Professional Documents

Culture Documents

Louvres Techguide

Uploaded by

Imtiaz AhmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Louvres Techguide

Uploaded by

Imtiaz AhmedCopyright:

Available Formats

External Louvres

Screening Applications

louvres Ravistar

Technical Data &

Selection Procedure

1. Large Format External Louvres - Model WG ....................... 1

2. Small Format External Louvres - Model YG ........................ 1

3. Sand Trap Louvres - Model SL .................................. 1

Contents

Louvres

Model SL

Large Format External Louvres -

Model WG

Introduction

Model WG large format high performance louvres are suitable

for most external walling/Screening applications and have

been proven weatherproof even under the most adverse

conditions. Available systems include horizontal and vertical

continuous or mullion screens, doors, access panels,

penthouse units. The louvres are constructed from high

quality aluminium alloy extrusions with welded/mitred frames.

Features

Continuous effect or mullion style joints.

Extruded aluminium frame and blade system.

Suitable for screening with doors etc.

Optional penthouse louvres.

Louvres are complete with bird screen.

Model WG

Small Format External Louvres -

Model YG

Introduction

Model YG small format louvres are suitable for intake or

exhaust systems where space or cost is at a premium. The

design incorporates features of the WG Systems but at half

the scale and this makes the YG ideal for small louvre

applications, sheltered situations and even internal screening

requirements. The louvres are constructed from high quality

aluminium alloy extrusions with cleated/mitred frames.

Features

Small format compact design.

Lightweight aluminium extrusions.

Louvres are complete with bird screen.

Sand Trap Louvres - Model SL

Introduction

Model SL sand louvres have been designed as first stage

separators of airborne sand and dust, thereby reducing the

dust loading on ventilation filtration equipment.

The attractive compact and yet simple design uses initial

separation techniques in a two stages baffle arrangement to

separate particles and return them to the face via a lower

blade chute. The louvres are constructed from high quality

aluminium sheet.

Features

Compact design.

Heavy duty aluminium frames and blades.

Attractive vertical blade arrangement.

Integral collection chute.

Louvres are complete with bird screen.

Model YG

1

Louvres

Description

Dimensions

Description W G YG SL

Panel Sizes (Min) 300W x 300H 100W x 100H 300W x 300H

(Max) 1500W x 1500H 1500W x 1500H 1500W x 1500H

System Options Continuous blade and frame joints Mullion joints Mullion joints

or mullions

Penthouse louvres Penthouse louvres Louvre walling

Corner mitres

Doors

Access panels

Screen systems

Louvre walling

Construction Aluminium alloy extrusions Light duty aluminium alloy extrusions Light duty aluminium sheets

Screwed blades Screwed blades Riveted blades

Welded frames Cleated frames Welded frames

Blade Format 75mm pitch horizontal blades 38mm pitch horizontal blades Standard: 80mm pitch ver. blades only

Performance See page 3

Frame EF = External Flanged Frame

Fixing Options SF = Flange Screw Fixing

LF = Rear Lug Fixing

Optional Extras FF = Filter Frame

DC = Drip Cill (for WG and YG only)

Finishes Standard

a) Epoxy Polyester Powder Coated off white/pure white.

b) Natural anodised.

Other powder coating finishes available on request.

Note : Recessed frame (in place of flanged frame) is available as an option.

38

76 5

O

v

e

r

a

l

l

s

i

z

e

=

d

u

c

t

s

i

z

e

+

5

7

m

m

38

76

5

O

v

e

r

a

l

l

s

i

z

e

=

d

u

c

t

s

i

z

e

+

5

7

m

m

25

38

5

O

v

e

r

a

l

l

s

i

z

e

=

d

u

c

t

s

i

z

e

+

3

1

m

m

W G Y G

2

SL

Louvres

Performance Data

Pressure Loss

The graph below gives static pressure loss across the louvres

for intake or exhaust applications (based on 1m

2

panels).

Effective Free Areas

Effective free areas are based on pressure loss tests

comparing the resistance of the louvre in relation to its clear

aperture one metre square.

Noise Generation

The graph below gives LwNR levels based on peak sound

power level plotted on noise rating (NR) curves (based on

1m

2

louvre). Correct for louvre area and octave band

spectrum.

Efficiency (SL-Sand Louvres)

Sand rejection efficiency using a standard sand having grains

sized between 100 and 1000 microns with 90% between 150

and 425 microns. Sand collected by the double channel

construction drops to the base of the louvre and a chute

directs the sand back to the face Efficiency defined by:-

=

weight of sand rejected

x 100

weight of sand injected

300

200

100

50

40

30

20

10

0.5 1.0 2.0 3.0 4.0 5.0

Type Effective Free

Area %

WG Exhaust 51

WG Intake 42

YG Exhaust 58

YG Intake 46

SL Exhaust 18

SL Intake 18

Octave Band Spectrum Corrections for

SWL re 10

-12

Watts

Type 125 250 500 1K 2K 4K

W G +6 +5 +2 0 -6 -12

Y G -7 +4 +3 0 -5 -10

SL +1 +4 +3 0 -10 -16

LwNR

70

60

50

40

30

20

10

0 1.0 2.0 3.0 4.0

Duct / Face Air Velocity (m/s)

S

t

a

t

i

c

P

r

e

s

s

u

r

e

L

o

s

s

(

P

a

)

100

80

60

40

20

0 1 2 3

Efficiency

Face/Duct Air Velocity (m/s)

E

f

f

i

c

i

e

n

c

y

(

%

)

3

Face/Duct Air Velocity (m/s)

Louvres

Installation

Fixing Options

Flange screw fixing

(SF)

Rear lug fixing

(LF)

DC Drip Cills

Supplied loose for fixing on site.

8

m

m

t

o

l

e

r

a

n

c

e

X

Y

A

B

Type X

W G

13mm

SL

Y G 8 m m

Type Y

W G

78mm

SL

Y G 58mm

Type A B

WG/EF 51mm 11mm

YG/EF 25mm 8 m m

4

Finish

Standard a) Epoxy Polyester Powder Coated off white/pure

white.

b) Natural anodised.

Other powder coating finishes available on request.

Ordering

Model Size Fixing options

(WxH)

W G 300x300 SF

Specifications and data are subject to change without prior notice due to continuous product development.

Normal tolerances shall be applicable.

Ravistar India Pvt. Ltd.

Office & Works : D-99, Sector-2, Noida-201301 (U.P.), India

Tel. : 95 (120) 2531869, 2531878, 2537624 Fax : 95 (120) 2543431

E-mail : ravistar@vsnl.net Visit us at : www.ravistar.com R

S

/

E

N

G

/

L

V

R

/

0

0

1

/

0

9

/

0

3

You might also like

- Confort 125 - Aluminium Sliding Doors - Sapa Building SystemDocument12 pagesConfort 125 - Aluminium Sliding Doors - Sapa Building SystemSapa Building SystemNo ratings yet

- External Venetian Blinds From Griesser.: AluflexDocument6 pagesExternal Venetian Blinds From Griesser.: AluflexjohncassolaNo ratings yet

- Proteção para MaquinasDocument7 pagesProteção para MaquinasWks EngenhariaNo ratings yet

- Rhino Grating PDFDocument16 pagesRhino Grating PDFoluomo1No ratings yet

- 1mesh TrackDocument92 pages1mesh TrackAbdon CastroNo ratings yet

- Avantis 55 Aluminium Windows and Doors - Sapa Building SystemDocument8 pagesAvantis 55 Aluminium Windows and Doors - Sapa Building SystemSapa Building SystemNo ratings yet

- Screen Sand ControlDocument20 pagesScreen Sand ControlsaptagunungNo ratings yet

- Leaflet Solar Shading SystemsDocument20 pagesLeaflet Solar Shading Systemsdalerobinson01No ratings yet

- Wadkin AGSP SawbenchDocument6 pagesWadkin AGSP SawbenchmarkandersonsaNo ratings yet

- Fascia PurlinsDocument4 pagesFascia PurlinsScooby DooNo ratings yet

- Technical SpecificationDocument12 pagesTechnical SpecificationAnkit Somani100% (1)

- Unilift de DGDDocument36 pagesUnilift de DGDLove SemsemNo ratings yet

- Chapter 3 Datasheets Roof PanelsDocument16 pagesChapter 3 Datasheets Roof PanelsMladen BilincNo ratings yet

- Sand Trap LouverDocument9 pagesSand Trap LouvergagokapalaNo ratings yet

- Systemair CatalogueDocument21 pagesSystemair CataloguePARVEZ AMEENNo ratings yet

- Rainwater Goods 18-09-2008Document22 pagesRainwater Goods 18-09-2008Sha Mas ShaNo ratings yet

- Mid GridDocument16 pagesMid GridnunosobralNo ratings yet

- KS1000 RW Panel UK Roof Poduct Data SheetDocument6 pagesKS1000 RW Panel UK Roof Poduct Data SheetThe Lone GunmanNo ratings yet

- Gyprock 512 Cinema Wall 201306Document12 pagesGyprock 512 Cinema Wall 201306Jane SweetNo ratings yet

- Lysaght OptimaDocument8 pagesLysaght OptimaAgung PriambodhoNo ratings yet

- Lindner KatalogDocument64 pagesLindner KatalogAnonymous hISvHbfiB1No ratings yet

- Self Drilling Anchors SUPANCHORDocument3 pagesSelf Drilling Anchors SUPANCHORMohd AftabNo ratings yet

- Ascot Roller Shutter General BrochureDocument16 pagesAscot Roller Shutter General Brochureiask5275No ratings yet

- External Metal LouvresDocument28 pagesExternal Metal LouvresQuitzs QuitzsNo ratings yet

- Cavity ShaftwallDocument14 pagesCavity Shaftwallatac101No ratings yet

- Layher Allround - Description and Technical SpecificationDocument3 pagesLayher Allround - Description and Technical SpecificationYogesh WadhwaNo ratings yet

- RuskinDocument4 pagesRuskin123gorgNo ratings yet

- Kingspan AccessoriesDocument9 pagesKingspan AccessoriesthedogishighNo ratings yet

- Alustar (Perfis & Secções)Document49 pagesAlustar (Perfis & Secções)Jeovani DanielNo ratings yet

- Flexidoor High Speed DoorsDocument20 pagesFlexidoor High Speed DoorsDentobiasNo ratings yet

- Donaldson Dust Collector System - Catalogue PDFDocument8 pagesDonaldson Dust Collector System - Catalogue PDFnidhincletusNo ratings yet

- Product CatalogDocument24 pagesProduct CatalogMilad EmilNo ratings yet

- Components Overview - Brochures V11 I400003GBDocument80 pagesComponents Overview - Brochures V11 I400003GBKirsten HernandezNo ratings yet

- Stramit Monoclad: Product Technical ManualDocument8 pagesStramit Monoclad: Product Technical Manualchillerz69No ratings yet

- Spokane Ind WearParts SiTecDocument10 pagesSpokane Ind WearParts SiTecballesterosa545No ratings yet

- 40867Document6 pages40867showvik_1962No ratings yet

- Gratings BrochureDocument22 pagesGratings BrochureN P Srinivasarao100% (2)

- 111 1400 Simon Black Jaguar Land RoverDocument29 pages111 1400 Simon Black Jaguar Land RoverseehariNo ratings yet

- Star BeamDocument6 pagesStar BeamarekgliNo ratings yet

- # Light Source Brightness ComparisonsDocument3 pages# Light Source Brightness ComparisonsJohn CenaNo ratings yet

- Hollow Core BushingDocument4 pagesHollow Core BushingAkhileshkumar PandeyNo ratings yet

- Steelway Brochure - Core-Products09Document20 pagesSteelway Brochure - Core-Products09Laura EddowesNo ratings yet

- Acoustic CatalogDocument12 pagesAcoustic CatalogrohizatNo ratings yet

- Makron Technology LogmacticDocument5 pagesMakron Technology LogmacticMAKRONNo ratings yet

- Kingspan AccessoriesDocument20 pagesKingspan AccessoriesCiprian VarlanNo ratings yet

- Brochure PanelSystems enDocument20 pagesBrochure PanelSystems enCristina StamateNo ratings yet

- KMG Stalpi SpecialiDocument196 pagesKMG Stalpi SpecialiBogdan HritcuNo ratings yet

- Steel AlloyDocument4 pagesSteel AlloyRuffy OiraNo ratings yet

- Sadev Classic FXR enDocument38 pagesSadev Classic FXR enPeter DudasNo ratings yet

- 26 Machine ViceDocument19 pages26 Machine ViceFajri HamdanNo ratings yet

- Hufcor Series 600Document4 pagesHufcor Series 600couteauNo ratings yet

- Rawl Bolts and CapacityDocument2 pagesRawl Bolts and Capacitykevinisonline0% (1)

- Concrete: Testing EquipmentsDocument15 pagesConcrete: Testing EquipmentsMorched TounsiNo ratings yet

- Confort 50 - Aluminium Windows and Doors - Sapa Building SystemDocument8 pagesConfort 50 - Aluminium Windows and Doors - Sapa Building SystemSapa Building SystemNo ratings yet

- Concrete Pipes: Scib Concrete Manufacturing SDN BHDDocument4 pagesConcrete Pipes: Scib Concrete Manufacturing SDN BHDSoonHan WaiNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Sun - Earth ModelDocument4 pagesSun - Earth ModelImtiaz AhmedNo ratings yet

- Mocomi TheZone WhyDoFishDieIfTheyAreOutOfTheWater 01Document7 pagesMocomi TheZone WhyDoFishDieIfTheyAreOutOfTheWater 01Imtiaz AhmedNo ratings yet

- Types of Computer & Their PartsDocument6 pagesTypes of Computer & Their PartsImtiaz AhmedNo ratings yet

- Top 10 Ceiling Fans in India by Electricity Consumption and Performance in 2016Document3 pagesTop 10 Ceiling Fans in India by Electricity Consumption and Performance in 2016Imtiaz AhmedNo ratings yet

- Terex DG TroubleshootingDocument48 pagesTerex DG TroubleshootingImtiaz Ahmed100% (2)

- Supporting Documents Required For Indian Visa RegistrationDocument42 pagesSupporting Documents Required For Indian Visa RegistrationVenkatesh MahalingamNo ratings yet

- Session B1 Preventive, Predictive, and Corrective MaintenanceDocument38 pagesSession B1 Preventive, Predictive, and Corrective MaintenancejuneNo ratings yet

- PipeSizing Is P736 0314Document4 pagesPipeSizing Is P736 0314Shishan AhmadNo ratings yet

- Cycles Program User GuideDocument9 pagesCycles Program User GuidecardossoNo ratings yet

- Air ChillerDocument12 pagesAir ChillerImtiaz AhmedNo ratings yet

- 3 ComputerskillDocument2 pages3 ComputerskillImtiaz AhmedNo ratings yet

- Abrt SwitchDocument1 pageAbrt SwitchImtiaz AhmedNo ratings yet

- Oxygen GeneratorDocument16 pagesOxygen GeneratorImtiaz Ahmed100% (2)

- Albani's DeviationsDocument2 pagesAlbani's DeviationsImtiaz AhmedNo ratings yet

- Deewan Busiri PDFDocument238 pagesDeewan Busiri PDFImtiaz AhmedNo ratings yet

- FixturesDocument16 pagesFixturesImtiaz AhmedNo ratings yet

- Tamheed Ul ImanDocument39 pagesTamheed Ul ImanImtiaz AhmedNo ratings yet

- Using and Referencing ISO and IEC Standards To Support Public Policy - enDocument56 pagesUsing and Referencing ISO and IEC Standards To Support Public Policy - enImtiaz AhmedNo ratings yet

- Transformers, RMUDocument6 pagesTransformers, RMUImtiaz AhmedNo ratings yet

- Diwan e BusiriDocument238 pagesDiwan e BusiriImtiaz AhmedNo ratings yet

- Lighting Design BasicsDocument83 pagesLighting Design BasicsImtiaz Ahmed100% (1)

- Iec - 61439 1 2Document8 pagesIec - 61439 1 2Imtiaz Ahmed100% (3)

- Tamheed Ul ImanDocument39 pagesTamheed Ul ImanImtiaz AhmedNo ratings yet

- Build An LED Propeller ClockDocument4 pagesBuild An LED Propeller ClockImtiaz AhmedNo ratings yet

- Night SkyDocument1 pageNight SkyImtiaz AhmedNo ratings yet

- How To Use This Chart: PolarisDocument1 pageHow To Use This Chart: PolarisImtiaz AhmedNo ratings yet

- Data Center CoolingDocument28 pagesData Center CoolingImtiaz Ahmed100% (3)

- Thank You For Being A Liberty Mutual Renters Customer Since 2014!Document29 pagesThank You For Being A Liberty Mutual Renters Customer Since 2014!RewaNo ratings yet

- Single Conductor 15KV, Shielded, MV-105Document2 pagesSingle Conductor 15KV, Shielded, MV-105henry hernandezNo ratings yet

- Material SelfDocument9 pagesMaterial Selfic perlasNo ratings yet

- Geotechnical Engineering GATE Previous QuestionsDocument35 pagesGeotechnical Engineering GATE Previous QuestionsSurya ChejerlaNo ratings yet

- LabStan - July 16-17, 23-24, 30-31, Aug 6-7Document25 pagesLabStan - July 16-17, 23-24, 30-31, Aug 6-7CandypopNo ratings yet

- Supplementary Spec To API Specification 17D Subsea Wellhead and Tree Equipment With Justifications S 561Jv2022 11Document81 pagesSupplementary Spec To API Specification 17D Subsea Wellhead and Tree Equipment With Justifications S 561Jv2022 11maximusala83No ratings yet

- Genius 7 On Bill Acceptor ManualDocument10 pagesGenius 7 On Bill Acceptor ManualJose Maria PerezNo ratings yet

- Astm D 1142Document11 pagesAstm D 1142yusria1982No ratings yet

- ST. LUKE'S MEDICAL CENTER EMPLOYEE'S FOUNDATION AFW v. NLRCDocument3 pagesST. LUKE'S MEDICAL CENTER EMPLOYEE'S FOUNDATION AFW v. NLRCjodelle11No ratings yet

- Conference Proceedings: Inhaled Nitric Oxide: Delivery Systems and MonitoringDocument27 pagesConference Proceedings: Inhaled Nitric Oxide: Delivery Systems and MonitoringPhanNo ratings yet

- Scooty PepDocument1 pageScooty PepYASHNo ratings yet

- Lipoma in Submandibular Region - A Case ReportDocument4 pagesLipoma in Submandibular Region - A Case Reportmaxfac2010No ratings yet

- BIS Ventilation Brochure enDocument16 pagesBIS Ventilation Brochure enBruno SantosNo ratings yet

- 2013 Medigate Profile PDFDocument26 pages2013 Medigate Profile PDFGabriel Duran DiazNo ratings yet

- Effects of Various Liquid Organic Solvents On Solvent-Induced Crystallization of Amorphous Poly (Lactic Acid) FilmDocument11 pagesEffects of Various Liquid Organic Solvents On Solvent-Induced Crystallization of Amorphous Poly (Lactic Acid) FilmqueteimportaNo ratings yet

- Dingenen 2017Document14 pagesDingenen 2017pedro.coleffNo ratings yet

- Fitting in and Fighting Back: Stigma Management Strategies Among Homeless KidsDocument24 pagesFitting in and Fighting Back: Stigma Management Strategies Among Homeless KidsIrisha AnandNo ratings yet

- Highest Efficiencies For Various Industrial Applications: PumpsDocument8 pagesHighest Efficiencies For Various Industrial Applications: Pumpsahmed MareiNo ratings yet

- Fulltext PDFDocument55 pagesFulltext PDFManikandan VpNo ratings yet

- Pay Slip SampleDocument3 pagesPay Slip SampleJoseph ClaveriaNo ratings yet

- At4 886-12Document110 pagesAt4 886-12scotty2hotty28100% (1)

- DICGC - For Depositors - A Guide To Deposit InsuranceDocument10 pagesDICGC - For Depositors - A Guide To Deposit InsuranceSachinNo ratings yet

- Grades 4-10: Search Jobs in IndiaDocument2 pagesGrades 4-10: Search Jobs in IndiaMD AKIL AHMEDNo ratings yet

- Machine Design II: Prof. K.Gopinath & Prof. M.M.MayuramDocument4 pagesMachine Design II: Prof. K.Gopinath & Prof. M.M.Mayurampredrag10No ratings yet

- Cocktails For A CrowdDocument117 pagesCocktails For A CrowdΓιώργης Δημητρίου100% (2)

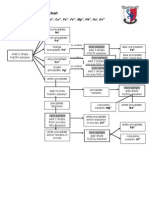

- Testing For Cations Flow ChartDocument2 pagesTesting For Cations Flow Chartapi-252561013No ratings yet

- Gerardus Johannes Mulder: 20 Aug 1779 - 7 Aug 1848Document25 pagesGerardus Johannes Mulder: 20 Aug 1779 - 7 Aug 1848NihalNo ratings yet

- Entomotherapy, or The Medicinal Use of InsectsDocument23 pagesEntomotherapy, or The Medicinal Use of InsectsJessica Revelo OrdoñezNo ratings yet

- UNIT-5 International Dimensions To Industrial Relations: ObjectivesDocument27 pagesUNIT-5 International Dimensions To Industrial Relations: ObjectivesManish DwivediNo ratings yet

- TD-XT-D004-003 V2.00 20131204 XG1.UCD-135M185M300M Operation Manual PDFDocument47 pagesTD-XT-D004-003 V2.00 20131204 XG1.UCD-135M185M300M Operation Manual PDFStan TC100% (1)