Professional Documents

Culture Documents

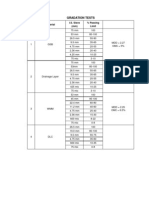

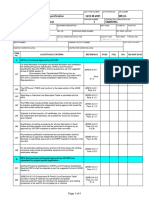

Bituminous Tests

Uploaded by

ikreddy0 ratings0% found this document useful (0 votes)

521 views23 pagesThis completely about Bituminous Tests and their Frequencies and Acceptance Crieteria

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis completely about Bituminous Tests and their Frequencies and Acceptance Crieteria

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

521 views23 pagesBituminous Tests

Uploaded by

ikreddyThis completely about Bituminous Tests and their Frequencies and Acceptance Crieteria

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 23

Determining Bitumen Content

Posted in Civil Engineering Tests | Email This Post

BITUMEN CONTENT

This test is done to determine the bitumen content as per ASTM 2172. The apparatus needed to determine

bitumen content are -

i) Centrifuge extractor

ii) Miscellaneous bowl, filter paper, balance and commercial benzene.

A sample of 500g is taken.

Procedure to determine bitumen content

i) If the mixture is not soft enough to separate with a trowel,place 1000g of it in a large pan and warm

upto 100

o

C to separate the particles of the mixture uniformly.

ii) Place the sample (Weight A) in the centrifuge extractor. Cover the sample with benzene, put the filter

paper on it with the cover plate tightly fitted on the bowl.

iii) Start the centrifuge extractor, revolving slowly and gradually increase the speed until the solvent

ceases to flow from the outlet.

iv) Allow the centrifuge extractor to stop. Add 200ml benzene and repeat the procedure.

v) Repeat the procedure at least thrice, so that the extract is clear and not darker than the light straw

colour and record the volume of total extract in the graduated vessel.

vi) Remove the filter paper from the bowl and dry in the oven at 110 + 5

o

C. After 24hours, take the

weight of the extracted sample (Weight B).

REPORTING OF RESULTS

Bitumen content = [(A-B)/B]100 %

Repeat the test thrice and average the results.

Determining the Ductility Of Bitumen

Posted in Civil Engineering Tests | Email This Post

This test is done to determine the ductility of distillation residue of cutback bitumen, blown type bitumen

and other bituminous products as per IS: 1208 1978. The principle is : The ductility of a bituminous

material is measured by the distance in cm to which it will elongate before breaking when a standard

briquette specimen of the material is pulled apart at a specified speed and a specified temperature.

The apparatus required for this test:

i) Standard mould

ii) Water bath

iii) Testing machine

iv) Thermometer Range 0 to 44

o

C, Graduation 0.2

o

C

Procedure to determine the Ductility Of Bitumen

i) Completely melt the bituminous material to be tested by heating it to a temperature of 75 to 100

o

C

above the approximate softening point until it becomes thoroughly fluid. Assemble the mould on a brass

plate and in order to prevent the material under test from sticking, thoroughly coat the surface of the

plate and the interior surfaces of the sides of the mould with a mixture of equal parts of glycerine and

dextrin. While filling, pour the material in a thin stream back and forth from end to end of the mould until

it is more than level full. Leave it to cool at room temperature for 30 to 40 minutes and then place it in a

water bath maintained at the specified temperature for 30 minutes, after which cut off the excess bitumen

by means of a hot, straight-edged putty knife or spatula, so that the mould is just level full. ii) Place the

brass plate and mould with briquette specimen in the water bath and keep it at the specified temperature

for about 85 to 95 minutes. Remove the briquette from the plate, detach the side pieces and the briquette

immediately.

iii) Attach the rings at each end of the two clips to the pins or hooks in the testing machine and pull the

two clips apart horizontally at a uniform speed, as specified, until the briquette ruptures. Measure the

distance in cm through which the clips have been pulled to produce rupture. While the test is being done,

make sure that the water in the tank of the testing machine covers the specimen both above and below by

at least 25mm and the temperature is maintained continuously within 0.5

o

C of the specified

temperature.

REPORTING OF RESULTS

A normal test is one in which the material between the two clips pulls out to a point or to a thread and

rupture occurs where the cross-sectional area is minimum. Report the average of three normal tests as

the ductility of the sample, provided the three determinations be within 0.5 percent of their mean value.

If the values of the three determinations do not lie within 0.5 percent of their mean, but the two higher

values are within 0.5 percent of their mean, then record the mean of the two higher values as the test

result.

Determining Penetration of Bitumen

Posted in Civil Engineering Tests | Email This Post

This test is done to determine the penetration of bitumen as per IS: 1203 1978. The principle is that the

penetration of a bituminous material is the distance in tenths of a mm, that a standard needle would

penetrate vertically, into a sample of the material under standard conditions of temperature, load and

time. The apparatus needed to determine the penetration of bitumen is

i) Penetrometer

ii) Water bath

iii) Bath thermometer Range 0 to 44

o

C, Graduation 0.2

o

C

SAMPLE

Bitumen should be just sufficient to fill the container to a depth of at least 15mm in excess of the

expected penetration.

Procedure to determine the penetration of bitumen

i) Soften the bitumen above the softening point (between 75 and 100

o

C). Stir it thoroughly to remove air

bubbles and water.

ii) Pour it into a container to a depth of at least 15mm in excess of the expected penetration.

iii) Cool it at an atmospheric temperature of 15 to 30

o

C for 1

1/2

hours. Then place it in a transfer dish in

the water bath at 25.0 + 0.1

o

C for 1

1/2

hrs.

iv) Keep the container on the stand of the penetration apparatus.

v) Adjust the needle to make contact with the surface of the sample.

vi) Adjust the dial reading to zero.

vii) With the help of the timer, release the needle for exactly 5 seconds.

viii) Record the dial reading.

ix) Repeat the above procedure thrice.

REPORTING OF RESULTS

The value of penetration reported should be the mean of not less than three determinations expressed in

tenths of a mm.

Determining Specific Gravity of Bitumen

Posted in Civil Engineering Tests | Email This Post

This test is done to determine the specific gravity of semi-solid bitumen road tars, creosote and

anthracene oil as per IS: 1202 1978. The principle is that it is the ratio of mass of a given volume of

bitumen to the mass of an equal volume of water, both taken at a recorded/specified temperature.

The apparatus needed to determine specific gravity of bitumen is

i) Specific gravity bottles of 50ml capacity

ii) Water bath

iii) Bath thermometer Range 0 to 44

o

C, Graduation 0.2

o

C

Take the sample (half the volume of the specific gravity bottles).

Procedure to determine specific gravity of bitumen

i) Clean, dry and weigh the specific gravity bottle along with the stopper (Weight A).

ii) Fill the specific gravity bottle with freshly boiled distilled water and insert the stopper firmly. Keep it in

the water bath having a temperature of 27.0 + 1

o

C for not less than half an hour and weigh it (Weight

B).

iii) Weigh the specific gravity bottle about half-filled with the material (Weight C).

iv) Weigh the specific gravity bottle about half-filled with the material and the other half with distilled

water (Weight D).

v) Weigh the specific gravity bottle completely filled with the material (Weight E).

REPORTING OF RESULTS

i) Specific gravity (Solids and semi-solids) = (C-A )/[ ( B-A) - (D-C)]

ii) Specific gravity (Liquids) = (E-A)/(B-A)

The average of the two results should be reported.

Determining Softening Point Of Bitumen

Posted in Civil Engineering Tests | Email This Post

This test is done to determine the softening point of asphaltic bitumen and fluxed native asphalt, road tar,

coal tar pitch and blown type bitumen as per IS: 1205 1978. The principle behind this test is that

softening point is the temperature at which the substance attains a particular degree of softening under

specified condition of the test.

The apparatus required for this test :-

i) Ring and ball apparatus

ii) Thermometer Low Range : -2 to 80

o

C, Graduation 0.2

o

C High Range : 30 to 200oC, Graduation

0.5

o

C

PREPARATION OF SAMPLE

i) The sample should be just sufficient to fill the ring. The excess sample should be cut off by a knife.

ii) Heat the material between 75 and 100

o

C. Stir it to remove air bubbles and water, and filter it through

IS Sieve 30, if necessary.

iii) Heat the rings and apply glycerine. Fill the material in it and cool it for 30 minutes.

iv) Remove excess material with the help of a warmed, sharp knife.

Procedure to determine Softening Point Of Bitumen

A) Materials of softening point below 80

o

C:

i) Assemble the apparatus with the rings, thermometer and ball guides in position.

ii) Fill the beaker with boiled distilled water at a temperature 5.0 0.5

o

C per minute.

iii) With the help of a stirrer, stir the liquid and apply heat to the beaker at a temperature of 5.0 0.5

o

C

per minute.

iv) Apply heat until the material softens and allow the ball to pass through the ring.

v) Record the temperature at which the ball touches the bottom, which is nothing but the softening point

of that material.

B) Materials of softening point above 80

o

C:

The procedure is the same as described above. The only difference is that instead of water, glycerine is

used and the starting temperature of the test is 35

o

C.

REPORTING OF RESULTS

Record the temperature at which the ball touches the bottom.

Determining Flash And Fire Point Of Bitumen

Posted in Civil Engineering Tests | Email This Post

This test is done to determine the flash point and the fire point of asphaltic bitumen and fluxed native

asphalt, cutback bitumen and blown type bitumen as per IS: 1209 1978. The principle behind this test is

given below :

Flash Point The flash point of a material is the lowest temperature at which the application of test

flame causes the vapours from the material to momentarily catch fire in the form of a flash under

specified conditions of the test.

Fire Point The fire point is the lowest temperature at which the application of test flame causes the

material to ignite and burn at least for 5 seconds under specified conditions of the test.

The apparatus required for this test is

i) Pensky-Martens apparatus

ii) Thermometer- Low Range : -7 to 110

o

C, Graduation 0.5

o

C

High Range : 90 to 370

o

C, Graduation 2

o

C

The sample should be just sufficient to fill the cup upto the mark given on it.

Procedure to determine the Flash And Fire Point Of Bitumen

A) FLASH POINT

i) Soften the bitumen between 75 and 100

o

C. Stir it thoroughly to remove air bubbles and water.

ii) Fill the cup with the material to be tested upto the filling mark. Place it on the bath. Fix the open clip.

Insert the thermometer of high or low range as per requirement and also the stirrer, to stir it.

iii) Light the test flame, adjust it. Supply heat at such a rate that the temperature increase, recorded by

the thermometer is neither less than 5

o

C nor more than 6

o

C per minute.

iv) Open flash point is taken as that temperature when a flash first appears at any point on the surface of

the material in the cup. Take care that the bluish halo that sometimes surrounds the test flame is not

confused with the true flash. Discontinue the stirring during the application of the test

flame.

v) Flash point should be taken as the temperature read on the thermometer at the time the flash occurs.

B) FIRE POINT

i) After flash point, heating should be continued at such a rate that the increase in temperature recorded

by the thermometer is neither less than 5

o

C nor more than 6

o

C per minute.

ii) The test flame should be lighted and adjusted so that it is of the size of a bead 4mm in dia.

REPORTING OF RESULTS

i) The flash point should be taken as the temperature read on the thermometer at the time of the flame

application that causes a distinct flash in the interior of the cup.

ii) The fire point should be taken as the temperature read on the thermometer at which the application of

test flame causes the material to ignite and burn for at least 5 seconds.

Determining The Marshall Stability of Bituminous

Mixture

Posted in Civil Engineering Tests | Email This Post

This test is done to determine the Marshall stability of bituminous mixture as per ASTM D 1559. The

principle of this test is that Marshall stability is the resistance to plastic flow of cylindrical specimens of a

bituminous mixture loaded on the lateral surface. It is the load carrying capacity of the mix at 60oC and is

measured in kg. The apparatus needed to determine Marshall stability of bituminous mixture is

i) Marshall stability apparatus

ii) Balance and water bath

The sample needed is

From Marshall stability graph, select proportions of coarse aggregates, fine aggregates and filler in such a

way, so as to fulfill the required specification. The total weight of the mix should be 1200g.

Procedure to determine Marshall stability of bituminous mixture

i) Heat the weighed aggregates and the bitumen separately upto 170

o

C and 163

o

C respectively.

ii) Mix them thoroughly, transfer the mixed material to the compaction mould arranged on the compaction

pedestal.

iii) Give 75 blows on the top side of the specimen mix with a standard hammer (45cm, 4.86kg). Reverse

the specimen and give 75 blows again. Take the mould with the specimen and cool it for a few minutes.

iv) Remove the specimen from the mould by gentle pushing. Mark the specimen and cure it at room

temperature, overnight.

v) A series of specimens are prepared by a similar method with varying quantities of bitumen content,

with an increment of 0.5% (3 specimens) or 1 bitumen content.

vi) Before testing of the mould, keep the mould in the water bath having a temperature of 60

o

C for half an

hour.

vii) Check the stability of the mould on the Marshall stability apparatus.

REPORTING OF RESULTS

Plot % of bitumen content on the X-axis and stability in kg on the Y-axis to get maximum Marshall

stability of the bitumen mix. A sample plot is given

Pavement materials: Bitumen

Overview

Bituminous materials or asphalts are extensively used for roadway construction, primarily because of their excellent

binding characteristics and water proofing properties and relatively low cost. Bituminous materials consists of bitumen

which is a black or dark colored solid or viscous cementitious substances consists chiefly high molecular weight

hydrocarbons derived from distillation of petroleum or natural asphalt, has adhesive properties, and is soluble in carbon

disulphide. Tars are residues from the destructive distillation of organic substances such as coal, wood, or petroleum and

are temperature sensitive than bitumen. Bitumen will be dissolved in petroleum oils where unlike tar.

Production of Bitumen

Bitumen is the residue or by-product when the crude petroleum is refined. A wide variety of refinery processes, such as

the straight distillation process, solvent extraction process etc. may be used to produce bitumen of different consistency

and other desirable properties. Depending on the sources and characteristics of the crude oils and on the properties of

bitumen required, more than one processing method may be employed.

Vacuum steam distillation of petroleum oils

In the vacuum-steam distillation process the crude oil is heated and is introduced into a large cylindrical still. Steam is

introduced into the still to aid in the vaporisation of the more volatile constituents of the petroleum and to minimize

decomposition of the distillates and residues. The volatile constituents are collected, condensed, and the various fractions

stored for further refining, if needed. The residues from this distillation are then fed into a vacuum distillation unit, where

residue pressure and steam will further separate out heavier gas oils. The bottom fraction from this unit is the vacuum-

steam-refined asphalt cement. The consistency of asphalt cement from this process can be controlled by the amount of

heavy gas oil removed. Normally, asphalt produced by this process is softer. As the asphalt cools down to room

temperature, it becomes a semi solid viscous material.

Different forms of bitumen

Cutback bitumen

Normal practice is to heat bitumen to reduce its viscosity. In some situations preference is given to use liquid binders such

as cutback bitumen. In cutback bitumen suitable solvent is used to lower the viscosity of the bitumen. From the

environmental point of view also cutback bitumen is preferred. The solvent from the bituminous material will evaporate

and the bitumen will bind the aggregate. Cutback bitumen is used for cold weather bituminous road construction and

maintenance. The distillates used for preparation of cutback bitumen are naphtha, kerosene, diesel oil, and furnace oil.

There are different types of cutback bitumen like rapid curing (RC), medium curing (MC), and slow curing (SC). RC is

recommended for surface dressing and patchwork. MC is recommended for premix with less quantity of fine aggregates.

SC is used for premix with appreciable quantity of fine aggregates.

Bitumen Emulsion

Bitumen emulsion is a liquid product in which bitumen is suspended in a finely divided condition in an aqueous medium

and stabilized by suitable material. Normally cationic type emulsions are used in India. The bitumen content in the

emulsion is around 60% and the remaining is water. When the emulsion is applied on the road it breaks down resulting in

release of water and the mix starts to set. The time of setting depends upon the grade of bitumen. The viscosity of

bituminous emulsions can be measured as per IS: 8887-1995. Three types of bituminous emulsions are available, which

are Rapid setting (RS), Medium setting (MS), and Slow setting (SC). Bitumen emulsions are ideal binders for hill road

construction. Where heating of bitumen or aggregates are difficult. Rapid setting emulsions are used for surface dressing

work. Medium setting emulsions are preferred for premix jobs and patch repairs work. Slow setting emulsions are

preferred in rainy season.

Bituminous primers

In bituminous primer the distillate is absorbed by the road surface on which it is spread. The absorption therefore depends

on the porosity of the surface. Bitumen primers are useful on the stabilized surfaces and water bound macadam base

courses. Bituminous primers are generally prepared on road sites by mixing penetration bitumen with petroleum distillate.

Modified Bitumen

Certain additives or blend of additives called as bitumen modifiers can improve properties of Bitumen and bituminous

mixes. Bitumen treated with these modifiers is known as modified bitumen. Polymer modified bitumen (PMB)/ crumb

rubber modified bitumen (CRMB) should be used only in wearing course depending upon the requirements of extreme

climatic variations. The detailed specifications for modified bitumen have been issued by IRC: SP: 53-1999. It must be

noted that the performance of PMB and CRMB is dependent on strict control on temperature during construction. The

advantages of using modified bitumen are as follows

Lower susceptibility to daily and seasonal temperature variations

Higher resistance to deformation at high pavement temperature

Better age resistance properties

Higher fatigue life for mixes

Better adhesion between aggregates and binder

Prevention of cracking and reflective cracking

Requirements of Bitumen

The desirable properties of bitumen depend on the mix type and construction. In general, Bitumen should posses

following desirable properties.

The bitumen should not be highly temperature susceptible: during the hottest weather the mix should not become

too soft or unstable, and during cold weather the mix should not become too brittle causing cracks.

The viscosity of the bitumen at the time of mixing and compaction should be adequate. This can be achieved by

use of cutbacks or emulsions of suitable grades or by heating the bitumen and aggregates prior to mixing.

There should be adequate affinity and adhesion between the bitumen and aggregates used in the mix.

Tests on bitumen

There are a number of tests to assess the properties of bituminous materials. The following tests are usually conducted to

evaluate different properties of bituminous materials.

1. Penetration test

2. Ductility test

3. Softening point test

4. Specific gravity test

5. Viscosity test

6. Flash and Fire point test

7. Float test

8. Water content test

9. Loss on heating test

Penetration test

It measures the hardness or softness of bitumen by measuring the depth in tenths of a millimeter to which a standard

loaded needle will penetrate vertically in 5 seconds. BIS had standardized the equipment and test procedure. The

penetrometer consists of a needle assembly with a total weight of 100g and a device for releasing and locking in any

position. The bitumen is softened to a pouring consistency, stirred thoroughly and poured into containers at a depth at

least 15 mm in excess of the expected penetration. The test should be conducted at a specified temperature of 25 C. It

may be noted that penetration value is largely influenced by any inaccuracy with regards to pouring temperature, size of

the needle, weight placed on the needle and the test temperature. A grade of 40/50 bitumen means the penetration value

is in the range 40 to 50 at standard test conditions. In hot climates, a lower penetration grade is preferred. The

Figure 1 shows a schematic Penetration Test setup.

Penetration Test Setup

Ductility test

Ductility is the property of bitumen that permits it to undergo great deformation or elongation. Ductility is defined as the

distance in cm, to which a standard sample or briquette of the material will be elongated without breaking. Dimension of

the briquette thus formed is exactly 1 cm square. The bitumen sample is heated and poured in the mould assembly

placed on a plate. These samples with moulds are cooled in the air and then in water bath at 27 C temperature. The

excess bitumen is cut and the surface is leveled using a hot knife. Then the mould with assembly containing sample is

kept in water bath of the ductility machine for about 90 minutes. The sides of the moulds are removed, the clips are

hooked on the machine and the machine is operated. The distance up to the point of breaking of thread is the ductility

value which is reported in cm. The ductility value gets affected by factors such as pouring temperature, test temperature,

rate of pulling etc. A minimum ductility value of 75 cm has been specified by the BIS. Figure 1 shows ductility moulds to

be filled with bitumen.

Figure 1: Ductility Moulds

Softening point test

Softening point denotes the temperature at which the bitumen attains a particular degree of softening under the

specifications of test. The test is conducted by using Ring and Ball apparatus. A brass ring containing test sample of

bitumen is suspended in liquid like water or glycerin at a given temperature. A steel ball is placed upon the bitumen

sample and the liquid medium is heated at a rate of 5 C per minute. Temperature is noted when the softened bitumen

touches the metal plate which is at a specified distance below. Generally, higher softening point indicates lower

temperature susceptibility and is preferred in hot climates. Figure 1 shows Softening Point test setup.

Figure 1: Softening Point Test Setup

Specific gravity test

In paving jobs, to classify a binder, density property is of great use. In most cases bitumen is weighed, but when used with

aggregates, the bitumen is converted to volume using density values. The density of bitumen is greatly influenced by its

chemical composition. Increase in aromatic type mineral impurities cause an increase in specific gravity.

The specific gravity of bitumen is defined as the ratio of mass of given volume of bitumen of known content to the mass of

equal volume of water at 27 C. The specific gravity can be measured using either pycnometer or preparing a cube

specimen of bitumen in semi solid or solid state. The specific gravity of bitumen varies from 0.97 to 1.02.

Viscosity test

Viscosity denotes the fluid property of bituminous material and it is a measure of resistance to flow. At the application

temperature, this characteristic greatly influences the strength of resulting paving mixes. Low or high viscosity during

compaction or mixing has been observed to result in lower stability values. At high viscosity, it resist the compactive effort

and thereby resulting mix is heterogeneous, hence low stability values. And at low viscosity instead of providing a uniform

film over aggregates, it will lubricate the aggregate particles. Orifice type viscometers are used to indirectly find the

viscosity of liquid binders like cutbacks and emulsions. The viscosity expressed in seconds is the time taken by the 50 ml

bitumen material to pass through the orifice of a cup, under standard test conditions and specified temperature. Viscosity

of a cutback can be measured with either 4.0 mm orifice at 25 C or 10 mm orifice at 25 or 40 C.

Flash and fire point test

At high temperatures depending upon the grades of bitumen materials leave out volatiles. And these volatiles catches fire

which is very hazardous and therefore it is essential to qualify this temperature for each bitumen grade. BIS defined the

flash point as the temperature at which the vapour of bitumen momentarily catches fire in the form of flash under specified

test conditions. The fire point is defined as the lowest temperature under specified test conditions at which the bituminous

material gets ignited and burns.

Float test

Normally the consistency of bituminous material can be measured either by penetration test or viscosity test. But for

certain range of consistencies, these tests are not applicable and Float test is used. The apparatus consists of an

aluminum float and a brass collar filled with bitumen to be tested. The specimen in the mould is cooled to a temperature of

5 C and screwed in to float. The total test assembly is floated in the water bath at 50 C and the time required for water

to pass its way through the specimen plug is noted in seconds and is expressed as the float value.

Water content test

It is desirable that the bitumen contains minimum water content to prevent foaming of the bitumen when it is heated above the

boiling point of water. The water in a bitumen is determined by mixing known weight of specimen in a pure petroleum distillate free

from water, heating and distilling of the water. The weight of the water condensed and collected is expressed as percentage by

weight of the original sample. The allowable maximum water content should not be more than 0.2% by weight.

Loss on heating test

When the bitumen is heated it loses the volatility and gets hardened. About 50gm of the sample is weighed and heated to a

temperature of 163 C for 5hours in a specified oven designed for this test. The sample specimen is weighed again after the heating

period and loss in weight is expressed as percentage by weight of the original sample. Bitumen used in pavement mixes should not

indicate more than 1% loss in weight, but for bitumen having penetration values 150-200 up to 2% loss in weight is allowed.

Table 1: Tests for Bitumen with IS codes

Type of test Test Method

Penetration Test IS: 1203-1978

Ductility test IS: 1208-1978

Softening Point test IS: 1205-1978

Specific gravity test IS: 1202-1978

Viscosity test IS: 1206-1978

Flash and Fire Point test IS: 1209-1978

Float Test IS: 1210-1978

Determination of water content IS: 1211-1978

Determination of Loss on heating IS:1212-1978

Summary

Requirements of bitumen as a binding material and its different forms were discussed. Various tests are conducted on bitumen to

assess its consistency, gradation, viscosity, temperature susceptibility, and safety. Standard test procedures on bitumen were also

covered in this chapter.

Problems

1. The minimum ductility value for bitumen specified by BIS is

1. 50cm

2. 25cm

3. 75cm

4. 100cm

2. The allowable maximum water content in bitumen should not be more than

1. 2% by weight

2. 0.2% by weight

3. 2.5% by weight

4. 5% by weight

Solutions

1. The minimum ductility value for bitumen specified by BIS is

1. 50cm

2. 25cm

3. 75cm

4. 100cm

2. The allowable maximum water content in bitumen should not be more than

1. 2% by weight

2. 0.2% by weight

3. 2.5% by weight

4. 5% by weight

Tests on Bitumen

Download Transportation Notes

Experience in using bitumen in engineering projects has led to the adoption of certain test procedures that are indicative

of the characteristics that identify adequate performance levels. Some of the tests have evolved with the development of

the industry and are empirical methods. Consequently it is essential that they are carried out in strict compliance with the

recommended procedures if they are to be accurate measurements of the bitumen's properties.

1. Penetration Test

2. Flash Point Test

3. Solubility Test

4. Ductility Test

5. Viscosity Test

Test 1. Penetration Test on Bitumen

The penetration test is one of the oldest and most commonly used tests on asphalt cements or residues from distillation of

asphalt cutbacks or emulsions. The standardized procedure for this test can be found in ASTM D5 [ASTM, 2001]. It is an

empirical test that measures the consistency (hardness) of an asphalt at a specified test condition.

Procedure of Penetration Test on Bitumen:

In the standard test condition, a standard needle of a total load of 100 g is applied to the surface of an asphalt or Liquid

bitumen sample at a temperature of 25 C for 5 seconds. The amount of penetration of the needle at the end of 5 seconds

is measured in units of 0.1 mm (or penetration unit). A softer asphalt will have a higher penetration, while a harder

asphalt will have a lower penetration. Other test conditions that have been used include

1. 0 C, 200 g, 60 sec., and

2. 46 C, 50 g, 5 sec.

The penetration test can be used to designate grades of asphalt cement, and to measure changes in hardness due to age

hardening or changes in temperature.

Read a detailed procedure of Bitumen Penetration Test with Sample Data

Test 2. Flash Point Test on asphalt:

The flash point test determines the temperature to which an asphalt can be safely heated in the presence of an open

flame. The test is performed by heating an asphalt sample in an open cup at a specified rate and determining the

temperature at which a small flame passing over the surface of the cup will cause the vapors from the asphalt sample

temporarily to ignite or flash. The commonly used flash point test methods include

1. The Cleveland Open Cup (ASTM D92)

2. Tag Open Cup (ASTM D1310).

The Cleveland Open-Cup method is used on asphalt cements or asphalts with relatively higher flash points, while the

Tag Open-Cup method is used on cutback asphalts or asphalts with flash points of less than 79 C. Minimum flash point

requirements are included in the specifications for asphalt cements for safety reasons. Flash point tests can also be

used to detect contaminating materials such as gasoline or kerosine in an asphalt cement. Contamination of an

asphalt cement by such materials can be indicated by a substantial drop in flash point.

When the flash point test is used to detect contaminating materials, the Pensky-Martens Closed Tester method (ASTM

D93), which tends to give more indicative results, is normally used. In recent years, the flash point test results have been

related to the hardening potential of asphalt. An asphalt with a high flash point is more likely to have a lower hardening

potential in the field.

Read a detailed procedure of Bitumen Penetration Test with Sample Data

Test 3. Solubility Test on asphalt bitumen

Asphalt consists primarily of bitumens, which are high-molecular-weight hydrocarbons soluble in carbon disulfide. The

bitumen content of a bituminous material is measured by means of its solubility in carbon disulfide.

Procedure for Solubility test on Bitumen

In the standard test for bitumen content (ASTM D4), a small sample of about 2 g of the asphalt is dissolved in 100 ml of

carbon disulfide and the solution is filtered through a filtering mat in a filtering crucible. The material retained on the filter is

then dried and weighed, and used to calculate the bitumen content as a percentage of the weight of the original asphalt.

Due to the extreme flammability of carbon disulfide, solubility in trichloroethylene, rather than solubility in carbon disulfide,

is usually used in asphalt cement specifications. The standard solubility test using trichloroethylene is designated as

ASTM D 2042.

The solubility test is used to detect contamination in asphalt cement. Specifications for asphalt cements normally require a

minimum solubility in trichloroethylene of 99.0 percent.

Unfortunately, trichloroethylene has been identified as a carcinogen and contributing to the depletion of the earths ozone

layer. The use of trichloroethylene will most likely be banned in the near future. There is a need to use a less hazardous

and non-chlorinated solvent for this purpose. Results of several investigations have indicated that the solvent n-Propyl

Bromide appears to be a feasible alternative to trichloroethylene for use in this application.

Read a detailed procedure of Bitumen Penetration Test with Sample Data

Test 4. Ductility Test on Asphalt

The ductility test (ASTM D113) measures the distance a standard asphalt sample will stretch without breaking under a

standard testing condition (5 cm/min at 25 C). It is generally considered that an asphalt with a very low ductility will

have poor adhesive properties and thus poor performance in service. Specifications for asphalt cements normally

contain requirements for minimum ductility.

Read a detailed procedure of Bitumen Penetration Test with Sample Data

Test 5. Viscosity Tests on Bitumen Asphalt

The viscosity test measures the viscosity of an asphalt. Both the viscosity test and the penetration test measure the

consistency of an asphalt at some specified temperatures and are used to designate grades of asphalts. The advantage

of using the viscosity test as compared with the penetration test is that the viscosity test measures a fundamental physical

property rather than an empirical value. Viscosity is defined as the ratio between the applied shear stress and

induced shear rate of a fluid.

When shear rate is expressed in units of 1/sec. and shear stress in units of Pascal, viscosity will be in units of Pascal-

seconds. One Pascal-second is equal to 10 Poises. The lower the viscosity of an asphalt, the faster the asphalt will flow

under the same stress. For a Newtonian fluid, the relationship between shear stress and shear rate is linear, and

thus the viscosity is constant at different shear rates or shear stress. However, for a non-Newtonian fluid, the

relationship between shear stress and shear rate is not linear, and thus the apparent viscosity will change as the

shear rate or shear stress changes.

Asphalts tend to behave as slightly non-Newtonian fluids, especially at lower temperatures. When different methods are

used to measure the viscosity of an asphalt, the test results might be significantly different, since the different methods

might be measuring the viscosity at different shear rates. It is thus very important to indicate the test method used when

viscosity results are presented.

The most commonly used viscosity test on asphalt cements is the Absolute Viscosity Test by Vacuum Capillary

Viscometer (ASTM D2171).

The standard test temperature is 60 C. The absolute viscosity test measures the viscosity in units of Poise. The viscosity

at 60 C represents the viscosity of the asphalt at the maximum temperature a pavement is likely to experience in most

parts of the U.S. When the viscosity of an asphalt at a higher temperature (such as 135 C) is to be determined, the most

commonly-used test is the Kinematic Viscosity Test (ASTM D2170), which measures the kinematic viscosity in units of

Stokes or centi-Stokes.

Kinematic viscosity is defined as: When viscosity is in units of Poise and density in units of g/cm, 3 the kinematic viscosity

will be in units of Stokes. To convert from kinematic viscosity (in units of Stokes) to absolute viscosity (in units of Poises),

one simply multiplies the number of Stokes by the density in units of g/cm

3

.

Read a detailed procedure of Bitumen Penetration Test with Sample Data

Composition and Properties of Bitumen

Advertisements

Composition of Bitumen

Materials in bituminous family are:

1) Tar:

Coal tar is a brown or dark black liquid of high viscosity, which smells of naphthalene and

aromatic hdydrocarbons. Being flammable, coal tar is sometime used for heating or to fire

boilers. It can be used in coal tar soap, and is used in medicated shampoo to kill and repel head

lice, and as a treatment for dandruff.

Depending upon its source of origin, TAR is classified as:

2) Coal Tar:

It is the liquid by-product of the distillation of coal to make coke. The gaseous by-product of this

process is commonly known as town gas. It is used for coating of wooden poles and sleepers,

iron poles.

3) Wood Tar:

See also: Construction Wood Properties

It is obtained by the distillation of resinous wood. Wood tar contains creosote and as such has strong preservative

properties. Search for "resin" in the above search box.

4) Mineral Tar:

It is obtained by the distillation of bituminous shale.

5) Coal Tar Pitch:

It is the residue of the direct distillation of crude tar produced by the high temperature carbonization of coal. It is used as a

water proofing compound in masonry, steel and timber structure. It is also used for water proofing concrete structures.

Chemical Composition of Bitumen:

Molecular weight wise, bitumen is a mixture of about 300 - 2000 chemical components, with an average of around 500 -

700. Elementally, it is around 95% carbon and hydrogen ( 87% carbon and 8% hydrogen), and up to 5% sulfur, 1%

nitrogen, 1% oxygen and 2000ppm metals. Bitumens are composed mainly of highly condensed polycyclic aromatic

hydrocarbons. They also contain several elements, a number of which are toxic.

Chemical Components in bitumen are:

1. Asphaltenes

2. Resinous components (polar aromatics)

3. Non-polar aromatics (naphtene aromatics) and

4. Saturates

Properties of Bitumen

See also: Applications of Bitumen

1.

Adhesion: Bitumen has the ability to adhere to a solid surface in a fluid state depending on

the nature of the surface. The presence of water on the surface will prevent adhesion.

2. Resistance to Water: Bitumen is water resistant. Under some conditions water may be

absorbed by minute quantities of inorganic salts in the bitumen or filler in it.

3. Hardness: To measure the hardness of bitumen, the penetration test is conducted, which

measures the depth of penetration in tenths of mm. of a weighted needle in bitumen after a

given time, at a known temperature.

Commonly a weight of 100 gm is applied for 5 sec at a temperature of 77 F. The

penetration is a measure of hardness. Typical results are 10 for hard coating asphalt, 15 to

40 for roofing asphalt and up to 100 or more for water proofing bitumen.

4. Viscosity and Flow: The viscous or flow properties of bitumen are of importance both at high temperature during

processing and application and at low temperature to which bitumen is subjected during service. The flow

properties of bitumens vary considerably with temperature and stress conditions. Deterioration, or loss of the

desirable properties of bitumen, takes the form of hardening. Resultantly, decrease in adhesive and flow

properties and an increase in the softening point temperature and coefficient of thermal expansion.

Various Lab Tests on Bitumen

Introduction to bituminous materials & applications of bitumen

Introduction to Bituminous materials

The term bituminous materials is generally used to denote substances in which bitumen is present or from which it can be

derived. Bitumen is defined as an amorphous, black or dark-colored, (solid, semi-solid, or viscous) cementitious

substance, composed principally of high molecular weight hydrocarbons, and soluble in carbon disulfide. For civil

engineering applications, bituminous mate-rials include primarily aphalts and tars. Asphalts may occur in nature (natural

asphalts) or may be obtained from petroleum processing (petroleum asphalts). Tars do not occur in nature and are

obtained as conden-sates in the processing of coal, petroleum, oil-shale, wood or other organic materials. Pitch is formed

when a tar is partially distilled so that the volatile constituents have evaporated off from it. Bituminous mixtures are

generally used to denote the combinations of bituminous materials (as binders), aggregates and additives.

This article presents the basic principles and practices of the usage of bituminous materials and mixtures in pavement

construction. In recent years, the use of tars in highway construction has been very limited due to the concern with the

possible emission of hazardous flumes when tars are heated.

Applications of Bitumen

One of the most important uses for geotextiles is as a filter in drainage and erosion control applications. Drainage

examples include trench and French drains, interceptor drains, blanket drains, pavement edge drains, and structural

drains, to name just a few. Permanent erosion control applications include coastal and lakeshore revetments, stream and

canal banks, cut and fill slope protection, and scour protection. In all these applications, geotextiles are used to replace

graded granular filters used in conjunction with the drainage aggregate, perforated pipe, rip rap, and so on. When properly

designed, geotextiles can provide comparable performance at less cost, provide consistent filtration characteristics, and

they are easier and therefore cheaper to install. Although erosion control technically does not improve the soil, prevention

of both external and internal erosion in residual and structured soils is an important design consideration.

Geotextiles can also be used to temporarily control and minimize erosion or transport of sediment from unprotected

construction sites. In some cases, geotextiles provide temporary protection after seeding and mulching but before

vegetative ground cover can be established. Geotextiles may also be used as armor materials in diversion ditches and at

the ends of culverts to prevent erosion. Probably the most common application is for silt fences, which are a substitute for

hay bales or brush piles, to remove suspended particles from sediment-laden runoff water.

Filtration Design Concepts: For a geotextile to satisfactorily replace a graded granular filter, it must perform the same

functions as a graded granular filter:

1. Prevent soil particles from going into suspension

2. Allow soil particles already in suspension to pass the filter (to prevent clogging or blinding); and

3. Have a sufficiently high permeability and flow rate so that no back pressure develops in the soil being protected.

The factors that control the design and performance of a geotextile filter are

1. Physical properties of the geotextile

2. Soil characteristics

3. Hydraulic conditions, and

4. External stress conditions

The level of design required depends on the critical nature of the project and the severity of the hydraulic and soil

conditions. Especially for critical projects, consideration of the risks involved and the consequences of possible failure of

the geotextile filter require great care in selecting the appropriate geotextile. For such projects and for severe hydraulic

conditions, very conservative designs are recommended. As the cost of the geotextile is usually a minor part of the total

project or system cost, geotextile selection should not be based on the lowest material cost. Also, expenses should not be

reduced by eliminating laboratory soilgeotextile performance testing when such testing is recommended by the design

procedure.

The three design criteria which must be satisfied are

1. Soil retention (piping resistance)

2. Permeability, and

3. Clogging criteria

For both permeability and clogging, different approaches are recommended for critical/severe applications. Furthermore,

laboratory filtration tests must be performed to determine clogging resistance. It is not sufficient to simply rely on retention

and permeability to control clogging potential. Finally, mechanical and index property requirements for durability and

constructibility are given. Constructibility is sometimes called survivability, and it depends on the installation conditions.

The best geotextile filter design in the world is useless if the geotextile does not survive the construction operations.

Applications of bituminous materials:

Prefabricated Drains In the last few years, prefabricated geocomposite drainage materials have become available as a

substitute for conventional drains with and without geotextiles. Geocomposites are probably most practical for lateral

drainage situations geocomposites is the use of prefabricated vertical (wick) drains to accelerate the consolidation of soft

compressible cohesive soil layers. Because they are much less expensive to install, geocomposite drains have made

conventional sand drains obsolete.

Typical Road Structure Cross Section - Road Cross Section Details

Advertisements

Composition of structure:

Road Structure Cross Section is composed of the following components

1. Sub Base

2. Base Course

3. Sub Grade

4. Surface/Wearing Course

1. Sub Bases:

It is layer of granular material provided above subgrade generally natural gravel. It is

usually not provided on subgrade of good quality.

a. Function of Sub base in Road

Cross Section

It enables traffic stresses to be

reduced to acceptable levels in

subgrade in the Road Cross

Section.

It acts as a working plate form for

the construction of upper

pavement layers.

Acts as a drainage layer, by

protecting the subgrade from

wetting up.

It intercept upward movement of

water by capillary action.

It acts as a separating layer b/w

subgrade and road base. By this it prevent the two layers from mixing up.

b. Characteristics of materials used in Sub Base:

The subgrade material should be clean and free from organic matter and should be able to be compacted by roller, to

form stable sub-base. The material should have following characteristic.

Well graded uniformity coefficient (D60/D10) should not be less than 3.

Fraction passing sieve #200 shall not be greater than 2/3rd of the fraction passing sieve #40.

Should have a L.L not greater than 25%.

P.I not greater than 6

CBR should not be less than 25. See also: CBR Test Procedure

In coarse grain, aggregate retained by #10 sieve, %age of wear shall not be greater than 5%.

The max dia of any particle shall not be greater than 2/3ed of the layer thickness of sub-base.

Typical particle size distribution for the sub-base (granular) when will meet strength requirement are

B.S Sieve Size % By mass of total Aggr passing test sieve

50 100

37.5 80-100

20 60-100

5 30-100

1.15 170-75

0.3 9-50

0075 5-25

* To avoid intrusion of silt and clay material in sub-base from subgrade

D15 (sub base) < 5

D15 (sub grade)

Recommended plasticity characteristic for granular Sub Base (Road Note 31) are;

Climate Liquid Limit (L.L) Plasticity Index (P.I)

Moist or wet tropical < 35 < 6

Seasonal wet tropical < 45 < 12

Arid & Semi Arid < 55 < 20

2. Sub Grade in Road Structure Cross Section:

3. Base courses in Road Structure Cross Section

It is the layer immediately under the wearig surface (Applies whether the wearing surface is bituminous or cement

concrete and or more inch thick or is but a thin bituminous layer).

As base course lies close under the pavement surface it is subjected to severe loading. The material in a base

course must be of extremely high quality and its construction must be done carefully.

a. Types of Base Course

1. Granular Base Course:

A mixture of soil particles ranging in size from coarse to fine. Processing involve crushing oversized particles and

screening where it is necessary to secure the desired grading. The requirements of a satisfactory soil aggregate surface

are;

Stability

Resistance to abrasion

Resistance to penetration of water

Capillary properties to replace moisture lost by surface evaporation upon the addition of wearing course

requirement change.

2. Macadam Base:

Successive layers of crushed rock mechanically locked by rolling and bonded by stone screening (rock duct,

stone chips etc).

3. In-water bound Macadam:

The crushed stones are laid, shaped and compacted and then finer materials are added and washed into surface to

provide a dense material.

4. Treated Bases:

Compose of mineral aggregate and additive to make them strong or more resistant to moisture. Among the treating

agents is bitumen.

4. Surface/Wearing Course in pavement cross section:

The top layers of pavement which is in direct contact with the wheel of the vehicle. Usually constructed of material in

which bitumen is used as binder materials.

a. Bituminous Pavement:

Consists of combination of mineral aggregate with bituminous binder ranging from inexpensive surface treatment in or

less thick to asphaltic concrete.

For good service throughout the full life bituminous pavement must retain following qualities.

Freedom from cracking or raveling.

Resistance to weather including the effect of surface water heat and cold.

Resistance to internal moisture, particularly to water vapors.

Tight impermeable surface or porous surface (if either is needed for contained stability of underlying base or

subgrade).

Smooth riding and non skidding surface.

The design should be done so that to meet the above requirements for considerable number of years (need proper design

and construction supervision)

Pavement meeting all the requirements above have been product if six distinctly different construction processes as

follows.

Heat a viscous bituminous binder to make it fluid, then in a plant mix it with heated aggregate place and compact

the mixture while it is hot.

Use fluid bituminous binder, mix it with aggregate at normal temperature. Mixing may be done at a plant (plant

mix) or on the prepared roadway base (road mix). Spread and compact the mixture at normal temperature.

Add solvent such as naphtha or kerosene to a viscose bituminous binder to make it fluid with aggregate at normal

temperature by either plant or road mix methods. Spread and compact at normal temperature before solvent

evaporates.

Use fluid emulsion of viscose bituminous binder in water, mix it with aggregate at normal temperature by either

plant or road mix method. Spread and compact at normal temperature before the emulsion breaks down with its

components.

Spread and compact clean crushed aggregate as for water bound macadam. Over it spray heated dissolved or

emulsified bituminous binder which penetrates open areas of the rock and binds the aggregate together. Thus is

commonly called Penetration Method.

Spread bituminous binder over the roadway surface then cover it with properly selected aggregate. This is

commonly called the Inverted Penetration Method.

Selections based on the requirements and economy, large volume of heavy vehicles, low traffic volume etc.

You might also like

- Research and Application of Hot In-Place Recycling Technology for Asphalt PavementFrom EverandResearch and Application of Hot In-Place Recycling Technology for Asphalt PavementNo ratings yet

- Ayni-Panjakent-Uzbekistan Border Road: List of Test FormsDocument58 pagesAyni-Panjakent-Uzbekistan Border Road: List of Test FormsGolam Masud100% (1)

- Modern Soil Stabilization TechniquesDocument25 pagesModern Soil Stabilization TechniquesSagar Jha100% (3)

- Aggregates: Classifiction of Aggregates Based On ShapeDocument7 pagesAggregates: Classifiction of Aggregates Based On ShapeOmar CesarNo ratings yet

- Flexible Pavement DistressesDocument4 pagesFlexible Pavement DistressesSivakumar M100% (1)

- Soil Stabilization by Using: Fly AshDocument12 pagesSoil Stabilization by Using: Fly AshRavi HirulkarNo ratings yet

- Rigid Versus Flexible Pavement DesignDocument3 pagesRigid Versus Flexible Pavement DesignAlbertJnBaptisteNo ratings yet

- Unbound Aggregates in RoadsFrom EverandUnbound Aggregates in RoadsR.H. JonesNo ratings yet

- International Society for Rock Mechanics: List of Members 1980From EverandInternational Society for Rock Mechanics: List of Members 1980Rating: 3.5 out of 5 stars3.5/5 (2)

- CBR Improvement of Clayey Soil With Geogrid ReinforcementDocument4 pagesCBR Improvement of Clayey Soil With Geogrid Reinforcementbkollarou9632No ratings yet

- Mix DesignDocument18 pagesMix Designawotina67% (3)

- 13-HPCL Vizag Soil Report-VOL.VDocument28 pages13-HPCL Vizag Soil Report-VOL.VDhananjay KumarNo ratings yet

- Effect of Aggregate Size and Gradation On PerviousDocument7 pagesEffect of Aggregate Size and Gradation On PerviousTianSing NgNo ratings yet

- Distress ID ManualDocument30 pagesDistress ID Manualramdasse100% (2)

- Premix Bituminous CarpetingDocument5 pagesPremix Bituminous CarpetingNehaSharma100% (1)

- CBR Test of SoilDocument3 pagesCBR Test of SoilRheymar Dela Rosa DiwaNo ratings yet

- Test Report Volume - 2 PDFDocument495 pagesTest Report Volume - 2 PDFakilan100% (1)

- Pavement AashtoDocument28 pagesPavement AashtoJoe Ady ShaputraNo ratings yet

- Highway Maintence, Repair and RehabilitationDocument32 pagesHighway Maintence, Repair and RehabilitationDIMariaAUnitedNo ratings yet

- Recycled Asphalt Pavement PDFDocument7 pagesRecycled Asphalt Pavement PDFUmesh MishraNo ratings yet

- Water Absorption Limits On AggregatesDocument2 pagesWater Absorption Limits On Aggregatesshahrilzainul77No ratings yet

- Flexible Rigid PavementsDocument66 pagesFlexible Rigid PavementsellenNo ratings yet

- Polished Stone Value - Test Procedures and Equipment PDFDocument6 pagesPolished Stone Value - Test Procedures and Equipment PDFSuman GautamNo ratings yet

- Tittle: Field Density Test. Scope: To Determine Density of Soil at The Field Itself ApparatusDocument6 pagesTittle: Field Density Test. Scope: To Determine Density of Soil at The Field Itself ApparatusChathura ChamikaraNo ratings yet

- Comparative Study of Flexible and Rigid Pavements For Different Soil and Traffic ConditionsDocument10 pagesComparative Study of Flexible and Rigid Pavements For Different Soil and Traffic ConditionsMano DragonNo ratings yet

- Mix Design by Marshall MethodDocument27 pagesMix Design by Marshall MethodS K SinghNo ratings yet

- Mix Design For Concrete Roads As Per IRC - 15-2011 PQCDocument11 pagesMix Design For Concrete Roads As Per IRC - 15-2011 PQCAnonymous MaSR3PNo ratings yet

- Flexible Pavement (Bituminous Road) : Compacted Soil SubgradeDocument3 pagesFlexible Pavement (Bituminous Road) : Compacted Soil SubgradeDinesh Kumar PatelNo ratings yet

- 4 - Design of Bitumen MixesDocument25 pages4 - Design of Bitumen MixesKwasi Agyeman-Boakye100% (2)

- Marshall Stability TestDocument10 pagesMarshall Stability TestkalyangaineNo ratings yet

- 3.3 Planning The Exploration ProgramDocument11 pages3.3 Planning The Exploration Programlianne lizardoNo ratings yet

- Pindan Sand Properties StudyDocument15 pagesPindan Sand Properties Studyganguly147147No ratings yet

- Lecture 5 Highway Construction MaterialsDocument15 pagesLecture 5 Highway Construction MaterialsCherylNo ratings yet

- Types of PavementsDocument17 pagesTypes of PavementsPereira KastroNo ratings yet

- Bitumen TestDocument13 pagesBitumen TestAnupam Verma100% (1)

- 3.1) Soil Compaction - Methods, Tests and EffectDocument18 pages3.1) Soil Compaction - Methods, Tests and EffectJoseph AsfourNo ratings yet

- Report On ENGINEERING COMPARISON BETWEEN FLEXIBLE AND RIGID PAVEMENTDocument35 pagesReport On ENGINEERING COMPARISON BETWEEN FLEXIBLE AND RIGID PAVEMENTTahmidul Islam FarabiNo ratings yet

- Road ResurfacingDocument16 pagesRoad ResurfacingLovish SinghalNo ratings yet

- GIT Unit-5Document8 pagesGIT Unit-5himabindugvsd71No ratings yet

- Study of Strength Properties of Polyester Fibre Reinforced ConcreteDocument5 pagesStudy of Strength Properties of Polyester Fibre Reinforced ConcreteJournal 4 ResearchNo ratings yet

- Geosythetic Reinforced Unpaved RoadDocument10 pagesGeosythetic Reinforced Unpaved RoadPalak ShivhareNo ratings yet

- Paving and Surface TreatmentsDocument11 pagesPaving and Surface TreatmentsLhaie BalasbasNo ratings yet

- Method B12 - The Determination of The Effect of Soluble Deleterious Material in Fine Aggregate For Concrete.Document5 pagesMethod B12 - The Determination of The Effect of Soluble Deleterious Material in Fine Aggregate For Concrete.GUO LEINo ratings yet

- Pavement DistressesDocument45 pagesPavement DistresseswedjefdbenmcveNo ratings yet

- 2015 Estimating MDD and OMCDocument9 pages2015 Estimating MDD and OMCKrmt Goji SamaratunggadewaNo ratings yet

- Flexible Pavement FailureDocument32 pagesFlexible Pavement FailureshivakumarNo ratings yet

- Literature Review On Effects of Saturation On Soil Subgrade StrengthDocument7 pagesLiterature Review On Effects of Saturation On Soil Subgrade StrengthIJRASETPublicationsNo ratings yet

- 2014 (NCPTC) Performance History of Concrete Overlays in The United StatesDocument30 pages2014 (NCPTC) Performance History of Concrete Overlays in The United StatesTim LinNo ratings yet

- Construction and Quality Control of Flexible PavementsDocument83 pagesConstruction and Quality Control of Flexible PavementsSayan GharNo ratings yet

- Pavement DesignDocument10 pagesPavement DesignkevalNo ratings yet

- Quality Control (QC) For Construction MaterialsDocument65 pagesQuality Control (QC) For Construction MaterialsSandeepNo ratings yet

- Behavior of Unsaturated Soils For Road Pavement Structure Under Cyclic LoadingDocument272 pagesBehavior of Unsaturated Soils For Road Pavement Structure Under Cyclic LoadingDiana CapisondaNo ratings yet

- CBR MDD Index Correlation Study-Addis Ababa University - 2013Document172 pagesCBR MDD Index Correlation Study-Addis Ababa University - 2013nimm1962No ratings yet

- National Institute of Technology, Patna: Submitted To:-Submitted ByDocument57 pagesNational Institute of Technology, Patna: Submitted To:-Submitted ByVipul MishraNo ratings yet

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985From EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985No ratings yet

- Roads & BridgesDocument66 pagesRoads & BridgesvivekranjanjamNo ratings yet

- Recommended Practice 2 CM Thick Bitumen and Tar Carpets: (Second Rev/S/On)Document11 pagesRecommended Practice 2 CM Thick Bitumen and Tar Carpets: (Second Rev/S/On)Milind GuptaNo ratings yet

- Is 2950 (Part-I) Code of Practice For Design and ConstructioDocument27 pagesIs 2950 (Part-I) Code of Practice For Design and ConstructioBhushan Patil100% (1)

- Guidelines For Evaluation of Load Carrying Capacity of BridgDocument33 pagesGuidelines For Evaluation of Load Carrying Capacity of Bridgnitinchavan30100% (3)

- ELS LevellingDocument21 pagesELS LevellingHironmoy DashNo ratings yet

- Indian Standard: Code of Practice For Determination of Breaking Capacity of Shallow Foundations (Document20 pagesIndian Standard: Code of Practice For Determination of Breaking Capacity of Shallow Foundations (api-19754583100% (1)

- Is 2502-1963 Bending and Fixing Rebars For Concrete ReinforcDocument29 pagesIs 2502-1963 Bending and Fixing Rebars For Concrete Reinforcikreddy100% (1)

- NAM Road Project Technical SpecificationDocument6 pagesNAM Road Project Technical SpecificationikreddyNo ratings yet

- Types of Survey ControlDocument12 pagesTypes of Survey ControlDragan VitasNo ratings yet

- Irc 003-1983Document9 pagesIrc 003-1983krish22041983No ratings yet

- Survey Camp Class NotesDocument26 pagesSurvey Camp Class NotesPatilRameshNo ratings yet

- Ramnj CoDocument2 pagesRamnj CoikreddyNo ratings yet

- Tests On BitumenDocument5 pagesTests On BitumenikreddyNo ratings yet

- IRC SP 54 Manual Bridges PDFDocument27 pagesIRC SP 54 Manual Bridges PDFdubeyvivek50% (2)

- Quality Assurance Quality ControlDocument15 pagesQuality Assurance Quality ControlikreddyNo ratings yet

- Tests On CementDocument11 pagesTests On CementikreddyNo ratings yet

- Q.A ManualDocument16 pagesQ.A ManualikreddyNo ratings yet

- Summary of ConcreteDocument6 pagesSummary of ConcreteikreddyNo ratings yet

- Tests On BitumenDocument5 pagesTests On BitumenikreddyNo ratings yet

- Summary of ConcreteDocument6 pagesSummary of ConcreteikreddyNo ratings yet

- 25.primavera & Ms Project Workbook - Civil & MechDocument21 pages25.primavera & Ms Project Workbook - Civil & Mechikreddy75% (4)

- Name of Work: E.W.E and F.E Including Constructin of CD & CM Works of S.V.P Bhainsa S. NO. CH KM G.L C.B.L F.S.L T.B.L D.O.C HT - of BankingDocument18 pagesName of Work: E.W.E and F.E Including Constructin of CD & CM Works of S.V.P Bhainsa S. NO. CH KM G.L C.B.L F.S.L T.B.L D.O.C HT - of BankingikreddyNo ratings yet

- BC, BM, WMM & DBM & GSBDocument5 pagesBC, BM, WMM & DBM & GSBikreddy68% (38)

- Chemical Industry ReleasesDocument152 pagesChemical Industry ReleasesKiran KrishnanNo ratings yet

- Ga Enu PDFDocument185 pagesGa Enu PDFFebriyono Ade PutraNo ratings yet

- Roadmark India: Manufacturing Unit: Plot No. 8, Kadipur Industrial Area, Gurugram, Haryana - 122001Document1 pageRoadmark India: Manufacturing Unit: Plot No. 8, Kadipur Industrial Area, Gurugram, Haryana - 122001ptk94287No ratings yet

- Exp. 7 Analysis of Milk For The Lipids Carbohydrates and ProteinsDocument6 pagesExp. 7 Analysis of Milk For The Lipids Carbohydrates and ProteinsClarice CatorceNo ratings yet

- CATALOG Uniweld-Products TYPE17-2Document13 pagesCATALOG Uniweld-Products TYPE17-2Máy cầm tay Hoàng TrungNo ratings yet

- Biodiesel Production From Broiler Chicken Waste: John Abraham, Ramesh Saravana Kumar, Francis Xavier, Deepak MathewDocument4 pagesBiodiesel Production From Broiler Chicken Waste: John Abraham, Ramesh Saravana Kumar, Francis Xavier, Deepak MathewClasherr AddaaNo ratings yet

- Abg Analysis-1Document22 pagesAbg Analysis-1PAMNo ratings yet

- Double Replacement Cep Lesson PlanDocument8 pagesDouble Replacement Cep Lesson Planapi-666239354No ratings yet

- Research Papers Structure of The Novel Ternary Hydrides Li TT D (TT Si and Ge)Document6 pagesResearch Papers Structure of The Novel Ternary Hydrides Li TT D (TT Si and Ge)Fadjar MulyaNo ratings yet

- Hygroscopic (Osmotic) Blisters Tiny, Pin Head Size, Water Filled Blisters. Caused by Hygroscopic Salts (Iron Sulphates and Iron Chlorides)Document25 pagesHygroscopic (Osmotic) Blisters Tiny, Pin Head Size, Water Filled Blisters. Caused by Hygroscopic Salts (Iron Sulphates and Iron Chlorides)Usab GamalNo ratings yet

- Chemical Dimension of TasteDocument31 pagesChemical Dimension of Tastemaithili joshiNo ratings yet

- DAQ Destroyer Hybrid RocketDocument48 pagesDAQ Destroyer Hybrid Rocketprakulmittal2100% (1)

- Dead Molecules and The Live Organism: Moh. Dliyauddin (176090100111019) Rubiyatna Sakaroni (176090100111006)Document14 pagesDead Molecules and The Live Organism: Moh. Dliyauddin (176090100111019) Rubiyatna Sakaroni (176090100111006)Muhammad DliyauddinNo ratings yet

- Cliq Cliqsmart Ap Technical Data SheetDocument2 pagesCliq Cliqsmart Ap Technical Data SheetSuravi BhaskarNo ratings yet

- PneumaticDocument13 pagesPneumaticVikas RaoNo ratings yet

- Personal Care: Industrial & Consumer SpecialtiesDocument17 pagesPersonal Care: Industrial & Consumer Specialtiescontentdrive4 drive4No ratings yet

- Miconium Btac80: Quaternary Ammonium SaltDocument1 pageMiconium Btac80: Quaternary Ammonium SaltJairo AlonsoNo ratings yet

- Dutch Pollutant StandardsDocument5 pagesDutch Pollutant Standardsumair2kplus492No ratings yet

- Class X Science Pre Board Sample PaperDocument23 pagesClass X Science Pre Board Sample PaperNasla ShiyasNo ratings yet

- Hectatone Universal ProductBulletinDocument1 pageHectatone Universal ProductBulletinFederico ArqueroNo ratings yet

- Measurement of Soil Thermal Stability Thermal Resistivity and Underground Cable Ampacity PDFDocument12 pagesMeasurement of Soil Thermal Stability Thermal Resistivity and Underground Cable Ampacity PDFJayabalan R KNo ratings yet

- Common Names (Organic Compounds)Document8 pagesCommon Names (Organic Compounds)Tushar100% (5)

- QCR W 2001Document4 pagesQCR W 2001Madhan KannanNo ratings yet

- Science Notes KS3 Part 2Document8 pagesScience Notes KS3 Part 2lamcass37No ratings yet

- Comparison of The Use of Rutile and Cellulosic Electrodes - TWIDocument11 pagesComparison of The Use of Rutile and Cellulosic Electrodes - TWISumantaNo ratings yet

- Manufacture of RadiopharmaceuticalsDocument9 pagesManufacture of RadiopharmaceuticalsRainMan75No ratings yet

- Specifications: Specifications & Material Safety Data Sheet Xyz General Cleaner LemonDocument3 pagesSpecifications: Specifications & Material Safety Data Sheet Xyz General Cleaner LemonnicholasyudhistiraNo ratings yet

- Poster Making and Gallery WalkDocument3 pagesPoster Making and Gallery WalkOdyssey Nicolle Esquejo LuisNo ratings yet

- Sedimentation and Sedimentation TanksDocument43 pagesSedimentation and Sedimentation TanksDevendra Sharma80% (10)