Professional Documents

Culture Documents

902 Piston

Uploaded by

Sumit SinhaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

902 Piston

Uploaded by

Sumit SinhaCopyright:

Available Formats

Page 1 (2)

MAN B&W Diesel

SAFETY PRECAUTIONS

Data

D01-05 Cylinder cover stud, check distance 148 - 149 mm

D02-01 Test pressure 7 bar

D02-02 Piston rod/crosshead, tightening torque 590 Nm

D02-03 Piston rod/crown, tightening torque 580 Nm

D02-05 Piston skirt, tightening torque 190 Nm

D02-06 Cooling oil pipe, tightening torque 80 Nm

D02-08 Piston ring new, radial width 20.2 mm

D02-09 Piston ring worn, min. radial width 17 mm

D02-10 Groove No.1, max. vertical height 14.7 mm

D02-11 Groove Nos. 2, 3 and 4, max. vertical height 11.7 mm

D02-13 Piston ring new, height of ring No. 1 13.9 mm

D02-14 Piston rings new, height of ring Nos. 2, 3 and 4 10.9 mm

D02-15 Minimum free ring gap ( before dismantling ) 30.5 mm

D02-16 Minimum ring gap, ring No. 1 ( new ring in new liner ) 4.1 mm

D02-17 Minimum ring gap, ring Nos. 2, 3 and 4 ( new ring in new liner ) 3 mm

D02-18 Vertical clearance, new parts 0.43 mm

D02-19 Vertical clearance, worn parts, max. 0.92 mm

D02-20 Piston complete 1600 kg

D02-21 Piston crown 310 kg

D02-22 Piston rod 1050 kg

D02-23 Piston skirt 95 kg

D02-24 Piston cooling pipe 36 kg

D02-25 Lifting tool, tightening torque 150 Nm

D02-46 CPR ring CL groove, min. depth 1.3 mm

D02-47 Piston top centre, max. permissible burn-away 9 mm

D02-48 Piston top centre diameter 280 mm

D02-49 Piston top outer ring area, max. permissible burn-away 6 mm

Piston

Data

102-1

When referring to this page, please quote Data D10201 Edition 0097

X

For detailed sketch, see 900-2

Stopped engine

Shut off starting air supply At starting air receiver

Block the main starting valve

Shut off starting air distributor/distributing system supply

Shut off safety air supply Not ME engines

Shut off control air supply

Shut off air supply to exhaust valve Only with stopped lubricating oil pumps

Engage turning gear

Shut off cooling water

Shut off fuel oil

Stop lubricating oil supply

Lock the turbocharger rotors

Ref. Description Value Unit

X

X

X

X

X

X

X

X

X

X

Page 2 (2)

MAN B&W Diesel

The task-specific tools used in this procedure are shown on the plates at the end of this chapter or in the

chapters indicated by the first three digits in the plate number, e.g. P90951 refers to chapter 909.

Piston

Data

102-1

When referring to this page, please quote Data D10201 Edition 0097

P90251 40 Lifting tool for piston rod foot

P90251 75 Template for piston top

P90251 87 Distance piece for stuffing box

P90251 99 Cover for stuffing box hole

P90251 110 Pressure test tool for piston

P90251 134 Piston ring expander

P90251 158 Guide screw for piston crown

P90251 171 Dismantling screw piston skirt

P90261 Guide ring for piston

P90265 Support for piston

P90266 Lifting tool for piston

P90366 Crossbar for cylinder liner

Plate Item No. Description

Page 1 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Checking

Piston

M

9

0

2

0

1

0

2

8

0

C

0

3

M

9

0

2

0

1

0

2

8

0

C

0

2

M

9

0

2

0

1

0

2

8

0

C

0

1

2.

3.

1.

Scavenge Port Inspection

To detect possible leakages from the piston

or cylinder cover, keep the cooling water

and cooling oil circulating during the scav-

enge port inspection.

1. The scavenge port inspection is carried out

from the s cavenge air receiver. An addi-

tional view of the rings is possible through

the cleaning cover on the manoeuvring

side.

Turn the engine at least a revolution, and

begin with a unit arriving downwards, just

above the scavenge air ports. Inspect the

piston rod and the lower part of the cylin-

der wall.

While the piston is passing downwards, in-

spect the piston skirt, all the piston rings,

the ring lands and the piston top.

2. Ring inspection:

Inspect the rings, one at a time, and note

down the results. See Volume I, Operation,

Chapter 707.

3. Ring tension:

Check the tens ion of the pis ton rings , by

pressing against them with a wooden stick.

Piston

Page 2 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Checking

M

9

0

2

0

1

0

2

8

3

C

0

6

M

9

0

2

0

1

0

2

8

0

C

0

4

D0218

Max. 2mm

E

F

D0219

M

9

0

2

0

1

0

2

8

0

C

0

5

D0246

5.

6.

4.

4. Ring grooves:

Meas ure the total clearance between the

pis ton ring and the ring groove. The total

clearance must not exceed the value stated

in Data.

Meas ure the clearance at the top (E) and

bottom (F) of the piston ring groove.

Total clearance = E + F.

5. Uppermost piston ring:

If possible, measure the depth of the pres-

sure relief grooves with a calliper. The pis-

ton rings mus t be replaced if the radial

depth of the grooves has worn down to

less than stated in Data D02-46.

Checking, in connection with piston

overhaul

6. Piston support:

Remove the pis ton from the cylinder and

place it on the piston support.

See Procedure 902-1.2. For evaluation of

the rings, see Volume I, Chapter 707.

Note!

It is recommended to replace all the pis-

ton rings whenever a piston is removed

from the engine.

Page 3 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Checking

Piston

M

9

0

2

0

1

0

2

8

0

C

0

9

D02-10

D02-11

Max 2mm

M

9

0

2

0

1

0

2

8

0

C

0

8

New

Worn

D0208

D0209

M

9

0

2

0

1

0

2

8

0

C

0

7

D0215

8.

9.

7.

7. Free ring gap:

Before dis mantling the pis ton rings , mea-

s ure the free ring gap of all the pis ton

rings.

For dismantling the piston rings, see Proce-

dure 902-1.3.

8. Radial ring width:

Measure the radial width of the rings. Note

down the results See Volume I, Operation,

Chapter 707.

9. Ring grooves:

Clean the ring grooves and check them for

burn marks or other deformation.

Meas ure the ring grooves with a calliper

gauge, see Data D02-10 and D02-11.

Clearance in piston ring grooves:

The maximum vertical height in a worn ring

groove must not exceed the value stated

in Data. The groove is als o worn out if

there is no chromium layer.

If the ring grooves are worn out, the piston

crown must be reconditioned, contact MAN

B&W Diesel A/S for advice.

Piston

Page 4 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Checking

M

9

0

2

0

1

0

2

8

0

C

1

1

D0249

D0247

M

9

0

2

0

1

0

2

8

0

C

1

0

D0248

R

C

10. Piston top template:

Check that the piston top template is per-

manently marked with the piston top centre

diameter D02-48.

Check that the centre area C has been

marked off, and write the maximum per-

missible burn-away rate on the template.

See data D02-47.

Mark the outer part of the template R for

ring area, and write the maximum permis-

s ible burn-away rate for the ring s haped

area. See data D02-49.

11. Piston crown top:

Clean the pis ton crown and check the

burn-away by means of the template.

For maximum permissible burn away on the

piston top centre area, see Data D02-47.

For the ring shaped area, see Data D02-49.

Check the burn-away on the whole circum-

ference of the piston crown top.

If the burn-away exceeds the values given

in Data, contact MAN B&W for advice.

Note down the results for later reference.

11.

10.

Page 5 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Dismantling

Piston

M

9

0

2

0

1

0

2

8

4

D

0

4

M

9

0

2

0

1

2

8

0

D

0

1

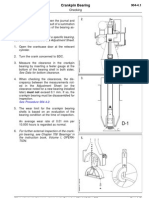

Preparations in the crankcase

1. Access:

Open the crankcas e door to the cylinder

concerned.

Turn the cros s head down far enough to

give access to the piston rod stuffing box

and the piston rod/crosshead connection.

2. Stuffing box:

Releas e the s tuffing box by removing the

innermos t s crews from the s tuffing box

flange.

On engine models where the drain pipe is

connected directly to the stuffing box:

Disconnect the stuffing box drain pipe.

3. Loosen the piston rod-crosshead connec-

tion:

Remove the screws from the piston rod.

1.

Note!

Do NOT remove the outermost screws

from the flange.

M

9

0

2

0

1

0

2

8

0

D

0

3

3.

2.

Piston

Page 6 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Dismantling

M

9

0

2

0

1

0

2

8

0

D

0

5

4. Stuffing box distance pieces:

Mount the two distance pieces on the pis-

ton rod foot to protect the lower s craper

ring and to guide the stuffing box.

Preparations on the cylinder top

5. Cylinder cover:

Remove the cylinder cover. See Procedure

901-1.2.

Make a s cratch mark in liner and pis ton

cleaning ring to ensure correct re-mounting.

Remove the piston cleaning ring.

Carefully remove any wear ridges at the

top of the cylinder liner. See Procedure

903-1.3.

4.

M

9

0

2

0

1

0

2

8

0

D

0

6

5.

Page 7 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Dismantling

Piston

M

9

0

2

0

1

0

2

8

3

D

0

7

D0225

6. Piston lifting tool:

Turn the piston to TDC. The top of the pis-

ton is now free of the cylinder liner.

Clean the lifting groove of the piston crown

and mount the lifting tool.

Limited lifting high:

If the engine not is equipped with long dis-

tance pieces, remove one or two cylinder

cover studs, using a stud setter.

6.

Note!

Make sure to mount the lifting tool cor-

rectly, so that the claws of the lifting tool

enter the lifting grooves of the piston

crown.

Piston

Page 8 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Dismantling

Piston lift

7. Lift the piston out of the cylinder liner and

guide the piston rod foot through the stuff-

ing box flange.

If the engine is equipped with long distance

pieces for the stuffing box, the piston rod

foot can pass between two cylinder cover

studs.

Place the two halves of the support around

one of the openings in the platform. Lower

the pis ton rod foot and s tuffing box

through the opening in the platform. Secure

the two s upport halves with s crews and

lower the piston on the support. Check the

piston is resting on the piston rod flange.

7.

D0220

M

9

0

2

0

1

0

2

8

3

D

0

8

Page 9 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Dismantling

Piston

M

9

0

2

0

1

0

2

8

3

D

0

9

8. Protect the crosshead bearing:

Place a cover over the opening for the pis-

ton rod s tuffing box in the bottom of the

cylinder unit.

Turn the cros s head down far enough to

permit mounting of the protective rubber

cover on the cros s head bearing cap. The

protective rubber cover is found on tool

panel 904.

The covers must remain in place to protect

the crosshead bearing journal from impuri-

ties until the piston is remounted.

Clean, measure and recondition the cylin-

der liner. See Procedure 903-1.

8.

Piston

Page 10 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Overhaul

M

9

0

2

0

1

0

2

8

4

O

0

3

D0221

+

D0223

M

9

0

2

0

1

0

2

8

0

O

0

2

M

9

0

2

0

1

0

2

8

0

O

0

1

D0220

1. Piston support:

Place the piston in the support and remove

the piston lifting tool.

See Procedure 902-1.2.

Clean the piston top and the piston rings.

Check the free ring gap and the burn-off

on the piston top. See Procedure 902-1.1.

Remove the s tuffing box. See Procedure

902-2.3.

2. Piston ring dismantling:

Take off the piston rings by means of the

ring expanders . If the engine is equipped

with two ring expanders, the short ring ex-

pander is for the uppermost ring.

First remove the uppermost ring, then ring

No. two, three and four.

Clean and ins pect the rings and the ring

grooves. See Procedure 902-1.1.

3. Piston crown dismantling:

Remove the locking wire and the innermost

s crews between the rod and the pis ton

crown.

Lift the piston crown and skirt clear of the

piston rod.

2.

1.

3.

Page 11 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Overhaul

Piston

M

9

0

2

0

1

0

2

8

4

O

0

5

D0223

M

9

0

2

0

1

0

2

8

0

O

0

4

D0206

D0224

D0222

4. Piston rod and cooling pipe:

Remove the s crews from the cooling oil

pipe flange.

Mount the eye bolts and lift out the cooling

oil pipe.

Clean and inspect the cooling oil pipe and

the piston rod, then remount the cooling oil

pipe, see Data.

Check that the s urfaces of the O-ring

groove is clean and smooth.

Mount a new O-ring on the pis ton rod

flange.

5. Piston crown dismantling and cleaning:

Place the pis ton crown with s kirt on a

wooden support as shown.

Remove the locking wire and the screws in

the skirt. If necessary use two dismantling

s crews to pull the s kirt out of the pis ton

crown. Mount two eye bolts in the skirt. Lift

the skirt and land it on a couple of planks.

Discard the sealing ring on the piston skirt.

Thoroughly clean and ins pect all parts of

the crown and s kirt. If coke depos its are

found in the cooling s paces of the pis ton

crown, they should be washed clean with

Carbon Remover or a similar cleaning fluid.

When all coke depos its have been dis -

solved, clean and inspect the piston crown

again.

5.

4.

Note!

Coke deposits reduce heat transfer from

the piston crown to the cooling oil. The

deposits must be removed as a routine

procedure when a piston is overhauled.

Piston

Page 12 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Overhaul

M

9

0

2

0

1

0

2

8

4

O

0

7

D0203

M

9

0

2

0

1

0

2

8

4

O

0

6

D0205

6. Piston crown assembly:

Mount a new O-ring on the pis ton s kirt.

Check that the s urfaces of the O-ring

groove are clean and smooth. Coat the ring

with lubricating oil before mounting.

Mount the piston skirt on the piston crown.

Tighten the screws to specified torque, see

data D02-05. Lock the screws with locking

wire, see Procedure 913-7.

7. Piston crown and skirt mounting:

Mount the guide screw to ensure the cor-

rect positioning of the piston rod in relation

to the piston crown.

Lubricate the O-ring on the pis ton rod

flange with lubricating oil.

Land the overhauled piston crown and skirt

on the piston rod.

Remove the guide screw.

Mount and tighten the screws between the

piston rod and the piston crown, see Data.

7.

6.

Page 13 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Overhaul

Piston

M

9

0

2

0

1

0

2

7

7

O

1

6

M

9

0

2

0

1

0

2

7

7

O

1

7

oil

D0201

Sealing ring and pressure test

According to current class rules, the piston

must be pressure tested hydraulically. It is

possible to carry out a test of the sealing

rings with compressed air before filling the

pis ton with oil. The s ealing ring tes t can

also be carried out when the piston is rest-

ing in the support tool.

8. Sealing ring test:

Mount the pressure-testing tool on the pis-

ton rod foot. Connect compres s ed air to

the tes ting tool and fill the pis ton to 4-5

bar. Close the valve on the testing tool and

remove the air connection. The piston must

now hold the pres s ure for minimum 30

minutes.

Spray a little soap water on to the surface

joints between pis ton rod/crown/s kirt and

around the bolt heads to detect leaks.

Dry off all soap water.

9. Pressure test:

For this test, the piston must be turned up-

s ide down (see next step to turn a com-

plete piston).

Fill the piston and piston rod with lubricat-

ing oil. Mount the pressure-testing tool on

the piston rod foot. Pressure-test the pis-

ton at the pres s ure s tated on the Data

Sheet. Check the contact s urfaces of the

piston and the sealing rings for tightness.

Check that there are no cracks in the pis-

ton crown.

Turn the piston upside up and drain out the

piston oil.

9.

8.

Piston

Page 14 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Overhaul

M

9

0

2

0

1

0

2

8

3

O

1

0

10. Piston turning:

Lift the piston with the normal lifting tool.

Lower the piston rod foot until it is close to

the platform. Land the foot on a wooden

block.

Lower the piston crown to the platform and

land it on a wooden block in s uch a way

that it is possible to remove the lifting tool.

Mount an eyebolt in the side of the lifting

tool, hook on the crane and remove the lift-

ing tool from the piston crown.

Attach the lifting bracket to the bottom of

the piston rod foot. Hook the crane on to

the lifting bracket. Lift the piston rod foot

clear of the wooden block. Keep lifting until

the piston rod is in a vertical position.

10.

Note!

During the lift, follow with the crane to

keep the crane positioned vertically

above the lifting point. The stuffing box

must be removed.

Page 15 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Overhaul

Piston

M

9

0

2

0

1

0

2

8

0

O

1

1

TOP

A

B

C

D

A

B

C

D

11.

11. Piston completion:

Fit the new pis ton rings (alternately right-

hand and left-hand cuts, with the ring gaps

staggered 180 and with the TOP mark up-

wards), using the ring expander.

When mounting the pis ton rings , us e the

ring expanders to prevent unintended de-

formation of the rings.

Do not expand the rings more than neces-

sary. The uppermost ring (CPR-ring) must

be mounted with the short ring expander.

Mount the piston rod stuffing box.

See Procedure 902-2.3.

Piston

Page 16 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Mounting

M

9

0

2

0

1

0

2

8

3

M

0

1

M

9

0

2

0

1

0

2

7

7

M

0

2

Preparation of piston

1. Check the piston rings and piston crown in

accordance with Procedure 902-1.1, if not

already done.

Mount the lifting tool on the piston crown.

See Data D02-25.

2. Stuffing box position:

Ensure that the stuffing box is correctly po-

sitioned over the distance pieces mounted

on the piston rod foot. Both the holes for

the flange and the drain hole for the drain

pipe must be positioned correctly.

2.

1.

Page 17 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Mounting

Piston

M

9

0

2

0

1

0

2

8

3

M

0

3

M

9

0

2

0

1

0

2

7

7

M

0

6

4

5

M

9

0

2

0

1

0

2

7

7

M

0

5

Preparation of cylinder liner

3. Mount the guide ring:

Mount the guide ring in the top of the cyl-

inder liner. The cut outs for the lifting tool

must be turned to fit the piston lifting tool.

4. Stuffing box cover:

Remove the cover from the pis ton rod

stuffing box opening in the bottom of the

cylinder unit.

Clean the stuffing box flange.

5. Crosshead position:

Turn the crosshead to a position 45 from

TDC (crank web pointing towards exhaust

side).

4.

3.

5.

Piston

Page 18 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Mounting

M

9

0

2

0

1

0

2

8

4

M

0

8

M

9

0

2

0

1

0

2

8

3

M

0

7

M

9

0

2

0

1

0

2

8

3

M

0

6

D0220

Mounting of piston

6. Coat the O-rings of the s tuffing box and

the pis ton rod with oil. Coat the pis ton

rings and cylinder liner with cylinder lubri-

cating oil.

Lower the pis ton into the cylinder liner

while guiding the pis ton rod foot through

the cut-out in the stuffing box flange until

the piston rings are inside the liner.

7. Protective cover:

Remove the protective rubber cover from

the crosshead.

8. Crosshead alignment:

Turn the cros s head almos t to TDC, while

checking that the guide ring of the cross-

head enters the centre hole in the pis ton

rod.

After turning the cros s head fully to TDC,

and ens uring that the pis ton rod has full

contact with the cros s head, uns crew the

lifting tool and remove the lifting tool and

the guide ring for piston rings.

6.

7.

8.

Page 19 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Mounting

Piston

M

9

0

2

0

1

0

2

8

4

M

1

0

D0202

or

D0207

M

9

0

2

0

1

0

2

7

7

M

1

4

9. Stuffing box:

Turn down and land the stuffing box on the

stuffing box flange. Check that the holes in

the stuffing box and stuffing box flange are

correctly centered.

Tighten the pis ton rod s tuffing box by

means of the s crews through the inner

holes in the stuffing box flange. For Data,

see Procedure 902-2.

On engine models where the drain pipe is

connected directly to the stuffing box:

Mount the stuffing box drain pipe.

Remove the distance pieces from the pis-

ton rod foot.

10. Tightening of the piston rod-crosshead

connection:

Mount and tighten the pis ton rod s crews .

Tighten the screws to the specified torque

and lock with locking wire.

See Data. Use either Data D02-02 or Data

D02-07.

11. Piston cleaning ring:

Mount the pis ton cleaning ring in accor-

dance with the scratch mark. If the PC-ring

is damaged (broken or cracked), it must be

M

9

0

2

0

1

0

2

8

0

M

0

9

10.

9.

11.

Piston

Page 20 (20)

902-1.1

When referring to this page, please quote Procedure M90201 Edition 0284

MAN B&W Diesel Mounting

M

9

0

2

0

1

0

2

7

7

M

1

5

M

9

0

2

0

1

0

2

8

0

M

1

4

D0105

12.

13.

replaced by another ring.

See Procedure 903-1.

12. Cylinder cover studs:

If the cylinder cover s tuds have been re-

moved, remount them. Carefully clean the

surfaces around the base of the studs and

check the O-rings on the studs.

Mount the cylinder cover s tuds with the

s tud s etter. Screw the s tud down to con-

tact and half a revolution back.

13. Cylinder cover:

Land the cylinder cover on the liner and

check the distance that the stud is protrud-

ing from the cylinder cover. If neces s ary,

adjust the distance D01-05 by turning the

stud.

Tighten the cylinder cover nuts and mount

the necessary pipes.

See Procedure 901-1.4.

14. Running-in:

Smear the pis ton rod with molybdenum

dis ulphide, and turn the cranks haft a

couple of revolutions.

At the firs t opportunity, s tart the engine

and keep it running for about 15 minutes at

a s peed corres ponding to Dead Slow

Ahead.

Then stop the engine and inspect the pis-

ton rod and stuffing box.

Page 1 (2)

SAFETY PRECAUTIONS

Data

D02-26 Stuffing box flange, outer screws tightening torque 80 Nm

D02-27 Stuffing box flange, inner screws tightening torque 80 Nm

D02-28 Stuffing box halves, tightening torque 80 Nm

D02-29 Uppermost rings, ring-end clearance 4x6 mm

D02-30 Lowermost rings, ring-end clearance 3x3 mm

D02-34 Sealing ring springs new, free length 618 mm

D02-38 Scraper ring springs new, free length 606 mm

D02-44 Stuffing box complete 100 kg

D02-45 Stuffing box half 35 kg

D02-50 Stuffing box halves fitted bolts, tightening torque 25 Nm

Piston Rod Stuffing Box

Data

102-2

When referring to this page, please quote Data D10202 Edition 0060

MAN B&W Diesel A/S

X

X

X

X

X

X

X

X

X

X

X

For detailed sketch, see 900-2

Stopped engine

Shut off starting air supply At starting air receiver

Block the main starting valve

Shut off starting air distributor/distributing system supply

Shut off safety air supply Not ME engines

Shut off control air supply

Shut off air supply to exhaust valve Only with stopped lubricating oil pumps

Engage turning gear

Shut off cooling water

Shut off fuel oil

Stop lubricating oil supply

Lock the turbocharger rotors

Ref. Description Value Unit

Page 2 (2)

The task-specific tools used in this procedure are shown on the plates at the end of this chapter or in the

chapters indicated by the first three digits in the plate number, e.g. P90951 refers to chapter 909.

Piston Rod Stuffing Box

Data

102-2

When referring to this page, please quote Data D10202 Edition 0060

MAN B&W Diesel A/S

P90251 109 Mounting tool for stuffing box spring

P90251 122 Worktable for stuffing box

P90451 120 Rubber cover for crosshead

Plate Item No. Description

Page 1 (10)

Piston Rod Stuffing Box

Checking

902-2.1

When referring to this page, please quote Procedure M90202 Edition 0229

MAN B&W Diesel A/S

M

9

0

2

0

2

0

2

2

7

C

0

2

D0234

D0238

M

9

0

2

0

2

0

2

2

9

C

0

1

D0229

D0230 D0229

D0230

A B

A

B

2.

1. 1. After the piston rod stuffing box has been

dismantled, check the following clearances:

See Procedure 902-2.2.

Uppermost scraper ring and sealing rings

Clearance at ring ends (scraper ring).

Total clearance (scraper ring). (D02-29)

Clearance at ring ends (sealing rings).

Total clearance (sealing rings). (D02-29)

Lowermost scraper rings

Clearance at ring ends.

Total clearance. (D02-30)

The ring clearances stated in Data apply to

new rings.

As a general guide, it is recommended

depending on the overhauling intervals and

ones own experience to replace sealing

rings and scraper rings when the specified

clearance values D02-29 and D02-30 have

been halved.

2. Garter springs:

Generally, it is recommended to renew the

springs when the sealing rings and scraper

rings are renewed.

The s prings can be checked as follows :

Place the springs on the table, measure Lo

(free length), and compare with Data. If a

spring is extended more than 8% from the

value given in data, it must be discarded.

Piston Rod Stuffing Box

Dismantling

Page 2 (10)

902-2.2

When referring to this page, please quote Procedure M90202 Edition 0229

MAN B&W Diesel A/S

M

9

0

2

0

2

0

2

2

9

D

0

3

M

9

0

2

0

2

0

2

2

9

D

0

2

M

9

0

2

0

2

0

2

2

9

D

0

1

2.

3.

1.

In connection with dis mantling of the pis ton,

only the innermost screws in the stuffing box

flange and the s crews for the drain oil pipe

should be removed.

If, in the period between pis ton overhauls , it

becomes necessary to inspect the piston rod

stuffing box, proceed as follows:

1. Turn the crosshead to about 90 from TDC.

Mount the rubber cover around the piston

rod to protect the crosshead bearing from

impurities.

2. Remove the drain oil pipe and all innermost

screws and all outer screws except for two

screws placed diametrically opposite in the

stuffing box flange, longitudinally to the en-

gine.

3. Mount the worktable around the piston rod

s o that the two remaining s crews in the

s tuffing box flange can be loos ened

through the holes.

Page 3 (10)

Piston Rod Stuffing Box

Dismantling

902-2.2

When referring to this page, please quote Procedure M90202 Edition 0229

MAN B&W Diesel A/S

M

9

0

2

0

2

0

2

2

9

D

0

6

M

9

0

2

0

2

0

2

2

9

D

0

5

M

9

0

2

0

2

0

2

2

9

D

0

4

5.

6.

4.

4. Remove the two long dis mantling s crews

from the worktable.

Mount them in the stuffing box through the

holes in the worktable.

Remove the remaining two screws from the

stuffing box.

5. Turn the piston to BDC, thereby withdraw-

ing the stuffing box from the cylinder frame

bottom.

6. Remove the two long dis mantling s crews

from the s tuffing box and mount them in

the worktable.

By means of the four s hort s crews in the

worktable, press the stuffing box out of the

flange.

For overhauling the stuffing box, see Pro-

cedure 902-2.3.

Piston Rod Stuffing Box

Overhaul

902-2.3

When referring to this page, please quote Procedure M90202 Edition 0229

MAN B&W Diesel A/S

Page 4 (10)

M

9

0

2

0

2

0

2

2

9

O

0

3

M

9

0

2

0

2

0

2

2

9

O

0

2

D0244

Normally, overhaul of the pis ton rod s tuffing

box is carried out by routine methods in con-

nection with the dismantling (pulling) of the pis-

tons.

During s uch overhauls , the pis ton res ts on a

support placed over one of the cut-outs in the

top platform.

Work on the s tuffing box is then carried out

from the platform below.

Overhaul inside the engine is carried out in the

same way as outside the engine.

1. Mount two eye bolts in the s tuffing box

flange, and hook on two tackles.

Lift the s tuffing box a little up the pis ton

rod, and mount the worktable round the

piston rod at a suitable working height.

Land the s tuffing box on the worktable,

and remove the tackles and eye bolts.

2. Remove the O-rings of the stuffing box. If

the O-rings are intact and are to be used

again, move them up the pis ton rod and

s ecure them in this pos ition, for example

with tape.

Remove the nuts from the stuffing box as-

sembling bolts.

1.

2.

M

9

0

2

0

2

0

2

2

9

O

0

1

Page 5 (10)

Piston Rod Stuffing Box

Overhaul

902-2.3

When referring to this page, please quote Procedure M90202 Edition 0229

MAN B&W Diesel A/S

M

9

0

2

0

2

0

2

2

9

O

0

8

M

9

0

2

0

2

0

2

2

7

C

0

2

D0234

D0238

M

9

0

2

0

2

0

2

2

9

O

0

4

D0245

3. Take out the six bolts, and pull away one

stuffing box half.

Mount two eye bolts on the s tuffing box

half and remove it from the worktable.

4. Using a feeler gauge, measure the vertical

clearance of the rings.

See Procedure 902-2.1.

5. Remove the remaining stuffing box half and

pres s all s ealing rings and s craper rings

down against the worktable.

6. Meas ure the clearance between the ring

s egments to determine whether replace-

ment is necessary.

See Procedure 902-2.1.

Dismantle and stack the rings in the same

order as when fitted in the stuffing box.

Carefully clean all the ring segments.

Ins pect and as s es s the s urface quality of

the s ealing rings . If their s liding s urfaces

have scratches or marks, replace the rings.

7. Check the lengths of the springs.

See Procedure 902-2.1.

8. Ins pect the s urface of the pis ton rod. If

small longitudinal scratches have occurred

(caus ed by poorly adapted s tuffing box

rings), smooth the piston rod surface care-

fully with a fine grained carborundum

s tone. In the cas e of coars e s cratches , it

may prove necessary to machine-grind the

surface in a workshop.

9. Clean the halves of the stuffing box hous-

ing.

3.

7.

8.

Piston Rod Stuffing Box

Overhaul

902-2.3

When referring to this page, please quote Procedure M90202 Edition 0229

MAN B&W Diesel A/S

Page 6 (10)

M

9

0

2

0

2

0

2

2

9

O

1

0

A

B

C

Scraper

ring

Scraper

ring

Sealing

ring

No relief

groove

Relief

groove

A

B

C

10. Lubricate the piston rod (in the area where

all the ring units in the stuffing box will be

pos itioned) with molybdenum dis ulphide

(MoS

2

).

For correct mounting of the s ealing and

scraper rings see the sketch. The scraper

ring in groove no. 4 must be without relief

grooves on the underside.

10.

Page 7 (10)

Piston Rod Stuffing Box

Overhaul

902-2.3

When referring to this page, please quote Procedure M90202 Edition 0229

MAN B&W Diesel A/S

M

9

0

2

0

2

0

2

2

9

O

1

2

M

9

0

2

0

2

0

2

2

9

O

1

1

11. As s emble all the s tuffing box ring units

round the piston rod, on the worktable, in

the following way:

Place the lowermos t s craper ring s eg-

ments on the worktable.

Place the s pring round the s egments ,

and hook the spring ends together.

Repeat this procedure for the remaining

scraper rings.

On top of the scraper rings, assemble the

two sealing ring units (each consisting of a

4-part and an 8-part ring).

As s emble the 8-part s ealing ring s o that

the two guide pins face upwards, place the

spring round the segments and, hook the

spring ends together.

Assemble the 4-part sealing ring above the

8-part sealing ring. Push the two rings to-

gether in s uch a manner that the guide

pins in the lower sealing ring engage with

the two holes in the upper sealing ring.

Finally, as s emble the uppermos t ring unit

(consisting of a 4-part scraper ring and an

8-part sealing ring).

12. Use the stuffing box half on the worktable

to adjus t the height of all the as s embled

ring units on the pis ton rod until the ring

units are oppos ite the corres ponding

grooves in the stuffing box housing. Subse-

quently, push the stuffing box half into con-

tact with the pis ton rod, round the ring

units.

Note!

If the stuffing box is assembled inside

the engine, place two pieces of plywood

of the same thickness as the flange on

the worktable, to ease the assembling.

11.

12.

Piston Rod Stuffing Box

Overhaul

902-2.3

When referring to this page, please quote Procedure M90202 Edition 0229

MAN B&W Diesel A/S

Page 8 (10)

M

9

0

2

0

2

0

2

2

9

O

1

4

D0244

M

9

0

2

0

2

0

2

2

9

O

1

3

D0228

D0250

13. Check the ring clearance again.

Then place the other half of the s tuffing

box hous ing on the worktable, pus hing it

into place round the rings.

In the middle holes mount and tighten up

the fitted bolts to the torque specified on

the Data Sheet, See Data D02-50

Mount the O-rings in the s tuffing box

grooves.

14. Mount eye bolts and wire ropes , and lift

the stuffing box a little.

Remove the worktable and lower the stuff-

ing box until it res ts agains t the dis tance

pieces on the piston rod foot.

Remove wire ropes and screws.

Mount and tighten the s tandard bolts to

specified torque, See Data D02-28

13.

14.

Page 9 (10)

Piston Rod Stuffing Box

Mounting

902-2.4

When referring to this page, please quote Procedure M90202 Edition 0229

MAN B&W Diesel A/S

M

9

0

2

0

2

0

2

2

9

M

0

1

M

9

0

2

0

2

0

2

2

9

M

0

3

M

9

0

2

0

2

0

2

2

9

M

0

2

1. In connection with mounting of the piston,

only the innermost flange screws are to be

mounted and tightened, see data.

After overhauling the stuffing box inside the

engine, as s emble the s tuffing box halves

on top of the four screws.

Mount the two long screws from the work-

table in the stuffing box.

Turn down the s hort s crews s o that the

stuffing box lands on the flange.

2. Turn the pis ton upwards until the s tuffing

box is in place in the cylinder frame.

3. Mount two screws in the flange through the

holes in the worktable.

Note!

Make sure that the two guide pins in the

flange enter the guide holes in the bot-

tom of the cylinder frame.

1.

2.

3.

Piston Rod Stuffing Box

Overhaul

902-2.3

When referring to this page, please quote Procedure M90202 Edition 0229

MAN B&W Diesel A/S

Page 10 (10)

M

9

0

2

0

2

0

2

2

9

D

0

1

M

9

0

2

0

2

0

2

2

9

M

0

5

D0226

D0227

M

9

0

2

0

2

0

2

2

9

M

0

4

4.

5.

6.

4. Remove the long screws from the stuffing

box and mount them itheworktable.

Remove the worktable from the piston rod.

5. Mount the drain oil pipe.

Mount and tighten all the inner and outer

screws for the stuffing box. See Data.

6. Remove the protecting rubber cover from

the piston rod/crosshead.

Smear the pis ton rod with molybdenum

disulphide.

Then turn the crankshaft a couple of revo-

lutions.

If possible: Start up the engine and keep it

running for about fifteen minutes at a num-

ber of revolutions corres ponding to very

slow or idle speed.

Then stop the engine and inspect the pis-

ton rod and stuffing box.

Plate

Page 1 (2) When referring to this page, please quote Plate Edition

MAN B&W Diesel A/S

Piston and Piston Rod Panel

P90251-0246

P90251 0246

Plate

Page 2 (2) When referring to this page, please quote Plate Edition

MAN B&W Diesel A/S

P90251-0246

Piston and Piston Rod Panel

Item

No.

Item Description

Item

No.

Item Description

P90251 0246

014 Panel for tools

026 Name plate

040 Lifting tool for piston rod foot

051 Lifting tool for cylinder liner

075 Template for piston top

087 Distance piece for stuffing box

099 Cover for stuffing box hole

109 Mounting tool for stuffing box spring

110 Pressure test tool for piston

122 Worktable for stuffing box

134 Piston ring expander

158 Guide screw for piston crown

183 Pulling tool for stuffing box

Plate

Page 1 (2) When referring to this page, please quote Plate Edition

MAN B&W Diesel A/S

Piston and Piston Rod - Tools

P90261-0107

P90261 0107

Plate

Page 2 (2) When referring to this page, please quote Plate Edition

MAN B&W Diesel A/S

P90261-0107

Piston and Piston Rod - Tools

Item

No.

Item Description

Item

No.

Item Description

P90261 0107

019 Guide ring for piston

Plate

Page 1 (2) When referring to this page, please quote Plate Edition

MAN B&W Diesel A/S

Piston and Piston Rod - Support Tools

P90265-0005

P90265 0005

Plate

Page 2 (2) When referring to this page, please quote Plate Edition

MAN B&W Diesel A/S

P90265-0005

Piston and Piston Rod - Support Tools

Item

No.

Item Description

Item

No.

Item Description

P90265 0005

010 Support iron for piston

Plate

Page 1 (2) When referring to this page, please quote Plate Edition

MAN B&W Diesel A/S

Piston - Lifting Tools

P90266-0002

P90266 0002

Plate

Page 2 (2) When referring to this page, please quote Plate Edition

MAN B&W Diesel A/S

P90266-0002

Piston - Lifting Tools

Item

No.

Item Description

Item

No.

Item Description

P90266 0002

016 Lifting tool for piston

You might also like

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Exhst VV Puncture VVDocument4 pagesExhst VV Puncture VVrakeshbiswa100% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Assignment On Diesel Engine OverhaulingDocument19 pagesAssignment On Diesel Engine OverhaulingRuwan Susantha100% (3)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Piaggio X9 500 Service Station Manual (2002-EnGLISH-70 Pages)Document69 pagesPiaggio X9 500 Service Station Manual (2002-EnGLISH-70 Pages)Enis MurgicNo ratings yet

- Removal Refitting Variable Geometry Turbocharger GARETTDocument6 pagesRemoval Refitting Variable Geometry Turbocharger GARETTiliecNo ratings yet

- M551 M552Document96 pagesM551 M552Игорь100% (1)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Procedure For Removing Main Bearing of MAN B&W MC-C EngineDocument16 pagesProcedure For Removing Main Bearing of MAN B&W MC-C EngineSuhas KassaNo ratings yet

- Engine Disassembly Assembly 1Document9 pagesEngine Disassembly Assembly 1Moaed KanbarNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- 78 Dt400e DT250E ManualDocument18 pages78 Dt400e DT250E Manualdisgustipate0% (1)

- Forged Steel Piston PDFDocument14 pagesForged Steel Piston PDFvictoverNo ratings yet

- D08 26 Oil CylinderDocument3 pagesD08 26 Oil CylinderVăn Tuấn NguyễnNo ratings yet

- Mazda FE y F2Document27 pagesMazda FE y F2jads30117971% (14)

- Engine AssemblyDocument13 pagesEngine AssemblyJacob SilverstielkNo ratings yet

- Em - Engine Mechanical PDFDocument24 pagesEm - Engine Mechanical PDFMoaed Kanbar86% (21)

- Engine Mechanical PDFDocument115 pagesEngine Mechanical PDFAndrey GladyshevNo ratings yet

- Bottem End Bearing RemovalDocument8 pagesBottem End Bearing RemovalRohit Mishra100% (2)

- Manual de Motor Elantra-Tiburón 1998 G4GRDocument6 pagesManual de Motor Elantra-Tiburón 1998 G4GRRodolfo SilvaNo ratings yet

- Engine (WL, WL Turbo, WL-3, WLT-3) : Drive BeltDocument16 pagesEngine (WL, WL Turbo, WL-3, WLT-3) : Drive Beltpavel35No ratings yet

- 2001 Toyota Prius L4-1.5L (1NZ-FXE) Hybrid: Timing Chain: Service and RepairDocument13 pages2001 Toyota Prius L4-1.5L (1NZ-FXE) Hybrid: Timing Chain: Service and Repairfernando ortizNo ratings yet

- 08 Engine MechanicalDocument80 pages08 Engine MechanicalmadcostaNo ratings yet

- Windstar 2000-2001 3.8 v6Document77 pagesWindstar 2000-2001 3.8 v6pegoNo ratings yet

- YD25DDTi and ZD30DDT Engines in NISSAN Repair ManualsDocument19 pagesYD25DDTi and ZD30DDT Engines in NISSAN Repair ManualsMoaed Kanbar91% (105)

- Engine Assembly - Dismantle and Assemble (Engine Removed) (21 134 8)Document30 pagesEngine Assembly - Dismantle and Assemble (Engine Removed) (21 134 8)judas1432No ratings yet

- Exhaust Valve: Special Running - Data S35MCDocument5 pagesExhaust Valve: Special Running - Data S35MClijinNo ratings yet

- Pump Repair ManualDocument17 pagesPump Repair ManualSergiSerrano100% (1)

- SB388CDocument13 pagesSB388CBenjamin LeedsNo ratings yet

- Compressor WabcoDocument6 pagesCompressor Wabcoruben_cruz_34No ratings yet

- S46MC-C, Edition 2Document168 pagesS46MC-C, Edition 2Nghia Duongdinh50% (2)

- DD15 Detroit DieselDocument10 pagesDD15 Detroit Dieselstarsky100% (4)

- 21-44 Charge Pressure System With Exhaust Turbocharger ServiceDocument22 pages21-44 Charge Pressure System With Exhaust Turbocharger Servicejromero_rpgNo ratings yet

- 1.6l 4 CylDocument29 pages1.6l 4 Cyl25912530100% (1)

- Patg Pamg Turbo PartsDocument12 pagesPatg Pamg Turbo Parts1luckywolf0% (1)

- CAMERON France S.A.S: Front SheetDocument24 pagesCAMERON France S.A.S: Front SheetkrishnsgkNo ratings yet

- Induction Module Assembly 9.5: GeneralDocument10 pagesInduction Module Assembly 9.5: Generalvette512No ratings yet

- Repair Instructions - Off Vehicle PDFDocument37 pagesRepair Instructions - Off Vehicle PDFFernando OrtizNo ratings yet

- General Information: Intake and ExhaustDocument8 pagesGeneral Information: Intake and ExhaustاحمدميدوNo ratings yet

- Toyota Nico PDFDocument33 pagesToyota Nico PDFDaniel GarciaNo ratings yet

- AVEO 2007-2010/wave - 07-10/engine Mechanical - 1.5L/Repair Instructions - Off VehicleDocument39 pagesAVEO 2007-2010/wave - 07-10/engine Mechanical - 1.5L/Repair Instructions - Off VehicleArley Hernandez100% (1)

- Toyota MR2 Spyder L4-1.8L (1ZZ-FE) 2001: Timing Chain: Service and RepairDocument18 pagesToyota MR2 Spyder L4-1.8L (1ZZ-FE) 2001: Timing Chain: Service and RepairROSA GIMENEZNo ratings yet

- Power Steering Pump Service and Repair, 1999 Toyota Truck 4 Runner 2WDDocument8 pagesPower Steering Pump Service and Repair, 1999 Toyota Truck 4 Runner 2WDCarlos VillaltaNo ratings yet

- Timing Renault Master 2 2.8tdi 84KWDocument10 pagesTiming Renault Master 2 2.8tdi 84KWAnonymous dLqSSVXbSc100% (1)

- 2012 Dorado Pro Service ManualDocument29 pages2012 Dorado Pro Service ManualSea RidersNo ratings yet

- C6 Torque Converter Removal and RefittingDocument4 pagesC6 Torque Converter Removal and RefittingDanielCostaXinaNo ratings yet

- 722 3Document12 pages722 3Daniel AlvaradoNo ratings yet

- Cylinder Head Removing and InstallingDocument9 pagesCylinder Head Removing and Installingblackj3ckNo ratings yet

- BMW E60 Engine Seals NotebookDocument24 pagesBMW E60 Engine Seals NotebookPeter McCracken100% (6)

- zxr400 H 04Document23 pageszxr400 H 04hugo_bikerNo ratings yet

- XD3P Bolero PDFDocument107 pagesXD3P Bolero PDFRuben Acosta Muñoz67% (21)

- B2 Engine Mechanical: To IndexDocument58 pagesB2 Engine Mechanical: To IndexKwun Hok ChongNo ratings yet

- Surge Tank Maint Bulletin PDFDocument2 pagesSurge Tank Maint Bulletin PDFihllhmNo ratings yet

- Nissan Z24Document29 pagesNissan Z24Gustavo Gamez100% (2)

- Maintenance On Unit 5Document10 pagesMaintenance On Unit 5Mazhar UddeenNo ratings yet

- Renault/ Proton SavvyDocument72 pagesRenault/ Proton Savvy胡瑞麟100% (5)

- TDS Pidifin 2K Eng Rev.09 23 07 19Document3 pagesTDS Pidifin 2K Eng Rev.09 23 07 19Sumit SinhaNo ratings yet

- Brochure 2022 23Document28 pagesBrochure 2022 23Sumit SinhaNo ratings yet

- Electrical Oral Question & AnswersDocument14 pagesElectrical Oral Question & AnswersKranthi KiranNo ratings yet

- IMO - Action DatesDocument4 pagesIMO - Action DatesSumit SinhaNo ratings yet

- Ship Energy Efficiency Management Plan (SEEMP) - Maritime WikiDocument11 pagesShip Energy Efficiency Management Plan (SEEMP) - Maritime WikiSumit SinhaNo ratings yet

- PumpsDocument8 pagesPumpsDeeran CarieNo ratings yet

- LifeboatDocument74 pagesLifeboatSumit SinhaNo ratings yet

- Function of Thermostatic Expansion Valve in Refrigeration SystemDocument5 pagesFunction of Thermostatic Expansion Valve in Refrigeration SystemSumit SinhaNo ratings yet

- Notes On Ball BearingsDocument10 pagesNotes On Ball BearingsSumit SinhaNo ratings yet

- Centrifugal Purifiers ClarifiersDocument9 pagesCentrifugal Purifiers ClarifiersSumit SinhaNo ratings yet

- Clover Lapping Compounds and Grinding Compound, Clover Brand, Clover, Fel-Pro, Felpro, Loctite Lapping Compounds, Lapping PasteDocument4 pagesClover Lapping Compounds and Grinding Compound, Clover Brand, Clover, Fel-Pro, Felpro, Loctite Lapping Compounds, Lapping PasteSumit SinhaNo ratings yet

- Oil Spill KitDocument8 pagesOil Spill Kitnqt14283No ratings yet

- c0n Rod Ovality For ADocument2 pagesc0n Rod Ovality For ASumit SinhaNo ratings yet

- Rudder and PropellerDocument5 pagesRudder and PropellerSumit SinhaNo ratings yet

- Ship StressesDocument7 pagesShip StressesSumit Sinha50% (2)

- PM High Strength Magnetic Alloys PDFDocument13 pagesPM High Strength Magnetic Alloys PDFSAMIT JAINNo ratings yet

- Is 7001 1989Document14 pagesIs 7001 1989Kevin100% (1)

- High School Clay For WeeblyDocument71 pagesHigh School Clay For Weeblyapi-293964578100% (6)

- Craftsman Tractor ManualDocument72 pagesCraftsman Tractor Manualbjhoxie106No ratings yet

- Section 2: Insulation Materials and PropertiesDocument10 pagesSection 2: Insulation Materials and PropertiesJersey PerlasNo ratings yet

- Strength and Microscale Properties of Bamboo FiberDocument14 pagesStrength and Microscale Properties of Bamboo FiberDm EerzaNo ratings yet

- Residual Stress in Induction HardeningDocument2 pagesResidual Stress in Induction HardeningRajesh MalikNo ratings yet

- SOP Reach Stacker01Document7 pagesSOP Reach Stacker01vozefjadav100% (1)

- Pakyaw RatesDocument36 pagesPakyaw RatesKesMercado100% (5)

- DIN EN 1563 (2012.03) en ST - NDocument1 pageDIN EN 1563 (2012.03) en ST - NNayana NaikNo ratings yet

- HTTP Bulletins - Wartsila.com Bulletins File WCH RTA-79 2Document4 pagesHTTP Bulletins - Wartsila.com Bulletins File WCH RTA-79 2Riddhi DasNo ratings yet

- Drywall HandbookDocument44 pagesDrywall Handbookdeepali bangeraNo ratings yet

- PNS 40 2020 Steel RebarsDocument9 pagesPNS 40 2020 Steel RebarscesuquilangNo ratings yet

- Berta BlastingDocument13 pagesBerta Blastingkandrian76100% (1)

- The Sub-Grade and Sub-Base of Concrete PavementDocument16 pagesThe Sub-Grade and Sub-Base of Concrete PavementPatrick TaylorNo ratings yet

- Drilling Rig Selection - Guidelines Only)Document79 pagesDrilling Rig Selection - Guidelines Only)Edo Gawa77% (13)

- Blue GoldDocument9 pagesBlue GoldDinesh RajNo ratings yet

- Cálculo de Eficiencia de Un HornoDocument29 pagesCálculo de Eficiencia de Un HornoFranklin Santiago Suclla PodestaNo ratings yet

- Klueber Paraliq-91 DsDocument2 pagesKlueber Paraliq-91 DsZulkiflee IsmailNo ratings yet

- Hydrometallurgical Process: Analysis of Free, Total & WAD Cyanide in Gold Leach Slurry & WastewaterDocument1 pageHydrometallurgical Process: Analysis of Free, Total & WAD Cyanide in Gold Leach Slurry & WastewaterJUNIORNo ratings yet

- Product Bulletin Fisher Large Ed Ewd Et Ewt Valves Nps 12 Through 30 en 122576Document20 pagesProduct Bulletin Fisher Large Ed Ewd Et Ewt Valves Nps 12 Through 30 en 122576franciscocruz29No ratings yet

- RESEARCH CHAPTER 1 (Guidelines)Document15 pagesRESEARCH CHAPTER 1 (Guidelines)evarizNo ratings yet

- 7000 EXL Generator Owners ManualDocument24 pages7000 EXL Generator Owners Manualabrote7114No ratings yet

- En71 SGSDocument46 pagesEn71 SGSMax Arias100% (1)

- Course OutlineDocument3 pagesCourse OutlineLIM ChanthaNo ratings yet

- RX 6-8 PDFDocument30 pagesRX 6-8 PDFCyrusNo ratings yet

- Kandhal - Recommended-Revisions-to-MORTH-Specifications-Section-500 PDFDocument44 pagesKandhal - Recommended-Revisions-to-MORTH-Specifications-Section-500 PDFJimmy ThomasNo ratings yet

- UAC SuperflexDocument6 pagesUAC SuperflexRosman Al-QadriNo ratings yet

- Promag 10L1FDocument36 pagesPromag 10L1FCharles MartinNo ratings yet

- Cement PPT-BMC PDFDocument120 pagesCement PPT-BMC PDFAdhyyan JoshiNo ratings yet