Professional Documents

Culture Documents

Cric Dubla Actiune Final

Uploaded by

Ciobanu MihaiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cric Dubla Actiune Final

Uploaded by

Ciobanu MihaiCopyright:

Available Formats

1.

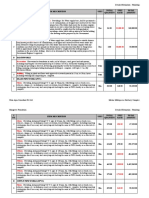

ESTABLISHING THE LOADS ON THE JACK ELEMENTS

Fig

1.1

2. CALCULUS OF THE MAIN SCREW

Choosing the material

We choose: OLC 45

Predimensioning Calculus

Load calculation

c

Q , N

N Q Q

c

22880 20800 1 , 1 = = = |

o o

1 , 1 ... 05 , 1 = |

Inner diameter of thread

3

d , mm

] [ 4 . 20

70 14 , 3

22880 4 4

3

mm

Q

d

ac

c

=

=

o t

Choosing the standard thread

We choose the trapezoidal thread Tr 28x5 SR ISO 2904, with next dimensions

from Fig 2.1 and Tabel 2.1

d

3

=20.4+2=22.4

d

3STAS

=22.5 mm

Fig 2.1

Tabelul 2.1

Nominal

Diameter

Pasul

Medium

Diameter

Exterior

Diameter

Interior Diameter

mm d,

mm p,

mm D d ,

2 2

=

mm D ,

4

mm d ,

3

mm D ,

1

28 5 25,500 28,500 22,500 23

Verifying the self braking condition

Inclination angle of thread spine

o

2

2

57 , 3

5 , 25 14 , 3

5

arctg

d

P

arctg =

=

t

= |

Apparent angle of friction

o '

78 , 6

2

30

cos

115 , 0

arctg

2

cos

arctg = =

o

= ,

o o

12 , 0 ... 11 , 0 =

The self braking condition

Checking the composite requests

Torque moment of the screw Nmm M

t

,

Fig 2.2

Effective tension of compresion

] [ 31 , 52

5 , 22 14 , 3

20800 4 4

2 2

3

MPa

d

Q

c

=

=

t

o

Effective tension of torsion

Equivalent tension

o '

2

78 , 6 57 , 3 = < = |

( )

] [ 8 ] [ 10 ... 6

] [ 32 4 28 6 ... 2

12 , 0 ... 11 , 0

] [ 25623

8 32

8 32

20800 11 , 0

3

1

3

1

0

2 2

3 3

2

0

2

3

0

3

mm mm d

mm mm d d

Nmm

d d

d d

Q M M

c

c

c

f t

= =

= + = + =

=

=

= =

] [ 11

5 , 22 14 , 3

25623 16 16

3 3

3

MPa

d

M

t

t

=

=

t

t

] [ 60 ] [ 56 11 4 31 , 52

] [ 4

2 2

2 2

MPa MPa

MPa

ac e

ac t c e

= s = + =

s + =

o o

o t o o

Buckling check

Slenderness coefficient

Fig 2.3

] [ 62 , 5

4

5 , 22

4

4

64

5 . 0

; 455

5 . 227 455 * 5 . 0

40 . 40

63 . 5

5 . 227

3

2

3

4

3

min

min

min

mm

d

d

d

A

l

i

k

m H l

l k l

i

l

i

f

f

= = =

~ =

=

= + =

= = =

= = =

t

t

3.CALCULUS OF THE SECONDARY SCREW

3.1.Choosing the material

We choose OL50 STAS 500/2-80 Tabel 3.1

3.2.Calculus of the number of spires of the maine screw (situated in the

interior of the secondary screw)

Fig 3.1

coil

p D d

Q

z

a

38 . 10

10 ) 23 28 (

20800 4

) (

4

2 2 2

1

2

=

=

t t

p

a

= 7.13MPa

We adopt

10

10 6

=

s s

z

z

Length of nut

mm P z H

pl

50 5 10 = = =

Steel Brand

Felul tratamentului

termic

Limita de

curgere R

p02

,

MPa

Rez la rupere, la

tractiune R

m

, MPa

Duritate Brinell in

stare de livrare

OLC45

Normalizat Recopt

N 360 Min 610 235 207

C,R 370500 630850

3.3.Choosing the exterior/outer thread

We adopt the preliminary interior diameter of the thread

( )

( ) ] [ 5 . 33 5 5 , 28 6 ... 4

] [ 5 . 42 9 5 . 33 10 ... 8

4 0

0 3

mm mm D D

mm mm D d

= + = + =

= + = + =

Choosing the standard thread

We a dopt the standard trapezoidal thread Tr 52x8 mm SR ISO 2904 with

next dimensions from Fig 3.2 and Tabel 3.1

Fig 3.2

Tabel 3.1

Diametrul

nominal

Pasul

Diametrul

mediu

Diametrul

exterior

Diametrul interior

mm d,

mm p,

mm D d ,

2 2

=

mm D ,

4

mm d ,

3

mm D ,

1

48 8 44 49 39 40

3.4.Verifying the self-braking

The angle of the coil thread

2

| ,

=

= 03 , 3

44 14 , 3

8

2

2

arctg

d

P

arctg

t

|

Apparent angle braking

| | mm

arctg arctg

12 , 0 ... 11 , 0

05 . 7

2

30

cos

12 , 0

2

cos

'

=

= = =

The self-braking condition

= < = 05 . 7 03 , 3

'

2

|

3.5.Checking the compound stress

Torsion moment of the screw Nmm M

t

,

( ) ] .[ 83655 ) 31 , 3 05 . 7 (

2

44

20800

2

2

' 2

Nmm tg tg

d

Q M M

insII t

= + = + = = |

Effective torsion of compresion

( )

] [ 66

) 5 . 33 39 ( 14 , 3

20800 4 4

3 3 2

0

2

3

MPa

D d

Q

c

=

=

=

t

o

Effectiv torsion of tension

( )

] [ 76 . 15

) 5 . 33 39 (

39 16

14 , 3

13 . 83655

16

4 4 4

0

4

3

3

MPa

D d

d

M

t

t

=

=

t

t

Equivalent torsion

] [ 80 ] [ 54 . 73 76 . 15 4 45 . 66

80 ... 60

4

2 2

2 2

MPa MPa

MPa

ac e

ac

ac t c e

= < = + =

=

s + =

o o

o

o t o o

MPa p

p D d

Q

z

a

a

13 ... 7

76 . 3

10 ) 40 48 (

20800 4

) (

4

2 2 2

1

2

=

=

=

t t

4. CALCULUS OF THE FIXED NUT

4.1.Choosing the material

Is chosen OLC45 STAS 500/2-80 with properties found in tabel 3.2

4.2.Caluclus of spire number

Numrul de spire, z

Fig 4.1

We adopt z = 6 spire

Length of nut

] [ 48 8 6 mm P z H

pII

= = =

4.3.Verifying the spire

4.3.1. Bending and shearing test

Steel nut (bending)

( )

( )

] [ 70 51 , 16

6 07 , 5 39

39 44 20800 3

] [ 80 ... 60

] [ 072 , 5 8 634 , 0 634 , 0

3

2

1

2

3

3 2

1

MPa

MPa

mm P h

z h d

d d Q

ai

ai

ai

= s =

=

=

= = =

s

=

o

t

o

o

o

t

o

Fig 4.2

Steel nut (shearing)

] [ 60 ] [ 58 . 5

6 072 , 5 39 14 , 3

20800

] [ 65 ... 50

3

MPa MPa

MPa

z h d

Q

af f

af

af f

= s =

=

=

s

=

t t

t

t

t

t

4.4.Choosing dimensions of the nut

External diameter of the body

Fig 4.4

( ) ] [ 58 9 49 10 ... 8

0

mm mm D D

e

= + = + =

Outer collar diameter

( ) ] [ 75 17 58 20 ... 16 mm mm D D

e g

= + = + =

Height of the collar

] mm [ 10 ] mm [ 12 ... 8 h

g

= =

]

4.5.Checking the nut for compund stresses

Effective traction tension

( )

] [ 5 . 27

) 49 58 ( 14 , 3

20800 4 4

2 2 2

4

2

MPa

D D

Q

e

t

=

=

=

t

o

Effective torsion tension

( )

] [ 02 . 5

) 49 58 (

58 16

14 , 3

83655

16

4 4 4

4

4

MPa

D D

D

M

e

e

insII

t

=

=

t

t

Equivalent tension

] [ 80 ... 60

] [ 70 ] [ 27 . 29 02 . 5 4 5 . 27 4

2 2 2 2

MPa

MPa MPa

at

at t t e

=

= s = + = + =

o

o t o o

4.6.Checking the collar

Crush checking

( )

] [ 60 ] [ 71 . 11

) 58 75 ( 14 , 3

20800 4 4

2 2 2 2

MPa MPa

D D

Q

as

e g

s

= s =

=

= o

t

o

Shearing checking

] [ 55 ... 40

] [ 50 ] [ 41 . 11

10 58 14 , 3

20800

MPa

MPa MPa

h D

Q

af

af

g e

f

=

= s =

=

=

t

t

t

t

4.7.Chosing the pin that fixes the nut into the body of the jack

Choosing the threaded pin

Fig 4.5

Is chosen the threaded pin M6x25mm, with notch, with cylindrical pin, with

shapes and dimensions as in fig 4.6 and as in tabel 4.6

Thread[

d]

[mm]

t

[mm]

n

[mm]

1

c

[mm]

4

d

[mm]

3

c

[mm]

1

d

[mm]

m

[mm]

M6 2 1 1,5 4,5 3,5 3 2

Fig 4.6

Moment of friction on the collar surface Mg,[N*m]

2 , 0 ... 15 , 0

] [ 118145

58 75

58 75

20800 17 , 0

3

1

3

1

2 2

3 3

2 2

3 3

=

=

Nmm

D D

D D

Q M

e g

e g

g

Pin stress moment

] [ 29 . 34490 . 118145 13 . 83655 Nmm M M M

g insII s

= = =

5. BODY CALCULUS

Choosing the dimensions of the body

Fig 5.1

( )

( )

( )

( ) ] [ 220 7 10 56 175 ] [ 10 ... 0

] [ 140

] [ 175 40 135 ] [ 50 ... 30

] 142 40 102 ] [ 50 ... 30

] [ 10 ] [ 12 ... 10

] [ 8 ] [ 8 ... 7

6 7 ... 5

] [ 60 2 58 ] [ 6 ... 2

1

1

mm mm h H H H

mm H H

mm mm H H

mm mm D D

mm mm

mm mm

mm mm D D

g pII c

II

II

bi be

t

e ei

= + + = + + =

= =

= + = + =

= + = + =

= =

= =

= =

= + = + =

o

o

Checking the body for compresion

( ) ( )

] [ 60 ] [ 07 . 13

60 75

20800 4 4

2 2 2 2

MPa MPa

D D

Q

ac

ci g

c

= s =

=

= o

t t

o

Checking the support surface for crushing

( ) ( )

] [ 5 , 2 ] [ 5 , 2

] [ 5 , 2 ... 2

] [ 5 , 2

100 142

20800 4 4

2 2 2 2

MPa MPa

MPa

MPa

D D

Q

as s

as

bi be

s

= = =

=

=

=

=

o o

o

t t

o

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Structural Analysis of Compression Helical Spring UsedDocument7 pagesStructural Analysis of Compression Helical Spring UsedCiobanu MihaiNo ratings yet

- Tau ThomsonDocument2 pagesTau ThomsonCiobanu MihaiNo ratings yet

- Design and Analysis of A Suspension Coil Spring PDFDocument7 pagesDesign and Analysis of A Suspension Coil Spring PDFCiobanu MihaiNo ratings yet

- Failure Analysis of A Coil SpringDocument7 pagesFailure Analysis of A Coil SpringCiobanu MihaiNo ratings yet

- ZF Automtic 8 SPDDocument14 pagesZF Automtic 8 SPDCiobanu Mihai100% (1)

- The Future of MobilityDocument16 pagesThe Future of MobilityCiobanu MihaiNo ratings yet

- Biodiesel Methyl EsterDocument10 pagesBiodiesel Methyl EsterCiobanu MihaiNo ratings yet

- CrankshaftDocument44 pagesCrankshaftCiobanu MihaiNo ratings yet

- Action ForcesDocument9 pagesAction ForcesCiobanu MihaiNo ratings yet

- Turbo ChargingDocument55 pagesTurbo ChargingCiobanu MihaiNo ratings yet

- Cooling SystemDocument36 pagesCooling SystemBogdan MustoceaNo ratings yet

- Chapter 5. MAIN THEOREMS in DynamicsDocument11 pagesChapter 5. MAIN THEOREMS in DynamicsCiobanu MihaiNo ratings yet

- General Chemistry 2nd Year Engineering CourseDocument35 pagesGeneral Chemistry 2nd Year Engineering CourseCiobanu MihaiNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ManagementLetter - Possible PointsDocument103 pagesManagementLetter - Possible Pointsaian joseph100% (3)

- Standards For Pipes and FittingsDocument11 pagesStandards For Pipes and FittingsMohammed sabatinNo ratings yet

- Design and Analysis of Intez Type Water Tank Using SAP 2000 SoftwareDocument7 pagesDesign and Analysis of Intez Type Water Tank Using SAP 2000 SoftwareIJRASETPublicationsNo ratings yet

- Amt in A Nutshell - ExplainedDocument2 pagesAmt in A Nutshell - ExplainedMis El100% (2)

- CV - Nguyen Quang HuyDocument5 pagesCV - Nguyen Quang HuyĐoan DoãnNo ratings yet

- APUS Court Cases: Escobedo V IllinoisDocument4 pagesAPUS Court Cases: Escobedo V Illinoisapi-3709436100% (1)

- Calculate PostageDocument4 pagesCalculate PostageShivam ThakurNo ratings yet

- LeasesDocument9 pagesLeasesCris Joy BiabasNo ratings yet

- Lets Talk About Food Fun Activities Games Oneonone Activities Pronuncia - 1995Document1 pageLets Talk About Food Fun Activities Games Oneonone Activities Pronuncia - 1995IAmDanaNo ratings yet

- Archer AX53 (EU) 1.0 - DatasheetDocument7 pagesArcher AX53 (EU) 1.0 - DatasheetLucNo ratings yet

- Chapin Dance Syllabus 23-24Document3 pagesChapin Dance Syllabus 23-24api-231581209No ratings yet

- Resistor 1k - Vishay - 0.6wDocument3 pagesResistor 1k - Vishay - 0.6wLEDNo ratings yet

- Which Among The Following Statement Is INCORRECTDocument7 pagesWhich Among The Following Statement Is INCORRECTJyoti SinghNo ratings yet

- LINDE Spare Parts ListDocument2 pagesLINDE Spare Parts Listsharafudheen_s100% (2)

- Controllogix EthernetDocument136 pagesControllogix Ethernetcnp0705No ratings yet

- Mcqs Ethics and CSR)Document9 pagesMcqs Ethics and CSR)Maida TanweerNo ratings yet

- Pat Lintas Minat Bahasa Inggris Kelas XDocument16 pagesPat Lintas Minat Bahasa Inggris Kelas XEka MurniatiNo ratings yet

- 2010 LeftySpeed Oms en 0Document29 pages2010 LeftySpeed Oms en 0Discord ShadowNo ratings yet

- 03 Marine Multispecies Hatchery Complex Plumbing Detailed BOQ - 23.10.2019Document52 pages03 Marine Multispecies Hatchery Complex Plumbing Detailed BOQ - 23.10.2019samir bendreNo ratings yet

- Mohamed Nagy Elsayed: Supply Chain ManagerDocument6 pagesMohamed Nagy Elsayed: Supply Chain Managerfasiha thathiNo ratings yet

- Chap 4 Safety Managment SystemDocument46 pagesChap 4 Safety Managment SystemABU BEBEK AhmNo ratings yet

- Income Tax Banggawan Chapter 10Document18 pagesIncome Tax Banggawan Chapter 10Earth Pirapat100% (5)

- Philippine Phoenix Surety & Insurance, Inc. Vs Woodworks, Inc Digest - MungcalDocument1 pagePhilippine Phoenix Surety & Insurance, Inc. Vs Woodworks, Inc Digest - Mungcalc2_charishmungcalNo ratings yet

- Surname 1: Why Attend To WMO? Who Would Not Trust The Brand That Their Friends Strongly Recommend? It IsDocument4 pagesSurname 1: Why Attend To WMO? Who Would Not Trust The Brand That Their Friends Strongly Recommend? It IsNikka GadazaNo ratings yet

- Sonos 5500 Service ManualDocument565 pagesSonos 5500 Service ManualScott Fergusson50% (2)

- ELEN 325 Lab 1 PrelabDocument8 pagesELEN 325 Lab 1 PrelabAndrew ZellerNo ratings yet

- Template For Public BiddingDocument3 pagesTemplate For Public BiddingFederico DomingoNo ratings yet

- BNBC 2017 Volume 1 DraftDocument378 pagesBNBC 2017 Volume 1 Draftsiddharth gautamNo ratings yet

- Determination of Molecular Radius of Glycerol Molecule by Using R SoftwareDocument5 pagesDetermination of Molecular Radius of Glycerol Molecule by Using R SoftwareGustavo Dos SantosNo ratings yet

- LSM - Neutral Axis Depth CalculationDocument2 pagesLSM - Neutral Axis Depth CalculationHimal KafleNo ratings yet