Professional Documents

Culture Documents

12 - Mechanical Reliability Assevbssment of Optical Fibres in Radiation Environments

Uploaded by

Bianca BăcanuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

12 - Mechanical Reliability Assevbssment of Optical Fibres in Radiation Environments

Uploaded by

Bianca BăcanuCopyright:

Available Formats

www.sckcen.

be

MECHANICAL RELIABILITY ASSESSMENT OF OPTICAL FIBRES IN

RADIATION ENVIRONMENTS

Background

After more than two decades of intensive research and even some pioneering applications in space, optical

fibres are now finding their way in various radiation environments, including both fission and future fusion

nuclear-power plants, and high-energy physics experiments. For example, next to distributed monitoring

applications of large nuclear infrastructures, fibre-optics can also be used for data communications during

maintenance operations in the reactor vessel of the future ITER (International Thermonuclear Experimental

Reactor), or for plasma diagnostics applications during operation of the reactor. These maintenance and

diagnostics tasks require the optical fibres to withstand extremely high doses of radiation, up to MGy dose

levels and temperatures above 150C.

Objectives

The reliability assessment of fibre-optic systems for their qualification in nuclear environments often requires

to meet stringent radiation tolerance levels. The majority of (usually accelerated) radiation assessments have

so far focused on optical properties, such as wavelength-dependent radiation induced attenuation and radio-

luminescence. The relation of these radiation effects with the fabrication methods and other environmental

parameters has been the subject of years of research. Only a few results are available on the long-term

evolution of mechanical properties of irradiated optical fibres. As a first step towards understanding the long-

term reliability of fibre-optic composite cables in hostile radiation environments, we therefore performed

dynamic fatigue tests with different commercial-grade optical fibres, both multi-mode and single-mode types.

Principal results

We selected for testing four standard telecom acrylate-coated Ge-doped single-mode fibres from three

different manufacturers, and one acrylate-coated Ge-doped multi-mode fibre. Fibre samples of 50 m were

loosely coiled with a diameter of 60 mm and exposed during a first experiment with a dose rate of 27 kGy/h

up to a total dose of 15 MGy at an ambient temperature of approximately 55 C.

In collaboration with both Draka Comteq Optical Fibre in Eindhoven and with the School of Engineering

(Metallurgy and Materials Department) at the University of Birmingham, we performed several mechanical

tests before and after irradiation, including the two-point bend test. These destructive two-point bend tests

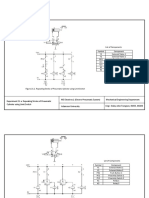

allow to determine the fibres' strength (50 % failure stress) and the dynamic fatigue factor. Both physical

quantities are estimated from the measurement of the failure stress as a function of the applied stress rate

[GPa/sec], resulting in typical Weibull plots as presented in the picture hereunder, which presents the

probability of failure versus the applied stress with logarithmic scales.

Our Weibull analysis reveals a strength reduction of about 50 % at these MGy dose levels. SEM (scanning

electronic microscope) images of the fibres samples, which were uncoated after irradiation, further suggest

that roughening of the outer glass surface can explain this degradation. These first results indicate that the

long-term mechanical strength of optical fibres could be seriously affected when exposed to MGy dose

levels.

Operational Office: Boeretang 200, B-2400 Mol Scientific Report 2005

www.sckcen.be

-2

-1

0

1

0.5 0.6 0.7

log(stress) [GPa]

l

o

g

(

-

l

n

(

1

-

F

)

)

5%

10%

20%

50%

100%

200%

5% f it

10% fit

20% fit

50% fit

100% f it

200% f it

Weibull plots : 2 Point Bending

F

a

i

l

u

r

e

p

r

o

b

a

b

i

l

i

t

y

[

%

]

Evolution of the mechanical strength as a function of the applied stress rate, after irradiation up to MGy dose levels.

(Courtesy of Draka Comteq Optical Fibre, Eindhoven)

Future work

During a second irradiation, we exposed three pristine samples from one single-mode fibre at 55 C with a

dose rate of 1.7 kGy/h, 3.4 kGy/h and 17 kGy/h up to total doses of respectively 1.0 MGy, 2.0 MGy and

10.1 MGy. In parallel, we thermally aged an identical pristine fibre sample in a climate chamber at 55 C with

a relative humidity of 50 %. This complementary experiment was conducted in order to distinguish between

thermal ageing and combined radiation-thermal ageing effects, while we also look for mechanical

degradation mechanisms at intermediate dose levels.

We also intend to evaluate the potential impact of different protective coating materials on the mechanical

reliability of optical fibres in radiation environments, including hermetic amorphous carbon and polyimide

coatings.

Main contact person

Marco Van Uffelen, marco.van.uffelen@sckcen.be

Main reference

M. Van Uffelen, S. Kukureka, Y. El Shazly, P. Matthijsse, G. Kuyt, F. Berghmans, Mechanical reliability

studies of optical fibres under high-dose gamma radiation, accepted for presentation at the conference on

Reliability of Optical Fiber Components, Devices, Systems, and Networks III, part of the SPIE Photonics

Europe Symposium, 3-7 April 2006 in Strasbourg, France.

Operational Office: Boeretang 200, B-2400 Mol Scientific Report 2005

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Visual Servoing of A Parallel Robot SystemDocument6 pagesVisual Servoing of A Parallel Robot SystemBianca BăcanuNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 8 9 Bonding IntDocument73 pages8 9 Bonding IntBianca BăcanuNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Fatigue Testing Procedures of Silica Optical FibresDocument7 pagesFatigue Testing Procedures of Silica Optical FibresBianca BăcanuNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Filehost AscDocument33 pagesFilehost AscBianca BăcanuNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- LCD panel and module replacement parts for saleDocument1 pageLCD panel and module replacement parts for saleValeria bolañosNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Stock PartDocument20 pagesStock PartGReyNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Fossa FO 0015 0035 A Technical Data en 9aaDocument2 pagesFossa FO 0015 0035 A Technical Data en 9aaFatih YAŞARNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- AbzenoDocument7 pagesAbzenojykhgpdrc5No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Casing & Compressor of Air ConditionerDocument22 pagesCasing & Compressor of Air ConditionerAbdullah Zakirin Abdul 'AzamNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Specialized Epic EVO 2021Document3 pagesSpecialized Epic EVO 2021MTB-VCONo ratings yet

- WELKIN - Price Reference - 2021-07-15Document1 pageWELKIN - Price Reference - 2021-07-15marcoaparrafNo ratings yet

- Definitions of CEC2017 Benchmark Suite Final Version UpdatedDocument34 pagesDefinitions of CEC2017 Benchmark Suite Final Version Updatedpc100% (1)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Easi-Pay Guide via e-ConnectDocument29 pagesEasi-Pay Guide via e-ConnectKok WaiNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Scoring Rubric For Oral Presentations Total Points ScoreDocument2 pagesScoring Rubric For Oral Presentations Total Points ScoreLezia pagdonsolanNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Padlock Sharper Image FingerprintDocument1 pagePadlock Sharper Image FingerprintHenryW.CampbellJr.No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Perkins T6.354 WorkshopDocument130 pagesPerkins T6.354 WorkshopAlexis SocarrósNo ratings yet

- Corporate Bridge Internship ProposalDocument5 pagesCorporate Bridge Internship ProposalHBhatlaNo ratings yet

- 1989 Volvo 740 Instruments and ControlsDocument107 pages1989 Volvo 740 Instruments and Controlsskyliner538No ratings yet

- Unethical Business Pratices in Corporates: March 2016Document13 pagesUnethical Business Pratices in Corporates: March 2016Manju Nadh ChakravadhanulaNo ratings yet

- BK - Scrum and CMMIDocument132 pagesBK - Scrum and CMMIcoolgoroNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Akeeba Backup Guide PDFDocument185 pagesAkeeba Backup Guide PDFJhon ArteagaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Formalin MsdsDocument10 pagesFormalin MsdsMank WidhieNo ratings yet

- BUK9Y53-100B DatasheetDocument12 pagesBUK9Y53-100B Datasheetisomeso21No ratings yet

- List of ComponentsDocument2 pagesList of ComponentsRainwin TamayoNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- SDLC Phases Feasibility Analysis RequirementsDocument4 pagesSDLC Phases Feasibility Analysis RequirementsBrandon Mitchell0% (1)

- Mario Stifano Graphic Designer CVDocument1 pageMario Stifano Graphic Designer CVmariostifanoNo ratings yet

- Tomtom Device ForensicsDocument5 pagesTomtom Device ForensicsSwaroop WaghadeNo ratings yet

- Week 6: Practice Challenge 1 - Charts: InstructionsDocument7 pagesWeek 6: Practice Challenge 1 - Charts: InstructionskiranNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- BDC Program To Create Routings Through BDCDocument10 pagesBDC Program To Create Routings Through BDCswapnil_265051509No ratings yet

- Project Management Book PDFDocument55 pagesProject Management Book PDFSerigne Mbaye Diop94% (16)

- Sevice Manual BOBCAT S630 PDFDocument890 pagesSevice Manual BOBCAT S630 PDFArtemio Garcia Barrientos100% (11)

- Abstract Substructure Conc - Frame Westgate RealDocument4 pagesAbstract Substructure Conc - Frame Westgate RealTashamiswa MajachaniNo ratings yet

- Course Overview CSC 1707 Maths For ComputingDocument16 pagesCourse Overview CSC 1707 Maths For ComputingSarah JNo ratings yet

- HRIS1Document24 pagesHRIS1UMESH VINAYAK ARVINDEKARNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)