Professional Documents

Culture Documents

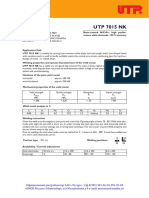

Production programme low-alloyed and basic electrodes

Uploaded by

Vanja Zoric Sundic0 ratings0% found this document useful (0 votes)

168 views12 pagesCommercial catalog AD FEP

Original Title

Commercial Catalog PIVA

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCommercial catalog AD FEP

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

168 views12 pagesProduction programme low-alloyed and basic electrodes

Uploaded by

Vanja Zoric SundicCommercial catalog AD FEP

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

PRODUCTION PROGRAMME

LOW-ALLOYED FLUX COATED CELLULOSE AND RUTILE ELECTRODES

JUS C.H3.011 Basic Data on Electrode (Wire) Mechanical properties of weld metal Electrode

(Wire) trade

name

EN 499

Weld metal

chemical

analysis

Welding

current

(mm)

Length

(mm)

Current

rate (A)

Rp0.2

(N/mm

2

)

Rm

(N/mm

2

)

A5 (%) AV (J)

Approvals Characteristics and applications

E432R12

PIVA 110 R

E350RC11

C 0.08

Mn 0.55

Si 0.25

AC

DC-

2.0

2.5

3.25

4.0

5.0

300

300

350

450

450

50-60

60-80

100-130

130-170

400-480 470-540 22-26 60-90

JR

LR

USSR

J

Medium coated rutile electrode with

metal recovery of 110%, suitable for

welding of steels with tensile strength

up to 490N/m

2.

Stable arc, free of

spattering; very easy slag removal;

very applicable in all positions including

vertical down.

E432R12

PIVA 101 R

E350RC11

C 0.08

Si 0.27

Mn 0.50

AC

DC-

2.0

2.5

3.25

4.0

5.0

300

300

350

450

450

50-60

60-80

100-130

130-170

170-210

400-480 470-540 22-26

+20C

60-90

Medium coated rutile electrode with

metal recovery of 110%, suitable for

welding of steels with tensile strength

up to 490 N/mm

2.

Stable arc, free of

spattering; very easy slag removal;

very applicable in all positions including

vertical down.

E431C12

PIVA CEL

E352C21

C 0.11

Si 0.19

Mn 0.48

DC+

DC

Root

penetrati

on

2.5

3.25

4.0

5.0

300

350

350

450

50-65

90-120

120-180

160-200

>440 450-530 24

+20C

130

-20C

60

Cellulose electrode for root penetration

and pipe welding in all positions.

Suitable for welding of cisterns, tanks

and similar vessels. Fast weld able at

very stable electric arc.

PIVA CEL Mo

E432MoC21

C 0.1

Si 0.15

Mn 0.6

Mo 0.5

DC+

DC

Root

penetrati

on

2.5

3.25

4.0

5.0

300

350

350

450

50-65

90-120

120-180

160-200

>420 510-610 >20

+20C

>70

Cellulose electrode suitable for root

penetration and welding of tube steels

and high tensile strengthsteels in all

positions.

HIGH EFFICIENT FLUX COATED RUTILE ELECTRODES

E432RR22

PIVA 130 RR

E350RR12

C 0.08

Mn 0.55

Si 0.30

AC

DC-

2.0

2.5

3.25

4.0

5.0

6,0

300

300

350

450

450

450

50-70

60-95

100-140

140-190

190-260

240-290

450-500 510-610 22 min 60

JR

LR

BV

USSR

ZJ

ABS

Thick coated rutile electrode with

excellent welding characteristics.

Suitable for welding of unalloyed and

certain low-alloyed steel with tensile

strength up to 510 N/mm

2

. Stable arc;

free of spattering. Surface of weld

metal is clean and level. Very easy

slang removal. Weld able in all

positions except vertical down.

E512RR22

PIVA 131 RR

E380RR12

C 0.08

Mn 0.5

Si 0.30

AC

DC-

2.0

2.5

3.25

4.0

5.0

6,0

300

300

350

450

450

450

50-70

60-95

110-140

140-180

180-250

230-280

440-510 510-580 22 min 60

Thick coated rutile electrode suitable

for welding of unalloyed and certain low

alloyed steel with tensile strength up to

510 N/mm

2

. Stable electric arc and

easy slag removal. Weld able in all

positions except vertical down.

E432R22

PIVA 132 RR

E350RR12

C 0.08

Mn 0.52

Si 0.25

AC

DC-

2.0

2.5

3.25

4.0

5.0

300

300

350

450

450

50-70

60-95

100-140

140-190

190-260

440-510 510-580 22 min

+20C

60

Thick coated rutile electrode with

excellent welding characteristics and

metal recovery of 125%, suitable for

welding of unalloyed and certain low

alloyed steel with tensile strength up to

510 N/mm

2

. Stable electric arc; free of

spattering. Surface of weld metal is

clean and level. Very easy slag

removal. Surface of weld metal is clean

and level.

E432RR14032

PIVA 140 RR

E380RR33

C 0.1

Si 0.30

Mn 0.50

AC

DC-

3.25

4.0

5.0

350

450

450

130-160

150-210

200-270

400 408-550 22 min 50 min

High efficient thick coated rutile

electrode with metal recovery of 140%.

Suitable for horizontal and corner

welding of steels with tensile strength of

up 510 N/mm

2

. Flat, event flow electric

arc; very easy slang removal. Surface

of weld metal is clean and level.

E512RR16031

PIVA 160 RR

E380RR53

C 0.08

Mn 0.8

Si 0.30

AC

DC-

3.25

4.0

5.0

6,0

350

450

450

450

130-160

180-230

260-330

300-360

430-500 430-500 22-28 70-110

High efficient thick coated rutile

electrode with metal recovery of

abt.160%. Suitable for filling grooves

and long corner welding of steels.

Stable arc; free of spattering; very easy

slag removal.

LOW-ALLOYED FLUX COATED BASIC ELECTRODES

E515B12026

2H

PIVA 150 B

E424B32H5

C 0.08

Mn 1.0

Si 0.45

DC+

AC

2.5

3.25

4.0

5.0

6,0

300

350

450

450

450

65-85

100-140

140-180

190-230

240-290

440-510 510-560 26-30

-20C

100 min

-40C

47

JR

LR

ABS

BV

USSR

ZJ

Thick coated basic electrode for

welding of unalloyed and low- alloyed

steels castings with tensile strength up

to 510 N/mm

2

and for welding of fine-

grain steels with yield strength up to

380 N/mm

2

. Seam surface is clean, fine

rippled and without undercutting. Weld

metal is tough at low temperatures.

Contents of hydrogen are less than 3

mm/100 g of weld metal.

PIVA 151 B

E515B13026

2H

C 0.08

Mn 1.0

Si 0.45

DC+

AC

2.5

3.25

4.0

300

350

450

70-100

110-150

150-190

440-510 510-560 26-30

-20C

100

-40C

JR

USSR

ZJ

Thick coated basic electrode for

welding of unalloyed and low- alloyed

steels castings with tensile strength up

E424B32H5

5.0

6,0

450

450

220-270

270-340

47 to 510 N/mm

2

and for welding of fine-

grain steels with yield strength up to

380 N/mm

2

. Seam surface is clean, fine

rippled and without undercutting. Weld

metal is tough at low temperatures.

Contents of hydrogen are less than 3

mm/100 g of weld metal. Metal

recovery is 130%.

PIVA 160 B

E502B42H5

C 0.1

Mn 1.6

Si 0.7

AC

DC+

2.5

3.25

4.0

5.0

6,0

300

350

450

450

450

60-90

100-140

140-190

180-230

240-290

480-560 580-680 22-26

-20C

90-140

-40C

47

Thick coated basic electrode for

welding of unalloyed and low- alloyed

steels castings with tensile strength up

to 670 N/mm

2

. Weld metal is tough at

low temperatures. Electrode is weld

able in all positions except vertical

down.

E515B262H

PIVA 250 B

C 0.08

Mn 1.0

Si 0.4

Ni 0.6

Cu 0.45

DC+

2.5

3.25

4.0

5.0

6,0

300

350

450

450

450

60-90

110-150

150-200

200-250

250-290

490-550 590-640 22-28

-20C

120

-60C

60

Thick coated basic electrode, alloyed

with Ni and Cu, suitable for welding of

water-resistant and seawater resistant

steels and for welding fine-grain steels

with up to 450 N/mm

2

yield strength

(jekor 35, Ni onicral 45, etc.). Seam

surface is clean, free of pores.

Contents of hydrogen are less than 3

ml/100g of weld metal.

E515B262H

PIVA 253 B

E5041NiB42

C 0.08

Mn 0.95

Si 0.5

Ni 1.1

AC

DC+

2.5

3.25

4.0

5.0

300

350

450

450

60-90

110-150

150-190

190-240

490-550 590-640 22-26

-20C

110-170

-40C

47

Thick coated basic electrode, alloyed

with Mn and Ni, suitable for welding

steels with tensile strength up to 680

N/mm

2

fine-grain steels with

guaranteed properties at low

temperatures. Weld able in all position

except vertical down.

PIVA 255 B

E5022NiB32

H10

C 0.06

Mn 0.95

Si 0.35

Ni 2.7

DC+

2.5

3.25

4.0

5.0

6,0

300

350

450

450

450

70-90

110-140

140-180

180-250

250-290

510-590 590-670 22-28

-20C

80

-60C

47

Thick flux coated 2.7%Ni alloyed

electrode for fine-grain steels up to 550

N/mm

2

yield strength and for welding of

low- alloyed steels up to 735 N/mm

2

tensile strength, high tough at low

temperatures. Clean, rippled seam

surface free of porosity. Contents of

hydrogen are less than 3 ml/100g of

weld metal.

PIVA 255 B

Mo

E5522NiMo

B42

C 0.08

Mn 0.95

Si 0.5

Ni 2.5

Mo 0.35

DC+

2.5

3.25

4.0

5.0

300

350

450

450

70-90

90-140

150-190

180-240

550-640 650-750 22-26

-20C

120-160

-40C

60-90

Basic thick coated NiMo alloyed

electrode for welding of Cr-Ni-Mo steels

up to 780 N/mm

2

tensile strength, for

welding on fine-grain steels which

require guaranteed mechanical

properties at low temperatures and for

welding of fine grain high temperature

resistant steels up to 590 N/mm

2

yield

strength. Weld able in all position

except vertical down. Contents of

hydrogen are less than 5 ml/100g of

weld metal.

MEDIUM-ALLOYED FLUX COATED BASIC ELECTRODES FOR WELDING OF HEAT

RESISTANT STEELS

JUS C.H3.015

EN1599

/EN499

EMoB262H

PIVA 350 B

EMoB42

C 0.08

Mn 0.95

Si 0.45

Ni 1.5

DC+

2.5

3.25

4.0

5.0

6,0

300

350

450

450

450

60-90

110-140

140-180

180-230

240-290

460-530 570-640 22-28 100-160

Basic flux coated Mo alloyed electrode.

Suitable for applications within

temperature range up to 500C, for

welding of unalloyed steels up to 640

N/mm

2

tensile strength and fine grain

steels up to 460 N/mm

2

yield strength.

For welding of plates thicker than 200

mm and with carbon contents over

0.2%. Electrode preheating at about

200C is recommended immediately

prior to welding.

E1CrMoB20

2H

PIVA 351 B

ECrMo1B42

C 0.08

Mn 0.85

Si 0.5

Cr 1.2

Mo 0.5

DC+

2.5

3.25

4.0

5.0

6,0

300

350

450

450

450

70-90

100-130

150-180

180-220

230-280

After tempering on 720C

460-560 560-660 22-26 100-140

Basic Cr-Mo alloyed electrode. Suitable

for applications within temperature

range up to 550C and for welding of

steel castings and heat-treatable steels

up to 900 N/mm

2

tensile strength. Prior

to welding of Cr-Mo steels, preheating

at 200-250C and heat treatment at

650-750C after welding is

recommended.

E2CrMoB20

2H

PIVA 352 B

ECrMo2B42

C 0.08

Mn 0.85

Si 0.5

Cr 2.3

Mo 1.0

DC+

2.5

3.25

4.0

5.0

6,0

300

350

450

450

450

65-85

100-130

140-180

180-230

220-270

After tempering on 760C

540-620 640-720 19-26 90-140

Basic Cr-Mo alloyed electrode. Suitable

for welding of steels having operating

temperature range up to 600C and for

welding of heat treatable up to 1100

N/mm

2

tensile strength. Prior to welding

of Cr-Mo steels, preheating at 200-

250C and heat treatment at 650-750C

after welding is recommended.

E5CrMoB26

2H

PIVA 353 B

ECrMo5B42

C 0.08

Mn 0.85

Si 0.5

Cr 5.0

Mo 0.55

DC+

2.5

3.25

4.0

5.0

300

350

450

450

65-85

100-130

140-180

180-230

After tempering on 760C

500-590 590-750 18-23 80-100

Basic thick coated Cr-Mo electrode.

Suitable for welding of 12 CrMo steels

and GS-12 CrMo 195 steel castings

stable at temperature of 600C and

hydrogen-resistant. Also suitable for

welding of heat treatable steels with

similar chemical composition heat-

treated to tensile strength up to 1175

N/mm

2

and for welding of tool steels.

Weld able in all positions except

vertical down.

MEDIUM-ALLOYED FLUX COATED RUTILES ELECTRODES FOR WELDING OF HEAT

RESISTANT STEELS

PIVA 130 RR

Mo

EMoR22

C 0.1

Mn 0.55

Si 0.30

Mo 0,55

AC

DC-

2.5

3.25

4.0

5.0

300

350

450

450

70-90

120-150

150-200

200-250

450-500 510-600 22-25

70-100

min

Thick coated Mo alloyed rutile

electrode. Suitable for welding of heat-

resistant steels for boilers and for

welding of unalloyed and low-alloyed

E46MoRR12

6,0 450 240-290 steels up to 590 N/mm

2

tensile

strength. Weld metal is resistant to high

temperatures up to 500C. Weld able in

all positions except vertical down.

FLUX COATED ELECTRODES FOR OVERWELDING

JUS C.H3.019

DIN 8555

PIVA UT 38

E3-UM-40-T

C 0.13

Cr 5.0

Mo 4.0

V 0.2

W+

DC+

2.5

3.25

4.0

5.0

300

350

450

450

70-90

110-135

130-170

180-220

Weld hardness = 36-40 (HRC)

Basic alloyed electrode for over welding

of tools used foe shaping of steels and

certain alloys in hot and cold condition

such as steel moulds, mandrels, rolls

etc. Over weld is tough, impact

resistant and machinable. Weld able in

all positions except vertical down. Weld

hardness is stable up to 600 C. Before

use, baking at 250 C/3h is

recommended.

PIVA UT 55

E6-UM-60-T

C 0.5

Cr 5.0

Mo 5.0

V 0.6

W+

DC+

2.5

3.25

4.0

5.0

300

350

450

450

70-90

110-135

130-170

180-220

Weld hardness = 55-60 (HRC)

Basic alloyed electrode for over welding

of tools used for shaping and cutting of

steels and, similar alloys in hot and cold

condition, such as extrusion mandrels,

cutting tools etc. Weld deposit is tough,

impact resistant and machinable after

soft annealing. Weld hardness is stable

up to 600C.

E1-300

PIVA 430 B

E1-300

UMhllt

C 0.15

Mn 1.3

Si 0.7

Cr 1.2

DC+

3.25

4.0

5.0

6.0

350

450

450

450

100-130

130-170

190-230

230-270

Weld hardness = 280-330 (HRC)

Basic flux coated electrode over

welding of worn-out parts such as

gears, shafts, stone chrushers, etc.

Weld deposit is wear resistant and

machinable.

E1-400

PIVA 440 B

E1-400

UMhllt

C 0.22

Mn 1.4

Si 0.8

Cr 1.5

DC+

3.25

4.0

5.0

6.0

350

450

450

450

100-130

140-170

190-230

230-290

Weld hardness = 350-460 (HRC)

Basic flux coated electrode over

welding of worn-out parts such as

crane wheels, rails, gears, parts of

vehicles with caterpillars and other

mechanical parts exposed to wearing.

Weld deposit is wear resistant and

impact resistant and machinable.

E2-60 *)

JUS C.H3.013

PIVA 460 B

E2-UM-60

C 0.5

Mn 3.0

Si 1.6

Cr 2.0

DC+

3.25

4.0

5.0

350

450

450

100-130

140-180

130-240

Weld hardness = 55-65 (HRC)

Basic flux coated electrode for hard

over welding of part exposed to heavy

abrasive wear. Very applicable for hard

facing areas of wear on loading

machines, forest machinery, hammer

mils, crusher jaws, earth removing

machines, metal cutting blades etc

Weld deposit is hard and tough and

unmashinable.

PIVA B 600

E6-60UMhllt

C 0.45

Si 0.70

Mn 0.65

Cr 9.5

Mo 0.50

V 1.1

DC+

2.5

3.25

4.0

5.0

300

350

450

450

50-70

90-120

130-160

170-210

Weld hardness = 60 (HRC)

Basic flux coated electrode over

welding of steel parts, high resistant to

wear, exposed to impact and reassure

such as crusher jaws, mill hammers,

earth removing machine parts, plough

parts, pneumatic tools, cold and hot

forming tools, shear blades, etc. For

multi- layer over welding intermediate

to be built- up with PIVA 29/9 or PIVA

18/18/6 electrode. For welding of parts

subject to cracks, preheating at 250-

350C and controlled cooling after over

welding is recommended. Before use,

drying at 250C/2-3h is recommended.

FLUX COATED ELECTRODES FOR OVERWELDING OF PARTS EXPOSED TO IMPACTS

PIVA Mn 13B

E7-UM-200 kp

C 1.2

Si 0.8

Mn 13.0

DC+

3.25

4.0

5.0

350

450

450

100-140

150-160

200-240

20 after over welding

40-50 after hardening

Basic thick coated electrode for over

welding of hard and high tough

austenite steels with 13% Mn, high

resistant to wear when exposed to

impact or stresses. Hardness and

resistance to wear become higher cold

forging or operation when overwelded

parts are exposed to impact or friction.

Weld metal is machinable with hard

carbide tools.

FLUX COATED ELECTRODES FOR GROOVING AND CUTTING

PIVA S1

DC-

AC

3.25

4.0

5.0

350

350

350

450

160-200

200-260

270-330

Acid thick coated cellulose electrode

designed for grooving and cutting of all

industrials metals and for removal of

pores and cracks caused by welding.

Grooving in possible in all positions

except vertical up. Main materials:

unalloyed and high alloyed steels, cast,

iron, copper, copper alloys, aluminum

and aluminum alloys.

HIGH-ALLOYED FLUX COATED FERRITE ECTRODES

JUS C.H3.017

EN 1600

PIVA B 17 Fe

E17B13036Y

C 0.10

Cr 16.5

Ni 0.5

DC+ 2.5

3.25

4.0

5.0

300

350

450

450

60-80

80-120

120-160

160-200

>440 590-740 Hardness (HRC)

25-30

After tempering 2h

on 650-750C ~20

Basic electrode designed for welding

and over welding of stainless ferrite

steels with 17% Cr. Suitable for over

welding of gas, water and steam

armatures made of unalloyed and low-

alloyed steels with leak-proof demands

E17B43

of overwelded surface, high corrosion

proof demands at operating

temperatures up to 450 C. Depending

on thickness and composition of main

material, preheating at 200-300C and

heat treatment at 650-750C is

recommended.

E17.0.1B1303

6Y

PIVA B 17

MoFe

C 0.15

Cr 16.5

Ni 0.5

Mo 1.1

DC+

2.5

3.25

4.0

5.0

300

350

450

450

60-80

80-120

120-160

160-200

Hardness (HRC)

40-45

After tempering 2h

on 650-750C 25-

30

Basic electrode designed for welding

and over welding of stainless ferrite

steels with 17% Cr. Suitable for over

welding of gas, water and steam

armatures made of unalloyed and low-

alloyed steels with leak-proof demands

of overwelded surface, high corrosion

proof demands at operating

temperatures up to 550 C. Depending

on thickness and composition of main

material, preheating at 220-300C and

heat treatment at 650-750C is

recommended.

HIGH-ALLOYED FLUX COATED AUSTENITE AND AUSTENITE-FERRITE ELECTRODES

E19.9NbR20

PIVA 19/9 R

Nb

E199NbR12

C 0.06

Cr 19

Ni 9

Nb 12 X%C

AC

DC+

2.5

3.25

4.0

5.0

300

350

350

450

60-80

90-110

120-150

150-175

340-450 550-680 30-40 80-110

High-alloyed rutile Nb-stabilized

electrode suitable for welding of high

alloyed Cr-Ni steels, Cr-Ni-Mo steels

and unalloyed and low-alloyed steels.

Weld metal of PIVA 19/9 Nb is inter-

crystal corrosion resistant up to 400C

and on oxidizing gases up to 800C.

Weld able in all positions except

vertical down.

E19.9NbR20+

PIVA 19/9 B

Nb

E199NbB22

C 0.06

Cr 19

Ni 9

Nb 12 X%C

AC

DC+

2.5

3.25

4.0

5.0

300

350

350

450

60-80

90-110

120-150

150-175

340-450 550-680 30-40 80-110

High-alloyed basic Nb-stabilized

electrode suitable for welding of high

alloyed Cr-Ni steels and Cr-Ni-Mo

steels. Weld metal tough and resistant

to cracking. Weld able in all positions

except vertical down.

E19.9LR26

PIVA 19/9 R

Lc

E199LR12

C 0.03

Cr 19

Ni 9

AC

DC+

2.5

3.25

4.0

5.0

300

350

350

450

60-80

90-110

120-150

150-175

340-450 550-680 30-40 80-110

High-alloyed basic electrode with

carbon content, suitable for high

alloyed Cr-Ni steels and Cr-Ni-Mo

steels. Weld metal is inter- crystal

corrosion resistant up to 400C and on

oxidizing gases up to 800C. Weld able

in all positions except vertical down.

E19.9LB20+

PIVA 19/9 B

Lc

E199LB12

C 0.03

Cr 19

Ni 9

Mn 0.9

Si 0.3

AC

DC+

2.5

3.25

4.0

5.0

300

350

350

450

60-80

90-110

120-150

150-175

340-450 550-680 30-40 80-110

High-alloyed basic electrode with low

carbon content, suitable for welding of

high-alloyed Cr-Ni steels and Cr-Ni-Mo

steels. Weld metal is resistant to

cracking and has high deformation

capacity and high notch impact

strength.

E19.12.3LR26

PIVA 19/12/3

R Lc

E19123LR12

C 0.03

Cr 19

Ni 9

Mo 2.5-3.0

AC

DC+

2.5

3.25

4.0

5.0

300

350

350

450

60-80

90-110

120-150

150-175

350-460 540-690 30-40 80-110

High-alloyed rutile electrode with low

carbon content, suitable for welding

and over welding of stabilized and un

stabilized Cr-Ni and Cr-Ni-Mo steels. It

can also be used for welding of ferrite

Cr steels and other low- alloyed and

medium- alloyed materials. Weld able

in all positions except vertical down.

E19.123LB20+

PIVA 19/12/3

B Lc

E19123LB12

C 0.03

Cr 19

Ni 9

Mo 2.5-3.0

Mn 1.0

Si 0.3

DC+

AC

2.5

3.25

4.0

5.0

300

350

350

450

60-80

90-110

120-150

150-175

350-460 540-690 30-40 80-110

High-alloyed basic electrode with low

carbon content, suitable for welding

and over welding of stabilized and un

stabilized Cr-Ni and Cr-Ni-Mo steels. It

can also be used for welding of ferrite

Cr steels and other low- alloyed and

medium- alloyed materials. Weld metal

is extremely resistant to cracking and

has high deformation capacity.

E19123NbR20

PIVA 19/12/3

R Nb

E19123NbR12

C 0.06

Cr 19

Ni 9

Mo 2.5-3.0

Nb 12 X%C

DC+

AC

2.5

3.25

4.0

5.0

300

350

350

450

60-80

90-110

120-150

150-175

350-460 540-690 30-40 80-110

High-alloyed rutile Nb-stabilized

electrode suitable for welding and over

welding of un stabilized and stabilized

Cr-Ni and Cr-Ni-Mo steels. It can also

be used for welding of ferrite Cr steels

and other low- alloyed and medium-

alloyed materials. Weld able in all

positions except vertical down.

E19123NbB20

PIVA 19/12/3

B Nb

E19123NbB12

C 0.06

Cr 19

Ni 9

Mo 2.5-3.0

Nb 12 X%C

DC+

AC

2.5

3.25

4.0

5.0

300

350

350

450

60-80

90-110

120-150

150-175

350-460 540-690 30-40 80-110

Basic flux coated stainless steel Nb-

stabilized electrode, suitable for

welding and over welding of un

stabilized and stabilized Cr-Ni and Cr-

Ni-Mo steels. It can also be used for

welding, of ferrite Cr steels and other

low- alloyed and medium- alloyed

materials. Weld metal is extremely

resistant to cracking and has high

deformation capacity.

HIGH-ALLOYED FLUX COATED ELECTRODES FOR WELDING OF HEAT RESISTANT STEELS

E25.20B20+

PIVA 25/20 B

E2520B42

C 0.12

Si 1.0

Mn 1.8

Cr 25

Ni 20

DC+

AC

2.5

3.25

4.0

5.0

300

350

350

450

65-80

90-120

120-150

150-210

350 540-640 30 70

Basic flux coated austenite electrode

for welding of high heat resistant 25/20

CrNi stainless steels, ferrite Cr steels

and steel castings. Resistant to scaling

of old deposit up to 1200C, with

excellent impact strength values down

to -196C. Easy slag removal.

E25.20R26

PIVA 25/20 R

E2520R12

C 0.12

Si 1.0

Mn 2.5

Cr 25

Ni 20

DC+

AC

2.5

3.25

4.0

5.0

300

350

350

450

65-80

90-120

120-150

150-210

350 540-640 30 70

Rutile flux coated austenite electrode

for welding of high heat resistant 25/20

Cr-Ni steels and heat resistant ferrite

and ferrite- pearlite steels. Weld metal

is heat resistant up to 1200C, arc is

stable and stag is removed easily.

Seam surface is clean and smooth.

HIGH-ALLOYED FLUX COATED ELECTRODES FOR SPECIAL PURPOSES

E18.8MnB20*

PIVA 18/8/6 B

E188MnB22

C 0.12

Mn 6

Cr 18

Ni 8

DC+

2.5

3.25

4.0

5.0

300

350

350

450

60-75

90-120

110-160

150-200

350 590-690 30 80

Basic flux coated austenite electrode

suitable for welding of corrosion

resistant Cr and Cr-Ni stainless steels

for welding of dissimilar steels, for

joining of steels, with high tensile

strength and bad weld ability. For

welding of buffer layers to avoid

residual stresses and for over welding

of corrosion and wear resistant steels.

Weld metal is unmagnetic, heat

resistant up to 800C with good impact

strength value down to 100C crack

resistant.

E18.8MnR20+

PIVA 18/8/6 R

E188MnR12

C 0.12

Mn 6

Cr 18

Ni 8

DC+

AC

2.5

3.25

4.0

5.0

300

350

350

450

60-75

90-120

110-160

150-200

350 580-690 30 80

Flux coated rutile austenite electrode

for welding high alloyed corrosion

resistant Cr and Cr-Ni steels, and for

welding of dissimilar steels. Suitable for

welding of buffer layers to avoid

residual stresses and for over welding

of corrosion and wear resistant steels.

Weld metal is corrosion resistant up to

800C and tough up to -100C.

E29.9R26

PIVA 29/9 R

E299R12

C 0.15

Mn 1.2

Cr 29

Ni 9

DC+

AC

2.5

3.25

4.0

5.0

300

350

350

450

50-80

80-120

110-150

150-200

500 740-840 20 230-270

Flux coated rutile austenite- ferrite

electrode for welding corrosion stable

steels and cast steels. Suitable for

welding of dissimilar steels, hard

manganese steels and bad weld ability

steels. Suitable also for welding of

buffer layers. Arc is stable, slag is

removed easily and seam is clean and

smooth.

FLUX COATED ELECTRODES FOR WELDING OF GREY CAST IRON

JUS C.H3.016

EniBG2

PIVA 98 Ni

Ni 98

AC

DC-

2.5

3.25

4.0

5.0

300

350

350

450

50-80

80-110

110-150

150-190

Hardness = 170 (HRB)

Special basic flux coated electrode

suitable for cold welding of gray cast

iron and cast steels. Suitable for

welding of unalloyed, low- alloyed and

high- alloyed steels for joining base

metal to steel, copper or copper alloys.

It is also used for repairing surface of

damaged parts of gray cast iron.

Welding and over welding joint is

machinable. PIVA 98 Ni is weld able in

all position except vertical down.

ENiCu2BG2

PIVA NiCu

Ni 70

Cu 30

AC

DC-

2.5

3.25

4.0

300

350

350

50-80

80-110

110-150

Hardness = 170 (HRB)

Special basic flux coated electrode with

monel (NiCu) core. Suitable for cold

welding and over welding of gray cast

iron, for repair welding of broken and

worn parts. Welding and over welding

joint is machinable. PIVA NiCu is weld

able in all position except vertical down.

E(FeC-2)BG49

PIVA 250 L

C 3.2

Si 3.5

Mn 0.6

AC

DC-

2.5

3.25

4.0

5.0

300

350

350

450

60-80

80-110

100-160

150-210

Hardness = 250 max (HRB)

Special electrode for repair welding and

over welding of gray cast iron. Suitable

for welding of moulds in steel industry

and other castings of gray cast iron.

Preheating at 450-600C.

WELDING WIRES FOR WELDING INTO CO

2

GAS SHIELDED

JUS C H.43

EN440

.3203

PIVA 60

G3Si1

C 0.1

Mn 1.5

Si 0.9

DC+

0.8

1.0

1.2

1.6

410-490 510-590 22-30 80-125

JR

LR

ABS

BV

SSSR

ZJ

Special copper coated wire for CO2

gas. Suitable for welding of unalloyed

and low- alloyed structure steels up to

590 N/mm

2

tensile strength, boiler

plates, shipbuilding plates A, B, C and

D.

PIVA 60 Ni

G3Ni1

C 0.1

Mn 1.5

Si 0.9

Ni 1.0

DC+

0.8

1.0

1.2

1.6

450-510 550-650 22-30

+20C

80-120

-40C

30-50

Special copper-coated Cu-Ni alloyed

wire for CO2 gas shield welding.

Suitable for welding of unalloyed and

low- alloyed steels and for welding of

fine grain steels up to 450 N/mm

2

yield

strength.

PIVA 60 NiCu

C 0.1

Mn 1.5

Si 0.9

Cu 0.5

Ni 0.5

DC+

0.8

1.0

1.2

1.6

430-530 530-630 22-30

(+20C)

80-120

(-40C)

30-50

Special copper-coated Ni-alloyed wire

for CO2 gas shield welding. Suitable for

welding of water- resistant steels,

unalloyed and low- alloyed steels up to

685 N/mm

2

tensile strength and for

welding of fine-grain structure steels up

to 450 N/mm

2

yield strength.

WELDING WIRES FOR AUTOMATIC SUBMERGED ARC WELDING

JUS C.H3.052

EN756*/

EN12072

1

PIVA EPP 1

C 0.08

Si 0.15

Mn 0.55

2.0

2.5

3.0

4.0

5.0

Unalloyed copper- coated wire for

automatic submerged arc welding of

structure steels, pipe steels, boiler and

shipbuilding plates and other unalloyed

and low- alloyed steels up to 510

N/mm

2

tensile strength.

2

PIVA EPP 2

S2

C 0.10

Si 0.15

Mn 1.0

Mo 0.5

2.0

2.5

3.0

4.0

5.0

Manganese alloyed copper- coated,

wire for automatic submerged arc

welding. Suitable for welding of

structure steels, pipe steels, boiler and

shipbuilding plates and other unalloyed

and low- alloyed steels up to 510

N/mm

2

tensile strength.

2Mo

PIVA EPP 2

Mo

S2Mo

C 0.10

Si 0.15

Mn 1.0

Mo 0.5

2.0

2.5

3.0

4.0

5.0

Manganese- molybdenum alloyed

copper coated wire for automatic

submerged arc welding of unalloyed

and low- alloyed steels up to 680

N/mm

2

tensile strength and for welding

molybdenum- alloyed heat resistant

steels and fine- grain steels up to 450

N/mm

2

yield strength.

WIRES FOR WELDING IN PROTECTION GAS TIG PROCEDURE

EN12072/

prEN1668

PIVA TIG 19/9

Nb

W199Nb

C 0.04-0.07

Si 0.3-0.6

Mn 1.5-1.9

Cr 19-20.5

Ni 9.5-10.5

Nb 0.4-0.8

2.0

2.5

3.25

1000 >350 570-670 >30 >65

Cr-Ni alloyed and Nb stabilized welding

wire suitable for welding of corrosion

resistant stabilized and unstabilized

steel of similar chemical composition.

Weld metal is resistant to oxidation up

to 196C. It is used in chemical

industry, pharmacy, cellulose-

processing and dyeing industry at

operating temperature up to 400C.

PIVA 19/12/3

Nb

W19123L

C 0.04-0.07

Si 0.3-0.6

Mn 1.5-2.0

Cr18.5-19.5

Ni 11.5-12.5

Mo 2.0-2.6

Nb 0.4-0.8

2.0

2.5

3.25

1000 >350 570-670 >30 >65

Cr-Ni-Mo alloyed, Nb stabilized welding

wire suitable for welding of Cr-Ni-Mo

stabilized and unstabilized steel. It is

used in chemical industry, pharmacy,

cellulose-processing and dyeing

industry, industry if drink and resin

industry. Weld metal is resistant to

corrosion up to 350C and to oxidation

up to 800C.

PIVA TIG

18/8/6

W188Mn

C 0.05-0.10

Si 0.5-0.8

Mn 6.5-7.5

Cr18.5-19.5

Ni 8-9

2.0

2.5

3.25

1000 >350 >560-660 >35 >100

Cr-Ni-Mn alloyed wire suitable for

welding of steel with high strength and

bad weldability. Weld metal is corrosion

resistant up to 800C and has good

impact value down to -100C.

PIVA TIG

25/20

W25/20

2.0

2.5

3.25

1000 >300 540-640 >30 >70

Alloyed austenite welding wire suitable

for welding of heat resistant steel and

25% Cr and 20% Ni cast steel. Weld

metal is corrosion resistant up to

1200C. It has good impact value down

to -196C

FLUX CORED WIRES FOR WELDING AND OVERWELDING

PrEN758

PIVA 300 B

T424BC3/

T424BM3

C 0.07

Si 0.40

Mn 1.5

DC

1.2

1.4

1.6

150-200

170-290

200-350

>400

>520

620

>26

(+20C)

160

(-20C)

>100

(+40C)

>60

Basic flux cored wire suitable for

welding of unalloyed structure steels,

boiler plates, pipe steels, shipbuilding

plates and fine grain steel. Suitable

also for overwelding of interlayer of bad

weldable steels. Free of spattering,

easy slag removal and excellent

mechanical properties of weld metal at

low temperature.

PIVA 600 B

C 0.50

Si 0.35

Mn 1.20

Cr 4.5

Mo 0.8

DC

1.2

1.4

1.6

130-250

180-340

220-420

Weld hardness = 58-62 (HRC)

Basic flux cored medium-alloyed wire

for hard overwelding of parts exposed

to heavy wear and friction. Overweld is

smooth, free of porosity or cracks,

resistant to impact or stresses. Weld

deposit is machineable by grinding

only. Suitable for overwelding of mixer

plates and vanes, earth removing

machine jaws, crusher parts, cones etc.

WELDING WIRE FOR OXYGEN-ACETYLENE WELDING

JUS C.H3.051

EN12536

VA 37

PIVA 37 G

OI

C 0.09

Mn 0.55

Si 0.1

1.0

1.5

2.0

3.0

4.0

5.0

Isporuka

u

ipkama

od 1 m

Hardness (HB)

100-120

340-410 15-21 47-70

Copper coated unalloyed wire for

oxygen-acetylene welding of plates,

tubes and other steel sections and

profiles up to 450 N/mm

2

tensile

strength. Weld metal is soft and well-

machineable.

P3

PIVA 42 G

OIII

C 0.1-0.15

Mn 0.8-0.9

Si 0.2-0.3

Ni 0.6-0.8

Mo 0.2-0.25

2.0

3.0

4.0

5.0

Isporuka

u

ipkama

od 1 m

Hardness (HB)

100-120

410-470 16-22 65-80

Copper coated Mn, Ni, Mo alloyed wire

for oxyacetylene welding of boiler

plates, shipbuilding plates and pipes.

CONTACT INFORMATION

Tel/fax: +382 (0) 40 271 900

271 901

271 902

271 903

271 904

President of Board of Directors: +382 (0) 40 271 911

Executive Manager: +382 (0) 40 271 910

Technical Manager: +382 (0) 40 271 907

Sales Manager: +382 (0) 40 271 912

Office in Niksic 213 630

Purchase Manager +382 (0) 40 271 906

Financial Manager: +382 (0) 40 271 805

e-mail: fep@t-com.me

fep-prodaja@t-com.me

Internet: http://www.fep.co.me/

You might also like

- Arc Welding Electrodes (Product Catalogue)Document28 pagesArc Welding Electrodes (Product Catalogue)ddprt123No ratings yet

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiNo ratings yet

- Section 2 - Nichia Welding ConsumableDocument9 pagesSection 2 - Nichia Welding ConsumableLodyNo ratings yet

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- AWS A5.1 E6010 SC-10 Mild Steel Electrodes SpecificationsDocument56 pagesAWS A5.1 E6010 SC-10 Mild Steel Electrodes SpecificationsFakhar WindratamaNo ratings yet

- Stick electrodes for welding steels and stainless steelsDocument46 pagesStick electrodes for welding steels and stainless steelsAdeKusumahNo ratings yet

- Avesta 2205 AC DCDocument1 pageAvesta 2205 AC DCpipedown456No ratings yet

- Select Arc Catalogue Part 2Document10 pagesSelect Arc Catalogue Part 2lionheartedNo ratings yet

- Description:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless SteelDocument1 pageDescription:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless Steel13421301508No ratings yet

- KST 309LDocument1 pageKST 309LTharman SupramaniamNo ratings yet

- WELDING SPREADER Electrode KALMAR PDFDocument1 pageWELDING SPREADER Electrode KALMAR PDFArtin HykoNo ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- 1 - UTP 614 KBDocument1 page1 - UTP 614 KBKrishna VachaNo ratings yet

- CERTILAS EN Edition2023 312Document1 pageCERTILAS EN Edition2023 312Alireza KhodabandehNo ratings yet

- Mild Steel 490mpa High Tensile Strength SteelDocument38 pagesMild Steel 490mpa High Tensile Strength SteelCarlos PadillaNo ratings yet

- CERTILAS EN Edition2023 313Document1 pageCERTILAS EN Edition2023 313Alireza KhodabandehNo ratings yet

- High corrosion resistant stick electrode for duplex and lean duplex alloysDocument1 pageHigh corrosion resistant stick electrode for duplex and lean duplex alloyscristian popescuNo ratings yet

- MIP Bohler Welding Austwqrwq2332e3eddwria 98Document1 pageMIP Bohler Welding Austwqrwq2332e3eddwria 98maxi27No ratings yet

- Официальный дистрибьютор ЗАО «Ресурс» т/ф 8 (383) 363-26-24, 291-93-02 630020 Россия г.Новосибирс ул.Объединения д.9 e-mail: resurszao@Document1 pageОфициальный дистрибьютор ЗАО «Ресурс» т/ф 8 (383) 363-26-24, 291-93-02 630020 Россия г.Новосибирс ул.Объединения д.9 e-mail: resurszao@brayanNo ratings yet

- SMAW high-alloy electrode applicationsDocument1 pageSMAW high-alloy electrode applications2003vinayNo ratings yet

- CERTILAS EN Edition2023 320Document1 pageCERTILAS EN Edition2023 320Alireza KhodabandehNo ratings yet

- Mild Steel Welding Electrodes: Salient FeaturesDocument16 pagesMild Steel Welding Electrodes: Salient FeaturesHandrea Hadi SaputraNo ratings yet

- Electrodos-Revestidos KiswellDocument116 pagesElectrodos-Revestidos KiswellJoel FloresNo ratings yet

- MMA Electrodes for Welding Stainless Steels AISI 321 and AISI 347Document1 pageMMA Electrodes for Welding Stainless Steels AISI 321 and AISI 347Gogo PNo ratings yet

- CERTILAS EN Edition2023 317Document1 pageCERTILAS EN Edition2023 317Alireza KhodabandehNo ratings yet

- Utp 7015 NKDocument1 pageUtp 7015 NKsergey.pu4kaNo ratings yet

- Catalogue MetalweldDocument17 pagesCatalogue MetalweldRadivojevic SasaNo ratings yet

- Brass MB30 Material PropertiesDocument2 pagesBrass MB30 Material PropertiesVinoth KumarNo ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- Atmospheric Corrosion Resisting SteelDocument10 pagesAtmospheric Corrosion Resisting SteelCarlos PadillaNo ratings yet

- DT-1.4462 WP 380: Stainless Steel Subarc Wire Fused Welding FluxDocument1 pageDT-1.4462 WP 380: Stainless Steel Subarc Wire Fused Welding Fluxmarketing.automatizatNo ratings yet

- L1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Document1 pageL1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Dimitris NikouNo ratings yet

- YAWATA 7018: Classification Applications Characteristics ApprovalsDocument1 pageYAWATA 7018: Classification Applications Characteristics ApprovalsDenny AgusNo ratings yet

- 02112015000000B_Boehler FOX EASN 25 M_ceDocument1 page02112015000000B_Boehler FOX EASN 25 M_ceABNo ratings yet

- Utp 86 FNDocument1 pageUtp 86 FNc131508No ratings yet

- Welding Technology Steelconstr - EngDocument32 pagesWelding Technology Steelconstr - EngLukman Tarigan SumatraNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- L1 34410 en Avesta 309 AC DC 2SE6A22E 3383012 ENDocument1 pageL1 34410 en Avesta 309 AC DC 2SE6A22E 3383012 ENkamals55No ratings yet

- CI-500 Cast Iron Repair ElectrodeDocument1 pageCI-500 Cast Iron Repair ElectrodeLasandu WanniarachchiNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- Fox CN 23-12-ADocument1 pageFox CN 23-12-AVIRPOPNo ratings yet

- Avesta 3D ElectrodesDocument2 pagesAvesta 3D ElectrodesOndrej PelešNo ratings yet

- En 10028 P355GHDocument2 pagesEn 10028 P355GHEvriMert RüzgArdaNo ratings yet

- CH-350RDocument1 pageCH-350RThanuja PereraNo ratings yet

- CERTILAS EN Edition2023 316Document1 pageCERTILAS EN Edition2023 316Alireza KhodabandehNo ratings yet

- D and H NewDocument37 pagesD and H NewBharat AhirNo ratings yet

- FOX CN 23-12 Mo-ADocument1 pageFOX CN 23-12 Mo-AVIRPOPNo ratings yet

- Copper Alloy ProductDocument7 pagesCopper Alloy ProductFernando Fernandes Da SilvaNo ratings yet

- E316L-17 Rutile electrode characteristicsDocument1 pageE316L-17 Rutile electrode characteristicsInaamNo ratings yet

- CERTILAS EN Edition2023 315Document1 pageCERTILAS EN Edition2023 315Alireza KhodabandehNo ratings yet

- Electrode Equivalaent NumbersDocument2 pagesElectrode Equivalaent NumbersRamdas100% (2)

- Cold Rolled 2010 DUNAFER HungriaDocument12 pagesCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNo ratings yet

- E 7016 Spezial electrode-oerlikon-en-TN110089Document2 pagesE 7016 Spezial electrode-oerlikon-en-TN110089Khhg AgddsNo ratings yet

- Utp Af A7Document1 pageUtp Af A7VIRPOPNo ratings yet

- Welding consumables for ferritic stainless steelsDocument1 pageWelding consumables for ferritic stainless steelsBranko FerenčakNo ratings yet

- Super Optimal 6010Document1 pageSuper Optimal 6010NIZAM NIZAMNo ratings yet

- Katalogas enDocument20 pagesKatalogas enEman AdelNo ratings yet

- BS 4360 50eeDocument1 pageBS 4360 50eeTimNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Lab-Scale Circulation Process of Electrolytic Manganese Production With Low-Grade Pyrolusite Leaching by SO2Document8 pagesLab-Scale Circulation Process of Electrolytic Manganese Production With Low-Grade Pyrolusite Leaching by SO2Filipe CruzNo ratings yet

- Sa 20 PDFDocument46 pagesSa 20 PDFmr.aghelNo ratings yet

- GAUHATI UNIVERSITY SOPHISTICATED ANALYTICAL INSTRUMENT FACILITYDocument1 pageGAUHATI UNIVERSITY SOPHISTICATED ANALYTICAL INSTRUMENT FACILITYSritam SwapnadarshiNo ratings yet

- g10 Chem ETT APR 2023 REVISION GUIDEDocument10 pagesg10 Chem ETT APR 2023 REVISION GUIDEHa Khanh Ngoc TranNo ratings yet

- Uw 11-MaterialDocument18 pagesUw 11-MaterialDenny AgusNo ratings yet

- Airblast Abrasives: Brown Fused AluminaDocument2 pagesAirblast Abrasives: Brown Fused Aluminamekhman mekhtyNo ratings yet

- Science Form 1 Chapter 4Document26 pagesScience Form 1 Chapter 4Beevy GB73% (11)

- The Golden Book of Chemistry Experiments - BrentDocument114 pagesThe Golden Book of Chemistry Experiments - BrentJosé Alberto Fernández100% (4)

- (c96d68d8 3419 42e8 b7c6 689afc850d61) TS Ebook XRF Technology in The FieldDocument32 pages(c96d68d8 3419 42e8 b7c6 689afc850d61) TS Ebook XRF Technology in The FieldLewy HandleNo ratings yet

- Pengolahan Bahan Galian Lanjut (1) : DR. Yusuf Rumbino, ST. MT Teknik Pertambangan-FST-UNDANA 2022Document21 pagesPengolahan Bahan Galian Lanjut (1) : DR. Yusuf Rumbino, ST. MT Teknik Pertambangan-FST-UNDANA 2022Paska SorminNo ratings yet

- Acid and BasesDocument15 pagesAcid and Basesharssh adhhiyaNo ratings yet

- Chem Project..finalDocument13 pagesChem Project..finalhuehueNo ratings yet

- FAO/WHO Expert Committee Heavy Metal Limits Food AdditivesDocument3 pagesFAO/WHO Expert Committee Heavy Metal Limits Food AdditivesediasianagriNo ratings yet

- Online Classroom RulesDocument30 pagesOnline Classroom RulesRogielyn P. Capin100% (1)

- Group 7 - Physical Properties: Www. .CO - UKDocument10 pagesGroup 7 - Physical Properties: Www. .CO - UKcharlesma123No ratings yet

- 1.4435 - C Stainless Steel DetailsDocument3 pages1.4435 - C Stainless Steel DetailsmeenakshiNo ratings yet

- NO Ingredient Per KG Product SatuanDocument2 pagesNO Ingredient Per KG Product SatuanprishixNo ratings yet

- November 2017 (v1) QP - Paper 4 CIE Chemistry IGCSEDocument16 pagesNovember 2017 (v1) QP - Paper 4 CIE Chemistry IGCSEGhulam Mehar Ali ShahNo ratings yet

- INCO-WELD 686CPT With Super Duplex PDFDocument10 pagesINCO-WELD 686CPT With Super Duplex PDFewillia13No ratings yet

- Cambridge Ordinary LevelDocument24 pagesCambridge Ordinary LevelDennis MuzilaNo ratings yet

- Chapter 3Document73 pagesChapter 3DjayusmannugrahantoNo ratings yet

- Write An Electron Configurations of ElementDocument10 pagesWrite An Electron Configurations of ElementMiccarina Fablina SatirNo ratings yet

- Avogadro's Number NotesDocument13 pagesAvogadro's Number Notesanon_983068579No ratings yet

- NDT 6946-6-44-0016 Rev1Document20 pagesNDT 6946-6-44-0016 Rev1sourabh100% (1)

- Extraction of IronDocument3 pagesExtraction of Irongosaye desalegnNo ratings yet

- Alloy 400 PDFDocument12 pagesAlloy 400 PDFwasatiah05No ratings yet

- Military Handbook For Manganese Phosphate and Black OxideDocument81 pagesMilitary Handbook For Manganese Phosphate and Black Oxidekhamai9No ratings yet

- Answers PDFDocument32 pagesAnswers PDFDharineeshNo ratings yet

- Edexcel As Chemistry TAG 2nd EdDocument99 pagesEdexcel As Chemistry TAG 2nd EdAkbar Iqbal82% (11)