Professional Documents

Culture Documents

The Measurement of The Crystallinity of Polymer by DSC

Uploaded by

Jack CheeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Measurement of The Crystallinity of Polymer by DSC

Uploaded by

Jack CheeCopyright:

Available Formats

The measurement of the crystallinity of polymers by DSC

Y. Kong, J.N. Hay

*

Plastic Materials Laboratory, The School of Metallurgy and Materials, The University of Birmingham, P.O. Box 363, Edgbaston, Birmingham B15 2TT, UK

Received 25 June 2001; received in revised form 22 January 2002; accepted 5 April 2002

Abstract

The procedures adopted and the inherent assumptions made in the measurement of crystallinity of polymers by differential scanning

calorimetry (DSC) are reviewed. The inherent problem in all DSC measurements is concurrent recrystallisation and melting of the polymer

sample on heating to the melting point and the variation of the enthalpies of crystallisation and melting, heat capacities and degree of

crystallinity with temperature. A First Law procedure is suggested which involves heating the sample between two set temperatures, T

1

and

T

2

. T

1

is selected by the requirement that the degree of crystallinity of the sample should not change either with temperature or time, and be

representative of the sample during its use. T

1

is taken to be ambient or just above the glass transition temperature. T

2

is taken to be just above

the observed last trace of crystallinity. Integrating the observed specic heat difference between the sample and the completely amorphous

material during these two temperature ranges determined the residual enthalpy of fusion at T

1

. Problems are noted in the use of this procedure

in that the specic heat of the liquid should not be arbitrarily chosen since this leads to systematic errors in the heat of crystallisation.

The degrees of crystallinity of metallocene polyethylene (m-PE) and polyethylene terephthalate (PET) measured by this procedure have

been compared with values measured by density, determined at room temperature. q 2002 Elsevier Science Ltd. All rights reserved.

Keywords: Weight fraction crystallinity; m-Polyethylene; Polyethylene terephthalate

1. Introduction

The degree of crystallinity is the single most important

characteristic of a polymer in that it determines mechanical

properties, such as yield stress, elastic modulus and impact

resistance [1,2]. In particular, amorphous polyethylene

terephthalate (PET) is of little commercial value since it

has poor mechanical properties, low dimensional stability

and high gas permeation rate; on the other hand, crystalline

PET has higher strength, good dimensional stability and

chemical resistance. It is widely used in the production of

bres and in carbonated beverage containers because of its

strength and low gas permeability, especially to carbon

dioxide and oxygen.

The degree of crystallinity of a polymer is temperature-

dependent [3] and in comparing its effect on material

properties it is vital to carry out these measurements at the

same temperature, invariably at ambient temperature and

not at the melting point.

The various analytical methods used to determine the

crystallinity of a polymer namely, wide angle X-ray diffrac-

tion (WAXD), density, differential scanning calorimetry

(DSC), infrared (IR) and nuclear magnetic resonance

(NMR) spectroscopy have been reviewed by Runt [4]. He

considered that DSC was `probably the most widely used

technique'. However, despite this, it is probably the most

widely misused method [511]. The usual procedure in

measuring the degree of crystallinity by DSC involves

drawing a linear arbitrary baseline from the rst onset of

melting to the last trace of crystallinity and determines the

enthalpy of fusion from the area under this endotherm. The

degree of crystallinity is then dened as

X

c

DH

f

T

m

=DH

o

f

T

o

m

1

where X

c

is the weight fraction extent of crystallinity,

DH

f

T

m

is the enthalpy of fusion measured at the melting

point, T

m

, and DH

o

f

T

o

m

is the enthalpy of fusion of the

totally crystalline polymer measured at the equilibrium

melting point, T

m

o

. No correction is usually made for the

variation in the specic heats with temperature or the

differences between the liquid and crystalline values.

Some allowances have also been made for the sample

crystallising on heating by separately integrating the

exotherm on cold crystallisation and endotherm on melting

over appropriate but different temperature regions. The

degree of crystallinity is then dened as [8,11]

X

c

DH

f

2DH

c

=DH

o

f

2

Polymer 43 (2002) 38733878

0032-3861/02/$ - see front matter q 2002 Elsevier Science Ltd. All rights reserved.

PII: S0032-3861(02)00235-5

www.elsevier.com/locate/polymer

* Corresponding author. Tel.: 144-121-414-4544; fax: 144-121-414-

5232.

E-mail address: j.n.hay@bham.ac.uk (J.N. Hay).

where DH

f

is the enthalpy of fusion, DH

c

the enthalpy of

crystallisation and DH

o

f

the heat of fusion of the completely

crystalline materials at the equilibrium melting temperature,

T

o

m

: All are measured at different temperatures and no

corrections are made for the change in specic heat. Never-

theless this method has appeared as a recommended method

[12]. Both these methods dene the degree of crystallinity

close to the melting point rather than at room temperature

where other analytical measurements are used, and there is

little agreement between them. There are several things

incorrect with both procedures. The integration baseline,

separating exotherms and endotherms, is drawn arbitrarily

and does not reect the specic heats of the partially crystal-

line material or the liquid and has no physical meaning [13].

Secondly, the range between the end of crystallisation and

the beginning of melting is not considered. It is assumed that

no melting or recrystallisation occurs on heating. Because of

these effects, the degree of crystallinity as measured by DSC

conicted with the values obtained by other methods

[14,15]. Conventionally, specic heat differences and the

temperature dependencies of the thermodynamic para-

meters are not considered [16,17]. Finally the enthalpy of

fusion of 100% crystalline materials is invariably taken as

the value at the equilibrium melting point, T

o

m

; rather than in

the temperature region of the measurement [3,18,19].

In measuring the degree of crystallinity of Nylon-6,

Khanna et al. [20] recommended a method, in which the

baseline was drawn between two set temperatures, i.e. one

post-T

g

and the other above T

m

. Although as the authors

admitted, the samples post-T

g

were a mixture of liquid and

solid and the observed specic heat was dependent on the

degree of crystallinity. It cannot be taken to represent the

specic heat of the liquid line. Despite this a linear baseline

between the two observed specic heats was drawn between

these set temperatures. This separated the exotherm and

endotherm due to recrystallisation and melting and deter-

mined the degree of crystallinity from Eq. (2) but over-

estimates the degree of crystallinity.

Some times ago, Gray [21] and Richardson [13]

separately proposed a correct procedure to measure the

crystallinity, in which the enthalpy of fusion was measured

at the onset of the melting point by subtracting the enthalpy

change for the super-cooled liquid from the total enthalpy

change over all melting temperature ranges and then the

crystallinity was measured at this temperature, i.e.

X

c

DH

f

T

onset

=DH

o

f

T

onset

: 3

Later this method was called the total enthalpy method [19],

however, it has appeared to be ignored by most polymer

scientists. Recently, Mathot et al. [2224] recommended

the enthalpy-based crystallinity by using the following

relationship, i.e.

X

c

h

a

T

1

2h

x

T

1

h

a

T

1

2h

c

T

1

; 4

where h

a

T

1

; h

c

T

1

and h

x

T

1

are the enthalpies of the

completely amorphous, crystalline and semicrystalline

sample at the temperature T

1

, respectively. Obviously,

h

a

T

1

2h

x

T

1

is the heat of fusion of semicrystalline

sample at T

1

and h

a

T

1

2h

c

T

1

is the heat of fusion of

the 100% crystalline at T

1

. Mathot et al. [24] found that the

crystallinity measured by this enthalpy procedure was in

good agreement with the density procedure although it not

necessary the same.

Recently Hay et al. [16,17] also proposed the First Law

method. This evaluated the residual enthalpy of the sample

at the lower temperature, T

1

, which should be room

temperature or above but close to the glass transition, and

determined the initial degree of crystallinity of the sample

prior to heating. The residual enthalpy, DH

R

, is the algebraic

sum of the enthalpies of crystallisation and melting together

with the specic heat changes with temperature for the

partially crystalline solid, and for the liquid on cooling, as

outlined in Fig. 2. This measured the crystallinity of the

sample at T

1

closely reecting the value at room temperature

since the crystallinity did not change on heating to the glass

transition.

Essentially, the last three methods are equivalent since

the enthalpy of fusion is measured at the lower temperature

and correction is made for the specic heat changes. In this

paper, the degrees of crystallinities of m-PE and PET have

been measured using the First Law method and the effect of

specic heat baseline corrections evaluated.

2. Experimental

PET was supplied by DuPont Ltd as moulding pellets. It

has a number average molecular weight of 19.6 kg mol

21

and weight average of 36.4 kg mol

21

. The m-PE was

purchased from Exxon Chemical Co. France, as the Exact

grade 3009. It is a copolymer of ethylene and hexene-1. The

number and weight average molecular weights are 40 and

100 kg mol

21

, respectively.

PET was dried in a vacuum oven at 100 8C for 12 h and

pressed at 280 8C for 2 min at a pressure of 7.5 MN m

22

into

100 mm 100 mm 0.8 mm plaques. The plaques were

quenched in ice water to obtain amorphous sheets. The

m-PE was moulded at 160 8C for 5 min under the same

pressure. The plaques were then either quenched directly

in water or slow-cooled in the hydraulic press to room

temperature for 5 h. Discs were cut directly from the

plaques for DSC analyses.

A PerkinElmer differential scanning calorimetry, DSC-

2, interfaced to a PC was used to measure the thermal

properties of the moulded samples. The calorimetry oper-

ated with a nitrogen ow 20 cm

3

min

21

. The temperature of

the calorimeter was calibrated from the observed melting

points of distilled water and ultra-pure materialsstearic

acid, indium, tin and leadat heating rate of 10, 5 and

2.5 K min

21

. Thermal lag corrections were made by extra-

polating to zero heating rate. DSC was used adopting the

Y. Kong, J.N. Hay / Polymer 43 (2002) 38733878 3874

procedure for measuring heat capacities. Empty aluminium

pans, matched in weight to within 0.02 mg, were used for

the sample and reference. Initially, the two empty pans were

scanned to determine the calorimeter baseline and this was

repeated with a sapphire standard sample to calibrate the

thermal response of the calorimeter. Finally this was

repeated with the polymer disc sample. The same heating

rate of 10 K min

21

and sample weight of 10.00 ^0.03 mg

was used to obtain comparable results.

Densities were measured on moulded specimens by

Archimedes' method: rst by weighing in air and then in

n-heptane at 296 K. An average of at least three determina-

tions on separate specimens, taken from the same sample,

were used.

3. DSC analysis

The First Law method is an application of the First Law

of Thermodynamics to the crystallisation and melting of a

polymer sample on heating in a calorimeter. It involves two

separate measurements. The rst one determines the overall

enthalpy changes on heating a partially crystalline polymer

from T

1

to above the melting point, T

2

. The second is a

virtual experiment of measuring the enthalpy change on

cooling the liquid from T

2

to T

1

without crystallisation

occurring, see Fig. 1. For a closed system, the difference

between these two steps is the enthalpy of fusion of the

sample at T

1

, i.e.

DH

R

DH

12

1DH

21

5

in which

DH

21

ZT

1

T

2

C

p;a

dT 6

where DH

R

is the residual enthalpy of fusion at T

1

, DH

12

and

DH

21

are the changes in enthalpy on heating and cooling,

respectively. C

p,a

is the specic heat of the amorphous

material. DH

12

includes the enthalpy changes due to the

change in specic heat of the partially crystalline sample

between T

1

and T

2

, i.e.

R

C

p;x

dT; allowing for it to change

with degree of crystallinity, crystallisation, annealing and

recrystallisation, DH

c

, as well as partial melting at inter-

mediate temperatures, and nal melting DH

f

. For an initially

amorphous sample DH

R

should be zero. The DSC analysis

for partially crystalline sample and the enthalpy changes in

these processes are shown diagrammatically in Figs. 1 and

2, respectively.

The amorphous liquid temperature dependence, C

p,a

, can

be obtained by several method, i.e. by a linear extrapolation

of the specic heat of the liquid measured in the melt; or

measured on an amorphous sample above the glass transi-

tion temperature prior to the onset of crystallisation or by

using reference data. In the rst two cases, heat ow

measurements in the calorimeter can be used directly

instead of the measured specic heat.

The weight fraction degree of crystallinity at T

1

, X

c

T

1

; is

then the ratio of the observed enthalpy of fusion of the

sample to that of the completely crystalline material at T

1

,

X

c

T

1

DH

f

T

1

=DH

o

f

T

1

DH

R

=DH

o

f

T

1

: 7

Normally, the DH

f

o

is measured at equilibrium melting point

T

m

o

, and not at T

1

; however,

d DH

o

f

C

p;a

2C

p;c

dT DC

p;c

dT 8

where DC

p,c

is the specic heat difference between the

completely liquid and crystalline solid, C

p,c

. The enthalpy

of fusion of 100% crystalline value at T

1

could be obtained

by integrating the above equation form T

1

to T

m

o

,

DH

o

f

T

1

DH

o

f

T

o

m

2

ZT

o

m

T

1

DC

p;c

dT: 9

Once DH

o

f

T

1

is obtained, the crystallinity is readily

calculated from Eq. (7).

Y. Kong, J.N. Hay / Polymer 43 (2002) 38733878 3875

Fig. 1. DSC analysis of a partially crystalline polymer sample showing the

presence of recrystallisation and melting.

Fig. 2. Schematic of the enthalpy changes on recrystallisation and melting

between two set temperatures, T

1

and T

2

.

4. Results and discussion

4.1. The fractional crystallinity of m-PE

Fig. 3 shows the DSC analyses of water and slow-cooled

m-PE samples. m-PE has good thermal stability above T

m

and the amorphous specic heattemperature dependence is

well-dened. It is drawn directly onto the DSC thermal

response above the melting point and extrapolated to

ambient temperature [19,24].

The heat of fusion at 298 K was determined using the

First Law method as 116 and 132 J g

21

for the water and

slow-cooled samples, respectively. The heat of fusion of

completely crystalline PE at 298 K was determined [25] to

be 243.8 J g

21

, which is approximately 17% less than the

more commonly used value of 293 J g

21

at the equilibrium

melting point. The fractional crystallinities of the water and

slow-cooled sample were 0.48 ^0.02 and 0.54 ^0.02,

respectively. These values compared well with the weight

fraction crystallinity measured by density at 296 K. They

are listed in Table 1. Mathot [24] found that the melting of

very low-density polyethylenes could occur as low as

260 8C and the crystallinities were as mush as 40% higher

than that at room temperature. In such situation, the degree

of crystallinity must be measured at the same temperature,

otherwise no comparison can be made with the values

determined by other means.

4.2. The fractional crystallinity of PET

PET, amorphous to WAXD and by density measure-

ments, was observed by DSC to have a glass transition at

about 353 K, see Fig. 4a and a large exothermic crystallisa-

tion at about 410 K. Melting nally occurred above 500 K,

although modulated temperature DSC studies indicated that

considerable melting and annealing occurred prior to nal

melting [28]. There were two temperature regions in which

only liquid existedone post-T

g

and prior to the onset of

crystallisation and the other above T

m

. Careful measurement

of the heat capacities in these temperature regions indicated

that they exhibited different temperature dependencies and

the PET was degrading above T

m

. As a result, the post-T

g

amorphous specic heattemperature dependence was

chosen. The residual enthalpy of fusion determined just

above the T

g

for these amorphous samples was zero. The

determinations were repeated 10 times and the variation in

fractional crystallinity was ^0.02, as shown in Table 2. The

results are highly reproducible and consistent with WAXD

and density results.

Fig. 4b displays the DSC analyses of PET samples

crystallised in a vacuum oven at 383 K for different period

times. They exhibited less well-dened glass transitions and

Y. Kong, J.N. Hay / Polymer 43 (2002) 38733878 3876

Fig. 3. DSC analyses of m-polyethylene samples along with the amorphous

specic heat temperature dependence, extrapolated from the molten state.

Table 1

Fractional crystallinities measured by density and residual enthalpies of fusion

Sample Density (g cm

23

) Residual enthalpy (J g

21

) Fractional crystallinity by

Density ^0.02 DSC ^0.02

m-PE

Water-cooled m-PE 0.923 116 0.51 0.48

Slow-cooled m-PE 0.931 132 0.57 0.54

PET

Amorphous 1.336 0.4 0.01 0.00

110 8C,

a

1 h 1.350 9.6 0.09 0.10

110 8C,

a

2 h 1.356 15.5 0.13 0.16

110 8C,

a

5 h 1.365 19.6 0.19 0.20

125 8C,

a

18 h 1.375 25.0 0.25 0.26

150 8C,

a

18 h 1.379 26.4 0.27 0.28

175 8C,

a

18 h 1.382 30.0 0.29 0.31

200 8C,

a

18 h 1.392 34.4 0.35 0.36

a

Crystallinity calculated by density for m-PE, r

a

0:855 g cm

23

; r

c

0:999 g cm

23

; Ref. [25]. Crystallinity calculated by density for PET, r

a

1:335 g cm

23

; r

c

1:515 g cm

23

; Ref. [26]. Heat of fusion of PE at 298 K: DH

o

f

298 243:8 J g

21

; Ref. [25]. Heat of fusion of PET at 375 K: DH

o

f

375

96:0 J g

21

; Ref. [27]. http://funnelweb.utcc.utk.edu/~athas/databank/phenylen/pet/petcalam.html, http://funnelweb.utcc.utk.edu/~athas/databank/phenylen/

pet/petcalcr.html.

smaller recrystallisation exotherm than previously observed

with the amorphous samples. It was not possible in these

samples to dene the amorphous specic heat dependence

with temperature either from the post-T

m

dependence for

reason discussed above or from the post T

g

dependence

since the materials were partially crystalline. Therefore,

the specic heattemperature dependence of amorphous

samples were separately determined and used to evaluate

DH

R

of Eq. (5). The fractional crystallinity was then

determined from the residual enthalpy of fusion at 375 K.

PET was also crystallised at different temperatures from

398 to 473 K for 18 h and the DSC thermal response with

temperature is shown in Fig. 4c. Multiple melting points

were observed with the lowest endotherm about 20 K

above the crystallisation temperature and the temperature

corresponding to the last trace of crystallinity almost

constant and independent of crystallisation temperature.

This has been attributed to the melting of lamellae produced

on heating [29,30]. The same amorphous specic heat

temperature dependence as determined in Fig. 4b was

used and the degree of crystallinity was obtained as outlined

above. These results are listed in Table 1 and compared with

the weight fraction crystallinity as measured by density.

There is excellent agreement within experimental error

between them.

5. Conclusions

The measurement of the degree of crystallinity in

polymers by DSC has been reviewed. Since crystallisation,

partial melting, annealing, recrystallisation and complete

melting occur during the heating of the sample to the melt-

ing point the degree of crystallinity changes. The procedure

of measuring the degree of crystallinity of the sample from

the First Law method is valid and it measures a fractional

crystallinity which compares favourably with that

determined by other methods. Great care must be taken in

selecting the specic heat temperature dependence of the

liquid around which the specic heat response of the sample

Y. Kong, J.N. Hay / Polymer 43 (2002) 38733878 3877

Fig. 4. (a) DSC analysis of amorphous polyethylene terephthalate along

with the amorphous specic heat temperature dependence extrapolated

from post-T

g

temperature region. (b) DSC analysis of PET crystallised at

383K for different periods along with the amorphous specic heat tempera-

ture dependence derived from a quenched PET sample. (c) DSC analysis of

PET crystallised for 18 h at different temperatures along with the amor-

phous specic heat temperature dependence derived from a quenched PET

sample.

Table 2

Residual enthalpies and measured fractional crystallinities of amorphous

PET

Sample Residual enthalpy (J g

21

) Fractional crystallinity

1 21.7 20.018

2 20.91 20.009

3 2.3 0.024

4 1.9 0.019

5 21.9 20.020

6 2.8 0.029

7 3.7 0.038

8 21.2 20.012

9 20.03 20.000

10 20.5 20.005

Average 0.004 ^0.020

with temperature is used as the baseline for integration.

Degradation and volatile production from the polymer in

the melt or on partially crystalline samples prior to heating

negates the use of a specic heat baseline derived from the

sample above the melting point or close to the glass transi-

tion. Instead the specic heat temperature dependence must

be determined separately either from amorphous samples, or

from the literature.

By using the First law method, the initial fractional

crystallinity of m-PE and PET have been measured and

found to be consistent with values determined by density

at ambient temperature.

Acknowledgements

Y.K. acknowledges the award of a research scholarship

from ORS Committee and the School of Metallurgy and

Materials of the University of Birmingham during the tenure

of this work. The authors are grateful to Mr M. Razavi-

Nouri for measuring the density of m-PE and providing

m-PE samples. The authors would also like to express

their appreciation to Mr F. Biddlestone for his valuable

technical support and assistance.

References

[1] Sperling LH. Introduction to physical polymer science. 2nd ed. New

York: Wiley, 1992. p. 198.

[2] Fann DM, Huang SK, Lee JY. Polym Engng Sci 1998;38:265.

[3] Mathot VBF. Thermal characterization of state of matter. In: Mathot

VBF, editor. Calorimetry and thermal analysis of polymers. Munich:

Hanser, 1994. Chapter 5.

[4] Runt JP. In: Mark HF, Bikales NM, Overberger CG, Meges G,

Kroschwitz J, editors. Encyclopedia of polymer science and engineer-

ing, vol. 4. New York: Wiley, 1986. p. 482.

[5] O'Malley JJ. J Polym Sci, Polym Phys Ed 1975;13:1353.

[6] Groeninckx G, Reynaers H, Berghmans H, Smets G. J Polym Sci,

Polym Phys Ed 1980;8:1311.

[7] Dawson PC, Gilbert M, Maddams WF. J Polym Sci, Polym Phys Ed

1991;29:1407.

[8] Murthy NS, Khanna YP, Signorelli AJ. Polym Engng Sci

1994;36:1254.

[9] Bassett DC, Olley RH, Al Raheil IAM. Polymer 1988;29:1745.

[10] Toda T, Yoshida H, Fukunishi K. Polymer 1995;36:699.

[11] Huang JM, Chu PP, Chang FC. Polymer 2000;41:1741.

[12] Kaisersberger E, Mohler H. DSC on polymeric materials, NETZSCH

annual for science and industry, vol. 1. Wurzburg; 1991.

[13] Richardson MJ. J Polym Sci, Part C 1972;38:251.

[14] Fakirov S, Fischer EW, Hoffmann R, Schmidt GF. Polymer

1977;18:1121.

[15] Fontaine F, Ledent J, Groeninckx G, Reynaers H. Polymer

1982;23:185.

[16] Mehmet-Alkan AA, Hay JN. Polymer 1992;33:3527.

[17] Mehmet-Alkan AA, Hay JN. J Therm Anal 1993;40:791.

[18] Seguela R. Polymer 1993;34:1761.

[19] Blundell DJ, Beckett DR, Willcocks PH. Polymer 1981;22:704.

[20] Khanna YP, Kuhn WP. J Polym Sci, Polym Phys Ed 1997;35:2219.

[21] Gary AP. Thermochim Acta 1970;1:563.

[22] Mathot VBF, Pijpers MFJ. J Therm Anal 1983;28:349.

[23] Mathot VBF, Pijpers MFJ. Thermochim Acta 1989;151:241.

[24] Mathot VBF, Pijpers MFJ. J Appl Polym Sci 1990;39:979.

[25] Quirk RP, Alsamarrie MAA. Physical constants of polyethylene. In:

Brandrup J, Immergut EH, editors. Polymer handbook, 3rd ed. New

York: Wiley, 1989. p. V/19.

[26] Lawton EL, Ringwald EL. Physical constants of poly(oxyethylene-

oxyterephthaloyl) (polyethylene terephthalate). In: Brandrup J,

Immergut EH, editors. Polymer handbook, 3rd ed. New York:

Wiley, 1989. p. V/101.

[27] Mehta A, Gaur U, Wunderlich B. J Polym Sci, Polym Phys Ed

1978;16:289.

[28] Bailey NA, Hay JN, Price DM. Thermochim Acta 2001;3678:425.

[29] Holdsworth PJ, Turner-Jones A. Polymer 1971;12:195.

[30] Zhou C, Clough SB. Polym Engng Sci 1988;28:65.

Y. Kong, J.N. Hay / Polymer 43 (2002) 38733878 3878

You might also like

- Zytel® 101F Nc010: Dupont Performance PolymersDocument4 pagesZytel® 101F Nc010: Dupont Performance PolymersagungNo ratings yet

- Global Polyester Staple Fiber PSF Industry 2020Document3 pagesGlobal Polyester Staple Fiber PSF Industry 2020Mustafa ColkesenNo ratings yet

- Paint and Surface CoatingsDocument3 pagesPaint and Surface Coatingssami_sakr0% (1)

- European Polymer Journal 61 (2014) 285-299 PDFDocument15 pagesEuropean Polymer Journal 61 (2014) 285-299 PDFEstudiante2346No ratings yet

- Ecg Utah EduDocument87 pagesEcg Utah EduMos Viorel DanutNo ratings yet

- TA Polymers enDocument40 pagesTA Polymers enljupcoaleksov100% (1)

- ECT Guide FINAL 5 17 11 PDFDocument16 pagesECT Guide FINAL 5 17 11 PDFsandi123inNo ratings yet

- Enthalpyof FusionanddegreeofcrystallinityDocument7 pagesEnthalpyof FusionanddegreeofcrystallinityCamila BascuNo ratings yet

- Rheological Properties of Some Thermotropic Liquid Crystalline PolymersDocument7 pagesRheological Properties of Some Thermotropic Liquid Crystalline PolymersAdityaNo ratings yet

- 10 1016@j Polymertesting 2013 05 007Document22 pages10 1016@j Polymertesting 2013 05 007Ricardo VelozNo ratings yet

- The Glass-Softening Temperature Range and Non-Arrhenius Dynamics: The Case of Vitri®ed WaterDocument11 pagesThe Glass-Softening Temperature Range and Non-Arrhenius Dynamics: The Case of Vitri®ed WaterJuan Van HalenNo ratings yet

- Differential Thermal Analysis (Dta)Document15 pagesDifferential Thermal Analysis (Dta)DanielNo ratings yet

- 1 s2.0 S0038109804000067 MainDocument4 pages1 s2.0 S0038109804000067 MainAbhishek ChaturvediNo ratings yet

- Dscpete PDFDocument10 pagesDscpete PDFmade hNo ratings yet

- AE4ASM002 Designing Materials With Aerospace Specific Properties SummaryDocument16 pagesAE4ASM002 Designing Materials With Aerospace Specific Properties SummaryJanJNo ratings yet

- Czech Technical University in Prague, Faculty of Civil Engineering Thákurova 7, 16629 Prague 6, Czech RepublicDocument11 pagesCzech Technical University in Prague, Faculty of Civil Engineering Thákurova 7, 16629 Prague 6, Czech RepublicJaleel ClaasenNo ratings yet

- Polymer Degradation and Stability: José L. de La Fuente, Marta Ruiz-Bermejo, César Menor-Salván, Susana Osuna-EstebanDocument6 pagesPolymer Degradation and Stability: José L. de La Fuente, Marta Ruiz-Bermejo, César Menor-Salván, Susana Osuna-EstebanNurmanita RismaningsihNo ratings yet

- Applications of DSCDocument18 pagesApplications of DSCprinceamitNo ratings yet

- DSC PeteDocument10 pagesDSC PeteSivaSaputraNo ratings yet

- CAPACCIODocument6 pagesCAPACCIOapi-3733260No ratings yet

- Differential Scanning CalorimetryDocument7 pagesDifferential Scanning CalorimetryGintoki SakataNo ratings yet

- DNS of Gas Solid ReactionsDocument25 pagesDNS of Gas Solid ReactionsShuiquan LanNo ratings yet

- Isothermal Crystallization of Isotactic Poly (Propylene) Studied by Superfast Calorimetry - 2007 - Macromolecular Rapid CommunicationsDocument7 pagesIsothermal Crystallization of Isotactic Poly (Propylene) Studied by Superfast Calorimetry - 2007 - Macromolecular Rapid CommunicationsLubomirBenicekNo ratings yet

- Cinetica de CristalizacionDocument18 pagesCinetica de Cristalizacionbeatriz salazarNo ratings yet

- Differential Scanning CalorimetryDocument6 pagesDifferential Scanning CalorimetrySurender MalikNo ratings yet

- Thermal Relaxation and Heat Transport in The Spin Ice Material Dy Ti ODocument25 pagesThermal Relaxation and Heat Transport in The Spin Ice Material Dy Ti OS GrixNo ratings yet

- Differential Scanning Calorimetry (DSC)Document9 pagesDifferential Scanning Calorimetry (DSC)DanielNo ratings yet

- (Ebook) - Thermal Analysis TechniquesDocument21 pages(Ebook) - Thermal Analysis Techniquesiordache0% (1)

- Thermal 1Document4 pagesThermal 1abhiyajithNo ratings yet

- Kapitza Resistance and Thermal Conductivity of Kapton in Superfluid HeliumDocument15 pagesKapitza Resistance and Thermal Conductivity of Kapton in Superfluid HeliumPaulo CesarNo ratings yet

- UntitledDocument33 pagesUntitledSachin ashokNo ratings yet

- DSC Error & InterpretationDocument3 pagesDSC Error & InterpretationUsman GhaniNo ratings yet

- DSCDocument24 pagesDSCShubham SuleNo ratings yet

- LINGOTE 10.1016@j.ijthermalsci.2016.10.010Document11 pagesLINGOTE 10.1016@j.ijthermalsci.2016.10.010Taguis VelascoNo ratings yet

- Epoxy CureDocument7 pagesEpoxy CuregdritzNo ratings yet

- DSCDocument24 pagesDSCShubham SuleNo ratings yet

- Thermal Behavior of Polymers PDFDocument9 pagesThermal Behavior of Polymers PDFjraman24No ratings yet

- DTADocument7 pagesDTAPrasad MaddyNo ratings yet

- DTADocument7 pagesDTAGaurav AcharyaNo ratings yet

- Thermogravimetric Analysis (TGA) 熱重量分析法Document33 pagesThermogravimetric Analysis (TGA) 熱重量分析法雨No ratings yet

- Effect of Heating Rate and Grain Size On The Melting Behavior of The Alloy NB 47 Mass% Ti in Pulse-Heating ExperimentsDocument12 pagesEffect of Heating Rate and Grain Size On The Melting Behavior of The Alloy NB 47 Mass% Ti in Pulse-Heating ExperimentsLakshan FonsekaNo ratings yet

- HTHP 1073 - V1Document15 pagesHTHP 1073 - V1Triều Huỳnh NhậtNo ratings yet

- Nanomaterials CharacterDocument70 pagesNanomaterials CharacterLogicAndFacts ChannelNo ratings yet

- Det (1) - of Heats of Reaction Under Reflux, J. Wyss, 00724385Document9 pagesDet (1) - of Heats of Reaction Under Reflux, J. Wyss, 00724385ninad.lokeNo ratings yet

- Characteristics of The Boundary Layer With Hydrogen Combustion With Variations of Thermal Conditions On A Permeable WallDocument9 pagesCharacteristics of The Boundary Layer With Hydrogen Combustion With Variations of Thermal Conditions On A Permeable WallYan PHNo ratings yet

- Che 135 Process Engineering LaboratoryDocument9 pagesChe 135 Process Engineering LaboratoryMichael Jemziel GulayNo ratings yet

- Thermal Properties - Dilatometry and TPRDocument17 pagesThermal Properties - Dilatometry and TPRAswathy MnNo ratings yet

- Tsierkezos, Filippou - 2006 - Thermodynamic Investigation of N, N-Dimethylformamidetoluene Binary Mixtures in The Temperature Range FromDocument10 pagesTsierkezos, Filippou - 2006 - Thermodynamic Investigation of N, N-Dimethylformamidetoluene Binary Mixtures in The Temperature Range FromTatiana VargasNo ratings yet

- Gough 2016Document19 pagesGough 2016Alejandro ZagalNo ratings yet

- Summary of TG and DtaDocument2 pagesSummary of TG and DtasriqadriNo ratings yet

- Thermal PropertiesDocument20 pagesThermal PropertiesMONIRUZZAMAN MONIRNo ratings yet

- Thermal AnalysisDocument37 pagesThermal AnalysisZaid Majed100% (1)

- Modulus: Effect On The Elastic of High-Density Polyethylene Differing Thermal TreatmentsDocument4 pagesModulus: Effect On The Elastic of High-Density Polyethylene Differing Thermal Treatmentsapi-3733260No ratings yet

- Lecture 5Document11 pagesLecture 5Rahmeh EL saaiedehNo ratings yet

- Sample Lab ReportDocument13 pagesSample Lab ReportJellyShapes0% (1)

- Miao JThermAnalCalorimDocument8 pagesMiao JThermAnalCalorimJoel E ValenciaNo ratings yet

- 5 - Experiment # 05 - Thermal Characterization of PolymersDocument5 pages5 - Experiment # 05 - Thermal Characterization of Polymersahmad.altaf7770No ratings yet

- BMFB 3263 Materials Characterization: Thermal AnalysisDocument75 pagesBMFB 3263 Materials Characterization: Thermal AnalysisalagurmNo ratings yet

- 1559024845Document29 pages1559024845habiba jamilNo ratings yet

- A Simple PDFDocument2 pagesA Simple PDFJaheer MakalNo ratings yet

- Prushield EBrochure EnglishDocument19 pagesPrushield EBrochure EnglishJack CheeNo ratings yet

- A Simple PDFDocument2 pagesA Simple PDFJaheer MakalNo ratings yet

- Sulphuric AcidDocument6 pagesSulphuric AcidJack CheeNo ratings yet

- PolymersDocument6 pagesPolymersJack CheeNo ratings yet

- HDPE CaCO3Document9 pagesHDPE CaCO3Jack CheeNo ratings yet

- Scheme Tehnologice 3Document23 pagesScheme Tehnologice 3adriansurduNo ratings yet

- Bubble and Dew Point Calculations in Multicomponent and Multireactive MixturesDocument9 pagesBubble and Dew Point Calculations in Multicomponent and Multireactive MixturesJack CheeNo ratings yet

- Malaysias Country ReportDocument46 pagesMalaysias Country ReportJack CheeNo ratings yet

- MAY Week Sunday Monday Tuesday Wednesday Thursday Friday Saturday 1 2 3 4Document5 pagesMAY Week Sunday Monday Tuesday Wednesday Thursday Friday Saturday 1 2 3 4Jack CheeNo ratings yet

- Flash Calculations NewDocument8 pagesFlash Calculations NewSantosh SakhareNo ratings yet

- Integration FormulaDocument1 pageIntegration FormulaJack CheeNo ratings yet

- Process Flow DiagramDocument1 pageProcess Flow DiagramJack CheeNo ratings yet

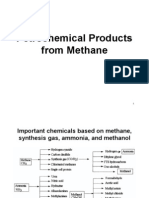

- Petrochemical Products From Methane (Compatibility Mode)Document62 pagesPetrochemical Products From Methane (Compatibility Mode)Jack Chee83% (6)

- Integration FormulaDocument1 pageIntegration FormulaJack CheeNo ratings yet

- Applications of X-Ray DiffractionDocument10 pagesApplications of X-Ray DiffractionZay Yar MNo ratings yet

- Applications of X-Ray DiffractionDocument10 pagesApplications of X-Ray DiffractionZay Yar MNo ratings yet

- Coffee Ground FibreDocument26 pagesCoffee Ground FibreANISHA KUJURNo ratings yet

- Polymer CHDocument39 pagesPolymer CHMuhammad NajamNo ratings yet

- Journal of Industrial and Engineering Chemistry: Seunghyun Ko, Yeon Ju Kwon, Jea Uk Lee, Young-Pyo JeonDocument10 pagesJournal of Industrial and Engineering Chemistry: Seunghyun Ko, Yeon Ju Kwon, Jea Uk Lee, Young-Pyo Jeonkhalid bouitiNo ratings yet

- TABLE A.20.4 (A) Examples of Commodities Not Addressed by Classifications inDocument10 pagesTABLE A.20.4 (A) Examples of Commodities Not Addressed by Classifications inAli OsmanNo ratings yet

- Conveyor Belt Design For Bottling Plant of Coca ColaDocument118 pagesConveyor Belt Design For Bottling Plant of Coca Colavivekpattni50% (4)

- Chemical Engineering April 2015Document86 pagesChemical Engineering April 2015XuanTung0% (1)

- 1044 FileDocument246 pages1044 FileGaurav SaxenaNo ratings yet

- Further Organic Chemistry: Lesson 4: Carboxylic Acid Derivatives (Ester)Document41 pagesFurther Organic Chemistry: Lesson 4: Carboxylic Acid Derivatives (Ester)Fariz SharudinNo ratings yet

- IFT # 3 School DeckDocument26 pagesIFT # 3 School DeckAMISH JHANo ratings yet

- Quo VadisDocument2 pagesQuo VadisPaoloMMNo ratings yet

- Effects of Thermoforming On The Physical and Mechanical Properties of Thermoplastic Materials For Transparent Orthodontic AlignersDocument11 pagesEffects of Thermoforming On The Physical and Mechanical Properties of Thermoplastic Materials For Transparent Orthodontic AlignersLady SolarteNo ratings yet

- Thermo Scientific Microphazir PC: Handheld Plastics AnalyzerDocument2 pagesThermo Scientific Microphazir PC: Handheld Plastics AnalyzerfaisalNo ratings yet

- Introduction Recycling EnglishDocument25 pagesIntroduction Recycling EnglishLeanne Angel Mendones MayaNo ratings yet

- Materials: Devulcanization Technologies For Recycling of Tire-Derived Rubber: A ReviewDocument16 pagesMaterials: Devulcanization Technologies For Recycling of Tire-Derived Rubber: A ReviewAbhishekBanerjeeNo ratings yet

- UntitledDocument396 pagesUntitledMr BigNo ratings yet

- Packaging - Dairy - AP.22.01 (ENG)Document12 pagesPackaging - Dairy - AP.22.01 (ENG)slim zeghalNo ratings yet

- RFP-RVM-Amritsar Smart City PDFDocument54 pagesRFP-RVM-Amritsar Smart City PDFICT WalaNo ratings yet

- Design and Study of Manufacturing of Polyester Plant Using Pta and MegDocument8 pagesDesign and Study of Manufacturing of Polyester Plant Using Pta and MegUgurNo ratings yet

- Kuraray Technical Brochure - EnglishDocument28 pagesKuraray Technical Brochure - EnglishrbucholzNo ratings yet

- Polymers: Classification Based On SourceDocument4 pagesPolymers: Classification Based On Sourceatulkumargaur26No ratings yet

- LURGI ZIMMER PolyesterPackagingTechnologyDocument12 pagesLURGI ZIMMER PolyesterPackagingTechnologyGeorge Markas100% (1)

- Abd El Messieh2008Document13 pagesAbd El Messieh2008maryeonee12No ratings yet

- New Microsoft Office Word DocumentDocument33 pagesNew Microsoft Office Word DocumentSudhanshu NagpalNo ratings yet

- Chemplasa Ebs L-205F-TdsDocument1 pageChemplasa Ebs L-205F-TdsÁnh Nguyễn100% (1)

- Cat - Cage - Engelsk 3 - 7Document82 pagesCat - Cage - Engelsk 3 - 7mhon_23No ratings yet

- Meta-Xylene Isophthalic Acid (MX-IPA) - FLYER (2019 Program)Document2 pagesMeta-Xylene Isophthalic Acid (MX-IPA) - FLYER (2019 Program)Mr KhosraviNo ratings yet

- Hydro Cero LDocument11 pagesHydro Cero LClint FosterNo ratings yet

- Petainer: Hybrid KegDocument9 pagesPetainer: Hybrid Kegdisturbed18No ratings yet

- Sympatex Factsheet Ecology EngDocument2 pagesSympatex Factsheet Ecology EngOstoja BjelajacNo ratings yet

- Upgrade Your Recycled Plastic JoncrylDocument8 pagesUpgrade Your Recycled Plastic JoncrylPopolupus100% (1)