Professional Documents

Culture Documents

Holistic Understanding For Design - Theory of Technical Systems

Uploaded by

Oliver RubioOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Holistic Understanding For Design - Theory of Technical Systems

Uploaded by

Oliver RubioCopyright:

Available Formats

Holistic Understanding for Design Theory of Technical Systems

W. Ernst Eder

Royal Military College of Canada (retired)

eder-e@kos.net

Abstract

Improvements at local to global levels needs holistic

understanding of the processes and actors (operators).

The theory of technical systems provides a model for a

holistic understanding, and a conceptual basis for

qualitative thinking. The theory describes a transfo-

rmation system, in an environment. Any artificial

change (transformation) can be modeled in this way.

The environment includes local influences and effects

acting on the system and its process, and a general

environment (regional, national and global) that

covers physical, chemical, societal, economic,

cultural, political, ideological, geographic and all

other influences, with a link to other areas of study.

Technical systems (as main operator) experience a

typical life cycle. This leads to consideration of supply

networks, globalization, financing, impacts on the

environment, and other concepts. The process, and all

operators, exhibit typical classes of properties. Each

process and operator consists of elements and

relationships that form structures of several useful

kinds. Anticipating a future involves establishing the

requirements, including those that arise from the

producing organization. The available technological

and scientific information influences the development

of individual sorts of transformation system, and

enables and limits the changes in culture that can be

implemented.

A rational methodology for designing newer

transformation systems can be proposed. This

systematic approach to designing allows use of other

design methods, including intuitive working.

1 Introduction

A major difference between science and engineering

has been stated as:

- scientific activity tries to extend the boundaries of

knowledge, preferably for a short boundary length

of a specific knowledge region at a time, with

reference to its existing knowledge base;

- engineering tries to create working systems, mostly

within the boundaries and complex interactions of

many knowledge and information regions.

The processes and actors (operators) for any

engineering improvements at local, regional, national

and global levels need to be understood in a holistic

way. Any change at one level will inevitably influence

other levels, the viewpoints are hierarchical a system

is a member of a higher-order system, and can usually

be divided into sub-systems. Changes will need to be

planned with care, and will have some foreseen

consequences, and some unexpected results.

Engineering education should thus aim to instil that

complex interactive holistic understanding.

The theory of technical systems (TTS) [1,2,3] provides

a comprehensive model from which this holistic

understanding can be obtained, and presents a

conceptual basis for qualitative thinking, especially

useful in engineering education. The following

sections present a brief and incomplete outline, with

comments on context, relevance and applicability.

2 Theory of Technical Systems

According to ISO 9000:2005 [4], a product is

defined as a result of any process. A product is the

operand in state Od2 at the end of a transformation

process (TrfP), and is classified as:

(a) hardware: a tangible, material object, with

countable quantity;

(b) software: information, and an intangible object (an

insurance policy, a computer program, etc.);

(c) service: the intangible result of an activity

performed at the interface between a supplier and a

customer; this includes provision of electricity,

water, fuel, transportation, garbage removal,

policing, wholesale and retail, advertising, delivery

of information, providing ambience, etc.; and

(d) processed material: a solid, liquid or gaseous

(bulk) material that can be measured in units of

volume, mass, energy, etc., e.g. plastics, fuel,

grease, coolant.

To (a): a range of products was described in [2] p.10-

12, and in [3] p. 336-337. Those tangible products that

have a substantial engineering content are called

technical system, TS. To (c): this also includes an

activity that results in a change in a tangible or

intangible operand, i.e. a process product, a

transformation process, TrfP. Further to (c): supplier

and customer are to be understood in a very wide

sense an employee on the manufacturing line is a

customer for the information delivered by the design

engineering department. Also to (c) and (d): energy is

only listed here as manifested by its carriers. This

definition is more explicit than the usual designation

of goods and services.

The theory of technical systems describes in general

terms and interconnected models the common traits of

all process products and tangible products that have a

substantial engineering content. The basic model

shows a transformation system (TrfS), within a

general environment, figure 1. This TrfS consists

typically of a transformation process (TrfP) which

transforms an operand (Od) in structure, form, space

and time, driven by effects delivered via a technology

(Tg) by five (classes of) operators: human systems

(HuS), technical systems (TS), active and reactive

environment (AEnv), information systems (IS), and

management systems (MgtS). The TrfP is external to

the operators, the operators can act and/or work even

if no operand is present.

Figure 1. General Model of a Transformation System

(TrfS) [3]

Any artificial change (transformation) can be modeled

in this way. Examples are: (1) hardening a steel

workpiece by heating and quenching, or inserting a

heart by-pass change of structure; (2) machining a

workpiece, or applying a prosthetic hand change of

form; (3) transporting goods or people from one place

to another change of location; and (4) storing goods,

or going to sleep change in time.

The transformation system according to this model is a

Product Service System but this term arose many

years after Hubka first proposed the TrfS model in

1967 [5]. The main purpose of any TS (as tangible

product) is usually to perform a transformation

process, TrfP. You look for something with which to

calculate with numbers and display results an

abacus, a pocket-calculator, or a computer.

The environment includes local influences acting on or

reacting to the system, and effects acting on or

reacting to the operand in its process. The general

environment (regional, national and global) covers

physical, chemical, societal, economic, cultural,

political, ideological, geographic and all other

influences indirectly acting on or reacting to the TrfS.

A link can thus be made to the humanities, politics,

and other areas of study, which can help to make

engineering into liberal education.

The operand input to a TrfP, Od1, includes all

influences on the environment caused by previously

reaching that input state. The operand output, Od2, is

intended to be improved from its input state, Od1

conservation of material and energy is observed,

information may be added or deleted. The operand

output, Od2, is usually accompanied by secondary

outputs, which may be useful for other purposes, or

add to waste and pollution a direct link to

environmental impact concerns. This demonstrates

that TTS is useful in engineering education as an

explanatory system for the context of design enginee-

ring, and for interactions of the engineering sciences.

3 Technical Systems Life Cycle

The technical system TS(s), as subject and main

operator of interest, is an artificial, human-made

tangible product. Its typical life cycle consists of seven

(classes of) transformation system, with relevant

processes of: LC1 product planning of the TrfP(s)

and the TS(s); LC2 designing of the TrfP(s) and/or

the TS(s); LC3 manufacturing planning, techno-

logical and organizational preparation for the

subsequent life-cycle phases; LC4 manufacturing

and assembly of the TS(s); LC5 distribution, sale,

delivery of the TS(s); LC6 operation of the TS(s)

and performance of the TrfP(s); LC6a servicing,

maintaining, repairing the TS(s); and LC7

liquidation of the TS(s), recycling. Each life-cycle

transformation systems is comprised of other

transformation systems a hierarchical network.

This leads to consideration of various concepts.

Supply networks are needed to deliver raw materials

and OEM (original equipment manufacturers) goods.

OEM goods appear mainly as machine elements [6],

including electronic, hydraulic and others not usually

found in mechanical products. The influences of

globalization, suppliers world-wide, reducing local

economies, and financing can be shown. Life-cycle

processes are influenced by their environments, but

also have impacts locally and globally. The context to

design engineering should be obvious.

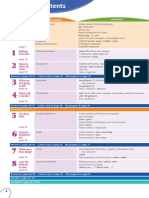

4 Properties, Behaviour

The process, and all operators in their existing as is

state, exhibit typical classes of properties. Each

process and TS-operator consists of elements and

relationships that form structures of several kinds that

have been found useful for conceptual design

engineering. The primary classes of properties for a

transformation process, TrfP, are shown in figure 2,

and for a technical system, TS, in figure 3. All actual

properties can be allocated into these classes no

other classes are needed. In each case, the observable

properties can generally be deduced, observed,

detected, assessed and/or measured by a lay person

from the appearance and literature of the product.

Figure 2. Primary Classes of Properties of a

Transformation Process (TrfP)

Figure 3. Primary Classes of Properties of a Technical

System (TS)

The classes of TS-mediating properties comprise (a)

the TS-intrinsic design properties of technical

information and accumulated experience, including

action locations, technological principles, mode of

action, available effects, principles of form-giving, and

many others, is often organization-specific, and is of

little interest to science; and (b) the TS-general design

properties which relate to the applicable engineering

sciences. The TS-elemental properties are directly

controlled by engineering designers, and some of these

are manifested in some TS-observable and TS-

intrinsic design properties.

Elements of a transformation process are also

hierarchically transformation processes, down to those

that are no longer usefully sub-divided operations.

Among the TS-elemental properties are the various

possible TS-structures, see figure 5.4, [1] pages 67-69,

figure 7-3, [2] pages 106-107, and [3] pages 294-295,

figure 6.3: Elements of technical systems are TS-

internal and cross-boundary functions, organs, and

constructional parts: (1) TS-Function structure using

TS-internal and cross-boundary functions as elements

functions describe (usually in words) the capability

for TS-internal and cross-boundary action; (2) TS-

organ structure using TS-internal and cross-boundary

organs as elements organs are sites where

interactions between constructional parts take place;

and (3) TS-constructional structure using TS-internal

and boundary constructional parts. The constructional

parts may have (classes of) level of abstraction of

modeling, form, size, material (with mechanical,

electrical, chemical, thermal, optical, technological

and other properties), size deviation, surface quality

(texture, reflectivity, color, ), etc.

Structure (of a TrfP and/or a TS) determines

behaviour, but behaviour allows several possible

structures that can provide that behaviour. This allows

the essence of design, a search for alternatives. The

TrfP/TS-intrinsic design properties and requirements,

and the TRFP/TS-general design properties and

requirements provide the links between structure and

behaviour especially the mode of action [7].

Technical systems are also hierarchical. The theory of

technical systems has identified four typical levels of

complexity: (Level I) constructional parts are mainly

simple parts that are not normally capable of further

disassembly, but that can usually only be sub-divided

by destroying the part bolt, shaft, spring, resistor;

(Level II) sub-assemblies of the parts, as intermediate

stages of assembly; and assembly groups, modules of

different complexity gear box, shaft coupling, read-

write head; (Level III) complete assemblies (TS) that

can perform a task lathe, crane, amplifier; (Level IV)

plant oil refinery, commercial kitchen. Any TS of

higher complexity consists of items of lower

complexity. Even a single constructional part is

regarded as a TS. The boundaries between these four

levels are fuzzy. An OEM may regard a VLSI

computer chip as a constructional part of complexity

level I (e.g. Dell), yet the manufacturer of that chip

may regard it as complexity level III (e.g. Intel). A TS

of higher complexity inherits all the properties of its

constituent TS of lower complexity. That TS of higher

complexity also exhibits additional properties that

arise from synergy among the constituent TS of lower

complexity. The complexity of a TrfP is related to the

complexity of the driving TS(s).

TS-behavior is one of the important properties of a

TS, and is defined as the succession of states that a TS

assumes in response to its TS-internal or external

stimuli. The TS-states are defined by the mixture of

properties, and/or their manifestation and/or values at

any one time. The states of properties exist and change

under various TS-operating states, the duty cycle of

the TS: (a) at rest, no operation; (b) during start-up; (c)

during normal operation idling, full-power and part-

load, overload, etc., for self-acting operation

(automatic), or running and ready to be operated by

another operator, e.g. human or another TS; (d) during

shut-down, ending an operational state and returning

to at rest conditions; (e) in fault conditions (e1)

internal faults overload, safe trip-out, breakage or

equivalent, and (e2) external faults damage,

wrecking, etc.; (f) during maintenance, repair, testing,

etc.; (g) at life ended; (h) any other states. TS-

behavior may be predictable (and therefore causal and

analyzable with the help of the engineering sciences),

and/or random, and may change with time.

5 TS-Inputs, Outputs, Effects

In order to fulfill its purpose, to drive a TrfP, the TS(s)

must receive expected (and assisting and secondary)

inputs consisting of materials, information and energy

(M,E,I). The TS(s) in its TS-internal processes

converts the M,E,I into its expected (and secondary)

outputs, using its mode of action. The most significant

output of a TS is its effects (M,E,I), deliverable via the

technology to cause change in the operand. Secondary

inputs can result in disturbances of the expected

behavior, secondary outputs may be useful for other

purposes, or add to waste and pollution. The modes of

action may include mechanical, hydraulic, pneumatic,

chemical, electronic/analog, electronic/digital, electri-

cal, nuclear, biomedical, and others, singly or in any

hybrid combination. The contexts and complex

interactions of the individual engineering sciences are

therefore an important element of engineering

education that has often been neglected. TS thus

include active or reactive hybrid and high-tech

devices, in a static and/or dynamic mode. The

transformation can only be achieved if the TS is

operational (capable of operating or being operated,

fulfilling its TS-internal and cross-boundary functions)

and delivers the desired effects, via the technology, to

the operand of the TrfP.

6 Development in Time

In the past, TS were developed and adapted to local

situations in slow evolution by directed trial and error

correction, by craftsmen using their accumulated

experience. An example is the range of horse-drawn

carts (e.g. in England) that vary according to the

geographic region and topography. Scientific research

on how the TS perform their tasks usually followed

much later, e.g. steam engines that sequence has

recently reversed, some scientific research now leads

to some new products.

As cultural needs progress, and technological and

scientific information increases, many products are

developed to a better state which in turn produces

other cultural needs and more technological and

scientific information. The level of available

technological and scientific information influences the

development of each individual sort of technical and

transformation system, and thus enables and limits the

cultural changes that can be implemented explaining

the development of civilizations over centuries. Such

developments in time can be traced, for instance the

generations of personal cars.

7 Requirements

Anticipating a future TrfS involves establishing the

requirements for the future conditions, including those

that arise from the producing organization.

Requirements are closely related to properties, but

their scope and information content are different.

Requirements can typically set limits. Properties show

the actual achieved values (preferably within the

required limits), but do not allow conclusions about

the initiating limits.

The two states of TrfP and TS can be illustrated, (1)

existing, as is, with properties measurable,

assessable or latent, e.g. a diameter of 15.9836 mm,

and (2) future, as should be, with only requirements

to demand or limit the properties, e.g. a diameter

requirement of 16 mm with tolerance grade h7, and

heuristics to guide designers to establish and select the

properties. The as is state precludes finding the as

should be requirements e.g. if the diameter as is

conforms to the requirement, the tolerance may have

been h7, h8 or h11. The as is TrfP(s) and TS(s)

cannot carry information about any alternatives that

were considered during life-cycle phases LC1 LC3.

It also cannot carry information about any

requirements or constraints from the life-cycle phases

the TrfP(s) and TS(s) remain within the constraints.

Consequently, the primary classes of requirements are

shown in figure 4. Class Rq1 contains requirements

for the organization, related to TS-life cycle phases

LC1 LC3. Class Rq2 contains requirements for the

transformation process, analogous to figure 2, classes

Trf-Pr1 TrfP-Pr5. Classes Rq3 Rq11 contain

requirements for the technical system, analogous to

figure 3, classes Pr1 Pr9. Classes Rq12 Rq14

contain any requirements from both Trf-Pr6 TrfP-

Pr8 and Pr10 Pr12.

Figure 4. Primary Classes of Requirements for a

Transformation System (TrfS) [8]

8 Theory of Design Processes, and Design

Method

The theory of design engineering as proposed by

Hubka [1,2,3] follows from the general model of a

transformation system, figure 1. Initially, the design

process is divided into five administrative phases:

product planning, task defining, conceptualizing,

embodying/laying out, and detailing. At the second

hierarchical level, the stages and steps of a novel

design process are summarized as:

- task defining:

(P1) establish a design specification for the future

system, a list of requirements, see section 7;

- conceptualizing:

(P2) establish the desirable and required output

(operand in state Od2) of the TrfP(s);

(P3) establish a suitable transformation process,

TrfP(s); and (if not stated as a requirement)

establish a suitable input (operand in state Od1);

(P4) decide which of the operations in the

transformation process will be performed by TS

(and which by other operators);

(P5) establish which TS(s) (or parts of them) need to

be designed;

(P6) establish a technology (structure, with

alternatives) for that transformation operation,

and therefore the effects (as outputs) needed

from the technical system;

(P7) establish what capabilities the TS(s) needs

(internal and cross-boundary functions,

alternatives);

(P8) establish what organs (function-carriers in

principle and their structure, with alternatives)

can perform the functions. These organs can be

found in the machine elements, as revised [6];

- embodying/laying out, and detailing:

(P9) establish with what constructional parts (in

sketch-outline, in rough layout, in dimensional-

definitive layout, then in detail and assembly

drawings, with alternatives) are needed.

Redesign can be accomplished by:

(Pa) establishing a design specification for the revised

system (step P1);

(Pb) analyzing the existing system into its organs and

(if needed) its functions (reversing steps (P8) and

(P7) of the novel procedure);

(Pc) then following the last one or two parts of the

procedure listed above for a novel system.

Superimposed on the set of design operations, at the

next lower level of the hierarchy, is a cycle of basic

operations of problem solving, which consists of: Op-

H3.1 - State the problem; Op-H3.2 - Search for

solutions; Op-H3.3 - Evaluate, decide; Op-H3.4 -

Communicate solution. These are supported by

auxiliary operations of: Op-H3.5 - Prepare

information; Op-H3.6 - Check, verify, reflect; Op-

H3.7 - Represent. The last three were recognized by

Hubka, but are rarely found in other schemes.

Only those parts of this engineering design process

that are thought to be useful are employed. This

systematic approach to designing and synthesizing

allows use of any other design method, including

intuitive and opportunistic working. The need for such

a theory-based systematic design process was

discussed in [9]. Such an idealized procedure cannot

be accomplished in a linear fashion, iterative working

is essential, using the model of problem solving [7].

Because TS are hierarchical, any proposed product can

be sub-divided, and each sub-division treated as a

design problem in its own right. The TS-internal and

cross-boundary functions in higher TS can then acts as

TrfP in designing the lower TS.

The application and productivity of this design method

based on the Theory of Technical Systems [1,2,3] has

been verified in several industrial projects from the

University of West Bohemia, e.g. [10]. It has also been

demonstrated in several case studies [3,11,12].

9 Closure

The context of the theory of technical systems [1,2,3]

shows clearly why engineers should develop a wide

and holistic outlook and insight. Engineering is not

merely applied science science can be applied for

analysis, and as heuristic for synthesis. Nevertheless,

engineering requires a wider collection of information,

skills and abilities.

Engineering provides the tools, and is one of the basic

building blocks (interacting with all others) for

influencing the development of any culture. TTS also

demonstrates clearly why in engineering education a

narrow emphasis on the analytical engineering

sciences is necessary, but by no means sufficient to

produce a well-rounded and functioning engineer.

10 References

[1] Hubka, V. and Eder, W.E. (1988) Theory of

Technical Systems (New York: Springer-Verlag

[2] Hubka, V. and Eder, W.E. (1996) Design

Science: Introduction to the Needs, Scope and

Organization of Engineering Design

Knowledge, London: Springer-Verlag

http://deseng.ryerson.ca/DesignScience/

[3] Eder, W.E. and Hosnedl, S. (2008) Design

Engineering: A Manual for Enhanced

Creativity, Boca Raton: CRC-Press

[4] ISO 9000:2005 Quality Management

Systems Fundamentals and Vocabulary,

Geneva: ISO, 2005 http://www.iso.ch

[5] Hubka, V., Der grundlegende Algorithmus fr

die Lsung von Konstruktionsaufgaben (Funda-

mental Algorithm for the Solution of Design

Problems) in XII. Internationales Wissen-

schaftliches Kolloquium der Technischen

Hochschule Ilmenau, Heft 12 Sektion L -

Konstruktion, Ilmenau: T.H.I., 1967, p. 69-74

[6] Eder, W.E. (2005) Machine Elements

Revision and Outlook for Design Education, in

Proc. Second CDEN International

Conference, University of Calgary, Alberta, 18-

19 July 2005 at Kananaskis Resort, paper 10006

on CD-ROM

[7] Eder, W.E., (2009) Analysis, Synthesis and

Problem Solving in Design Engineering, in

Proc. International Conference on Engineering

Design, ICED09, 24 - 27 August 2009, Stanford

University, Stanford, CA, USA (in review)

[8] Eder, W.E. (2009) Properties, Requirements and

Problem Solving, in in Proc. International

Conference on Engineering Design, ICED09, 24

- 27 August 2009, Stanford University, Stanford,

CA, USA (in review)

[9] Eder, W.E. (2008) Design Engineering Needs

for a Systematic Design Process, in Proc. 10

th

Engineering and Product Design Education

Conference 2008, 4-5 Sept 2008, Universitat

Politecnica de Catalunya, Barcelona (Institution

of Engineering Designers (UK) and The Design

Society)

[10] Hosnedl, S., Srp, Z. and Dvorak, J. (2008)

Cooperation of Engineering and Industrial

Designers on Industrial Projects, in Proc. 10th

International Design Conference - DESIGN

2008, D. Marjanovic (Ed.), FMENA, Zagreb, p.

1227-1234

[11] Hubka, V. (1982) Principles of Engineering

Design, London: Butterworth Scientific,

(translated and edited by W.E. Eder from Hubka,

V. (1980) WDK 1 Allgemeines

Vorgehensmodell des Konstruierens (General

Procedural Model of Designing), Zrich,

Heurista; translated into several other languages:

French, M. Wyss (1980) Zrich: Heurista;

Italian, U. Pighini (1982) Marsilo ed.; Czech, S.

Hosnedl (1995) Zrich: Heurista, and others

[12] Hubka, V., Andreasen, M.M., and- Eder, W.E.

(1988) Practical Studies in Systematic Design,

London: Butterworths

You might also like

- How Do The NEC and IEC 60364 Help Provide Electrical Safety PDFDocument9 pagesHow Do The NEC and IEC 60364 Help Provide Electrical Safety PDFnecmettinsengunNo ratings yet

- Behavior Model, Create A Structure Model, Perform Trade-Off Analysis, and Create Sequential Build & Test PlanDocument22 pagesBehavior Model, Create A Structure Model, Perform Trade-Off Analysis, and Create Sequential Build & Test Planpranjalbaruah8No ratings yet

- Practical Engineering Management of Offshore Oil and Gas PlatformsFrom EverandPractical Engineering Management of Offshore Oil and Gas PlatformsRating: 4 out of 5 stars4/5 (7)

- LUMP SUM PRICE BREAKDOWN FOR SITE CONSTRUCTIONDocument117 pagesLUMP SUM PRICE BREAKDOWN FOR SITE CONSTRUCTIONgunturlp100% (2)

- Civil Engineering Orientation ModuleDocument108 pagesCivil Engineering Orientation ModuleRingor Fam100% (2)

- Engineered Over 10,000 km Transmission LinesDocument2 pagesEngineered Over 10,000 km Transmission Linesmhergonzales100% (1)

- Systems Engineering PresentationDocument31 pagesSystems Engineering PresentationhrsreenathNo ratings yet

- CDOT Bridge Design Manual - 20180101Document431 pagesCDOT Bridge Design Manual - 20180101albertoxina100% (1)

- Computational Frameworks: Systems, Models and ApplicationsFrom EverandComputational Frameworks: Systems, Models and ApplicationsNo ratings yet

- From Systems of Innovation To Socio Technical Systems PDFDocument24 pagesFrom Systems of Innovation To Socio Technical Systems PDFHercilio DuarteNo ratings yet

- BS 1434 Copper For Electrical PurposesDocument14 pagesBS 1434 Copper For Electrical PurposesCristi Grosu0% (1)

- Plant Simulation Basics Tutorial English Andersson AslamDocument40 pagesPlant Simulation Basics Tutorial English Andersson AslamOliver RubioNo ratings yet

- Technology Roadmapping - Phal Et AlDocument22 pagesTechnology Roadmapping - Phal Et AlmavelazquezNo ratings yet

- Kobbacy, Murthy - Complex System Maintenance HandbookDocument648 pagesKobbacy, Murthy - Complex System Maintenance HandbookStipe Krečak100% (1)

- The Knowledge Base in The Engineering SectorDocument15 pagesThe Knowledge Base in The Engineering SectorsreesajeshNo ratings yet

- Basic concepts and definitions of industrial technologyDocument26 pagesBasic concepts and definitions of industrial technologyjeneairNo ratings yet

- Case Example of Systematic Design Engineering - Linear Friction Test EquipmentDocument6 pagesCase Example of Systematic Design Engineering - Linear Friction Test EquipmentvcockscribdNo ratings yet

- Chapter 2 The Aircraft SystemsDocument19 pagesChapter 2 The Aircraft SystemsfahadNo ratings yet

- SystemDocument7 pagesSystemArun Kumar NairNo ratings yet

- 4 The Systems Approach: by Gwilym Al. JenkinsDocument34 pages4 The Systems Approach: by Gwilym Al. JenkinsFasutino ManceraNo ratings yet

- Embedded Systems - Challenges and Work DirectionsDocument2 pagesEmbedded Systems - Challenges and Work DirectionsناصرھرەNo ratings yet

- Information Technology (IT) Is The Application of Computers and Telecommunications Equipment ToDocument3 pagesInformation Technology (IT) Is The Application of Computers and Telecommunications Equipment ToMichelle AvilesNo ratings yet

- Digital_Twin_DT_in_Smart_Energy_SystemsDocument18 pagesDigital_Twin_DT_in_Smart_Energy_Systemschandraippa2No ratings yet

- Change Mining in Adaptive Process Management Systems: (C.w.gunther, W.m.p.v.d.aalst) @TM - Tue.nlDocument2 pagesChange Mining in Adaptive Process Management Systems: (C.w.gunther, W.m.p.v.d.aalst) @TM - Tue.nlpuarachchigeNo ratings yet

- ENG4Document2 pagesENG4Jayri FelNo ratings yet

- Reactory SystemDocument29 pagesReactory SystemFREDRICK MUSAWONo ratings yet

- Systems EngineeringDocument2 pagesSystems EngineeringLeninjer MartinezNo ratings yet

- L1 SDT 2021 Highlighted ClassDocument12 pagesL1 SDT 2021 Highlighted Classama kumarNo ratings yet

- Good Practice Guide For ESP-r Developers: DR Ir Jan HensenDocument36 pagesGood Practice Guide For ESP-r Developers: DR Ir Jan HensenLTE002No ratings yet

- Introduction To Logistics: EctureDocument22 pagesIntroduction To Logistics: EcturemawandeNo ratings yet

- SE Unit 1Document6 pagesSE Unit 1PAVANNo ratings yet

- Socio-Technical Transition (Sustainability Transition) : PlatformDocument3 pagesSocio-Technical Transition (Sustainability Transition) : PlatformWen-temi ApeaningNo ratings yet

- Review Engineering StandardsDocument15 pagesReview Engineering StandardsHector BarronNo ratings yet

- INCOSE Critical Infrastructure Protection and Recovery (CIPR) Working Group (WG), Incose, 2015Document8 pagesINCOSE Critical Infrastructure Protection and Recovery (CIPR) Working Group (WG), Incose, 2015garidosebastNo ratings yet

- An Obsolescence Management FrameworkDocument20 pagesAn Obsolescence Management FrameworkJhoan Smith Chaves PeñaNo ratings yet

- The Technology-Organization-Environment FrameworkDocument15 pagesThe Technology-Organization-Environment FrameworkMugluuNo ratings yet

- Lecture Note On Introduction To Industrial EngineeringDocument105 pagesLecture Note On Introduction To Industrial EngineeringPeter Iyere50% (2)

- Systems Theory: Home Work No. 1Document7 pagesSystems Theory: Home Work No. 1Bogdan BîngăNo ratings yet

- 2014.1.PLM14-SystemLifecycleManagement-InitialApproachforaSustainableProductDevelopmentProcessBasedonMethodsofModelBasedSystemsEngineeringDocument15 pages2014.1.PLM14-SystemLifecycleManagement-InitialApproachforaSustainableProductDevelopmentProcessBasedonMethodsofModelBasedSystemsEngineeringkaff110.aqNo ratings yet

- System EngineeringDocument11 pagesSystem Engineeringapi-26349602100% (2)

- Matrices in Environmental Impact AssessmentDocument10 pagesMatrices in Environmental Impact AssessmentEsayase AsnakeNo ratings yet

- Solution Manual For Logistics Engineering Management 6 e 6th Edition Benjamin S BlanchardDocument24 pagesSolution Manual For Logistics Engineering Management 6 e 6th Edition Benjamin S BlanchardJodiHuangDDSgmqfy100% (43)

- Guidellines On Technology Selection and TransferDocument16 pagesGuidellines On Technology Selection and TransferBrhane WeldegebrialNo ratings yet

- Requirements Traceability Seminar ReportDocument12 pagesRequirements Traceability Seminar ReporthaythamnasefNo ratings yet

- Lean Production Controlling and Progress Tracking Using Digital MethodsDocument8 pagesLean Production Controlling and Progress Tracking Using Digital MethodsJoseph ZANo ratings yet

- Computers and Chemical EngineeringDocument15 pagesComputers and Chemical EngineeringsourcemenuNo ratings yet

- Sustainable Logistics Management in The 21st Century Requires Wholeness Systems ThinkingDocument26 pagesSustainable Logistics Management in The 21st Century Requires Wholeness Systems ThinkingRESHMANo ratings yet

- Socio-technical scenarios as a policy tool for transport transitionsDocument25 pagesSocio-technical scenarios as a policy tool for transport transitionscpongpNo ratings yet

- Mechatronics Robotics and Components For Automation and Control - IfAC Milestone ReportDocument14 pagesMechatronics Robotics and Components For Automation and Control - IfAC Milestone ReportToan NguyenNo ratings yet

- Incose Se Vision 2035 Executive SummaryDocument12 pagesIncose Se Vision 2035 Executive Summaryagomezalejo99No ratings yet

- Analysing Emerging Innovation Systems: A Functions Approach To ForesightDocument22 pagesAnalysing Emerging Innovation Systems: A Functions Approach To ForesightmaczeroesNo ratings yet

- Intro To Avionics and Navigation Systems (Avionics) : Kamlesh KumarDocument32 pagesIntro To Avionics and Navigation Systems (Avionics) : Kamlesh KumarLnsfvNo ratings yet

- Environmental Project LifeDocument13 pagesEnvironmental Project LifeInyene OkonNo ratings yet

- Incose Se Vision 2035Document76 pagesIncose Se Vision 2035Mario EnriqueNo ratings yet

- The Technology Life Cycle Conceptualization and Managerial Implications 2012 PDFDocument13 pagesThe Technology Life Cycle Conceptualization and Managerial Implications 2012 PDFasrmltNo ratings yet

- Shaping user-side innovation through standardisation in ICTDocument14 pagesShaping user-side innovation through standardisation in ICTReneNo ratings yet

- Evolution of Technology and Tec - 2020 - Journal of Open Innovation TechnologyDocument16 pagesEvolution of Technology and Tec - 2020 - Journal of Open Innovation TechnologyAika Liwag PerezNo ratings yet

- Innovation System Hillman - Et - Al - 2009Document20 pagesInnovation System Hillman - Et - Al - 2009Ramanpreet KaurNo ratings yet

- FP GuideDocument102 pagesFP GuideVipin RajputNo ratings yet

- Hierarchical Design Models in The Mechatronic ProductDocument12 pagesHierarchical Design Models in The Mechatronic ProductLau Yeowhong100% (1)

- TFA Methods IntegrationDocument17 pagesTFA Methods IntegrationLucas GiraldoNo ratings yet

- Acm Computing SurveyDocument59 pagesAcm Computing Surveyjaya_koNo ratings yet

- 2006 Geels - Multi-Level Perspective On System InnovationDocument25 pages2006 Geels - Multi-Level Perspective On System InnovationDanielNo ratings yet

- Simulation-Based Sustainable Manufacturing System DesignDocument9 pagesSimulation-Based Sustainable Manufacturing System DesignssfofoNo ratings yet

- NIT DURGAPUR PROCESS CONTROL COURSEDocument2 pagesNIT DURGAPUR PROCESS CONTROL COURSEpiyush dwivediNo ratings yet

- Present and Future of Flexible Automation Towards New Paradigms As A Modern Industrial Revolution To The Present and The FutureDocument6 pagesPresent and Future of Flexible Automation Towards New Paradigms As A Modern Industrial Revolution To The Present and The Futuregedebe_koolNo ratings yet

- Systems Engineering in Public Administration: Proceedings of the IFIP TC8/WG8.5 Working Conference on Systems Engineering in Public Administration, Luneburg, Germany, 3-5 March 1993From EverandSystems Engineering in Public Administration: Proceedings of the IFIP TC8/WG8.5 Working Conference on Systems Engineering in Public Administration, Luneburg, Germany, 3-5 March 1993No ratings yet

- Drilling ProblemsDocument3 pagesDrilling ProblemsOliver RubioNo ratings yet

- Articulo PublicadoDocument26 pagesArticulo PublicadoOliver RubioNo ratings yet

- Session 3 - 5 - Logistics - Fraunhofer IML - Akinlar PDFDocument20 pagesSession 3 - 5 - Logistics - Fraunhofer IML - Akinlar PDFOliver RubioNo ratings yet

- The Design MethodDocument6 pagesThe Design MethodOliver RubioNo ratings yet

- Learn English with fun units on vocabulary, grammar, skillsDocument2 pagesLearn English with fun units on vocabulary, grammar, skillsOliver RubioNo ratings yet

- Mechanical Measurements and Measuring Devices 6-25-08Document58 pagesMechanical Measurements and Measuring Devices 6-25-08Oliver RubioNo ratings yet

- Evolution of Radial Drilling MachineDocument52 pagesEvolution of Radial Drilling MachineHari Krishna75% (4)

- Engineering Materials and Design: Fatigue Analysis and Gearbox DesignDocument9 pagesEngineering Materials and Design: Fatigue Analysis and Gearbox DesignOliver RubioNo ratings yet

- PLM Implementation Effects in Aerospace IndustryDocument9 pagesPLM Implementation Effects in Aerospace IndustryOliver RubioNo ratings yet

- B WEEbio 13Document2 pagesB WEEbio 13Oliver RubioNo ratings yet

- Take ShapeDocument8 pagesTake ShapeOliver RubioNo ratings yet

- Activate A 2Document11 pagesActivate A 2Oliver Rubio100% (1)

- PLM07 - Full Book July 2007Document844 pagesPLM07 - Full Book July 2007Oliver RubioNo ratings yet

- A Multi-Process Actors Strategic AnalysisDocument5 pagesA Multi-Process Actors Strategic AnalysisOliver RubioNo ratings yet

- Automotive PLM for Supplier IntegrationDocument8 pagesAutomotive PLM for Supplier IntegrationOliver RubioNo ratings yet

- Wee2013 P175Document7 pagesWee2013 P175Oliver RubioNo ratings yet

- Hospital SimulationDocument11 pagesHospital SimulationOliver RubioNo ratings yet

- A Preamble 13Document1 pageA Preamble 13Oliver RubioNo ratings yet

- DFR IntroDocument58 pagesDFR IntroOliver RubioNo ratings yet

- Application EVOP Paper 2013Document11 pagesApplication EVOP Paper 2013Oliver RubioNo ratings yet

- Software Architecture PDFDocument14 pagesSoftware Architecture PDFFrancesHsiehNo ratings yet

- Ground AnchorsDocument31 pagesGround AnchorsHammer HeadNo ratings yet

- TL 1110-1-185 Guidelines On Ground Improvement PDFDocument115 pagesTL 1110-1-185 Guidelines On Ground Improvement PDFCarlNo ratings yet

- Iii - Ii It DPPMDocument20 pagesIii - Ii It DPPMBalajiNo ratings yet

- M.tech (CASAD) Course Structure 2012-14-Revised-Evaluation SchemeDocument13 pagesM.tech (CASAD) Course Structure 2012-14-Revised-Evaluation SchemeKrunal MehtaNo ratings yet

- CP S07 Work Package Procurement Plan UpdateDocument1 pageCP S07 Work Package Procurement Plan Updateedmar jay conchadaNo ratings yet

- ITP Box Setting On CHB or Macro WallDocument3 pagesITP Box Setting On CHB or Macro WallRitchie OcampoNo ratings yet

- Computer System MaintenanceDocument4 pagesComputer System MaintenanceJeruNo ratings yet

- 20232107441358tangazo La KaziDocument5 pages20232107441358tangazo La KaziHamis KandomeNo ratings yet

- NTU SCSE Brochure 2020Document9 pagesNTU SCSE Brochure 2020AllalannNo ratings yet

- Proposal Ccs e WeekDocument5 pagesProposal Ccs e WeekXandra LeeNo ratings yet

- Climaveneta - 350 Euston RoadDocument20 pagesClimaveneta - 350 Euston RoadrobasiNo ratings yet

- Fundamentals of Earthquake Engineering: Those Familiar With Newmark - S and RosenDocument1 pageFundamentals of Earthquake Engineering: Those Familiar With Newmark - S and RosenBladimir Jesús Ccama Cutipa0% (1)

- PVPE Pneumatic Valve Packing EquipmentDocument12 pagesPVPE Pneumatic Valve Packing EquipmentAustralian Weighing EquipmentNo ratings yet

- Concrete Problems in AI SafetyDocument29 pagesConcrete Problems in AI SafetyCris D PutnamNo ratings yet

- Instruments Used in Engineering DrawingDocument15 pagesInstruments Used in Engineering Drawingasus nyahendraNo ratings yet

- Traffic Control SolutionDocument24 pagesTraffic Control Solutioncome24 dealNo ratings yet

- List of Engineering Colleges in Andhra PradeshDocument52 pagesList of Engineering Colleges in Andhra PradeshSonya Reddy50% (2)

- An Introduction To CNC MachinesDocument20 pagesAn Introduction To CNC MachinesBHAVESHNo ratings yet

- NOVA Servo CatalogueDocument7 pagesNOVA Servo CatalogueDip Narayan BiswasNo ratings yet

- Speakers Moderator: Rid9Yg5AicxggDocument2 pagesSpeakers Moderator: Rid9Yg5AicxggAnonymous wosn1lyNo ratings yet

- Projecte#: Subject: 98Th Upgrading of Rank of AccreditedDocument2 pagesProjecte#: Subject: 98Th Upgrading of Rank of Accreditedbrian paul ragudoNo ratings yet

- Capstone - Design, Installations and Testing of Electrical Systems in BuildingDocument10 pagesCapstone - Design, Installations and Testing of Electrical Systems in BuildingHaziq10101No ratings yet

- Part 541 - Drafting and DrawingsDocument8 pagesPart 541 - Drafting and DrawingsLuis David Molina CarvalhoNo ratings yet