USgpm)

41 Seal flush piping Seal flush piping plan

42

43 Seal fluid requirements and available flush liquid

44 Supply temp Max Min (F) Auxiliary flush plan

45 Specific gravity @ (F)

46 Fluid description

47 Specific heat (c

p

) (Btu/lbF) Piping assembly

48 Vapour pressure (psia) @ (F)

49

50 Flow rate Max Min (USgpm)

51 Pressure required Max Min (psig)

52 Temperature required Max Min (F) Remarks:

External loads (lb & lbft)

Centerline

Foot

Inline

Axial

Near Centerline

Separate mounting plate

Radial

Single volute

Diffuser

Between bearings

Multiple volute

Overhung

Pump vendor Other

Flush

Aux seal device Jacket required

Quench

Heating

Lubr.

Drain

Cooling

Leakage

External fluid injection

Barrier/Buffer

Balance Fluid

Pumped Fluid

Tubing

Pipe

Carbon steel

Stainless steel

Tubing

Pipe

Carbon steel

Stainless steel

Threaded

Flanged

Unions Socket welded

Tube type fittings

Press Switch

Press gauge

Level switch

Level gauge

Temp indicator

Heat exchanger

CW CCW

Hazardous Flammable

Source Doc: DS.131.0001US.CAL.R00 Page 2 of 5

Rev: 0

WO #: Equip. Name:

Client:

DATA SHEET

Project: CENTRIFUGAL PUMP - API 610

Plant/Area: Equip. No:

ADL Doc. No: ENG-DAT-000089

1 Rev PACKING (By vendor) MOTOR DRIVE (By vendor)

2 Type Manufacturer

3 Size No. of rings Rated output (hp) Speed RPM

4 Packing injection required Horizontal Vertical

5 Flow (USgpm) @ (F) Frame

6 Lantern ring Service factor

7 BEARINGS AND LUBRICATION (By vendor) Volts/Phase/Hz

8 Radial: Type Number Type

9 Thrust: Type Number Enclosure

10 Lubrication: Minimum starting voltage Run up time (s)

11 Temperature rise (F)

12 Full load amps (amp)

13 Constant level oiler preference Locked rotor amps (amp)

14 Pressure lube system Insulation

15 Oil Visc ISO grade Starting method DOL/VSD/VFD

16 Vertical thrust capacity Up Down (lb)

17 Remarks: Bearings type/number

18 Radial

19 STEAM AND COOLING WATER PIPING Thrust

20 Cooling water piping plan Lube

21 Cooling water requirements Remarks:

22 Seal jacket/brg hsg (USgpm) @ (F)

23 Seal heat exchanger (USgpm) @ (F)

24 Quench (USgpm) @ (F) SURFACE PREPARATION, PAINT and SHIPMENT

25 Total cooling water (USgpm) Manufacturer standard

26 Steam piping:

27 Remarks: Other

28 Pump Pump surface prep

29 INSTRUMENTATION Primer

30 Vibration Non contacting (API 670) Transducer Finish coat

31 Provision for mounting only Baseplate Baseplate surface prep

32 Flat surface required Primer

33 Temperature and pressure Finish

34 Radial bearing metal temp (F) Shipment

35 Thrust bearing metal temp (F)

36 Provision for instruments only Remarks:

37 Temp gauges (with thermo wells)

38 Pressure gauge type Location SPARE PARTS

39 WEIGHT Start up

40 MOTOR DRIVEN TURBINE DRIVEN Normal maintenance (2 years)

41 Pump (lb) Baseplate (lb) Other (specify)

42 Baseplate (lb) Turbine (lb)

43 Motor (lb) Gear (lb)

44 Gear (lb) (lb)

45 Total (lb) Total (lb)

46 Remarks:

47

48

49

50

51

52

53

Grease

Ring oil

Purge oil mist

Flood

Flinger

Pure oil mist

Oil heater req. Electric Steam

API 610 API 614

Domestic Export Export boxing req.

Outdoor storage more than 6 months

Tubing Pipe Client standard See specification

Source Doc: DS.131.0001US.CAL.R00 Page 3 of 5

Rev: 0

WO #: Equip. Name:

Client:

DATA SHEET

Project: CENTRIFUGAL PUMP - API 610

Plant/Area: Equip. No:

ADL Doc. No: ENG-DAT-000089

1 Rev QA INSPECTION AND TEST VERTICAL TYPE PUMPS ONLY (By vendor)

2 Review vendors QA programme Pump thrust: (+) Up (-) Down

3 Performance curve approval At min flow (lb) (lb)

4 Shop inspection At rated flow (lb) (lb)

5 Test with substitute seal At max flow (lb) (lb)

6 TEST NON-WIT WIT OBSERVE Max thrust (lb) (lb)

7 Hydrostatic Soleplate (in) X (in)

8 Performance Soleplate thickness (in)

9 NPSH Column pipe: Flanged Threaded

10 Complete unit test Diameter (in) Length (in)

11 Sound level test Guide bushing:

12 Cleanliness Number

13 Nozzle load Line shaft bearing spacing (in)

14 BRG HSG resonance Guide bushing lube:

15 Hydrodynamic bearings

16 Aux equipment

17 Vibration Line shaft:

18 Line shaft diameter: (in) Tube diameter: (in)

19 Material certs Line shaft coupling:

20 Sleeve & key Threaded

21 Suction can thickness (in)

22 Casting repair procedure Length (ft)

23 Welding Diameter (in)

24 Suction strainer type

25 Castings Float & rod Float switch

26 Impeller collets acceptable

27 Hardness test for: Hardened sleeves under bearings

28 Running clearances Resonance test

29 Structural analysis

30 Drain piped to surface

31 OTHER REQUIREMENTS Sump arrangement (see API 610 sketch):

32 Review vendor documents Sump depth (ft)

33 Alignment checks Sump dimension (ft)

34 Dynamic balance Low liquid (ft)

35 NOTES Pump length (ft)

36 Submergence required (ft)

37 Centerline discharge height (ft)

38 Datum elevation (ft)

39 Vertical pumps see Attachment 1

40

41

42

43

44

45

46

47

48

49

50

51

52

53

Water

Grease

Open

Oil

Pumpage

Enclosed

Casing

Impeller

Shaft

MP

RT

DP

UT

MP

RT

DP

UT

Source Doc: DS.131.0001US.CAL.R00 Page 4 of 5

Rev:

1 Rev SUMP ARRANGEMENT

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18 Refer to Hydraulic Institute Standards for definitions

19

20

21 Sump depth (ft) Pump length (ft)

22 Sump dimension (ft) Submergence Req'd (ft)

23 Low liquid (ft) Centerline of discharge height (ft)

24 Datum elevation (ft)

25 NOTES

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

Client:

DATA SHEET

Project: CENTRIFUGAL PUMP - ATTACHMENT 1 - API 610

Plant/Area: Equip. No:

Doc. No:

WO #: Equip. Name:

LOW

LIQUID

SUMP DIMENSION

SUMP

DEPTH PUMP

LENGTH LOW

LIQUID

PUMP

LENGTH

DATUM

ELEVATION

(1ST STG

IMPELLER)

CENTERLINE OF DISCHARGE

SUBMERGENCE REQ'D

GRADE

You might also like

- Heater DataDocument2 pagesHeater DataEDUARDONo ratings yet

- Data Sheet: Description Unit Design DataDocument1 pageData Sheet: Description Unit Design DataEDUARDONo ratings yet

- Hid Ro CycloneDocument1 pageHid Ro CycloneEDUARDONo ratings yet

- PSV Sizing (Steam)Document2 pagesPSV Sizing (Steam)Saeid Rahimi Mofrad100% (1)

- LP Gas Amine Contactor Process DataDocument6 pagesLP Gas Amine Contactor Process DataEddy RainNo ratings yet

- Reciprocating CompressorDocument6 pagesReciprocating CompressorEDUARDONo ratings yet

- Heat Exchanger Ball Cleaning Package Data SheetDocument2 pagesHeat Exchanger Ball Cleaning Package Data SheetEDUARDONo ratings yet

- FW PumpDocument15 pagesFW PumpAJAY1381100% (1)

- Technical Bid Tabulation: Vendor Description SpecificationDocument8 pagesTechnical Bid Tabulation: Vendor Description SpecificationGunturMudaAliAkbarNo ratings yet

- Centrifugal PumpDocument68 pagesCentrifugal Pumpsafald100% (2)

- CCC1Document5 pagesCCC1Uok RitchieNo ratings yet

- Rotary Pump Data SheetDocument2 pagesRotary Pump Data SheetRuzi Falahi KautsarNo ratings yet

- Machine production overview reportDocument233 pagesMachine production overview reporthenryhariyadiNo ratings yet

- Liq Expansion CalculationsDocument4 pagesLiq Expansion CalculationsGary JonesNo ratings yet

- Calculate Steam Pipe Sizing and CapacityDocument2 pagesCalculate Steam Pipe Sizing and CapacityjoeljdiazNo ratings yet

- Mixer design parametersDocument2 pagesMixer design parametersEDUARDONo ratings yet

- 1 Inlet 1 Outlet 2 Inlet 2 Outlet 3 Inlet 3 Outlet 12333 11 184 0Document1 page1 Inlet 1 Outlet 2 Inlet 2 Outlet 3 Inlet 3 Outlet 12333 11 184 0AbdulNo ratings yet

- Vent Sizing - SpreadsheetDocument2 pagesVent Sizing - SpreadsheetPradip ShindeNo ratings yet

- Plate Exchanger Performance and Design DataDocument2 pagesPlate Exchanger Performance and Design DataEDUARDONo ratings yet

- Pump Horsepower CalculationDocument5 pagesPump Horsepower Calculationkanpur12345100% (1)

- Gas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetDocument5 pagesGas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetNaqqash Sajid0% (2)

- Sizing ExercisesDocument20 pagesSizing ExercisesfdkaNo ratings yet

- Datasheets For Bucket Type StrainerDocument2 pagesDatasheets For Bucket Type StrainerbecpavanNo ratings yet

- Process Calculation Sheet Tag No.: 1. PurposeDocument10 pagesProcess Calculation Sheet Tag No.: 1. PurposeAJAY1381No ratings yet

- Pump SelectionDocument2 pagesPump Selectiongroup2sd1314No ratings yet

- Pump CalcDocument1 pagePump CalcMoch WildanNo ratings yet

- 20120507091359 (1)Document6 pages20120507091359 (1)Noman Abu-FarhaNo ratings yet

- Line Sizing Criteria As Per Different StandardsDocument4 pagesLine Sizing Criteria As Per Different Standardsadil alameenNo ratings yet

- Calculation Sheet For Pump Hydraulic (Fps Unit)Document1 pageCalculation Sheet For Pump Hydraulic (Fps Unit)chemical todiNo ratings yet

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 pagesMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNo ratings yet

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetDocument1 pageCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaNo ratings yet

- Pump (English) TemplateDocument1 pagePump (English) TemplateMichael HaiseNo ratings yet

- Centrifugal Pump Calculation SpreadsheetDocument8 pagesCentrifugal Pump Calculation SpreadsheetsamvendanNo ratings yet

- Sizing For Two PhaseDocument6 pagesSizing For Two PhaseKong LingweiNo ratings yet

- Restriction Orifice Final CalculationDocument1 pageRestriction Orifice Final CalculationJasperTanNo ratings yet

- Line Sizing Criteria As Per Different International StandardsDocument12 pagesLine Sizing Criteria As Per Different International StandardsbadelitamariusNo ratings yet

- Selección de CompresoresDocument23 pagesSelección de CompresoresjowarNo ratings yet

- 100 P 102Document33 pages100 P 102AJAY1381No ratings yet

- SN74LVC07Document23 pagesSN74LVC07abcdNo ratings yet

- How To Size A Pump - Blackmonk EngineeringDocument12 pagesHow To Size A Pump - Blackmonk EngineeringbinoshjamesNo ratings yet

- Orifice Plate Flow Calculator Pressure DropDocument6 pagesOrifice Plate Flow Calculator Pressure Droplutfi awnNo ratings yet

- Data SheetDocument6 pagesData Sheetnalawade_pradeepNo ratings yet

- Pipes. Maxi 1Document1 pagePipes. Maxi 1Nasrul AdliNo ratings yet

- Pressure Drop CalculatorDocument12 pagesPressure Drop CalculatorKevin PratyatamaNo ratings yet

- Line Sizing Design Basis - General Specification PDFDocument11 pagesLine Sizing Design Basis - General Specification PDFSaiKumarNo ratings yet

- Waste Heat Recovery UnitDocument15 pagesWaste Heat Recovery UnitEDUARDONo ratings yet

- Pump Sizing SpreadsheetDocument2 pagesPump Sizing Spreadsheetandrew rachmanNo ratings yet

- Appendix 1 - Production Separator Sizing - Rev.0Document5 pagesAppendix 1 - Production Separator Sizing - Rev.0Thái Xuân QuangNo ratings yet

- Line Sizing GuidelinesDocument2 pagesLine Sizing GuidelinesHarryBouterNo ratings yet

- Pump Selection - Teluk Kabung (07.10.2015) - With CommentDocument15 pagesPump Selection - Teluk Kabung (07.10.2015) - With CommentPriyo Jati WahyonoNo ratings yet

- Sheet A - 1 Volume CalculationDocument3 pagesSheet A - 1 Volume CalculationNurcahyo Djati WNo ratings yet

- 3206 - RotameterDocument9 pages3206 - RotameterVidya MuthukrishnanNo ratings yet

- Liquid Orifice SizingDocument4 pagesLiquid Orifice SizingrmaganNo ratings yet

- Filter CalculationDocument4 pagesFilter CalculationRashmi RanjanNo ratings yet

- Control Valve Sizing - Gas Rev 3.1bDocument3 pagesControl Valve Sizing - Gas Rev 3.1bLuis RamirezNo ratings yet

- Cavitation-Pump-Pipe-Skid CalcDocument56 pagesCavitation-Pump-Pipe-Skid CalcOltun KAYANo ratings yet

- Calculation Cover SheetDocument3 pagesCalculation Cover SheetKids StrolaNo ratings yet

- Data Sheet: Hydraulic Power UnitDocument3 pagesData Sheet: Hydraulic Power UnitEDUARDONo ratings yet

- HRD Hot Water Pump P001Document6 pagesHRD Hot Water Pump P001nguyenquoc1988No ratings yet

- Dry CobbingDocument1 pageDry CobbingEDUARDONo ratings yet

- 820 CB 120G WM26 - Rev0Document1 page820 CB 120G WM26 - Rev0EDUARDONo ratings yet

- Durban Classic Cover + Caposide in One Side (Shougang Project)Document4 pagesDurban Classic Cover + Caposide in One Side (Shougang Project)EDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document12 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document14 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONo ratings yet

- 5720 D E DWG 0201 - RevADocument4 pages5720 D E DWG 0201 - RevAEDUARDONo ratings yet

- 830 CB 120 M06 - Rev0Document1 page830 CB 120 M06 - Rev0EDUARDONo ratings yet

- 820 CB 120G WM25 - Rev0Document1 page820 CB 120G WM25 - Rev0EDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document14 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONo ratings yet

- 5921 D E DWG 0205 - RevADocument6 pages5921 D E DWG 0205 - RevAEDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit PlantDocument10 pagesMine Operation Expansion Project and Benefit PlantEDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document12 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit PlantDocument10 pagesMine Operation Expansion Project and Benefit PlantEDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.09.2014Document14 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.09.2014EDUARDONo ratings yet

- 830 CB 120 M07 - Rev0Document1 page830 CB 120 M07 - Rev0EDUARDONo ratings yet

- 5921 D E DWG 0105 - RevADocument6 pages5921 D E DWG 0105 - RevAEDUARDONo ratings yet

- Data Sheet: DescriptionDocument6 pagesData Sheet: DescriptionEDUARDONo ratings yet

- 5921 D E DWG 0205 - RevADocument6 pages5921 D E DWG 0205 - RevAEDUARDONo ratings yet

- Schedule Levels - Major Projects: Core Scheduling Papers: #6Document5 pagesSchedule Levels - Major Projects: Core Scheduling Papers: #6EDUARDONo ratings yet

- Sewagw Treatment FilterDocument1 pageSewagw Treatment FilterEDUARDONo ratings yet

- Silencer Data Sheet ReviewDocument2 pagesSilencer Data Sheet ReviewEDUARDONo ratings yet

- StrainerDocument3 pagesStrainerEDUARDONo ratings yet

- Sewage Treatment Ultraviolet DeinfectionDocument1 pageSewage Treatment Ultraviolet DeinfectionEDUARDONo ratings yet

- Steam BoilerDocument10 pagesSteam BoilerEDUARDONo ratings yet

- Sewage Treatment FloculantDocument1 pageSewage Treatment FloculantEDUARDONo ratings yet

- Sewage Treatment MenbraneDocument1 pageSewage Treatment MenbraneEDUARDONo ratings yet

- Sewage Treatment Tank MixerDocument1 pageSewage Treatment Tank MixerEDUARDONo ratings yet

- Sewage Treatment PlantDocument2 pagesSewage Treatment PlantEDUARDONo ratings yet

- Separation CellDocument11 pagesSeparation CellEDUARDONo ratings yet

- Sewage Treatment EfluentDocument5 pagesSewage Treatment EfluentEDUARDONo ratings yet