Professional Documents

Culture Documents

Implementing a comprehensive CUI program

Uploaded by

Chelsea Skinner100%(1)100% found this document useful (1 vote)

563 views4 pagesThis document discusses the importance of implementing a comprehensive corrosion under insulation (CUI) program at chemical process facilities. CUI occurs when piping and vessels corrode under insulation and can cost the chemical and oil/gas industries over $100 million annually in damage. The best approach is a facility-wide CUI program with three phases: 1) determining what equipment is susceptible to CUI, 2) performing field walkdowns of susceptible equipment, and 3) conducting effective inspections of that equipment. Non-destructive testing methods for detecting CUI like visual inspection, radiography, and ultrasonics are described. The program should aim to prevent, detect early, and mitigate CUI to reduce risks to safety, equipment, and operations

Original Description:

Corrosion detection under insulation

Original Title

Implementing a Corrosion Under Insulation Program

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses the importance of implementing a comprehensive corrosion under insulation (CUI) program at chemical process facilities. CUI occurs when piping and vessels corrode under insulation and can cost the chemical and oil/gas industries over $100 million annually in damage. The best approach is a facility-wide CUI program with three phases: 1) determining what equipment is susceptible to CUI, 2) performing field walkdowns of susceptible equipment, and 3) conducting effective inspections of that equipment. Non-destructive testing methods for detecting CUI like visual inspection, radiography, and ultrasonics are described. The program should aim to prevent, detect early, and mitigate CUI to reduce risks to safety, equipment, and operations

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

563 views4 pagesImplementing a comprehensive CUI program

Uploaded by

Chelsea SkinnerThis document discusses the importance of implementing a comprehensive corrosion under insulation (CUI) program at chemical process facilities. CUI occurs when piping and vessels corrode under insulation and can cost the chemical and oil/gas industries over $100 million annually in damage. The best approach is a facility-wide CUI program with three phases: 1) determining what equipment is susceptible to CUI, 2) performing field walkdowns of susceptible equipment, and 3) conducting effective inspections of that equipment. Non-destructive testing methods for detecting CUI like visual inspection, radiography, and ultrasonics are described. The program should aim to prevent, detect early, and mitigate CUI to reduce risks to safety, equipment, and operations

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

C

orrosion to the external sur-

face of process piping and ves-

sels that is hidden under the

insulation is referred to as

corrosion under insulation (CUI).

Aging piping and equipment in

chemical plants and petroleum re-

fineries have made CUI detection

and assessment requirements in-

creasingly important. Because the

need to detect and assess CUI is

critical in chemical process indus-

tries (CPI) facilities, inspection and

testing methodologies have been

pushed to improve. However, many

CPI facilities lack an insulation-

repair program. The best approach

to address the problem of CUI is to

develop and adopt a comprehensive

and facility-wide CUI program. This

article describes the components of

such a program and is designed to

help facility managers and engi-

neers identify strategies to imple-

ment it.

Industry estimates indicate that

CUI costs the chemical and oil-and-

gas industries in excess of $100 mil-

lion annually. This cost represents

only the estimated damage to the

equipment, and does not include

the losses that may be associated

with process downtime. Taking

equipment and piping out of ser-

vice when they are needed to make

product will raise the level of losses.

This estimate also does not include

the risk posed by CUI for potential

exposure to hazardous chemicals, as

well as the potential fire and explo-

sion hazards, resulting from the loss

of containment of highly hazardous

chemicals. Sometimes, corrosion-

preventive painting programs are

cut when budgets are tight.

CUI primarily affects carbon-

steel and low-alloy steel vessels and

piping. Operating conditions noted

for making equipment susceptible

to CUI range from 10F (12C)

to 400F (205C). Austenitic stain-

less steels and duplex stainless

steels are also susceptible to CUI,

especially in coastal geographic re-

gions where the normal atmosphere

contains chlorides and where the

equipment operates between 140F

(60C) and 400F (205C). Chloride-

induced stress corrosion cracking

(SCC) has been found in austenitic

stainless steels due to the chloride

content of the normal environment.

Program components

It is essential that a programmatic

approach to reducing the risk of

operations includes a focus on CUI

Feature Report

40 CHEMICAL ENGINEERING WWW.CHE.COM MARCH 2014

Cover Story

Russ Davis

The Mistras Group, Inc.

CPI facilities need to put

in place a systematic

program for preventing

and mitigating corrosion

under insulation

Implementing a Corrosion-

Under-Insulation Program

Is

construction

material carbon

steel?

NO

NO

NO

NO

NO

YES

YES YES YES

YES

YES

Initiate CUI

evaluation, identify

suspect equipment

Is it

austenitic

stainless

steel?

Operates

between 10

and 400F?

Potential for

CUI exists

No CUI expected

Implement

risk-based

inspection

program

Cycling

in and out of

10 and 400F

range?

Cycling

in and out

of 120 and

400F?

Is

operating

temperature

between 120 and

400F?

IDMS download

of identifed

equipment

susceptible to CUI

Perform risk

assessment

to prioritize

inspection plan

Perform feld

walkdown, review

asset history,

cyclic service,

plant turnaround

schedule

Potential for

stress-corrosion

cracking exists

Consult

with materials

engineer for CUI

susceptibility

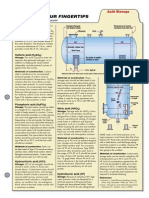

Phase 1 CUI Initial Descision Tree

Pre-inspection

FIGURE 1. The initial phase

of a comprehensive CUI pro-

gram involves a team assess-

ment of process vessels and

piping to determine which

pieces of equipment may be

susceptible to CUI

detection and mitigation. In gen-

eral, a comprehensive CUI program

should consist of at least the follow-

ing aspects:

Prevention of CUI

Early detection

Mitigation

Mechanical-integrity preventa-

tive maintenance programs de-

signed to continually address the

hazards of CUI

The process for addressing CUI

within the comprehensive facility-

specific program should consist of

at least these three phases:

Determining what equipment is

in the program

Performing a field walkdown of

the vessels and piping identified

in the first phase

Performing effective and effi-

cient inspection and testing of the

equipment and piping

For each phase of the CUI program,

this article includes a decision tree

that is designed to assist engineers

and managers to systematically ap-

proach CUI assessments, repairs

and documentation. The decision

trees can be found in Figures 14.

Phase I

The initial Phase 1 determination

of what equipment is to be included

in the CUI program generally con-

sists of a team assessment of the

process vessels and piping to de-

termine what is susceptible to CUI.

The team should evaluate and con-

sider the operating temperatures

and material of construction of

each of the pieces of equipment to

make the determination. This in-

formation may come from plant en-

gineering files and operational his-

tory, or it can be downloaded from

the inspection data management

system (IDMS).

After the team has determined

what equipment will be included

in the program, it is good practice

to prioritize those equipment items

by performing a risk assessment to

determine where the higher-conse-

CHEMICAL ENGINEERING WWW.CHE.COM MARCH 2014 41

TABLE 1. NON-DESTRUCTIVE EXAMINATION (NDE) METHODS FOR DETERMINING

THE PRESENCE OF CUI: ADVANTAGES AND DISADVANTAGES

Method Advantages Disadvantages

Visual inspection of pipes

and equipment

Qualitative inspection

Immediate validation of results

Requires stripping of all insulation

Extensive staging or scaffolding may be

required

Slow

Expensive where hazardous materials

are present

Potential to miss critical locations

Radiography film

Conventional X-ray technol-

ogy where radiation passes

through material and

creates image on film

Qualitative and quantitative results

possible

Thickness measurements are possible

Can identify conditions of both outer

diameter and inner diameter

Longer exposure times

Accuracies are 10%

Film processing is required, so results are

delayed

Environmental issues with chemicals

Image adjustment is not possible

Archival restrictions

Radiography CR (com-

puted radiography)

X-ray images are digitized

and displayed on computer

Qualitative and quantitative results

possible

Accurate measurements possible

Can identify conditions of both outer

diameter and inner diameter

No insulation removal required

Software image enhancement possible

Electronic media for easy archiving

Covers limited area

Requires direct access to inspection

area

Cost control is based on access and

production rate

Radiation hazards

Imaging plate care required

Realtime (RT) radiography

Low-power X-ray- or isotope-

based digital fluoroscopy

equipment that provides

view of outer diameter of

pipe

Identifies outer surface conditions

Allows fast (immediate) results

No insulation removal required

No radiation hazards

Close-proximity piping runs and pipe ge-

ometry can restrict inspection

Production slower in close-spaced

piping

Inspection unit is cumbersome in tight

spaces

Guided wave inspection

Uses low-frequency ultra-

sonic waves to detect gen-

eral corrosion and wall loss

Rapid inspection of long lengths of pipe

are possible (1,500 to 3,500 ft/d)

100% volumetric coverage

Limited insulation removal for inspection

Accurate location of pipe features and

corrosion

Semi-qualitative analysis of wall loss

Temperature range to 550F

Most cost-effective method for very long

lengths of pipe

Qualitative screening

Requires secondary method for verifica-

tion of anomalies

Geometry can restrict inspection

Pulsed eddy current (PEC)

Electric current is intro-

duced, then switched off

to generate eddy currents,

which are detected by re-

ceiver coils

Fast

No insulation removal required

Easily deployed

High-temperature capability

Non-contact method

Qualitative data

Close-proximity piping can limit access

Inspection of piping less than 3 in. in di-

ameter is not possible

Hydrotector

Determines moisture con-

tent in insulation by measur-

ing neutron scatter by hy-

drogen atoms in the water

Initial screening for wet insulation before

employing other CUI methods

Fast

No insulation removal required

Only useful for wet insulation; does not

detect dry insulation that has been wet

Screening tool only

No data on actual pipe condition

Cover Story

42 CHEMICAL ENGINEERING WWW.CHE.COM MARCH 2014

quence events would occur if there

was a loss of containment. The team

must always fully understand the

operating process and include those

vessels that are frequently idle,

even if they operate in a tempera-

ture range not usually noted for

susceptibility to CUI.

The team should be composed

of at least one member who is fa-

miliar with the materials of con-

struction of the vessels and piping

being evaluated, as well as at least

one member knowledgeable in the

process temperatures at which the

equipment operates, and a mem-

ber knowledgeable about the CUI

damage mechanism. In addition

the team should include a member

who is familiar with the inspection

history of the vessels and piping

within the program.

The analysis team should use a

formalized approach to the deter-

mination. A logic decision tree can

be very helpful (Figure 1).

The teams initial assessment

should pay particular attention to

the following equipment and piping

susceptible to CUI:

Areas exposed to mist over-spray

from cooling water towers

Areas subjected to process spills,

ingress of moisture or acid vapors

Dead-legs and attachments; that

is, drains, vents and so on

Pipe hangers and other supports

Vibrating piping systems

Steam-traced piping systems that

may experience tracing leaks

Phase 2

Phase 2 consists of a field walkdown

by qualified subject-matter experts

(SMEs). These experts determine

what non-destructive examination

(NDE) methodology is best suited

for discovering whether and how

CUI may be affecting each vessel

and piping system. The SMEs can

also determine the most efficient

and effective method for perform-

ing the inspection and tests. Table

1 shows a brief analysis of NDE

methods that can be used to deter-

mine the presence of CUI.

During the Phase 2 field assess-

ment, accessibility issues associated

with each piece of equipment and

piping can also be analyzed. Deter-

mining, for example, where scaffold-

ing must be utilized or where rope

access is needed can be of signifi-

cant value. Rope access has made

a tremendous contribution to the

inspection and testing field. Inspec-

tors are able to perform any NDE

method from ropes, thus reducing

the need for scaffolding and greatly

reducing the cost of inspections.

There must be anchor points avail-

NO

NO

YES

YES

YES

Field work and

follow up

inspection

Remove

insulation

at suspect

locations

Inspection

complete.

Document fnding

Mark ISO drawing

with location

inspected, update

asset fles

Follow up

re-insulation

and close

work order

Excecute

inspection

plan

Follow up on

NDE fndings and

make necessary

repairs

Perform

engineering

ftness for service

when required

Document

corrective action

Update ISO and

follow closure of

work order

and document

Recommend

paint and

re-insulate asset

Document

recommendation

Follow-up

re-insulation

of asset and

close work

order

Inspector

performs

visual asset

inspection

at exposed

locations

Is

evidence of

corrosion present?

(cracks or

thinning)

Does

paint meet

plant

criteria? Inspection

decision

Inspector to decide between:

a. advanced NDE;

b. additional insulation removal;

c. engineering assessment;

d. combination of a, b, c options

Phase 3 Field Inspection

FIGURE 3. When the feld inspection

plan is carried out, the need for more

extensive testing can be determined

and possible recommendations for

repair can be developed

Are

there any areas

with damaged

insulation

NO

NO

YES

YES

Initiate visual

inspection of

applicable assets

Field walkdown

Perform

engineering

assessment

to defer

inspection

Document areas

on asset ISO

drawing.

Perform moisture

detection to isolate

suspect areas

Document areas on

asset ISO drawing

that are suspect

for CUI.

Establish

inspection

methodology

to be utilized

Inspection

methodology

selection

Implement

inspection plan

Determine

recommended

inspection plan

methodology

Phase 2 Initial Field Visit

FIGURE 2. In the feld-walkdown

stage of the CUI program, subject-

matter experts inspect equipment

to determine which method(s) will

be most effective to evaluating

whether and how CUI is affecting

each equipment item

CHEMICAL ENGINEERING WWW.CHE.COM MARCH 2014 43

able for the rope access team to use

for anchoring their ropes. The field

assessment can determine where

rope access would be effective and

which NDE method will yield the

most significant data at the right

cost level. Figure 2 is an example of

the logic flow the field team can fol-

low to determine the most effective

inspection and test methodology.

The field walkdown team should

pay particular attention to:

The bottom of horizontal lines

in piping systems susceptible to

CUI

Any break in the vapor retarder

on cold lines

Damaged or missing insulation

jacketing

Location where inspection plugs

have been removed

Piping systems with deteriorated

coatings or wrappings

Termination of insulation

at flanges and other piping

components

Phase 3

Phase 3 of the program should con-

sist of the most effective and efficient

methods of testing and inspection

for the detection of CUI. Inspection

and testing findings can be evalu-

ated, and additional inspection and

testing needs can be quickly deter-

mined. Recommendations can then

be developed to address those issues

that were identified in the previ-

ous phase. Vessel and piping repair

plans can be developed and next

inspection dates set. Figure 3 is an

example of a logic flow for Phase 3

that the testing and inspection team

can use during the screening part of

the implementation phase.

It is not economical or feasible to

expect that the inspection and test-

ing will cover 100% of the equip-

ment and piping susceptible to CUI.

Screening inspections and testing

will be conducted to identify suspect

areas. Once these areas are identi-

fied, the decision will be made on

the most effective and economical

method for follow-up inspections.

Figure 4 is a logic flow for determin-

ing whether or not follow-up inspec-

tions should be performed, as well

as if advanced non-destructive eval-

uation (ANDE) methods should be

used in lieu of insulation stripping.

It is costly to remove and replace in-

sulation, especially if it is not fully

necessary. In many cases, the most

economical method could be an

ANDE method. The advantages and

disadvantages of ANDE methods

are also discussed in Table 1.

Summary remarks

CUI is a serious hazard affecting

the safety and reliability of chemi-

cal plants, petroleum refineries,

midstream terminals and just about

all oil-and-gas operating facilities.

To best address the problem, CUI

must be addressed in a systematic

or programmatic approach. The

program must be fully defined and

staffed with qualified personnel. Ef-

fective and economical inspection

and testing methodologies should

be utilized as part of the CUI detec-

tion program. By addressing CUI

effectively, the risk of operations

is reduced significantly and the

equipment and plant reliability is

increased. A safely and reliably op-

erating facility is the product of a

proactive CUI program.

Edited by Scott Jenkins

Is

wall loss

greater than

corrosion

allowance?

Inspect 100%

of carbon steel

asset with ANDE

Does

the piping

cross waterway?

Is the piping a class 1

or class 2 circuit?

Is the calculated risk-

based inspection

consequence

A or B?

Carbon steel

asset with

corrosion scale

or pits

SCC crack

present

Document

and close

Is

asset

suitable for

advanced

ANDE?

Note 1:

1. If there are additional fndings, then follow-up inspection will be required in accordance

with this process. If there are no additional fndings, then spot repairs will be completed

and inspection results documented in the asset inspection fles.

NO

NO

NO

NO

YES YES

YES

YES YES

If stainless-steel

asset, perform

localized

penetrant-test

exam

Inspector to determine:

a. advanced NDE

b. insulation removal

c. engineering analysis

d. combination of a, b, c options

Inspection

decision

Perform

additional

inspections

Strip the larger of:

a. all suspect

and damaged

insulation

locations;

b. 20% of asset

area/length

Perform ANDE

FIGURE 4. If corrosion is observed at suspect CUI locations, more in-depth assess-

ments, probably involving advanced non-destructive testing methods, are undertaken

Author

Russ Davis is the National

Asset Integrity Management

Services (AIMS) manager in

the services division of the

Mistras Group Inc. (4000

Underwood Road, LaPorte,

TX 77571; Phone: 281-478-

1636; Email: Russ.Davis@

mistrasgroup.com). Davis

has spent over 26 years in

mechanical-integrity pro-

gram development and

implementation. His experience includes pres-

sure vessels, aboveground storage tanks, and

piping inspection, testing and evaluation. Davis

has an extensive background in process safety

management, including hazard assessment and

consequence evaluation. He has developed and

directed mechanical integrity (MI) programs for

a global chemical company. Davis has served as

an MI consultant, as well as external consul-

tant for the implementation of MI programs. He

has a solid working knowledge of NDE, damage

mechanisms, and materials of construction for

equipment in the petroleum refining, chemical

and energy industries. He is also experienced

in equipment failure analysis, lifecycle analysis

and failure frequencies. Davis is an API-certi-

fied inspector, an ISA 84 Fundamentals Spe-

cialist and a certified safety professional.

You might also like

- Corrosion Under Insulation PP PDFDocument36 pagesCorrosion Under Insulation PP PDFCüneyt Gökhan TosunNo ratings yet

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- Cathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesFrom EverandCathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesRating: 4.5 out of 5 stars4.5/5 (5)

- Corrosion Control in the Oil and Gas IndustryFrom EverandCorrosion Control in the Oil and Gas IndustryRating: 4 out of 5 stars4/5 (12)

- Eni corrosion integrity management standardDocument32 pagesEni corrosion integrity management standardamra_4175% (4)

- Inspection Techniques For Detecting Corrosion Under InsulationDocument4 pagesInspection Techniques For Detecting Corrosion Under Insulationsllim776100% (3)

- A Refinery Approach To Address Corrosion Under Insulation & External CorrosionDocument35 pagesA Refinery Approach To Address Corrosion Under Insulation & External CorrosionIshan ShahNo ratings yet

- BP-CUI PpsDocument48 pagesBP-CUI Ppslaz_kNo ratings yet

- Asset Integrity Management A Complete Guide - 2020 EditionFrom EverandAsset Integrity Management A Complete Guide - 2020 EditionNo ratings yet

- Assess Eqpt Integrity PDFDocument85 pagesAssess Eqpt Integrity PDFswapan kumar hazraNo ratings yet

- 20557e00 Corrosion Risk Assessment MethodologyDocument38 pages20557e00 Corrosion Risk Assessment Methodologyamra_4182% (11)

- Piping Circuitization and RBI Requirements Lynne KaleyDocument79 pagesPiping Circuitization and RBI Requirements Lynne Kaleyparag_koyande100% (9)

- Paper9 LorentzDocument24 pagesPaper9 LorentzAsadAliNo ratings yet

- 00 Saip 74 - CuiDocument8 pages00 Saip 74 - CuiAbdelrahman HosnyNo ratings yet

- Corrosion & Integrity MGMTDocument81 pagesCorrosion & Integrity MGMTMohamedSadek100% (3)

- Corrosion Under Insulation of Plant and Pipework v3Document6 pagesCorrosion Under Insulation of Plant and Pipework v3patrick6364No ratings yet

- Establishing Integrity Operating Windows John ReynoldsDocument28 pagesEstablishing Integrity Operating Windows John Reynoldsprematscribd100% (4)

- White Paper Asset Reliability and IntegrityDocument20 pagesWhite Paper Asset Reliability and IntegrityGeert Henk Wijnants100% (1)

- Asset IntegrityDocument140 pagesAsset Integrityghostforever0No ratings yet

- Detection of Corrosion Under Insulation (CUI) by Pulse Eddy Current TechniqueDocument8 pagesDetection of Corrosion Under Insulation (CUI) by Pulse Eddy Current Techniquedeepak912No ratings yet

- Guide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingFrom EverandGuide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingNo ratings yet

- Life-Cycle Management of Pressurized EquipmentDocument36 pagesLife-Cycle Management of Pressurized Equipmentthawatchai11222512100% (3)

- CML/TML Optimization StrategiesDocument53 pagesCML/TML Optimization Strategiesgopidhan100% (4)

- Shell Downstream Manufacturing SM-1510002-SP-30 Management of Injection Points and Mix Points1Document17 pagesShell Downstream Manufacturing SM-1510002-SP-30 Management of Injection Points and Mix Points1Gail Holt75% (4)

- Corrosion Under InsulationDocument28 pagesCorrosion Under InsulationNurulFatimahalzahra100% (7)

- Mechanical Integrity Risk-Based Inspection Program EssentialsDocument24 pagesMechanical Integrity Risk-Based Inspection Program Essentialsesamhamad100% (1)

- Meridium Mechanical Integrity Standard Practice 2013 Rev 4Document400 pagesMeridium Mechanical Integrity Standard Practice 2013 Rev 4Tommy100% (1)

- Asset Integrity ManagementDocument5 pagesAsset Integrity ManagementLuis100% (2)

- CUI Issues in Ethylene PipingDocument14 pagesCUI Issues in Ethylene PipingSethuraman Saravanakumar100% (2)

- IOW's MainDocument5 pagesIOW's MainbotinesdeoroNo ratings yet

- Ageing Plant Summary GuideDocument53 pagesAgeing Plant Summary GuideEyoma EtimNo ratings yet

- Failure Modes, Effects and Causes of Microbiologically Influenced Corrosion: Advanced Perspectives and AnalysisFrom EverandFailure Modes, Effects and Causes of Microbiologically Influenced Corrosion: Advanced Perspectives and AnalysisNo ratings yet

- Corrosion Under Insulation White Paper PDFDocument4 pagesCorrosion Under Insulation White Paper PDFMoeen Khan Risaldar100% (1)

- Asset Integrity Management HandbookDocument107 pagesAsset Integrity Management Handbookpokeboy1995% (20)

- Corrosion Under Insulation (CUI)Document4 pagesCorrosion Under Insulation (CUI)p2pcreep100% (1)

- Asset IntegrityDocument21 pagesAsset Integrityrimas004No ratings yet

- 2011 Summit Fixed Equipment Inspection Programs - r6Document34 pages2011 Summit Fixed Equipment Inspection Programs - r6Nasrul Salman0% (1)

- CUIDocument28 pagesCUInaren57No ratings yet

- A Strategy For Preventing Corrosion Under Insulation On Pipeline in The Petrochemical IndustryDocument6 pagesA Strategy For Preventing Corrosion Under Insulation On Pipeline in The Petrochemical Industry이영준No ratings yet

- Study of Corrosion Risk Analysis in Oil Pipeline Using Risk Based Inspection Method Based On API 581Document5 pagesStudy of Corrosion Risk Analysis in Oil Pipeline Using Risk Based Inspection Method Based On API 581Galang Sandy PrayogoNo ratings yet

- Corrosion Management Shell PDFDocument25 pagesCorrosion Management Shell PDFShubhodeep Sarkar100% (3)

- Mitigate Buried Pipeline CorrosionDocument27 pagesMitigate Buried Pipeline Corrosionhitm357No ratings yet

- Corrosion Damage (Forms of Corrosion)Document105 pagesCorrosion Damage (Forms of Corrosion)Andiappan Pillai100% (4)

- Nsspu-Gp 06-10-1Document103 pagesNsspu-Gp 06-10-1John DryNo ratings yet

- Oil and Gas Corrosion Prevention: From Surface Facilities to RefineriesFrom EverandOil and Gas Corrosion Prevention: From Surface Facilities to RefineriesRating: 5 out of 5 stars5/5 (6)

- 2015 Summit RBI and IOWs - r12 - 1 PDFDocument32 pages2015 Summit RBI and IOWs - r12 - 1 PDFalNo ratings yet

- CUI III Tech Paper Fundamentals Layout - EN - 201901 - f2 - WebDocument24 pagesCUI III Tech Paper Fundamentals Layout - EN - 201901 - f2 - WebVarlyvarlyanNo ratings yet

- Guidelines For AIMSDocument28 pagesGuidelines For AIMSJefferson SoaresNo ratings yet

- CUI - Corrosion Under InsulationDocument5 pagesCUI - Corrosion Under Insulationtranhuy3110No ratings yet

- Thickness Monitoring GuideDocument16 pagesThickness Monitoring Guidedosetiadi100% (4)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Asset Integrity ManagementDocument9 pagesAsset Integrity ManagementSaqib AliNo ratings yet

- Mitigation of Corrosion Under Insulation (Cui) of Carbon Steel of Different Insulating MaterialsDocument35 pagesMitigation of Corrosion Under Insulation (Cui) of Carbon Steel of Different Insulating MaterialsGeert Henk Wijnants100% (1)

- Corrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesFrom EverandCorrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesNo ratings yet

- Establishing IOW'sDocument28 pagesEstablishing IOW'sjose corrosion100% (1)

- Corrosion Monit GuidelinesDocument35 pagesCorrosion Monit GuidelinesPaulaNo ratings yet

- Importance of Inspection For CorrosionDocument23 pagesImportance of Inspection For CorrosionabyNo ratings yet

- Piping System Leak Detection and MonitoringDocument7 pagesPiping System Leak Detection and MonitoringChelsea SkinnerNo ratings yet

- Safety - Lessons Relearned - Inadequate IsolationsDocument5 pagesSafety - Lessons Relearned - Inadequate IsolationsChelsea SkinnerNo ratings yet

- Soda AshDocument1 pageSoda AshChelsea Skinner100% (1)

- Acid StorageDocument1 pageAcid StorageChelsea SkinnerNo ratings yet

- Safety - Lessons Relearned - Inadequate IsolationsDocument5 pagesSafety - Lessons Relearned - Inadequate IsolationsChelsea SkinnerNo ratings yet

- Acids HandlingDocument8 pagesAcids HandlingChelsea SkinnerNo ratings yet

- LESSONS FROM CONFINED SPACESDocument5 pagesLESSONS FROM CONFINED SPACESChelsea SkinnerNo ratings yet

- Acid StorageDocument1 pageAcid StorageChelsea SkinnerNo ratings yet

- Processing Industrial Byproducts To Yield As FertilizerDocument13 pagesProcessing Industrial Byproducts To Yield As FertilizerChelsea SkinnerNo ratings yet

- Methyl ChlorideDocument1 pageMethyl ChlorideChelsea SkinnerNo ratings yet

- Light Crude Oil Treatment SulfurDocument7 pagesLight Crude Oil Treatment SulfurChelsea SkinnerNo ratings yet

- Updating the Chemical Engineering Plant Cost Index for the 21st CenturyDocument9 pagesUpdating the Chemical Engineering Plant Cost Index for the 21st CenturyChelsea SkinnerNo ratings yet

- Acids HandlingDocument8 pagesAcids HandlingChelsea SkinnerNo ratings yet

- Phoenix Contact 3247055 enDocument6 pagesPhoenix Contact 3247055 enDGNo ratings yet

- 4 General Types of Polymers Molecular StructureDocument3 pages4 General Types of Polymers Molecular StructureArgel Linard Francisco MabagaNo ratings yet

- Tank Size CalculatorDocument6 pagesTank Size CalculatorVijayakumar Chandrasekaran100% (2)

- Fsls 11.10 Adminguide EngDocument67 pagesFsls 11.10 Adminguide Engsurender78No ratings yet

- RC F18 Super Hornet - Manual v2.0Document13 pagesRC F18 Super Hornet - Manual v2.0Darren-Edward O'NeillNo ratings yet

- Undergraduate Architectural Thesis Site and Village Study PDFDocument4 pagesUndergraduate Architectural Thesis Site and Village Study PDFMalavika LaxmanNo ratings yet

- CCH Power CalculateDocument4 pagesCCH Power Calculateangga measNo ratings yet

- Pfaff 360 Sewing Machine Instruction ManualDocument55 pagesPfaff 360 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- DP TV Aver 15022 DriversDocument94 pagesDP TV Aver 15022 DriversMohammed Tahver Farooqi QuadriNo ratings yet

- pd1185 Fire CodeDocument3 pagespd1185 Fire CodeCamille MangaranNo ratings yet

- Reliability and Integrity Management 1Document37 pagesReliability and Integrity Management 1Giannos Kastanas100% (1)

- Queen Sala Celinda Del Rosario LECCION2 Actividad de Produccion 2.4Document4 pagesQueen Sala Celinda Del Rosario LECCION2 Actividad de Produccion 2.4Salustino AbreuNo ratings yet

- 2.ARC - ARC Binh Duong ASRS - Quotation For PK2 - Panel and Refrigeration System - Phase 2 - 2020 10 28Document12 pages2.ARC - ARC Binh Duong ASRS - Quotation For PK2 - Panel and Refrigeration System - Phase 2 - 2020 10 28vu nguyen ngocNo ratings yet

- p6 ReportDocument19 pagesp6 ReportAnonymous yrcU1kNo ratings yet

- JGEE UG Syllabus 2013-14Document65 pagesJGEE UG Syllabus 2013-14Animesh MannaNo ratings yet

- WT Lab ManualDocument44 pagesWT Lab ManualVenkatanagasudheer Thummapudi100% (1)

- BPM Third Wave Smith Fingar Apr2003 PDFDocument10 pagesBPM Third Wave Smith Fingar Apr2003 PDFNadeem AzadNo ratings yet

- Kali Linux For BeginnersDocument13 pagesKali Linux For Beginnersnihal0% (1)

- 9mm!ূຌዡገ๕ۉ࿋ഗ Rotary Potentiometers With Metal Shaft Series: WH9011A-1-18TDocument26 pages9mm!ূຌዡገ๕ۉ࿋ഗ Rotary Potentiometers With Metal Shaft Series: WH9011A-1-18TpeterfunNo ratings yet

- Inductance Measurements For Synchronous MachinesDocument2 pagesInductance Measurements For Synchronous MachinesYusuf YaşaNo ratings yet

- Curriculum Vitae: Vivek PatilDocument3 pagesCurriculum Vitae: Vivek PatilVivek PatilNo ratings yet

- Xtrons - TD609 User ManualDocument16 pagesXtrons - TD609 User ManualadrianNo ratings yet

- Furuno GMDSS Installation Manual PDFDocument64 pagesFuruno GMDSS Installation Manual PDFEric PskdNo ratings yet

- Life 365 V 2 Users ManualDocument67 pagesLife 365 V 2 Users ManualAmanda VegaNo ratings yet

- Life Pixel - Nikon D5500 DIY Digital Infrared Conversion TutorialDocument6 pagesLife Pixel - Nikon D5500 DIY Digital Infrared Conversion TutorialCNo ratings yet

- Design and Development of Swashplate-Less HelicopterDocument68 pagesDesign and Development of Swashplate-Less HelicopterNsv DineshNo ratings yet

- Measure Wood DimensionsDocument6 pagesMeasure Wood DimensionsThilak BalakrishnanNo ratings yet

- Dual vs Core 2 DuoDocument5 pagesDual vs Core 2 Duomahisharma123456No ratings yet

- Categoria ApiDocument61 pagesCategoria ApiHector MARTINEZ DEL ANGELNo ratings yet

- Partition WallDocument24 pagesPartition WallSHRADDHA GHUGENo ratings yet