Professional Documents

Culture Documents

Organization Study

Uploaded by

sharonjohney0 ratings0% found this document useful (0 votes)

632 views59 pagesYarn is a long continuous length of interlocked fibers, suitable for use in the production of textiles, sewing, crocheting, knitting, weaving, embroidery, and rope making. Cotton staple is usually between 3 / 8 and 21 / 4 long. The quality of cotton is determined by the length of staple. Long staple means high quality and vice versa.

Original Description:

Original Title

organization study

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentYarn is a long continuous length of interlocked fibers, suitable for use in the production of textiles, sewing, crocheting, knitting, weaving, embroidery, and rope making. Cotton staple is usually between 3 / 8 and 21 / 4 long. The quality of cotton is determined by the length of staple. Long staple means high quality and vice versa.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

632 views59 pagesOrganization Study

Uploaded by

sharonjohneyYarn is a long continuous length of interlocked fibers, suitable for use in the production of textiles, sewing, crocheting, knitting, weaving, embroidery, and rope making. Cotton staple is usually between 3 / 8 and 21 / 4 long. The quality of cotton is determined by the length of staple. Long staple means high quality and vice versa.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 59

INTRODUCTION

Yarn is a long continuous length of interlocked fibers, suitable for use in

the production of textiles, sewing, crocheting, knitting, weaving, embroidery, and rope

making. Thread is a type of yarn intended for sewing by hand or machine. Modern

manufactured sewing threads may be finished with wax or other lubricants to withstand the

stresses involved in sewing. Embroidery threads are yarns specifically designed for hand or

machine embroidery.

Cotton Spun Yarn and Cotton Staple(Fiber)

Spun yarn is a kind of yarn made by gathering together a bundle of staple by spinning the

spindles at a very high speed to twist the staples together to form a piece of yarn. The

usual length of the staple of any kind, such as wool, ramie, or any type of synthetic fiber

for spinning should be less than 7. Cotton staple is usually between 3/8 and 2- long.

Cotton staple of less than long is usually not used for quilt, padding or spinning into

yarn because spun yarn of such short staple will have very weak tensile strength which is

not suitable for these fabrics. The quality of cotton is determined by the length of staple.

Long staple means high quality and vice versa.

By quality cotton is basically divided into the following four major groups.

1. Sea Island Cotton: This is the best quality cotton in the world. It has the longest and

finest staple reaching 2- which is the maximum length by nature. It is named so because

this type of cotton is particularly found in South Carolina, Georgia and Florida and many

islands off the coast of these states.

2. Pima Cotton: It is the name given to the cotton of the second longest staple reaching 1-

3/4. It is grown in Peru and Egypt (also called as Peruvian and Egyptian Cotton).

However, it is also grown in the south western U.S.

3. U.S Cotton : generally refers to cotton in United States other than Sea Island cotton .The

staple length varies but may reach 1- .

4. Asian Cotton: This cotton is grown in Asia, Japan, China, Pakistan and India. The staple

length is usually not longer than 1- 1/8

Other than the length of cotton staple which is of great importance, the thickness of it is

important too because only cotton of long and fine staple to make high quality fine fabrics.

The wool thickness varies depending on the kind of wool and origin of it. Synthetic fiber

is made by machine and we can adjust the thickness usually between 0.01 mm and 0.04

mm based on our needs. The staple length of each kind of the above mentioned cotton, can

be substantially shorter than indicated.

Before spinning yarn, cotton of different staple length are sorted into groups such as:

1. Cotton of all long staple length (called as fully combed cotton) are sorted for

making fully combed yarn.

2. Cotton of medium length staple (called as semi combed cotton) for making semi

combed yarn.

3. Cotton of all short staple (called as carded cotton) for making carded yarn.

Fabrics of fully combed yarn would have a smooth silky surface where as fabrics made of

carded yarn would have nubs or dead cotton on the surface, which are usually less color

absorbent. As a result it is coarse and not very soft. Therefore, we usually use combed

yarn to make light weight fabrics such as shirtings etc. but use carded yarn which is

cheaper to make heavy fabrics such as heavy denim canvas. Theoretically, a piece of yarn

can be made of any size, usually from 4 count to 120 count or even heavier than 4 count or

finer than 120 count.1 count yarn means 840 yards to weigh 1 lb. 2 count yarn means

1,680 yards (twice as long as 1 lb), and of 10 count yarn means 8400 yards (10 times as

long) to weigh 1 lb and so on. Therefore split the one count yarn into almost any number

and call it yarn of that count .This is the system used to control the size of the spun yarn of

100% cotton, polyester, wool, acrylic, ramie, rayon or any mixture of them.

Characteristics of textile spun yarn

composed of short staple fibers of definite length

Made from natural cotton, flax or wool staple fibers

Made from natural or man-made filaments which are chopped or cut into short

lengths and referred to as filament staple yarns

Individual fiber length vary

Bigger and wider in diameter than filament fiber yarns

Fuzzy appearance and feel, fiber ends protrude from yarn

Uneven number of fibers throughout

Range from soft, loose construction to hard finished, fine twist yarns

Thick and thin areas highly twisted

Fall apart when untwisted

Dull or flat in appearance

Rough to touch

Natural textural appearance and feel

Bulkier to the feel

Provide good covering power snagging

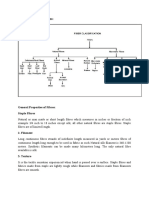

The Textile and Apparel Supply Chain

Distribution Channel (Export & Domestic Markets)

Garments & Accessories

Process House

Unorganized Segment Composite Mills

Powerlooms Handlooms Knitting

Spinning

Ginning

Man- Made Filament Extraction

Process

Cotton

Wool/Silk Petrochemical

2.3.2 Raw Material Base and Capacity in India

Cotton: Cotton is one of the major raw materials for the Indian textiles industry. India is

the second largest producer of cotton in the world, has the largest cultivated area ofover9

million hectares and accounts for around 20% (4.8 million tons) of globalproduction (over 25

million tons). The performance of the cotton sector has been increasing over the years and

during the cotton season (Aug-Sept) 2007-08, the output recorded was 310 lakh bales (170 kg

each). Even the consumption has been increasing over the years from 195.03 lakh bales in

2004-05 to 245 lakh bale sin 2007-08, by both mill and non -mill sectors. During 2007-08,

India exported 65 lakh bales of cotton. Technology Mission of Cotton (TMC), Mini mission

III, and Mini Mission 1V are some of the developmental measures taken by the Government

in this sector. The cotton sector provides employment to more than 50 million people in

various activities starting from cultivation to trade and processing.

Silk: In the world silk production, India is a distant - second largest producer, with a share

of around 15%, next to China, which holds a share of 82% in the world With a total silk

production of aroundl8, 500 MT in 2006-07, India has the distinction of producing all

varieties of silk, viz; mulberry, en, tasar and muga. Mulberry accounted for nearly 90% of

total silk production in India. The silk sector provides employment to around six million

persons in rural and semi urban areas, and the majority belonging to the economically weaker

sections of the society, including women. With Japanese technology and cooperation, Indian

sericulture industry is able to evolve and popularize Bivoltine silkworm races, which can

yield raw silk, matching the international standards.

Wool: India is the 7th largest producer of raw wool in the world accounting for little

over 2% of the world production. with about 4.2% of the total sheep population. Although

the woolen textile and clothing industry is relatively small compared to the cotton and

man-made fiber based textiles and clothing industry, yet the woolen sector plays an

important role as it is linking the rural sector with the textile manufacturing sector. The

product portfolio is also diverse, ranging from textile intenried.uas to finished textiles.

garments, knitwear, blankets and carpets Indian woolen sector has also a small presence

in manufacture of technical textiles, catering to the civil defense requirements for warm-

clothing Most of the u 001 produced in India (around 85) is of course quality used

mainly in the manufacture of hand-knotted carpets. And 5 a is of apparel grade, and 10%

is of course grade. used mainly for production of blankets.

Jute: India is the largest producer and consumer of raw jute in the world. In the year

2006-07, India imported raw jute worth US S 25 million (over83, 000 tons). During the

period April-February 2007-08, India imported raw jute valued US $31 6million (over

119,000 tons).Export of jute products (including floor coverings) from India was around US

$ 257 million in 2006-07, which has reached to US $ 296milIion, for the period April

February 2007-08. There are 77jute mills in India; 60 in West Bengal, 3 each in Bihar and

Uttar Pradesh, 7 in Andhra Pradesh and one each in Assam, Orissa, Tripura and Chhattisgarh.

Manmade Fibers: The man-made fiber industry comprises fiber and filament yarn

manufacturing units of cellulosic and non-cellulosic origin. The production of man-made

fibers in India has shown an increasing trend in 2007-08, a growth of around 10% over the

previous year. India also imports man-made fibers and synthetic & regenerated fibers for

processing and value addition. In the year 2006-07, India imported man-made fibers valued

US $ 555 million, and synthetic and regenerated fibers worth US $ Q7million. In the year

2007-08, during the period April-February, Indias imports of man-made filament and spun

yarn amounted to US $ 578rnillion, and Indias import of synthetic and regenerated fibers

amounted to US $ 100 million.

Current Scenario

The Indian Textile Industry has an overwhelming presence in the economic life of the

country Apart from providing one of the basic necessities of life; the textiles industry also

plays a vital role through its contribution to industrial output, employment generation, and the

export earnings of the country. The Indian textile industry contributes about 1 4 per cent to

industrial production, 4 per cent to the countries gross domestic product (GDP) and I per cent

to the countrys export earnings. The industry provides direct employment to over 35 million

people and is the second largest provider of employment after agriculture.

The total cloth production is increased by 10.2 percent during September 2010 as compared

to September 2009. The highest growth was observed in the power loom sector (13.2 per

cent), followed by hosiery sector (9 1 per cent). The total cloth production during Apnl-

Septemher2010 has increased by 2 1 per cent compared to the same period of the previous

year. The total textile exports during April July 2010 (provisional) were valued at US $ 7.58

billion as against Us $ 7.21 billion during the corresponding period of the previous

Year. Registering an increase of 5 20 per cent in rupee terms, 1 he share of textile exports in

total expois was 11.04 per cent during April-July 2010. Cotton textiles has registered a owth

of 8.2 per cent during April-September 20 10-lI, while wool, silk and man-made fiber textiles

have registered a growth of 2.2 per cent while textile products including wearing apparel

have registered a growth of 3 per cent.

India has the potential to increase its textile and apparel share in the world trade from the

current level of 4.5 per cent to 8 per cent and reach US$ 80 billion by 2020. Textiles and

apparel industry exports.valued at US$ 20.02 billion (TNR 963.05 billion), contributed about

11.5 per cent to the countrys total exports in 200809. Thus, the growth and all round

development of this industry has a direct bearing on the improvement of the economy of the

nation.

2.4 STATE -SCENARIO

The textile sector comprising of spinning and handloom is the single largest industry in the

state. The textile industry is dominated by handlooms, which enjoy a huge production base

and account for 10 per cent of the country exports. Total sales of the sector accounted for 1.8

per cent of sales by industry in the state in 2010. The handloom industry dominated by

cooperative societies, accounts for 86 per cent of the looms and produces 97 per cent of the

states textiles. Cotton yarn is the most popular product in the state followed by knitted

garments and fabrics such as cotton and wool. The textile-processing complex at

Kanjikode,.the International Apparel Park at Thiruvananthapuram and the Industrial Export

Park at Kochi offer walk- in-and-manufacture environments.

Hardly 20% of the textiles requirement of the state is met by local production. which 3

Coniprises principally of the handloom and khaki sectors, the power loom sector (Which

produces over 75% of the requirement nationally) not having been encouraged Adequately in

Kerala for fear of aggravating the already problematic traditional Sectors. The Government

desires to con-act this policy on the lines of the Government of Indias Textile Policy with

adequate safeguards to prevent massive redundancies in the handloom and khaki sectors.

2.4.1 Profile of Textile Sub-Sectors

Organlied Mill Sector: As of December 31. 2007. there were 1700 conon-Obre and man-

made Oher textiles mills (noii-SS() in the country with a capacity of round 35 milion

spindles, and around 0.5 million rotors. lndas organized mill sector produced about 4000

million kgs of yarn and oer 1 700 million sq. mirs of cloth.

Power looms Sector: The power looms sector provides a wide variety of cloth, both grey as

well as processed fabrics. As on January 3 1, 2008, there was 20.83lakh power looms

distributed in over4.64 lakh units, constituting over0% of the global power loom age. The

sector also contributes around62% to the total cloth production in the country, provides

employment to about 50 lakh people, which constitutes around 14% of the total employment

in the textiles sector and contributes 60% of the fabric, meant for exports.

Handlooms: The handlooms sector has been playing an important role in creating an

awareness of the Indian cultural diversity and fashion, which is unique only to the Indian

textile industry. The handloom cloth production was 6536 million square meters in 2006-07

and dunng2007-08, the production of cloth by handlooms sector was over 7000 million

square meters.

Readymade Garments: The clothing sector is fragmented and predominantly in the small

scale sector. It is estimated that there are over 13,000 apparel units (excluding tailoring units)

in India, majority of which are in the SME sector. The total production of clothing sector was

around 8 billion pieces with a value of Rs. 1 trillion during 2005-06 of which over one fourth

in quantity terms are being exported. The clothing sector is concentrated primarily in 8

clusters ,viz., Tirupur, Ludhiana, Bangalore, Delhi Noida Gurgaon, Mumbai, Kolkata, Jaipur

and Indore. Tirupur, Ludhiana and Kolkata ate major centers for knitwear, while Bangalore,

Delhi/Noida/Gurgaon. Murnbai.Jaipur and Indoreare major centers for woven

clothing.Indias exports of ready-made garments.consisting of cotton, silk, man-made fibres,

wool arid other textile materials showed a marginal increase of 0.8%, from 2005-06 to2006-

07; and it is expected toperform marginally better in the year 2007-08.

Technical Textiles: Textile materials and products, which are used for industrial purposes

and manufactured primarily for their technical performance and functional properties, rather

than for decoration, are called technical textiles. The maximum consumption of technical

textiles is in the USA, Western Europe, China and Japan. These regions account for 65% of

the total consumption of technical textiles in the world. In India, the production of different

items of the technical textile industryha been slowly and steadily increasing All the twelve

items are produced in India in varied quantities. India has also made notable contribution in

the production of textile for strategic applications viz. national security. e.g. parachute

canopy fabric used the carrying human, dropping of supply brake parachute application etc.

that are indigenized and exposed to other countries as well, The market size and potential of

technical textiles was estimated at Rs 19,130 crores in 2003M4, and it is estimated to have

reached Rs 30,000 crores in 2007-08.Being an emerging field, Government of India is

launching a (Rs 1000 crore) Technology Mission on Technical Textiles (TMTT) to ensure

that there are necessary profitable benefits from the enduring investments. To combat the

issue of technology backwardness and infrastructure issues, The Ministry of Textiles,

Government of India, plans to create clusters on technical textiles, so that thenecessary

textiles may be produced with adequate technology, thereby making the products

technologically competitive too.

COMPANY PROFILE

NAME & LOCATION

GTN TEXTILES LTD is incorporated on August 2nd 1962 at Aluva, near Cochin in Kerala

state and commissioned in 1964. The company has its registered office Erumathala near

Aluva in Ernakulum district. The company was started for the manufacture of cotton yarn

with a capacity of 12000 spindles. Company has got roots in the textile business for almost

100 years. GT Narayana Swami was the founder of GTN TEXTILES LTD. In 1966, the

company was taken over by the present management of the company. The founders were

from the raw cotton and yarn trading family business. They entered into manufacturing of

cotton in 1965 by starting GTN TEXTILES LTD in the small town of Aluva, Kerala, in the

southern part of India.

The GTN group which started with a single unit at Aluva has gradually grown into multi

location multi-unittextile group with a spindlage nearing, 1,60.000 GTN Textiles Ltd. Aluva

unit has an installed capacity around 50,000 spindles. GTN Textiles ltd is an ISO

s

PRODUCTS & SERVI CES PROFI LE

GTN Textiles is one the largest cotton yarn exporting organization from

india and is currently exporting at most 100% of its total production to countries like Japam,

Italy, South korea. Taiwan, Indonesia, Singapore, Malaysia and West Germany. The

company pioneered exports of cotton yarn to Japan and Italy where it has maintained its

leadership.

GTNs Product Range

GTN group manufacture 100% cotton yarn/ knitted fabrics:

Yarn of count 30s to 140s

Two for one twisted & Ring double

Knitting & Weaving yarn

Gassed yarn

Gassed and processed yarn

Knitted garments

Activities

Manufacturer, Exporters & Importers of Cotton Yarn, Knitted Fabric and Garments.

Import

Egypt, United States, Austria, Greece

Export

Japan, Italy, South Korea, China, Hong Kong, Austria, Belgium, Israel, Australia, Taiwan,

Malaysia, Mauritius, Turkey

OBJECTIVES OF THE STUDY

The objectives of the study are divided into two.

Primary Objective

The primary objective of the study is to know the organization structure and the functions of

different department.

Secondary Objectives

To know about the textile industry

To study the structure of the company

The functions of various department

To analyze the strengths weaknesses opportunities and threates of the company

To provide suitable suggestions of the effective functioning of the company

To know the interaction between different departments.

METHODOLOGY OF THE STUDY

Collection of Data

1. Area of Data Collection

The area of data collection is from GTN Textile Ltd Aluva.

2. Source of Data

The data can be classified as:

a. Primary data

For this study the primary data were collected from different departments, by direct

interview. Primary data are those which are collected for the first time. Primary data

collected through discussions and interviews with management personnels of varioys

departments. We collect primary data during the course of doing experimental

research but in case we do research of the descriptive and perform surveys whether

sample surveys or census surveys.

b. Secondary Data

For this study secondary data were collected from published reports of the company

magazines and websites.

Period of study

This study in GTN Textiles Ltd manufacturing company was done from 5

th

August to 10

tth

September. The data was mainly collected through the primary source by interviewing or

having a conversation with the executives and the workers of the organization.

DEPARTMENTAL PROFILE

1. Raw Material Department

2. Quality Assurance Department

3. Production Department

4. Stores Department

5. Maintenance Department

6. Management Information Systems Department

7. Finance Department

8. HR Department

9. Sales, Export/ Marketing Department

10. Security Department

11. Research and Department

8.1 RAW MATERIAL DEPARTMENT

Introduction

Cotton is the sole raw material for the manufacture of cotton yarns. Since it is a

seasonal product and is available only during the months from October- March, the required

quality is purchased and stocked for the production of cotton yarn. The fiber processors seek

to acquire the highest quality at the lowest price, and attempt to meet processing requirements

by blending bales with different average fiber properties.

Blends that fail to meet processing specification show marked increase in processing

distribution and product defect that cut into the profits of the yarn and textile manufacture.

The cotton picked folds are ginned and taken to the factory site from the ginning

centers through agents. The purchase is done on a massive scale, before which the material

undergoes a series of tests. The basic sample considered should satisfy three parameters viz.,

sample length, strength and value. Once the sample clears this high volume instrument

testing, the company goes for bulk purchase on lot basis. These samples again undergo the

quality check which once cleared for delivery. The approval lot again undergoes HVI tests.

Once cleared these lots are accepted for manufacturing.

Functions:-

Verification of properties

Finding suppliers

Import of cotton

Purchase of raw materials

Waste management

Procedures

1. Verification of Properties

Successful processing of cotton depends on appropriate management during and after

harvest of those highly variable fiber properties that have been shown to affect finished

product quality manufacturing efficiency. If fiber-blending specific end uses and profitability,

production managers in textile mills need accurate and effective descriptive and predicative

quantitative measures of both the means and ranges of these highly variable fiber properties.

The components of cotton fiber quality are usually defined as those properties

reported for every bale which currently include length, length uniformly index, strength,

micron ire, and yellowness (+b), and trash content, all quantified by the High Volume

Instrument Line (HVI).

2. Finding Suppliers

Cotton is produced from different cotton producing states of India i.e., Gujarat,

Maharashtra, Karnataka, Andhra Pradesh, Tamil Nadu, Punjab, Haryana, etc. The various

varieties of Indian cotton are J34, S6-S4, Y-1, JAYADHAR, MECH, BRAHMA, DCH,

DIGVIJAY, H-4 etc. A part from these American supima giza42, Giza70, Giza77, Giza76,

Giza85, and Giza80 which are imported from America, Egypt and Sudan are used for

processing cotton yarns.

Earlier the company used to depend solely on Indian cotton, but the quality was not

up to the mark as it was contaminated with foreign particles. Later imported cotton was used

and now 90% of American cotton is used.

3. Import of Cotton

The company purchase more than 40% cotton raw materials from foreign countries

like America and Egypt. The main reason or import is better quality and productivity. Raw

material used for production is Suvin. One of the finest extra-long staple cottons available in

the world. Suvin cotton is superior in all aspects like fineness Staple length, silkiness, and

luster. The exclusive cotton of India origin is a luxury and its products are considered

premium and niche worldwide.

a) Supima

It is a superior, extra-long staple variety of cotton growth in America. Yarns produced

from Supima cotton are used to produce softer and more lustrous fabrics. Supimarepresent

highest quality in cotton yarns. GTN is the first spinning company in India to obtain a

Supima trademark license.

b) Egypt Giza

Giza cotton is a true mark of excellence with extremely superior quality in the extra-

long staple and long staple variety. These varieties are also renowned for their excellent

fitness and feel.

c) Indian Cotton

GTN use high quality verity of MCUS and Shanker cotton known for their superiority

in terms of fitness and goodness.

d) Australian Cotton

Medium staple contamination free, varieties of cotton and one of the best grades of

raw materials from among the best suppliers.

e) American sjv Acala

GTN was the first Indian spinner to be given a cotton USA license. Medium staple

contamination free, varieties of cotton and one of the best grades of raw materials from

among the best suppliers.

4. Purchase of Raw Materials

The purchase is based on three production plan made the departments according to the

forecasted requirements for production. The production plan does not allow shortage as it can

lead to heavy loss. Random samples of purchased cotton, is tested in the quality lab for fiber

quality specification. Test for fibre fitness is conducted as spinning larger number of fitness

fibre together results in stronger, more uniform yarn than if they hard be made up of fewer,

thicker fibers. The 4 ultimate acceptance tests for fibre colour as well as for finished yarns

and fabrics is the human eye. Therefore instrumental colour measurement must be correlated

closely with visual judgment.

5. Waste Management

Long fibres are best suited for yarn production. Short fibre content is defined as the

percentage of fiber less than 12.7mm the short fibers obtained as waste from processing is

packed and sold.

Key factors for success

Procurement of the right quality at right time.

Ability to procure large quantum of raw material and keep long time stock which

ensures consistent quality.

The GTN has an associated concern trading in cotton for the last 40 years which gives

it added advantage.

Organization Structure- Raw Material Department

8.2 QUALITY ASSURANCE DEPARTMENT

Introduction

This department is responsible for the quality assurance of raw materials, quality

assurance in process and quality of finished goods. The department is also responsible for

implementation of research and development quality improvement activities in the

organization and also tries to establish and maintain procedure for inspection, calibration of

measuring and testing equipment.

The department is situated inside the factory with state- of art laboratory for testing

the quality of cotton yarn at various stages of production and the finished goods. Some of the

machines used in the quality assurance department and USER Spin Lab excusing these

machines, testing is done for the raw materials and finished goods. GTN Textiles Ltd., Aluva

Officer

MANAGER

Senior Officer

Supervisors

Workers Workers

Supervisors

is ISO 9002 for quality assures in production, installation and servicing. The company has a

quality manual that makes commitments to the customers that they shall comply with all their

requirements for improvement in all the activities to serve them.

Quality assurance department is the department where the quality is checked and there

are various parameters that affect the quality of cotton fiber, some of them are length,

evenness, fiber strength. These parameters are tested in the quality assurance lab.

Quality Policy

GTN textiles would ensure manufacturing and marketing of cotton yarn by complying

with:

GTN Textiles ltd. Would achieve the highest level of customer satisfaction by

meeting their stated and perceived requirements manufacturing consistency and

timely delivery.

GTN 41 endeavours continual up gradation of product quality and technology

supported by R &D efforts in a cost effective manner.

To meet changing global demands and stay headed in competition GTN would adapt/

innovate methods in its manufacturing activities.

GTN would inculcate a sense of quality awareness at all levels by using appropriate

training and motivation techniques.

GTN would aim at preserving the environmental conditions y adopting eco- friendly

measures in its manufacturing and other activities.

The man activities of QAD are:

Raw material selection and stock

Bale management

Online process monitoring of production and quality.

100% zero/ quantum clearer

UV lamp testing

Duties and responsibilities

Senior Manager: Takes care of the overall administration of the quality assurance

department.

s.

Organization Structure- Quality Assurance Department

Senior Manger

Manager

Assistant Manager

Supervisors

Assistant Manager

Supervisors

Operators

Operators

8.3 PRODUCTION DEPARTMENT

Introduction

Production department is the most important part of this organization. Here

production is carried out in required quality at minimum cost. The production department in

coordination with the marketing divisions does managing and controlling of the production

process. Customer requirement in terms of quality, quantity, delivery, packaging are obtained

an analyzed as per the sales contract from the export division.

Production capacity

GTN have 165000 Spindles Capacity, consisting of 30000 Compact spindles and

135000 Ring Spinning in addition process like twisting Gassing, Dye package winding,

Knitting etc. in- house in order to server different customers requirements effectively.

Product

The reason for success in this competitive environment I that all the products are

customized and are produced on a made to order bases

GTNs Product Range

GTN group manufacture 100% cotton yarn/ knitted fabrics:

Yarn of count 30s to 140s

Two for one twisted & Ring double

Knitting & Weaving yarn

Gassed yarn

Gassed and processed knitted yarn

Knitted garments

Main counts

Over 90% of products are fine and superfine 100% yarns carded and combed with

counts ranging from 30s to 140s, both single and multi-fold, as well as gassed, suitable for

knitting and weaving.

Flow chart of production process

Production process

The production process is mainly going through five stages:

1) Bale opening: In this process cotton are opened, foreign matters are segregated and

processed in the bale- opening machine. From this process, cotton is subject to

maximum.

2) Mixing: Here different varieties of cotton are blended in define proportion. The

objective of blending different varieties of cotton is to spin the required yarn

economically. Unimix is the machine that is used to mix the cotton and to convert in

to chute.

Stack mixing is the best way of doing the mixing compared to using automatic bale

openers which picks up the material from 40-70 bales depending on the length of the

machine and bale size, provided stack mixing is done perfectly. Improper stack

Packaging

Bale Opening Mixing Blow Room

Drawing Combing Carding

Ring Spinning Automatic Cone

Winding

Doubling

Conditional Yarn Singeing Waxing

mixing will lead to shade variation problem, stack mixing with bale opener takes care

of short term blending and two mixers in series take care of long term blending.

3) Blow Room: In this, the mixed cotton is opened, cleaned and made in to a continuous

sheet in the wound from. This product is called Blow Room Lap.

4) Carding: In carding operation, the Blow Room Lap material is cleaned, fibers are

made parallel and then wastes are extracted from fibers and assemble in to a

continuous stand. This stand is called card Sliver. This silver are coiled and stored in

cans. There are two rules of carding.

The fibre must enter the carding machine, be efficiently carded and taken from it in as

little time as possible.

The fiber must be under supervision from entry to exit.

The purpose of carding:-

To open the flocks individual fibers.

Cleaning or elimination of impurities.

Elimination of dust.

Elimination of short fibers

Fiber blending

Fiber orientation or alignment

Sliver formation

5) Combing: The carded sliver is then prepared for combing in Sliver Lap and Ribbon

Lap machines. The product thus prepared is called Ribbon Lap. This Ribbon Lap are

then fed to comber machine. In comber, the short fibers and minute impurities are

removed and the fibers are made parallel and assembled in fro of sliver.

6) Drawing: In drawing process, s definite number of combed sliver is doubled and

drawn together to make the resulting sliver more even and parallelized fibers. The

sliver is stored in cans in coiled form.

7) Simplex: The object of simples or speed frame process is to attenuate the drawn sliver

into a finer strand, twist and wind it on a plastic tube this product is called Roving.

8) Spinning: In ring spinning process the roving is attenuated with the help of drafting

system and the drafted fibers strand is twisted and wound on a tube. The twisting and

winding operations are performed with the help of Ring Traveler and spindle. The

yarn count s also set at this stage. The arrangement is being progress to sin the latest

form of compact yarn by the employment of Elite and Com4 machines.

9) Automatic Cone Winding: In the automatic cone winding process, yarn from the

ring frame cops passed through electronic yarn cleaners to detect and remove

objectionable fault in the yarn. The yarn ends are joined with the splicing provision. A

definite length of yarn will be wounded on ones. Waxing can also be done in this

process.

10) Doubling: In doubling process, two or more single yarns are twisted together. This

consists of two processors- assembly winding and twisting. In assembly winding the

required number of single yarns of definite length is wound in parallel to a single

package. Twisting may be carried out either with Ring Doubling machine or two- for

one twister.

11) Conventional winding: In conventional winding a definite length yarn is wounded on

ones. During winding yarn is passed through electronic yarn cleaner to detect and

remove objectionable yarn fault waxing also can be done in this process.

12) Singeing: In singeing process yarn is passed through a flame at high speed to remove

the protruding fibres. The object of singeing is to make the yarn lustrous, which can

be used for some special end uses. The flame and speed of the should be constant as

ay change can cause damage to the yarn.

13) Conditional yarn: Apart from gassed yarn conditional yarn is also produced.

According to the customer requirement the yarn is conditioned in a conditioning

machine. The yarn conditioned for half n hour in specific temperature and moisture.

The time limit is imported as over conditioning may lead to absorption of moisture by

the yarn and hence may result in poor quality.

14) Precision Winding:- In this process yarn is passed through a special type of tension

assembly to get the package more softly so as to get the dye package directly. The

softness can be increased or decreased as per the requirement.

Organization structure- Production Department

8.4STORES DEPARTMENT

Introduction

Stores department is the department whose main service is maintaining several

types of inventories. Also it functions as maintenance of materials, spare parts and general

store as required. Purchase is made with reputed companies who offer good quality of

products at reasonable cost.

Functions:

Storing of purchased raw material

Assistant

Manager

Production -1

Officers

Supervisors

Workers

Senior Manager

Manager

Assistant

Manager

Production -2

Assistant

Manager

Production -3

Assistant

Manager

Production -4

Officers Officers Officers

Supervisors Supervisors Supervisors

Workers

Workers

Workers

Issuing reorder level

Material inspection

Listing and selling of scrap

Procedure

Storing of raw material

It is the duty of the stores department to store the purchased raw material. All the

purchase are made online. SAP is the software used for this purpose. The purchases are made

through quotations for a period of six months. Quotations are received from dealers who

provide maximum discount.

Mainly 3 type of material are purchased and stored.

Mill stores: this inculds spear parts, bearings, consumable goods etc.

Packing goods: These include material which is used for packing.

Utility item: This include engineering items, electric items etc.

All purchases are made within the limit of 8-12 days and on the same day itself it is fed into

the computer.

Issuing Re Order Level

All the purchase and issue of raw materials are entered in the computer and computer will

show the re order level.

First release

The requirement of each department is listed out by the respective department staff.

This list is then sent to the department head.

Second release

The list prepared b the department is approved by the department head and then sent

to the vice- chairman.

Order Placement

After the second release, the requirement list is sent to the stores department, where

the order is placed. The description and quality of the product is specified in the order

form.

Order release

The store manager places the order with the suppliers and is knows as order release.

The re order time and lead time is estimated with the help of past record. Tax free

goods are specified

Order acceptance

The order acceptance is the receipt of goods ordered. The quality of the item is

checked by the stores department.

Material Inspection

The quality of the items delivered by the suppliers is inspected by the investigation in the

quality assurance department. Then the materaisl are issued to the respective departments.

The purchase entry is also made during this time. The items received by the stores department

are stocked in the stores.

Monthly reports are generated. Consumption reports are generated to find out the

consumption rate. The reports are alsso used to tally the physical stock with consumption.

Listing and selling of scrap

The scrap materials are listed out once in every six months. A call for quotation is made to

find the best price that can be obtained for scarp. ABC analysis is used for regular items,

which directly affect the quality like packaging materials and machinery spares.

Organization structure- stores Department

Stores Manager

Supervisor

Worker

8.5 MAINTENANCE DEPARTMENT

Introduction

GTN being a manufacturing concern, the number of equipment and machines are

involved directly with production process and hence the effective functioning of maintenance

department is inevitable.

The objective of maintenance department includes minimizing long run

maintenance cost, minimizing breakdowns to keep operation stable, providing reliable

conditions for equipment to perform at specified technical conditions through service, repairs

replacement and modifications. They conduct the maintenance program at tervals intended to

reduce the like hood of equipment conditions falling below a required level of acceptability

and also modernization works are done by the department.

In order to assist maintenance department, computer are provided with the details

and reminder dates of the maintenance of a machine in a department and details of its

services and replacement. All the machines are cleaned periodically and their functioning is

checked in order to assure that the machines are working smoothly with no troubles. Other

than daily checks, weekly, monthly or yearly checks are carried out. A time interval is set for

all machines. A monthly schedule is prepared to see which machine is to be attended first and

then at the time the concerned foreman will attend the machine.

GTN Textiles being a manufacture of fine and super fine quality cotton threads,

modernization has become the inevitable part of the production. Replacement of machines

and machine parts also is done by this department. Good quality machines are selected

according to the count rate.

Functions:

Minimizing maintenance cost

Minimizing breakdowns of machines.

Replacement and modification of machine.

Replacement and modification of machines

Providing safer working condition.

Ensure machine are working properly

The maintenance operations are divided into two.

Preventive Maintenance

The manger and other concerned officers will fix the life of all machines spare

parts and will replace the particular spare part at the end of the period. All the machines

used in the company 9Indian as well as imported ones) are under the annual maintenance

contract. So the serious mechanical problems are rectified by the company, who supplied

the machines.

Breakdown maintenance

If any faults occur at any part of the machine, the assigned person from the

maintenance department will check out the problem repair the part.

Levels of maintenance

Mechanical Maintenance

To ensure the protection is carried out in a controlled condition.

Electrical maintenance

Ensure that process equipment or machinery are maintained and fit for the purpose.

Organization Structure- Maintenance Department

8.6 IT MANAGEMENT INFORMATION SYSTEM DEPARTMENT

Introduction

About 90% of the organization is computerized. The main network is the SAP/

ERP implemented within the raw material finance, export and stores department. Other

applications like Payroll software in Fox Pro and production Control in Visual Basic are

implemented in the organization.

Senior Manager

Manager

Assistant Manager

(Mechanical

Maintenance)

Assistant Manager

(Mechanical

Maintenance)

Supervisors Supervisors

Operators Operators

Functions:

Maintenance: The system has to be maintained and updated according to the increasing

needs of the organization.

Process Monitoring: The production process is completely monitored by the department.

The Payroll Software is handled by the personnel department. The wage and salary

calculation is done using this software. The organization provided intranet facilities for ease

of access of information. The intranet is accessible by the top level management. The main

server is at Cochin through which the transactions are communicated. The information

regarding the transactions are shared and passed to the organization through routers.

Organization Structure: Management Information System Department

8.7FINANCE DEPARTMENT

Introduction

This department has to raise necessary funds, mange them, prepare finance budgets

and administer its working capital. The department functions on public issue of capital,

maintains records for helping the finance manager access the appropriateness of capital

structure. It provides data for the preparation of budget and various financial statements. The

accounting function of the department includes the preparation of trial balance on a yearly

basis. They also prepare managerial reports regarding expenditure of travelling, postal

telephone and courier transactions.

Manager

System Analyst System

Administrator

Programmers

Functions of Finance Department

The company maintains a clear and perfect accounting system. The main activity

of the finance department is working capital management. Preparation of fund flow

statement, cash flow statement, balance sheet, profit and loss accounts are also the activities

of finance department. Secretarial work relating to board comes under the finance

department. Most the activities carried out by the finance department are preparing to long

term and short term requirement of the operation, closing purchase bill, maintaining the

account contractors, subcontractors, income tax, deduction, salary discrepancy, dealing with

the financial institutions with import and exports.

Maintaining Books of Accounts like,

a. Purchase Records

The finance department of the company keeps the account of raw material and

accounting entries are made in the books of accounts of the company. The department

analyses the details of purchase afterwards.

b. Salary accounts

The main function of the department is preparation and disbursement of salary of

officers, office staff and workers. The department keeps salary register pertaining to each of

the above said person and facilities charges in salary due to granting of annul increment and

deduction from the salary. The department is maintaining sub ledgers for deduction made in

the salary such as PF, insurance premium advance and income tax. Another important

function is computation of income tax.

c. Sales and Revenue Accounts

The department functions on calculation of paying sales tax and central excise duty

to the concerned government every year, provision for current tax is made on the basis

estimated taxable income for the current accounting year in accordance with income tax

1961.

d. Cash and bank accounts

The department does all the matters relating to the day to day cash transactions.

They receive and make payment for purchase and sales.

e. Cost sheet

Annual budget and cost sheet is prepared at the outset of every year and the

company is following Process costing method. It helps the company to ascertain the cost of a

product at each stage of the production, i.e., cost at each process through which the raw

cotton passes through for the production of fine years. The total incurred at each stage of

production is carried out to ascertain the final cost. The pricing policy adopted by GTN

textiles is Cost plus- pricing and hence a certain percentage of the profit is added to the final

cost incurred.

f. Depreciation

Department has been provided at the rates and in the manner prescribed in

Schedule XIV to the Companies act 1956. Plant and machinery and electrical installation

have been, on technical assessment, considered as continuous process.

Accounting system

The financial statements are prepared on historical cost and convention.

All fixed assets are states at cot adjusted by revaluation in case of certain land,

building, land and machinery and electrical installation, less accumulated

depreciation.

Long term investments are stated at cost less provision

Values of fixed assets are devalued by technicians

Valuation of investment is done at cost.

Depreciation is done as per the companys act 1956.

Management of Payables and Receivables:

As 90% of the sales are as exports, it takes place with the support of letter of credit

or bank guarantee. Therefore, management of payables and receivables has not been a

problem for the company. In this total amount, 50% of the total amount is written off as bad

depts. Likewise 80% of the raw cotton purchased is imported. So L/C is made us here too.

Local purchase is made by the company for a credit period of 30 to 90 days. The company

claims to have an efficient management of both payables as well as receivables.

Accounting Policies:

Basis of presentation:

The financial statements have been prepared to comply with the mandatory

Accounting Standards issued by the Institute of Charted Accountants of India and the

relevant provisions of the Companys Act 1956. The financial statements have been prepared

under the historical cost convention, 0 the basis of a going concern, on accrual basis.

Use of Estimates:

The preparation of financial statements requires Management to make estimates and

assumptions that affect the reported amounts of assets and liabilities and the disclosure of

contingent liabilities on the de of financial statements and reported amounts of revenue and

expense of that year. Actual result could differ from these estimates. Any revision accounting

estimates is recognized prospectively in current and future periods.

Fixed assets:

i. All fixed assets are stated at cost less accumulated depreciation. Expenditure during

construction period in respect of new project/ expansion is allotted to the respective

fixed assets on their being ready for commercial use. Also refer Policy G and J below.

ii. Impairment of assets the company assesses at each Balance sheet data whether there is

any indication that any asset may be impaired. If any such indication exists, the

carrying value of such assets is reduced to recoverable amount and the impairment

loss is charged to Profit and Loss account. If at the Balance sheet data there is any

deduction thats previously assessed impairment loss on longer exists, then such loss

is reversed and the asset is restated to that effect.

Investments:

Long term investments are stated at cost les provision, if any, for other than temporary

diminution in the value of investments.

Inventories:

Inventories are valued at lower of cost or net reliable value. Cost of Raw Materials is

computed by using Specific identification method and for other inventories Weighted

Average method. The cost includes costs of purchase, cost of convention and other costs

incurred in bringing the inventories to their present location and condition.

Sales:

Sales are recognized as and when risks and rewards of ownership are passed on to the

buyer and ultimate realization of price is reasonable certain. Export sales are inclusive of

deemed exports while local sales a re net of sales Tax/ VAT.

Borrowing Cost:

Borrowing Cost attributable to acquisition and construction of qualifying assets are

capitalized as a part of the cost of such asset up to the date when such asset is ready for its

intended use. Other borrowing costs are charged to profit and Loss Account.

Employee benefit:

Short Term employee benefits including accrued liability for leave Encashment

(other than termination benefits) which are payable within 12 months after the end of the

period in which the employee render service are paid/ provided during the year as per the

Rules of the company.

Foreign currency transactions:

Transactions in foreign currency are recorded at the rate of exchange in force at the

date of transactions. Foreign currency assets and liabilities are stated at the rate of exchange

prevailing at the year- end and resultant gains/ losses are recognized over the life of the

contacts. In accordance, with the AS-11 (revised 2003) the exchange difference arising on the

contacts/ transactions enters into on or after 01-04-2004 on the settlement of monetary items

or on reporting monetary items at rates different from those at which they were initially

recorded during the period, or reported in previous financial statements, is recognized as

income or expenses in the period in which they arise.

Taxation:

Income tax expense comprises current tax and fringe benefit tax (i.e. amount of tax

for the period determined in accordance with the Income Tax Law) and deferred tax charge or

credit reflecting the tax effects of timing difference between accounting income and taxable

income for the year). Deferred tax charge or credit and the corresponding deferred tax

liabilities or assets are recognized using the tax rates that have been enacted or substantively

enacted by the balance sheet date. Deferred tax assets are recognized only if there is a virtual

certainly of realization of such assets. Deferred tax assets are reviewedat each balance sheet

date and written up to reflect the amount that is reasonably I virtually certain as the case may

be to be realized. Tax credit is recognized in respect of Minimum Alternative Tax (MAT) as

per the provisions of section IISJAA of the Income Tax Act, 1961 based on evidence that the

company will pay normal income tax within the statutory time frame and is reviewed at each

balance sheet date.

Costing and pricing:

As GTN textiles Limited is a manufacturing concern and involves a large number of

processes, process costing method is followed. It helps the company ascertain the cost of a

product at each stage of production, i.e. cost at each process through which the row cotton

passes through for the production of fine yarn. The total cost incurred at the each stage of

production is carried out to ascertain the final cost. The pricing method adopted by the GTN

Textile is cost- plus- pricing and hence a certain percentage of the profit is added to the final

cost incurred.

Budget and budgetary control:

Budgets are prepared by this department on a quarterly basis and based in this the

annual budgets are prepared. The budgets can be sales budget, production budget, expenses

budget and the total budget. At the month end, a comparison is made between budgets and

actual right from the raw cotton procurement till the last process. The reasons for variations

(if any) will be found out.

Organization structure- finance Department

8.8 HUMAN RESOURCE DEPARTMENT

Introduction

Personnel Department plays a crucial role in the management of the company. The

department try to create and utilize an able and motivated workforce to accomplish the

organizational goal, and try to satisfy individual and group needs by providing adequate and

equitable wages and incentives, employee, benefit and social security and measures for

challenging work prestige, recognition security, status etc.

The personal department is responsible for recruitment, selection, placemen training

performance, appraisal, promotion and separation. This department is headed by DGM

Manager

Assistant Manager

Accounting

Assistant Manager

Taxation

Assistant

Manager

Costing

Officers Officers Officers

(industrial relations). He is in charge of implementation systematic recruitment procedures

for providing facility for the overall development and motivation of all the employees. He is

also in charge of ensuring safety aspect in the mill and maintaining cordials industrial relation

with the workers. The categories of workers employees in GTN are permanent and

temporary. The recruitment, employment, leave disciplinary actions, retirement etc. are done

as per the standing order. This department is also responsible for training, performance

appraisal compensation and separation.

Work staffs

The company works round the clock in three shifts

1

st

shift : 8 am- 4 pm

2

nd

shift : 4pm- 12 pm

3

rd

shift : 12pm- 8am

Staff shift : 9 am- 5.30 pm

Employees : 721

Staff : 109

For each shift there would be 3 supervisors: 1 shift in charge and supervisors.

Functions of personal department

Recruitment and selection

Induction training procedure

Training

Evaluation

Performance appraisal

Wage and salary Administration

Recruitment and selection

GTN textile Ltd recruits its manpower resources through recruitment agencies and

advertisement in leading newspapers. The other sources are form reference service and

relatives of employees and from apprentices. Recruitment is done b the G.M. of personnel

and industrial Relation Department. At GTN textile selection is done through tests and

interview.

Induction Training Procedure

Technical and non technical fresh recruits are given general exposure to the overall

activities of the organization during initial days. There after they are given in depth training

in assigned areas of work followed by on the job training.

Work men fresh recruits are given general exposure to the overall activities of the

organization. They are on the job training under the supervision of the jobber/ mastery,

guided by supervisors or deputy Manger (training).

Training

Training is given to all workers for developing their skills and proficiency in work.

The probationary period for also workers and office staff is six months. A formal induction

training program is provided for fresh recruits as per the program given in the induction

training manual. Also training is given to each worker when a new machine is installed

respective to their department.

Introduction Program

Induction Report

Training

On the

Job

Off the

Job

Evaluation

On completion of training an evaluation regarding effectiveness of training received is

sought from the department concerned.

Performance Appraisal

Performance appraisal is systematic evaluation of the capacity for development. It is

usually done by the supervisors at GTN. Check list method is used for personnel evaluation.

It helps the superior or the manager to judge the honesty, sincerity, loyalty and responsibility

of the employees. It is usually done in the duration of six months. The performance of each of

the workers, their strengths, merits, weakness etc. is discussed in detail with them and these

are considered for their promotion. However at the managerial level, the through maintains

the performance appraisal system, does not discuss with the officers. It is not carried out in a

transparent manner.

Wage and Salary Administration

GTN follows time rate wage system. For this purpose the attendance records are

maintained strictly also there is card punching system for recording entry and exit of the

employees and workers. The remuneration for the work of service rented by the employees is

paid in the form of salaries, wages or fringe benefit. Wages include both monetary benefits

and non monetary benefits. The employees pay/ wage includes basic pay, DT, TA, HRA,

LTC, PF and ESI for 26 days. A certain percentage of annual earning is distributed as bonus/

of the total pay 12 % is for PF and 1.75% is for ESI. Over time work is also paid at the rate of

1.75 times that of a normal days pay. There is no PF and ESI for over time and holiday

work.

Employee welfare schemes

The company provides all the statutory welfare measure as per the factorys act 1948.

There are general measures and the company also administers activities that come under non-

statutory items.

Employee co-operative society

There is an employee co-operative consumer stores to cater the requirement of

provisions stationary and textile articles. They also arrange for supple of household

appliances like TV, Two wheeler, sewing machines et coin installment basis

Employee credit society

GTN Textile employees credit society advanced loans to the employees ranging from

Rs. 2000/- to 25000/- for various purposes on a reduced rate of interest. They also run

recurring deposit schemes for the employees.

Silver Jubilee educational Assistance

Under the sliver jubilee educational assistance scheme, employees can avail benefits

up to 2 children towards their educational expenses, it ranges form Rs. 600/- up to VII std.

student, RS. 2500/- to medical/ engineering students per year

Marriage assistance

Interest free loans of Rs. 10000/- are being given to the employees in the event of

marriage of their daughter.

Insurance linked gratuity scheme

The company has adopted insurance liked gratuity scheme for the benefit of the

employees. Under the scheme, in case of death of an employee, his dependents will be

eligible to receive full gratuity for the total calculated period of service including the

balance of years of service after death.

Holidays

Each employee can avail 13 paid holidays in a calculating year. List of holidays will

be notified each year.

Canteen

A subsidized canteen managed by the employee representatives is taken care of

catering needs of the employees. Meals, snacks, coffee/ tea are available in the canteen

during the prescribed timings.

Quality Circles

Quality circle activities are being organized in Aluva Unit with the effective

participation of the employees.

Safety

Safety, housekeeping activities are arrived out on a continuous basis. A part from the

statutory compliance; a safety committee is effectively working.

GTN textiles employee welfare fund

There is fund constituted for the welfare of the employees. There are different benefits

like death benefit, retirement benefit, disablement benefit, loans assistance, etc. contemplated

under the scheme

Assistance for the handicapped children

There is a scheme to assist the handicapped children of employees; this includes

supply of artificial limbs, aids or any other assistance to such cases.

Blood Donor Group

Blood Group of almost all employees has been ascertained. In case of emergency,

employees will come forward to donate blood.

Suggestion scheme

The company conducts suggestion scheme in the areas of productivity, housekeeping,

quality, safety, etc. employees who submit suggestions are being properly rewarded

Attendance award

To recognize the employees to attend word regularly special prices given every year.

Membership in professional bodies

The company has membership in various professional bodies viz. SIMA, ATIRA,

SASMIRA, SITRA, Kerala state productivity Council Etc.

Subscription to News Paper and Journals

Various News papers and journals are being subscribed for the benefit of employees

Anti addiction program

The company provides all assistance to employees who wish to come out form their

addiction habit.

Worker Education through worker

In association with central board of workers education, employees are given classes in

batches for a period of 2-3 months on various subjects. There are trained worker teacher who

take such classes.

Standing orders

There is an approved standing order, which regulates the conditions of employment

Excursion tours

Excursion tours are arranged regularly for the staff member and for the participation

the workers education classes

Twenty years service award

As a token of appreciation for the continuous service put in, the employees are given

memento after completion of 20 years of service.

Family planning program

Encouragement like special level of finance incentive is given to employees in the field of

family planning activities.

Conveyance facility

Subsidized conveyance facility is provided between Alwaye and factory for the

second and third shifts.

Social Activities

The company take care of the need of the local people with due consideration. This

includes construction of building ,waiting shed ,donation to various charitable organization

etc. Steps are taken for pollution control.

First Aid Facilities

The company has direct touch towards he nearby hospital the company can use the

service of the hospital in case of emergence.

Welfare office

Welfare activities are under the supervision of the welfare officer MR. Wilson Joseph

appointed by the company.

Health and safety

There is a safety committee for looking after the safety of the workers drinking water

drinking water facilities are priced different spots inside the company.

Employee state insurance scheme

ESI scheme is unique multidimensional self financing social security scheme in which

every contributor is a benefactor and beneficiary. This integrated scheme of health insurance

prides comprehensive medical cover and cash benefit in contingencies of sickness, maternity,

disablement and health.

Trade unions

There are four registered and one unregistered union in the organization

INTUC (Alwaye Textiles Employee Association)

AITUC (Alwaye Textiles Workers Union)

CITU (AlwayeMekhala District Textiles Labour Union)

BMS (BharathiyaMasdoorSangam)

The unregistered union is GTN Workers (Jobbers) Association

Organization structure- personnel department

8.9 EXPORT AND MARKETING DEPARTMENT

Introduction

Export department is serving as a link between the customers. The main duties of the

department includes sales enquiry conformation, sales contract, preparation of work order

which in turn aids the preparation of production plan sending samples and finally shipment.

Thus the export department does not have separate marketing department. Once the lot is

ready the production department makes arrangements for lot dispatch. The goods are shipped

in containers, which undergo house stuffing or port stuffing; the cartons are covered with

Hessian Cloth and loaded in to trucks by experienced personnel under the supervision of the

factory trained expert more over the truck is covered with water proof tarpaulins to protect

GM Personnel

Security Officer Personnel Officer Manager Training

Security Guards Junior Officer

Time Keeper Assistant

the cartons while transpiration. The containers used for transportation is of international

standards, which are leased and provided to shipping line.

The customer of the company include consumer who are directly use the product for

further processing and trader who sell it to other customers. The company promotion efforts

include MDs visit to foreign countries and participation in Textile exhibition abroad. Their

major customers are Italy, japan, China, Australia, Spain and UK etc.

The payments of almost of all the transactions are through the letter of credit system.

The export department office is at Cochin where the transaction re carried out. The

information regarding the transaction are shared and passed to the organization through

routers. The main server of the company is at Cochin.

India continues to be dominant supplier of cotton yarn in the world. However,

Pakistanis closely following India and it may outpace India because of its advantageous

factors like favourable exchange rate, cheaper power tariff and lower wages. Of late, Pakistan

has started importing extra long staple cottons for manufacture of finer counts of yarn for

exports. Therefore, India will have to become more cost- effective to withstand Pakistani

competition in this segment. Chinas imports of cotton yarn are raising Cotton. India is now

poised to become a prominent exporter of raw cotton and cotton yarn.

Export procedure

The export transaction of GTN textiles ltd starts with the receipt of an intent or order

from the foreign importer. After obtaining the license and complying with the exchange

regulations, they proceed to assemble the product as per the terms of the indent. Once the lot

is ready, the production department makes necessary arrangement for lot dispatch and

arrange the secure shipping space on convenient terms and obtain shipping order after

complying with the customer formalities, i.e. paying customs duty and obtaining customs

export pass the company goes for bill or lading certificate of origin and insurance policy.

Finally they prepare invoice showing the price, quantity and description of the product and

negotiates with the bank with necessary documents for securing payment under letter of

credit agreement. The procedure is:

Export procedure chart

The GTN textiles ltd has a well established and managed export department under the

control of well qualified professionals. Its strict delivery schedules, consistent quality and

after sales service had given the company an important position in the textile export area.

Even though there is no separate marketing department for the company the marketing

activities of the company are performed by the export department.

Marketing

Receipt of Indent /Order

Production, Packing &

Forwarding of Goods

Secure Shipping Order

Customer Formalities

Obtain B/L, Certificate

of Origin & Insurance

Negotiates with Bank for

Payment L/C

GTN textiles ltd continues to maintain its leadership in exports of fine and superfine-

combed cotton compact yarns. It has export to cover 25 countries across the world selling

high value and high quality products to the niche market. With a substantially large export

market and a growing domestic presence, GTN certainly has its quality control measure and

production standards in place. Not surprisingly the company has been the recipient of

Texprocil Gold award excellence in exporting for 18 years.

The company has been constantly focusing its efforts to carter to high priced end user

in sophisticated markets. Apart from predominant exports of cotton yarn to Japan and Italys

companys yarn has also been well received in other countries viz. South Korea, China, Hong

Kong, USA, Austria, Belgium, Israel, Australia, Taiwan, Malaysia, Mauritius among others.

The company enjoys excellent relations with all its overseas customers, which have been

assiduously quality and providing prompt after sales service. For the past few years, the

company has been aggressively marketing its products to high end users in the domestic

market who have set up downstream projects for export of high value fabrics, made- ups and

garments.

The tie up with Japan has not only helped in penetrating the Japanese market, but also

in other parts of the o\world where ITOCHU, the marketing conglomerate has officers. The

connection has helped the company is sewing up business opportunities.

Supplier to Higher and market

Used for- shirting, stretch fabrics, voiles, velvets, velour, fine bed liner, fashion

knitwear, lingerie

Worldwide customer list- mark & spencer, gap, Benetton, Victorias secret, Ann

Taylor

The payment of almost all the transaction is through the letter of credit of credit

system. The export department office at Cochin, where the transactions are shared and passed

o the organization through routers. The main server of company is at Cochin.

Major markets

Table

Sl No Markets % Share

1. Japan 36

2. Italy 15

3. Korea 12

4. Israel 10

5. China 6

6. Hong Kong 1

7. Taiwan 1

8. Malaysia 4

9. UK 1

10. Portugal 2

11 Germany 1

12 Austria 2

13. Australia 2

14. Mauritus 1

15 Chile 2

16 SriLanka 5

Organization structure export department

General Manager

(Export)

Manager (Export)

Deputy Manager

(Export)

Assistant Manager

(Export)

Officers

8.10 SECURITY DEPARTMENT

Through security is a part of the personnel department, the functions performed by

them are above that of just as guard. The main functions of security department are:

Security keeping

Fire finding

First- aid

The company has only one gate through which entry and exit of men and material is

permitted. The workers should compulsorily punch during entry and exit. Use of rugs and

smoking is strictly prohibited inside the company. Breath analysers are used for this purpose.

Vehicles are also checked during entry and exit for inflammable materials

There are 173 free extinguishers placed at various places inside the company. Apart

from this, the guards are trained for fire finding.

Five guards are trained for administering first- aid in case of any accidents. A first aid

kit is available in the security officers room

There is one security officer, one head guard and 12 guards. There will be four guards

in each shift. During the night shift to ensure that the guards are going for patrolling an Anglo

Swiss watch is used. This is placed at different laces outside the company. The time of

patrolling is recorded using this, at times of accidents; immediate action is taken by the

security officer.

8.11 RESEARCH AND DEVELOPMENT DEPARTMENT

The research and development department of GTN Textiles Ltd is well equipped with

latest testing and measuring equipment. The R&D Manger is the Head of the Department.

The supervisors follow him the technicians assist them.

Product design

One way to build the image of the product is done through its design. A distinctive

design may be the only feature that significant differentiates the product many firms and done

product design by considerable glamour and general promotional appeal in product design

and designers name. In the case of GTN product design is done as operate requirements of

the customers.

Product development

Organizations are increasing by recognizing the necessity and advantage of regularly

developing new products and services. Product development must be done because of

declining their product sale the department head should control it.

Duties research and development manner

The person who manages the R&D Department has the role to translating customers

quality requirements in to achievable specification and to continuously improve product

quality and reliability based n information feedback on product performance.

The responsibilities of R&D Manager are:-

Distribute the various stage wise works among the staff in the department and ensure

timely completion.

Regularly oversee the works carried out by the staff and guide them to achieve the

desired goals.

Clear the techniques doubts arising during the designing of requirement by interacting