Professional Documents

Culture Documents

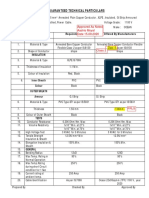

GRN Entry: Receipt Type Reference Dococument Desc

Uploaded by

api-194893860 ratings0% found this document useful (0 votes)

52 views5 pagesThe document describes various types of goods receipt and dispatch entries in a company. It includes the receipt/dispatch type and the associated reference documents for each type. It also lists various shapes and their fixed and variable parameters. The parameters include dimensions, thickness, specific gravity. It provides specific gravity values for different metals. It further provides conversion formulas and factors to calculate weight or quantity for different shapes like hex bar, square bar, round bar, flats, plate, forging and pipe.

Original Description:

Original Title

DOC

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes various types of goods receipt and dispatch entries in a company. It includes the receipt/dispatch type and the associated reference documents for each type. It also lists various shapes and their fixed and variable parameters. The parameters include dimensions, thickness, specific gravity. It provides specific gravity values for different metals. It further provides conversion formulas and factors to calculate weight or quantity for different shapes like hex bar, square bar, round bar, flats, plate, forging and pipe.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

52 views5 pagesGRN Entry: Receipt Type Reference Dococument Desc

Uploaded by

api-19489386The document describes various types of goods receipt and dispatch entries in a company. It includes the receipt/dispatch type and the associated reference documents for each type. It also lists various shapes and their fixed and variable parameters. The parameters include dimensions, thickness, specific gravity. It provides specific gravity values for different metals. It further provides conversion formulas and factors to calculate weight or quantity for different shapes like hex bar, square bar, round bar, flats, plate, forging and pipe.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 5

GRN ENTRY

RECEIPT TYPE REFERENCE DOCOCUMENT DESC.

Purchase Purchase order

From Job work-Excess Work Order

Purchase-Reject Replacement Purchase order

Free Samples No Documents

For Job work-Not Returnable Work Order

Sales Return Excess Work Order

Without PO No Documents

For Maintenance – Repairing No Documents

Sales Return Reject Work Order

For Job work-Returnable Work Order

From Job work-Returnable Work Order

Returnable Received No Documents

Returnable Returned Outward Challan

From Maintenance – Repairing Outward Challan

DELIVERY CHALLAN ENTRY

DISPATCH TYPE REFERENCE DOCOCUMENT DESC.

For Maintenance - Repairing No Document

Returnable Dispatch No Document

Returnable Returned Good Receipt

For Job work-Returnable Work Order

From Job work-Returnable Work Order

Sales-Reject Replacement Work Order

From Maintenance - Repairing Good Receipt

Purchase Return Reject Good Receipt

Free Samples No Document

Sales Work Order

From Job work-Excess Work Order

For Job work-Not Returnable Work Order

Purchase Return Excess Good Receipt

Without WO No Document

SHAPES AND PARAMETERS

S.No. SHAPE FIXED PARAMETERS VARIABLE PARAMETERS

1. Circular Flange Sp. Gravity Thickness

OD

ID

2. Rectangular Flange Sp. Gravity Thickness

Side

3. Circle Sp. Gravity Thickness

OD

4. Flats Size 1 Length

Thickness

Sp. Gravity

5. Hex Bar Sp. Gravity Length

Side

6. Angle Equal Sp. Gravity Length

Kg/m

7. Angle Not-Equal Size 1 Length

Size 2

Thickness

Sp. Gravity

8. Box Section Size 1 Length

Size 2

Thickness

Sp. Gravity

9. High Beam Size 1 Length

Size 2

Thickness

Sp. Gravity

10. Junior Beam Size 1 Length

Size 2

Thickness

Sp. Gravity

11. Medium Channel Size 1 Length

Size 2

Thickness

Sp. Gravity

S.No. SHAPE FIXED PARAMETERS VARIABLE PARAMETERS

12. Pipe OD Length

ID

Sp. Gravity

13. Plate Thickness Size1

Sp. Gravity Size2

14. Round Bar Sp. Gravity Length

OD

15. Square Bar Sp. Gravity Length

Size 1

Fixed Parameters: Fixed parameters are fixed for particular item. For example M.S. Seamless Pipe 1000

Dia OD x 882 Dia ID, here OD and ID are fixed variables.

Variable Parameters: Variable parameters are to be set at the time of BOM. For above example Length

may vary for job to job.

Specific Gravity: Specific Gravity for different metals is given below:

Metals Weight of 1cu.ft Specific Gravity

lb Water=1

Platinum 1342 21.522

Gold 1200 19.245

Lead, milled sheet 712 11.418

Silver 655 10.505

Copper, sheet 549 8.805

Gun-metal, 84 copper, 16 tin 534 8.56

Gun-Metal, 79 copper, 21 tin, mill bearings 544 8.73

Brass, cast 505 8.1

Steel, fair average 489.6 7.852

Iron, wrought, fair average 480 7.698

Iron, cast, fair average 450 7.217

Tin 462 7.409

Zinc, sheet 449 7.2

Aluminum, cast 160 2.56

Magnesium 108.5 1.74

Nickel 548 8.8

Bismuth 617 9.9

Mercury 849 13.6

METAL OR ALLOY KG/CU.M METAL OR ALLOY KG/CU.M

Aluminum - melted 2560 - 2640 Nickel 8800

Aluminum bronze (3-10% Al) 7700 - 8700 Nickel silver 8400 - 8900

Aluminum foil 2700 -2750 Platinum 21400

Antifriction metal 9130 -10600 Plutonium 1980

Beryllium 1840 Silver 10490

Beryllium copper 8100 - 8250 Steel - rolled 7850

Brass - casting 8400 - 8700 Steel - stainless 7480 - 8000

Brass - rolled and drawn 8430 - 8730 Tin 7280

Bronze - lead 7700 - 8700 Titanium 4500

Bronze - phosphorous 8780 - 8920 Tungsten 19600

Bronze (8-14% Sn) 7400 - 8900 Uranium 18900

Cast iron 6800 - 7800 Vanadium 5494

Cobolt 8746 White metal 7100

Copper 8930 Zinc 7135

Delta metal 8600

Electrum 8400 - 8900

Gold 19320

Iron 7850

Lead 11340

Light alloy based on Al 2560 - 2800

Light alloy based on Mg 1760 - 1870

Magnesium 1738

Mercury 13593

Molybdenum 10188

Monel 8360 - 8840

CONVERSION FACTOR

SHAPE/ITEM FORMULA CONVERSION FACTOR

Hex Bar 2

(size a/f in mm) x .006798 = Kg/m 1/FORMULA

Square Bar (size a/f in mm)2 x .00785 = Kg/m 1/FORMULA

Round Bar (Diameter in mm)2 x .006165 = kg/m 1/FORMULA

Flats Width in mm x thickness in mm x .00785 = kg/m 1/FORMULA

Plate Thk. In mmX 7.85 = kg/m 2 1/FORMULA

Forging ((Dia in mm)2x0.62x(Thick. In mm/100))/1000 = Kg./No. 1/FORMULA

Note: +10 in Dia and Thickness if Dia<=500 and +15 if Dia>500

Pipe (OD in mm -Thick. in mm)xThick. in mmx0.0245 = Kg./m 1/FORMULA

You might also like

- University of Dar Es SalaamDocument8 pagesUniversity of Dar Es SalaamChris AdaminovicNo ratings yet

- Die Design B11 PDFDocument14 pagesDie Design B11 PDFநளின் கான்No ratings yet

- GB T 706 2008 Hot Rolled Section Steel English PDFDocument28 pagesGB T 706 2008 Hot Rolled Section Steel English PDFArash SotoudehNo ratings yet

- Gen. Shed BoqDocument18 pagesGen. Shed BoqManuelito ZapataNo ratings yet

- Niigata Welding GaugeDocument2 pagesNiigata Welding GaugeFriady HalimNo ratings yet

- Structural Anaysis and Details TimelineDocument15 pagesStructural Anaysis and Details TimelineJems MansuetoNo ratings yet

- Excel TemplateDocument15 pagesExcel TemplateKofi DanielNo ratings yet

- Engineering Standards For Manufacture: Can SpecificationDocument14 pagesEngineering Standards For Manufacture: Can SpecificationMohammed AlkhwajaNo ratings yet

- Heritage Institute of Technology: Tools UsedDocument7 pagesHeritage Institute of Technology: Tools UsedAnurag MukherjeeNo ratings yet

- Design of PedestralDocument1 pageDesign of PedestralAbu KhatriNo ratings yet

- OOT PulsFrac Input Request - OEF-1000-001 TPN-211Document5 pagesOOT PulsFrac Input Request - OEF-1000-001 TPN-211Christian BimoNo ratings yet

- Mild Steel Mild Steel: MS Gram MS Round 395.136 SquareDocument6 pagesMild Steel Mild Steel: MS Gram MS Round 395.136 Squarepintu sinojiyaNo ratings yet

- Mild Steel Mild Steel: MS Gram MS Round 395.136 SquareDocument6 pagesMild Steel Mild Steel: MS Gram MS Round 395.136 Squarepintu sinojiyaNo ratings yet

- 9 MiningDocument12 pages9 MiningSuelen BarbosaNo ratings yet

- Chapter 8 Students' HandoutDocument31 pagesChapter 8 Students' HandoutLee Wei YinNo ratings yet

- Detailed Design of Free Pot BearingDocument7 pagesDetailed Design of Free Pot BearingDevesh SinghNo ratings yet

- DANA-T230 Through Coating Ultrasonic Thickness GaugeDocument4 pagesDANA-T230 Through Coating Ultrasonic Thickness Gaugecesardario90No ratings yet

- 13 Nipple Outlet - 3D PDFDocument1 page13 Nipple Outlet - 3D PDFWenceslao Campos CastruitaNo ratings yet

- Slab Design OldDocument14 pagesSlab Design Oldshreejay maneNo ratings yet

- Experimental Study On The Structural Behavior of Circumferentially and Diametrical Braced DomesDocument13 pagesExperimental Study On The Structural Behavior of Circumferentially and Diametrical Braced DomesHaitham HassanNo ratings yet

- Curved BeamDocument2 pagesCurved Beamلازلت احلمNo ratings yet

- Din 2441-78 Steel Tubes Heaby Weight For Suitable For ScrewingDocument3 pagesDin 2441-78 Steel Tubes Heaby Weight For Suitable For ScrewingVadimNo ratings yet

- EarthingDocument17 pagesEarthingtangouzeNo ratings yet

- Combined FootingDocument4 pagesCombined FootingSita G ShresthaNo ratings yet

- 2C X 95CU POWER - Revised Datasheet Solar CableDocument1 page2C X 95CU POWER - Revised Datasheet Solar CableAashish MoyalNo ratings yet

- Sem 5 ABS Market Survey Group 4Document18 pagesSem 5 ABS Market Survey Group 4Khushi BambNo ratings yet

- Executive Summary 3.6 EVAPORATOR (V-102) Table 3.6.7 Evaporator Chemical Design Summary Design PropertiesDocument3 pagesExecutive Summary 3.6 EVAPORATOR (V-102) Table 3.6.7 Evaporator Chemical Design Summary Design PropertiesKangae IlhamNo ratings yet

- UT-Bai 5-Han Va KTDocument43 pagesUT-Bai 5-Han Va KTWill SmithNo ratings yet

- Materials Selection ChapterDocument45 pagesMaterials Selection ChapterUYÊN TRẦN NGUYỄN KHÁNHNo ratings yet

- GB Hot Rolled Section SteelDocument40 pagesGB Hot Rolled Section SteelGovind Rao100% (1)

- Spark Test - Materials EngineeringDocument7 pagesSpark Test - Materials EngineeringFloramhel Joy HicongNo ratings yet

- Tank WT & Volume ConvertoreDocument11 pagesTank WT & Volume ConvertorenileshNo ratings yet

- Composite Beam Secondary: Construction StageDocument8 pagesComposite Beam Secondary: Construction StageSimon LsmNo ratings yet

- Middle East Technical University Department of Mechanical Engineering Me303 - Manufacturing Engineering FALL 2019 Experiment 1Document7 pagesMiddle East Technical University Department of Mechanical Engineering Me303 - Manufacturing Engineering FALL 2019 Experiment 1joseph beckhamNo ratings yet

- Specification For Nickel-Copper Alloy Rod, Bar, and WireDocument12 pagesSpecification For Nickel-Copper Alloy Rod, Bar, and WireAnilNo ratings yet

- Additional Width Reduction For HRPO SteelDocument24 pagesAdditional Width Reduction For HRPO SteelDali HariswijayaNo ratings yet

- Legend Bp1525: Bass GuitarDocument2 pagesLegend Bp1525: Bass GuitarAji VerdeNo ratings yet

- Experiment # 01: To Determine The Buckling in Column Due To LoadingDocument6 pagesExperiment # 01: To Determine The Buckling in Column Due To LoadingNoman AliNo ratings yet

- SputteringDocument29 pagesSputteringHebin RoyNo ratings yet

- Two Way Simply Support CautionDesign Excel SheetDocument11 pagesTwo Way Simply Support CautionDesign Excel SheetKrushNo ratings yet

- RoofingDocument3 pagesRoofingRicalyn AlfonsoNo ratings yet

- GeM Bidding 4148770 PDFDocument46 pagesGeM Bidding 4148770 PDFJob ManpowerNo ratings yet

- BS1400 HTB1Document2 pagesBS1400 HTB1Atul KulkarniNo ratings yet

- 700 TR ChillerDocument1 page700 TR ChillerSamir AkramNo ratings yet

- Genset Pad BalkasarDocument3 pagesGenset Pad BalkasarAmmad AlizaiNo ratings yet

- Apriando Pratama Group 4Document9 pagesApriando Pratama Group 4Nando ApriNo ratings yet

- Jis G-3444Document10 pagesJis G-3444Maulana YusufNo ratings yet

- Cantilever Slab Design Engr ArslanDocument4 pagesCantilever Slab Design Engr ArslanMuhammadNo ratings yet

- Heat Exchanger Selection GuideDocument2 pagesHeat Exchanger Selection GuiderodrigoperezsimoneNo ratings yet

- Steel Weight CalculatorDocument4 pagesSteel Weight CalculatorShaikh Mohd QaisarNo ratings yet

- AAN - 2C X 95CU POWER - Revised Datasheet Solar Cable 15.09.2020Document1 pageAAN - 2C X 95CU POWER - Revised Datasheet Solar Cable 15.09.2020Aashish MoyalNo ratings yet

- BV-RINA Propeller Thickness CalculationDocument1 pageBV-RINA Propeller Thickness Calculationakbaradi123No ratings yet

- Steel Weight CalculatorDocument4 pagesSteel Weight CalculatorAKKI KUMARNo ratings yet

- Lec 01 - Steel and Introduction To AISC Steel ManualDocument26 pagesLec 01 - Steel and Introduction To AISC Steel ManualbilalNo ratings yet

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsFrom EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsNo ratings yet

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred Experiments Performed with Simple, Home-made ApparatusFrom EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred Experiments Performed with Simple, Home-made ApparatusNo ratings yet

- Chain Maille Wire Weaving: How to Make Chain Maille With Affordable Metals and Minimal ToolsFrom EverandChain Maille Wire Weaving: How to Make Chain Maille With Affordable Metals and Minimal ToolsNo ratings yet

- Radio and Line Transmission: Electrical Engineering Division, Volume 1From EverandRadio and Line Transmission: Electrical Engineering Division, Volume 1Rating: 5 out of 5 stars5/5 (1)

- Copper AlloysDocument61 pagesCopper Alloysbvalinhas100% (2)

- QCS-2010 Section 21 Part 21 Lightning ProtectionDocument4 pagesQCS-2010 Section 21 Part 21 Lightning Protectionbryanpastor106No ratings yet

- Supergene Metal DepositsDocument6 pagesSupergene Metal DepositsRalph Carlo EvidenteNo ratings yet

- Phosphonates, Method 8007, 02-2009, 9th EdDocument6 pagesPhosphonates, Method 8007, 02-2009, 9th EdFaiz HamidNo ratings yet

- Chemical Reactions and EquationsDocument6 pagesChemical Reactions and EquationsLushila MinjNo ratings yet

- Msds Standard Weld Metal Domestic InternationalDocument8 pagesMsds Standard Weld Metal Domestic InternationalKate HowardNo ratings yet

- Influence of Aluminum and Copper Alloy MachinabilityDocument13 pagesInfluence of Aluminum and Copper Alloy MachinabilitySathish KumarNo ratings yet

- Chemistry Module: 1. Carbon Compounds 2. Manufactured Substancesin Industry 3. Chemicals For ConsumersDocument66 pagesChemistry Module: 1. Carbon Compounds 2. Manufactured Substancesin Industry 3. Chemicals For ConsumersWen YaoNo ratings yet

- Nomenclature and Applications of MetalsDocument38 pagesNomenclature and Applications of MetalsJaveed AkhtarNo ratings yet

- Tech Mahindra Model PapersDocument59 pagesTech Mahindra Model PaperskarithkakarthikaNo ratings yet

- Ferrous and Non Ferrous Materials - Dr. ChalimbaDocument61 pagesFerrous and Non Ferrous Materials - Dr. ChalimbaTadala Angella GomondaNo ratings yet

- Optimum Dig Lines For Open Pit Grade ControlDocument18 pagesOptimum Dig Lines For Open Pit Grade Controleisaaks2No ratings yet

- 2016-6um Pitch High Density Cu-Cu Bonding For 3d Ic StackingDocument8 pages2016-6um Pitch High Density Cu-Cu Bonding For 3d Ic Stacking湯晴羽No ratings yet

- Metals in The Causation and Treatment of Wilson's Disease and Alzheimer's DiseaseDocument7 pagesMetals in The Causation and Treatment of Wilson's Disease and Alzheimer's DiseaseDani AlmeidaNo ratings yet

- N 218 HistoryDocument4 pagesN 218 HistoryDrako 2001No ratings yet

- Proposal FYPDocument9 pagesProposal FYPNadzirah RedzuanNo ratings yet

- Msds HCLDocument7 pagesMsds HCLbagus kustantoNo ratings yet

- Unit 9 - Metals and Their Compounds Student VersionDocument23 pagesUnit 9 - Metals and Their Compounds Student VersionMalike ShamelNo ratings yet

- 1p2 2013 14 Materials Examples Paper 6Document5 pages1p2 2013 14 Materials Examples Paper 6davidsmith24026No ratings yet

- Electromagnetic Field Shielding FabricsDocument20 pagesElectromagnetic Field Shielding FabricsJorj PaduraruNo ratings yet

- Allen Wrot PricelistDocument11 pagesAllen Wrot PricelistShocker Joe CovilleNo ratings yet

- Mineral Resources, Environmental Issues, and Use: ArticleDocument8 pagesMineral Resources, Environmental Issues, and Use: ArticleDonNo ratings yet

- Datasheet: CATEGORY: Tin-Plated Copper Tape NAME: 30x2mm Tin-Plated Copper Tape Reference: At-052DDocument2 pagesDatasheet: CATEGORY: Tin-Plated Copper Tape NAME: 30x2mm Tin-Plated Copper Tape Reference: At-052DSaadat ZafarNo ratings yet

- Dalsteel Metals Pty Limited Aluminium Alloy 6063 T6 Extrusions 158Document3 pagesDalsteel Metals Pty Limited Aluminium Alloy 6063 T6 Extrusions 158Zac Francis DaymondNo ratings yet

- Theory Workbook (TE) Chapter 2Document24 pagesTheory Workbook (TE) Chapter 2scribduser0811972No ratings yet

- Corrosion Resistance With Electroplating C12!6!11 & 12Document10 pagesCorrosion Resistance With Electroplating C12!6!11 & 12horascanmanNo ratings yet

- Cu Metallurgy in Medieval PeriodDocument14 pagesCu Metallurgy in Medieval PeriodDarshan BkNo ratings yet

- Investor Presentation: South32 To Acquire A 45% Interest in The Sierra Gorda Copper MineDocument40 pagesInvestor Presentation: South32 To Acquire A 45% Interest in The Sierra Gorda Copper MineBill LiNo ratings yet

- Evans Ancient Bronze Implements 1881Document540 pagesEvans Ancient Bronze Implements 1881alexdavies56100% (2)

- IRMS Supplement.A4.Rev2022.WebDocument28 pagesIRMS Supplement.A4.Rev2022.Webindra defistaNo ratings yet