Professional Documents

Culture Documents

Mao-Investigation of The Diffusion Flames

Uploaded by

KrozeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mao-Investigation of The Diffusion Flames

Uploaded by

KrozeCopyright:

Available Formats

INVESTIGATION OF THE DIFFUSION FLAME

NGUYEN Sy MAO

Department of Heat Engines

Technical University, H-1521 Budapest

Received February 25, 1988

Presented by Prof. Dr. Gabor Bassa

Abstract

In this paper, the analysed problem is how to explain the geometrical structure of flames in

the combustion chamber, and how to establish the relationship between geometrical characteristics

and flow parameters at the burner orifice. On the basis of our experimental data we have made a

regression analysis to present numerical equation for practical use.

Introduction

The heat release and utilization from burning fuel takes place in the combus-

tion chamber, with the simultaneous interaction of chemical, heat transfer and

flow processes. From a firing technical point of view in a combustion chamber the

following requirements must be met:

- effective and safe ignition of the fuel,

- the flame should not impinge on the combustion chamber wall,

- complete burning of fuel up till the end of the combustion chamber,

- the load of the combustion chamber in the burner zone is to prevent pollu-

tion and scorification in a particularly dangerous range.

Ensuring the most important conditions with some mean values based on

empirical date give information on the loads related to volume, cross section, cooling

surface, cross section and surface around the burner zone.

The quantitative and qualitative characteristics of the processes taking place

in the combustion chamber depend on the construction and characteristics of the

flame shape in it.

However the geometrical characteristics of flame as well as the physical and

chemical ones are very important in a firing technical study, because we can cal-

culate the above-mentioned characteristics based only on the determination of the

length, volume and surface of the flame. But these geometrical characteristics of

flame can not be calculated based only on theory, since only experimental results are

available.

68

NGUYEN SY MAO

There are many methods to determine the size, volume of the simple or com-

bined flame based on different experimental views, thus:

Visual observation: the size of flame is established by the eye,

Photographical: the size of flame is photographed,

Ionization, ion conductivity: the limit of the reaction zone, i.e. the "edge of

flame" is determined by the signal (e--O) of the electric conductivity.

CO component measurement: it is the limit of the chemical reaction, where no

CO component is found. Of course, we can say that there is limit of flame, where

the value of the CO component is less than 20 ppm,

Schlieren: the limit of the flame is determined where the refractivity of the

flame is equal with the refractivity of the surrouding (air).

Fundamental theory

The fundamental equations of the flame discussed as aerothermochemical sys-

tem are represented by those related to mass, impulse and energy. The system of

the fundamental equations forms so very complex equations, that writing them,

but especially their solution needs certain simplifying reductions. Approximations

used to be considered of the source functions, space-time dependenc of state deter-

mination, interaction of different substances during flow.

For the mass of the different components, impulse and energy, the general

form of continuity equation can be used as

oQ d' I

a:r+ IV = q.

Using the general equation of the flow its differential equation can be set up.

F or the mass of the chemical component k: if the mass density ofthe chemical

component k is Qk' flow density is If' source density is H{, which means the reaction

velocity in case of flame, the system flows with velocity w, diffusion coefficient of

the component is Db concentration is Cb then the differential equation related to

the mass of component k:

O ~ +div(Qw-DkgradC

k

) = H{.

Concerning the impulse

Disregarding the external forces, the impulse generated in the unit volume is

given by the divergence of the tension tensor. In case of velocity w with components

of directions It, v, 11', X, y, z the general equation for impulse:

~ [Qw] + div [Qw . ow] = div P.

INVESTIGATION OF THE DIFFUSION FLAME

69

The usual form of the tensor gives the fundamental equation of hydrodynamics,

Navier-Stokes' equation in a general form:

W ow q u

D-AC+-,,-+[w, grad]w = --grad+-Aw.

e 07: Q Q

Concerning energy transport

1

The energy density consists of the kinetic energy? Qll;2 and the specific internal

energy denoted with e: -

ee = ~ mW

2

+e] e

taking into account the thermalconductivity }, and the reaction heat related the

unit mol weight, qb the generated thermal energy is

and the differential equation related to the energy:

Application of the general differential equation for hydrogen and oxygen turbulent

free-jet flames, is done by using some reduction.

In order to estimate the process in technical flames it is necessary to know the

local gas conditions of the reactjon zone, first of all temperature ancI mass distribu-

tion. These distributions are the results of complex interactions between the flow,

elementary chemical kinetics, as well as the energy and mass transport processes.

The regularities of the individual processes taking place in the flames are theoretically

well founded for laminar flows, however, the analysis of the turbulent fields is pos-

sible only with semiempirical correlations, that have to reckon with local fluctua-

tions and their effects, first of all on the transport processes.

The velocity distributions at the cross section of the free-jet along the length

of the jet, after H. Eickhoff and B. Lenze [6] as follows:

where

6,410,,0 _89 (y"')'

U = li

o

-- -e - ...

x:d

o

e

x - component of the mean flow

y - perpendicular component of flow

do - diameter of the burner mouth.

70

NGUYEN SY MAO

The mass concentration distributions at the cross section of the free-jet:

where:

C = Co 5,26 1/70 e-

54

(y:x')

x:d

o

V Qk

Qk - density of the surrounding.

The closing angle of the free-jet is often 19.

Because of the difference of mass-densities a buoyancy force exists in the jet,

however the impulse flow is not constant along the jet and increases quickly within

it. Along the length of flame the admixture is larger if the impulse flow is larger.

As a matter of course the buoyancy force has brought about the mixing rapidly and

because of it the length of flame is shorter, too.

It can be concluded that in case if Froude's number is larger than 10

5

the effects

of the buoyancy force on the length of flame have not been considered.

Concerning the turbulent flame: the impulse flow at the optional cross-section

along the jet length is equal with the initial cross-section of the jet:

and mass flow:

r

I = 2rr J Q u

2

Y d y = 10

o

r

111 = 2rr J QCuy dy = il1

o

o

After H. Eick and B. Lenze [6] the velocity distributions along the axis of

the jet:

1 lPi-o II =- --

III X Qk

1

The concentrarion distributions along the axis of jet:

of course

if the fuel flo\\' (with density 120 and \vith a density Qk of the air flow) takes place in

the mixture:

CIII k do lfQ;

-C = 3 ~ 1 -

o _. r QI:

In case of the reaction zone Qk changes to QJ

Cm = k3!!2.. 1 fQ; .

Co x V g;

INVESTIGATION OF THE DIFFUSION FLAME 71

We may thus say, that the end of flame is to be found where the concentration along

the axis of the jet is equal with the theoretical stoichiometric concentration

(Cm=C

st

). Of course the length of flame is calculated as follows:

where:

Xf - the distance from the beginning until the end of the flame.

It is remarkable that usually the beginning of the flame is not at the outlet

orifice of the burner. Based on different experiments the following may be considered:

- in case of a little number Re the beginning of the flame is at the outlet orifice

of the burner,

- in case of the double concentric burner: because of the relativ velocity

between two jetflows is minished, as well as turbulent exchange the beginning of

the flame is displaced from the initial of the jet into flow.

Concerning the rotation jets

In case of a simple rotation-jet, the decrease of the concentration is as follows:

However the length of flame may be written as follows:

where

le - constant established by experiments

Dol' [D:do=GJ - rotation parameter.

Experimental method

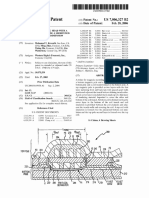

The experimental apparatus is shown in Fig. 1.

According to experiences the burner block is made up with 3 kinds: Benson

diffusive, preparative mixture rotative and injector burners. The orifice of the bur-

ners is variable to determine the size of flame at different flow conditions and dif-

72

I

1

/

NGUYEN SY MAO

13 if. 9 10 15

\ \ / / /

El El OOID 00

I 2 i.'.'. I' = I i / 3",

I ,i ' '.

!i',' ,

<, '.'.1 I 10

"'L '/ i

, ' 11E=f!1

/71

1

,

City gcseous fuel

Fig. i. The experimental apparatus

1. Schlieren's head; 2. Burner block; 3. Normal light source; 4. Impulse light source; 5. Gas-closing

\'alve; 6. Closing \'alve; 7. Electric fan; 8. Distribution valve; 9. Manometer; 10. Manometer;

11. Unit of supplemer,t; 12. The support of the burner; 13. Unit of temperature; measuring 14. Unit

of measuring electric conduction; 15. Unit of measuring CO, CO,; 16. Probes (T, E, CO, CO,)

ferent geometrial parameters. In each experiment there are five burners in the block.

They are aggregated that their axises are parallel together. The burner is shown

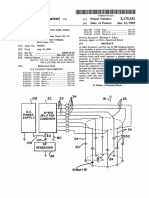

in Fig. 2. We can see that the outlet orifice of the burner is varied by change the

orifice diameter from 2 mm to 3,5 mm. The gas comes from the main system, flows

into the distribution chamber and then flows through the closing valve and the

mass measurement, and last flows into the burner. The velocity of the gas and air

streams is oppositely varied by a change in the flow pressure of the gas or air stream

after the closing valve. In our experiments the velocity of the gas stream is varied

from 5 m/s to 50 m/s and for the air flow from 2 m/s to 30 m/so

Schlieren's block

The twin-lens Toeples-type SchIieren apparatus is shown in Fig. 3. The essential

part of the apparatus is the collecting lens K, the so-called Schlieren head, which

transilluminates the object S with a convergent beam of rays. Spark gap is used to

study the light sourse L phenomenon, projected to knife-edge aperture B through

the condenser. In respect of an uniform illumination of the field of vision it is essential

that the light cone should illuminate completely the Schlieren head K which projects

the aperture B directly in front of camera Ka. Here we find the knife-edge aperture

.oB". The suitable adjustment of the two knife-edge apertures enables, in case of a

Schlieren-free object, the uniform illumination of the image plane S' with a cor-

responding slight aperture displacement. The SchIieren head consists of a Tes-

sar-4,5/300 object and a knife-edge aperture, whose constant is e=2 mm. The

size of the first knife-edge aperture is 30X40 cm!! and its negative is 6,5x9 cm

2

The object is in the middle of the distance between the first- and the negative knife-

INVESTIGATION OF THE DIFFUSION FLAME

$ 32

$12..1

A t Eti

COt

~ Q . \

;;r .+-.

":L :

The burner mouths

L

I B

I

o

o

C'")

Fig. 2. The experimental burner

5

Ko

\ B ~ 0 B", .

Fig. 3. ToepJes-type SchJieren apparatus

ivi 1: 1

73

74

NGUYEN SY MAO

edge aperture. The size of visualization of the object is 15x20 cm

2

So the photo-

grafical relation of the object is N=0.5, however the refractivity is

e N

Bmin = 401' N + 1 (rad)

The light source consists of a normal and an impulse source.

The normal light source is made up by a matrix of 30 spherical lamps (with a

power of 60 W).

The impulse light source is made up by 6 spherical lamps (their power is 60 W)

and 3 electronic tubes filled with "argon" gas with a pressure of 400 torr. Of course,

we have to have a supplement consisting of a transformer (max. pressure 15 kV)

and 3 condensors in 250 mF.

Ionization measurement

It consists of an electric conductivity sensor and electric circuitry. The electric

conductivity probe is made up by a cylindrical tube with a length of 3 mm and an

internal diameter of 2 mm. One rod (external diameter of 1 mm) is placed in the

centre of the cylindrical tube thus it is a condenser with a capacitance of 1-2 PF.

Two electrodes are matched parallel to the impedometer. Of course, we have to have

an amplifier for the use. The measurements are carried out spot wise in the axial

cross section of the flame and the mean time 'values of the variables were determined

from signals registered by an oscillograph.

The flame temperature is measured by Ni-CrNi thermocouples. They are used

with a ceramic protectiv tube, which is made up by a 0.5 mm internal diameter

double whole tube. The probe is set on the oscillator. The probes are shown in

Fig. 4.

Gas analyser

Gas analysis waS performed by "URAS" complex CO and CO

2

analyser. It ,vorks

on the basis of the theory of infrared heat radiation displacement. The probe is a

1.0/0.2 mm diameter ceramic tube. The probe is shown in Fig. 4.

Results

Diffusion flame is a flame where the fuel and the oxidant meet in a reaction

zone by molecular and turbulent diffusion. The distincti';e characteristics of a dif-

fusion flame is that the burning (or consumption) rate is determined by the rate at

which the fuel and oxidant are brought together in a propcrtion suitable for reac-

tion.

Between the extremes in which the chemical reaction rate on the one hand,

and the mixing on the other control tbe burning rate, there is the region in 'Nhich

chemistry and mL'{ing have similar rates and must be considered together.

INVESTIGATION OF THE DIFFUSION FLAME

CcN ;;I

j

"

-p=:- +1---

1

- <'1"1

Ni 1 2 135 85 3

r 330 J

1) tube

Probe for measuring temperature

Ul

2) Copper tube

3) Thermocouples

Ni-CrNi

-li 1 2 -.sf A 3

f a / V

I I 1 135 I 135 J

LI' r 330 T I

A

-8

1) Ceramic tube

2) Copper tube

Probe for measuring electric condution

3) Condenser

150

!

1 I 2 ' , 0

\ -, !

Fig. 4. Experimental probes

,

j) Probe tube

2) Cooling tube

3\ Support tube

75

The diffusion flame has a wide region over v:hich the composition of the gases

changes. These changes are principally due to the interdifl'usion of reactants and

products since the actual reaction apparently takes place in a narrow zone.

The concentration of fuel and oxidizer is minimal at the flame front where

the product concentration is maximal. These conditions arise, of course, due to

diffusion.

Based on the previous theory we undertook a lot of experiments with our ex-

perimental apparatus.

76

o

240

.c

200

160

'120

10

NGUYEN SY MAO

d

o

=2-3.5 mm

...... n

-W---ft--

o By photographs

i:l CO component measure

o Ionization

v SchlierEn

I

20

I

30

I

40

I

SD

I

50

I ....

70

W,m/s

Fig. 5. The relationship between the length of flame and outward velocity flowing

Based on our experimental results, the relationships between the geometrical

characteristics of flame and the size of burners and physical chemical characteris-

tics of gas were introduced as follows:

Flame length

The length of flame is a function of the diameter of the burner orifice and the

ollt\vard flow velocity, as shown in Fig. 5.

It is clear that there are differences in diffusion flames: such as laminar, transi-

tion and turbulent diffusion flames.

In case of the laminal' region the length of flame is increased by increasing the

jet velocity and the burner diameter, calculated by an experimental approximate

equation:

where:

h flame length lil

do diameter of the burner orifice J1l

L

min

- theorically necessary amount of air 111

3

/m

3

]V gas velocity flowing out from burner orifice l11/s (outward flow velocity)

k1 constants were established experimentally, as follows

k1 =2,58 by photographs

k1 =2,81 by CO component measurement

k1 =2,98 by ionization

kl =3,5 by Schlieren.

INVESTIGATION OF THE DIFFUSION FLAME

/1

1

- exponent was established experimentally, as follows:

/11 =0,94 by photographs

III =0,923 by CO component measurement

111 =0,915 by ionization

111 =0,89 by Schlieren.

77

It is remarkable that the length of flame obtained by photography is the shortest

and is the longest by Schlieren's method, other methods resulting in between values.

In case of a turbulent region the length of flame is thus independent of the out-

'ward flow velocity and proportional to the diameter of the burner orifice only, as

shown in Fig. 5. Based on our experimental data an equation may be obtained to

calculate the length of turbulent flame, as follows:

where:

k2 constant was established experimentally as follows

k2=18 by photographs

k2 =20 by CO component measurement

k2=21 by ionization

k2=24 by Schlieren.

111 case of a transition region the length of flame is thus inverse proportional

to the outward flow velocity and may be written as follows:

where:

k3 - constant was established experimentally as follows:

k3 = 1895 by photographs

k3=1982 by CO component measurement

k3= 1892 by ionization

k3= 1864 by Schlieren.

113 - exponent was established by experiments too,

113 = -1,31 by photographs

113= -1,29 by CO component measurement

113 = -1,26 by ionization

113= -1,22 by Schlieren.

It is important to note that the above equations and diagrams can be applied in

case of diffusion flames at a free flow state.

Flame diameter

Based on our experimental results it is known that the diameter of the diffusion

flame is a function of the outward flow velocity and the burner orifice diameter.

Figure 6 shows the relationship between the maximum flame diameter and outward

flow velocity and orifice diameter.

78

!

-00 24

")

-0

20

16

12

NGUYEN SY MAO

d

o

=2-3.5 mm

I

10

o By photographs

A CO component measure

o Ionization

v Schlieren

,

20

I

30

,

40

I

se

I

60

W,m/s

Fig. 6. The relationship between the max. diameter of flame and outward flowing velocity

As with the length of flame there are different formations and calculation

equations concerning the flame diameter for different combustion states.

In case of a laminar region, the flame diameter is increased by the increase of

the outward flow velocity and the diameter of the burner orifice. Thus in case of a

transition region, the flame diameter is increased too, when the flame length is de-

creased through the velocity increase. Using an approximating method, the equa-

tion for calculation of the maximum diameter of flame may be established as follows:

where:

k4 - constant depended on experiments

k4=0.8 by photographs

k4=0.86 by CO component measurement

k4 =0.94 by ionization

k4 =0.79 by Schlieren.

i14 - exponent also depended on experiments:

114 = 0.328 by photographs

114=0.315 by CO component measurement

114 = 0.299 by ionization

114 =0.447 by Schlieren.

In case of a turbulent region, the flame diameter does not depend on the out-

ward flow velocity, which is written as follows:

INVESTIGA TION OF THE DIFFUSION FLAME

where:

k5 - constant was obtained experimentally, as follows:

k5=2,25 by photographs

k5=2,33 by CO component measurement

k5=2,38 by ionization

k5=3,97 by Schlieren.

Flame sWface

71:)

The surface of a flame can be obtained directly by experimental data. Fig-

ure 7 shows the variation of the dimensionless surface of flame at different gas-flow

velocities and the diameter of the burner orifice. It is interesting to see that the

surface of the flame depends only on its length of flame but also on its diameter.

Owing to this the dimension less surface of the flame increases in case of a laminar

region, and does not change in case of a turbulent region with the increase of the

outward flow velocity, but it is then intricate in case of a transition region.

Based on our experimental data, the equation for calculating the flame surface

is as follows:

where:

F - the flame surface

Fo - the surface of the burner orifice

A

le 10

li::

"'0

x 8

6

4

o By photographs

A CO component measure

0 Ionization

V Schlieren

W,mis

Fig. 7. The relationship between the surface of flame and outward flowing velocity

so

NGUYEN SY MAO

ks - constant depended on experiments

k

s

=297 by photographs

k

s

=333 by CO component measurement

k6=399 by ionization

k

6

=501 by Schlieren.

n6 - exponent also depended on experiments:

116=0.352 by photographs

l1

s

=0.326 by CO component measurement

11s=0.278 by ionization

116=0.537 by Schlieren.

[/1 case of a turbulent region, the flame surface can be calculated as follows:

where:

k7 - constant was established by experiments:

k7= 1000 by photographs

k7= 1040 by CO component measurement

k 7 = 1090 by ionization

k7=1450 by Schlieren.

Flame volume

Knowing the length and the diameter of the flame we can calculate the flame

volume, but on the other hand the flame volume may be established directly by

experimental data. Based on our experimental results, Fig. 8 demonstrates the

variation of dimensionless volume of the flame with the outward flow velocity and

the diameter of the burner orifice. From the diagrams it can be seen as follows:

In case of a laminar region, the flame volume increases with the velocity increase

and orifice diameter. With the approximation method an equation may be estab-

lished to calculate the flame volume as follows:

where:

kg - constant was established by experiments

k

s

=332 by photographs

ks=406 by CO component measurement

ks=478 by ionization

k

s

=555 by Schlieren.

118 - exponent also was established by experiments

118=0.486 by photographs

11

8

=0.425 by CO component measurement

71

8

=0.384 by ionization

n

8

=0.416 by Schlieren.

8

6

INVESTIGA TION OF THE DIFFUSION FLAME

d

o

= 2-3.5 mm

__ IV'----:=---J;;'

o By photographs

A CO componE.'nt mE.'OsurE.'

o Ionization

v SchliE.'rE.'n

W,mls

Fig. 8. The relationship between the volume of flame and outward flowing velocity

81

In case of a turbulent region, flame volume is likely that the same value, with a

variation of the outward flow velocity, may be written as follows:

where:

k9 - constant was established by experiments

k9=1468 by photographs

k9= 1520 by CO component measurement

k9= 1563 by ionization

k9=2073 by Schlieren.

Conclusion and discussion

In combustion and heat transfer calculation, it is very important to reliably

define the flame and establish its physical and geometrical characteristics more

exactly.

From previous of view usually the flame is a space, in which the fuel and oxidant

come together in a reaction zone. In the flame chemical and physical processes take

place with heat transfer and photo radian phenomena. Of course, the flame structure

(length, diameter, surface and volume) is established easily on basis of the photo-

graphic method, from our experimental data, it may be seen that the flame size is

82 NGUYEN SY AfAO

smallest by photographs and largest by Schlieren's method. From a firing technical

point of view we think it is more suitable to use the CO component measurement

to calculate the combustion and heat transfer of the flame structure. Of course also

Schlieren's flame structure may be used for the investigation of the intereffects of

flame, specifically at a temperature distribution in intereffective zones. This will be

discussed later on.

n is remarkable that previous diagrams and equations may be applied in

case of a free-jet diffusion flame with city gaseous fuel. Owing to this reason, we

have to apply corrections in these equations when calculating the flame size forming

in the combustion chamber, as follows:

h

c

./ = (1,1-1,3) h/./

F::./ = (1,25 - 1,5) Ff./

V

c

./ = (1,3-1,6)v/./

where:

index c f - flame forming in the combustion chamber

ff - free-jet diffusion flame.

In case of a parallel stream burners, owing to the mixing brought about by an

impulse of the air stream, the flame will be shorter. By approximation the ratio of

the flames is as follows

where:

hp the length of flame in case of a parallel stream

hd - the length of flame in case of a diffusion flame

10' /1 - intensity of the gas flow in jet and impulse of the air stream surrounding

the gas stream.

Of course, the flame surface and volume are changed, too.

Acknowledgement

The author wishes to thank Psof. Dr. Gabor Bassa, head of Department of Heat Engines,

Techical University of Budapest for his careful revision of the paper, his linguistic help in

English and his support in publication.

INVEST/CA TIO.Y OF THE DIFFUSION FLA,VE

83

References

1. NGUYEN SY MAO: Investigation of flowing flame in combustion chambers. Thesis of Cand. of

tech. Sc. Budapest, 1979.

2. N. S. MAo-ZENTAI, K.: Investigation of gaseous flame. Energiagazdalkodas. Budapest, 1979. 12.

3. MEDGYEs, B.: Introduction of the Schlieren method. OKGT -GKV A, 1976.

4. BALOGH. L.-NE: Relationship of the energy exchange conditions of hydrocarbon flames and

electric conductivity. VEIKI, 1976.

5. GLASSMAN, 1.: Combustion. Academic Press, New York, 1977.

6. EICKHOFF, H.-LENzE, B.: Grundformen von Strahlflammen. Chemie Ingenieur Technik. 41.

1969.

Nguyen Sy MAO, H-1521, Budapest.

You might also like

- Simulation Heat Transfer Convection Fired HeatersDocument8 pagesSimulation Heat Transfer Convection Fired HeatersPedro DiazNo ratings yet

- Apollo Experience Report Electronic Systems Test Program Accomplishments and ResultsDocument70 pagesApollo Experience Report Electronic Systems Test Program Accomplishments and ResultsBob AndrepontNo ratings yet

- Bernette Ramirez Mariano Bernette Ramirez MarianoDocument1 pageBernette Ramirez Mariano Bernette Ramirez Marianomia palacioNo ratings yet

- Introduction To Gas Dynamics All Lecture Slides: Autumn 2009Document107 pagesIntroduction To Gas Dynamics All Lecture Slides: Autumn 2009Enrique FloresNo ratings yet

- THE Swirl Effect PDFDocument9 pagesTHE Swirl Effect PDFsb aliNo ratings yet

- Predicting EmissivitiesDocument4 pagesPredicting EmissivitiesFranny CasasolaNo ratings yet

- Flat Plate CollectorsDocument9 pagesFlat Plate CollectorsEsam Fathi0% (1)

- Pso MPPTDocument10 pagesPso MPPTDileep GNo ratings yet

- 000-Za-E-M09403 - C-MS For Cable Tray InstallationDocument15 pages000-Za-E-M09403 - C-MS For Cable Tray Installationsyam prasad100% (1)

- United States Patent (19) : (45) Date of Patent: Oct. 12, 1999Document17 pagesUnited States Patent (19) : (45) Date of Patent: Oct. 12, 1999KrozeNo ratings yet

- Compartment Fire Temperature A New Simple Calculation MethodDocument14 pagesCompartment Fire Temperature A New Simple Calculation Methodbuha_buhaNo ratings yet

- Defect EliminationDocument4 pagesDefect EliminationHossein100% (1)

- Dynamics Model of Fire Tube Shell BoilerDocument10 pagesDynamics Model of Fire Tube Shell BoilerViro AkahanNo ratings yet

- Modeling of A High-Temperature Direct Coal Gasific PDFDocument8 pagesModeling of A High-Temperature Direct Coal Gasific PDFvictorNo ratings yet

- Investigation of The Diffusion Flame: Nguyen MAODocument17 pagesInvestigation of The Diffusion Flame: Nguyen MAOSagar ChandegaraNo ratings yet

- The Effect of Explosion Venting: IN Empty VesselsDocument12 pagesThe Effect of Explosion Venting: IN Empty Vesselsigor VladimirovichNo ratings yet

- Mixing and Chemical Reaction in Steady Confined Turbulent FlamesDocument9 pagesMixing and Chemical Reaction in Steady Confined Turbulent Flamesmohamadhosein mohamadiNo ratings yet

- The Visible Shape and Size of A Turbulent Hydrocarbon Jet Diffusion Flame in A Cross-WindDocument16 pagesThe Visible Shape and Size of A Turbulent Hydrocarbon Jet Diffusion Flame in A Cross-WindNikos ToixosNo ratings yet

- P13-Analysis of Burning CandleDocument5 pagesP13-Analysis of Burning CandleRingo042No ratings yet

- Saljnikov AleksandarDocument8 pagesSaljnikov AleksandarMatias MancillaNo ratings yet

- Pool Fire Mass Burning Rate and Flame Tilt Angle Under Crosswind in Open Space (2016)Document14 pagesPool Fire Mass Burning Rate and Flame Tilt Angle Under Crosswind in Open Space (2016)Torero02No ratings yet

- SolarsDocument11 pagesSolars11751175No ratings yet

- The Visible Shape and Size of A Turbulent Hydrocarbon Jet Diffusion Flame in A Cross-WindDocument16 pagesThe Visible Shape and Size of A Turbulent Hydrocarbon Jet Diffusion Flame in A Cross-WindRoberto CoelhoNo ratings yet

- Analytical Theory of Coalbed Methane Recovery by Gas InjectionDocument9 pagesAnalytical Theory of Coalbed Methane Recovery by Gas Injectionmsmsoft90No ratings yet

- 1961 Kutateladze S.S. Kutateladze S.S. Int. J. Heat Mass TransfDocument15 pages1961 Kutateladze S.S. Kutateladze S.S. Int. J. Heat Mass TransfMutant_DNANo ratings yet

- Capacidad Calorica en La BECDocument9 pagesCapacidad Calorica en La BECSebastian MoránNo ratings yet

- Jurnal Tentang Mekanika StatistikDocument5 pagesJurnal Tentang Mekanika StatistikRo RohadiNo ratings yet

- Bruyere Paper PDFDocument7 pagesBruyere Paper PDFMATHEWSKIZHAKKEVEETTNo ratings yet

- Numerical Simulation of Wood - Volatiles & Air Combustion in Differentially Heated Diffuser Tube Under Free ConvectionDocument7 pagesNumerical Simulation of Wood - Volatiles & Air Combustion in Differentially Heated Diffuser Tube Under Free ConvectionseventhsensegroupNo ratings yet

- Nox Reduction in A Monolithic Reactor: Created in Comsol Multiphysics 6.0Document30 pagesNox Reduction in A Monolithic Reactor: Created in Comsol Multiphysics 6.0mohitNo ratings yet

- Martin Sichel - A Simple Analysis of The Blast Initiation of DetonationsDocument16 pagesMartin Sichel - A Simple Analysis of The Blast Initiation of DetonationsJuaxmawNo ratings yet

- Modeling of Coal Combustion and NOx Formation in A W-Shaped Boiler Furnace (SJ) (FAN Et Al) (Chem Eng J v71 1998) (10s) #PG (233-242)Document10 pagesModeling of Coal Combustion and NOx Formation in A W-Shaped Boiler Furnace (SJ) (FAN Et Al) (Chem Eng J v71 1998) (10s) #PG (233-242)R_M_M_No ratings yet

- TermoDocument14 pagesTermoGagah ArofatNo ratings yet

- Analysis of The Characteristics of The Blast Furnace Peripheral Zone.Document4 pagesAnalysis of The Characteristics of The Blast Furnace Peripheral Zone.Samanway DasNo ratings yet

- Flames Laminar DiffusionDocument4 pagesFlames Laminar DiffusionsamadonyNo ratings yet

- Laminar Flame Propagation With Volumetric Heat Loss and Chain Branching-Termination ReactionsDocument8 pagesLaminar Flame Propagation With Volumetric Heat Loss and Chain Branching-Termination ReactionsermkermkNo ratings yet

- Institute o F Space and Aeronautical Science, University o F Tokyo, Tokyo, JapanDocument13 pagesInstitute o F Space and Aeronautical Science, University o F Tokyo, Tokyo, Japanhuda akromulNo ratings yet

- 7th and 8 TH Week Revised-DonusturulduDocument68 pages7th and 8 TH Week Revised-DonusturuldunaverfallNo ratings yet

- Teemu Salmi Et Al - Calculation of The O-H Stretching Vibrational Overtone Spectrum of The Water DimerDocument8 pagesTeemu Salmi Et Al - Calculation of The O-H Stretching Vibrational Overtone Spectrum of The Water Dimer4534567No ratings yet

- Adiabatic FBR DesignDocument10 pagesAdiabatic FBR DesignRana UzairNo ratings yet

- Research Article: Parametric Study of High-Efficiency and Low-Emission Gas BurnersDocument8 pagesResearch Article: Parametric Study of High-Efficiency and Low-Emission Gas BurnersRolando PradaNo ratings yet

- Laminar Flame Speeds of Hydrocarbon + Air Mixtures With Hydrogen AdditionDocument9 pagesLaminar Flame Speeds of Hydrocarbon + Air Mixtures With Hydrogen AdditionEduardoNo ratings yet

- Lewis Number Effects On Turbulent Burning VelocityDocument8 pagesLewis Number Effects On Turbulent Burning VelocitycoccoNo ratings yet

- The Effect of Thermal Radiation and Radiation Models On Hydrogen-Hydrocarbon Combustion Modelling-Ilbas2005Document14 pagesThe Effect of Thermal Radiation and Radiation Models On Hydrogen-Hydrocarbon Combustion Modelling-Ilbas2005Mohammadreza NaghaviNo ratings yet

- 13 09 Domenico Tech ReportDocument10 pages13 09 Domenico Tech Reportoscop2009No ratings yet

- Linan 1972Document13 pagesLinan 1972Nicolas HernandezNo ratings yet

- EPJ Web of Conferences Volume 82 Issue 2015 KhaustovComputer Simulation of Vortex Combustion ProcessesDocument5 pagesEPJ Web of Conferences Volume 82 Issue 2015 KhaustovComputer Simulation of Vortex Combustion ProcessessergioteroNo ratings yet

- Adiabatic Expansion Cooling of GasesDocument7 pagesAdiabatic Expansion Cooling of GasesVereneNo ratings yet

- Combustion and Extinction in The Stagnation Point Boundary Layer of A Condensed Fuel 1978 Combustion and FlameDocument14 pagesCombustion and Extinction in The Stagnation Point Boundary Layer of A Condensed Fuel 1978 Combustion and FlameraharjoitbNo ratings yet

- (2001) 1-S2.0-S0010218001003182-MainDocument14 pages(2001) 1-S2.0-S0010218001003182-Mainmahmoudlotfy309No ratings yet

- Droplet Vaporization: Single Spherically Symmetric DropletDocument7 pagesDroplet Vaporization: Single Spherically Symmetric DropletrcalaforraNo ratings yet

- Influence of Volume Initialization in Large Eddy Simulation of Turbulent Combustion Inside Closed VesselDocument9 pagesInfluence of Volume Initialization in Large Eddy Simulation of Turbulent Combustion Inside Closed Vesselmladen018No ratings yet

- The 1D Iterative Model For Predicting Thermal Radiation From A Jet FireDocument11 pagesThe 1D Iterative Model For Predicting Thermal Radiation From A Jet Fireuserscribd2011No ratings yet

- 2013-D. Bradley-PCIDocument8 pages2013-D. Bradley-PCIAhmed YasiryNo ratings yet

- Analysis of The Method For Furnace Thermal CalculaDocument5 pagesAnalysis of The Method For Furnace Thermal Calculaigarcia18No ratings yet

- Numerical Simulation of Electrical Spark Ignition in A Methane-Air MixtureDocument12 pagesNumerical Simulation of Electrical Spark Ignition in A Methane-Air MixtureAghajaniNo ratings yet

- The Heat Efficiency of Thermal Recovery Processes: SPE-AIME, Shell Development CoDocument10 pagesThe Heat Efficiency of Thermal Recovery Processes: SPE-AIME, Shell Development CoWaldinho Gaucho da SilvaNo ratings yet

- Study On Calculation of Flue Gas Temperature at THDocument8 pagesStudy On Calculation of Flue Gas Temperature at THsharebntzNo ratings yet

- Ver Hoek 1969Document4 pagesVer Hoek 1969Gustavo Alexis Leon Perez100% (1)

- Us 3616264Document4 pagesUs 3616264KrozeNo ratings yet

- Us 3376803Document26 pagesUs 3376803KrozeNo ratings yet

- Us 6250486Document14 pagesUs 6250486KrozeNo ratings yet

- Us8608097 PDFDocument10 pagesUs8608097 PDFKrozeNo ratings yet

- Aug. 5, 1969 ?. R. ???.?.?.? 3,459,957: Woltage Regulator CircuitDocument6 pagesAug. 5, 1969 ?. R. ???.?.?.? 3,459,957: Woltage Regulator CircuitKrozeNo ratings yet

- Dec. 12, 1967 F. Grossoehme 3,358,210: Filed June 25, 1964Document4 pagesDec. 12, 1967 F. Grossoehme 3,358,210: Filed June 25, 1964KrozeNo ratings yet

- United States Patent (19) : Kaye Oct. 15, 1996Document44 pagesUnited States Patent (19) : Kaye Oct. 15, 1996KrozeNo ratings yet

- United States Patent: (21) Appl. N0.: 13/226,109 (Continued)Document17 pagesUnited States Patent: (21) Appl. N0.: 13/226,109 (Continued)KrozeNo ratings yet

- United States Patent (19) (11) Patent Number: 6,142,130: Ward (45) Date of Patent: Nov. 7, 2000Document18 pagesUnited States Patent (19) (11) Patent Number: 6,142,130: Ward (45) Date of Patent: Nov. 7, 2000KrozeNo ratings yet

- Us 6633161Document21 pagesUs 6633161KrozeNo ratings yet

- Us 7006327Document11 pagesUs 7006327KrozeNo ratings yet

- Us 3195038Document10 pagesUs 3195038KrozeNo ratings yet

- United States Patent (19) (11) Patent Number: 6,130,863: Wang Et Al. (45) Date of Patent: Oct. 10, 2000Document18 pagesUnited States Patent (19) (11) Patent Number: 6,130,863: Wang Et Al. (45) Date of Patent: Oct. 10, 2000KrozeNo ratings yet

- United States Patent (19) (11) Patent Number: 6,142,130: Ward (45) Date of Patent: Nov. 7, 2000Document18 pagesUnited States Patent (19) (11) Patent Number: 6,142,130: Ward (45) Date of Patent: Nov. 7, 2000KrozeNo ratings yet

- United States PatentDocument14 pagesUnited States PatentKrozeNo ratings yet

- United States Patent (19) : Nºzizi EDocument11 pagesUnited States Patent (19) : Nºzizi EKrozeNo ratings yet

- United States Patent (19) (11) Patent Number: 5,179,332Document14 pagesUnited States Patent (19) (11) Patent Number: 5,179,332KrozeNo ratings yet

- Us 5818319Document30 pagesUs 5818319KrozeNo ratings yet

- United States Patent (19) : Sinclair Et AlDocument21 pagesUnited States Patent (19) : Sinclair Et AlKrozeNo ratings yet

- United States PatentDocument25 pagesUnited States PatentKrozeNo ratings yet

- United States Patent (19) : Nºzizi EDocument11 pagesUnited States Patent (19) : Nºzizi EKrozeNo ratings yet

- Us 4774914Document25 pagesUs 4774914KrozeNo ratings yet

- United States PatentDocument15 pagesUnited States PatentKrozeNo ratings yet

- United States Patent (19) (11) Patent Number: 5,207,074Document18 pagesUnited States Patent (19) (11) Patent Number: 5,207,074KrozeNo ratings yet

- Us 6577888Document12 pagesUs 6577888KrozeNo ratings yet

- United States PatentDocument15 pagesUnited States PatentKrozeNo ratings yet

- Us 5379832Document16 pagesUs 5379832KrozeNo ratings yet

- Us 4866424Document14 pagesUs 4866424KrozeNo ratings yet

- United States Patent (19) : 16 VoltageDocument12 pagesUnited States Patent (19) : 16 VoltageKrozeNo ratings yet

- Safety Is Your Top Priority: Explosion-Proof LED LightingDocument62 pagesSafety Is Your Top Priority: Explosion-Proof LED LightingPhi LongNo ratings yet

- Tech. Specs. For 11 KV DP StructureDocument7 pagesTech. Specs. For 11 KV DP StructureSaraswatapalitNo ratings yet

- Pt. Hans Jaya Utama: Lsagi FactoryDocument46 pagesPt. Hans Jaya Utama: Lsagi FactoryMatthew SiagianNo ratings yet

- Excel 2010 Cheatsheet PDFDocument2 pagesExcel 2010 Cheatsheet PDFVinith VimalNo ratings yet

- Demineralization Mechanism and Influence of Parameters On High Ash Indian Coal by Chemical Leaching of Acid and Alkali SolutionDocument1 pageDemineralization Mechanism and Influence of Parameters On High Ash Indian Coal by Chemical Leaching of Acid and Alkali SolutionSushanta Kumar BeheraNo ratings yet

- Froth Flush ProcessDocument33 pagesFroth Flush ProcessnivasssvNo ratings yet

- Ghorbani - AlfalfaDocument7 pagesGhorbani - AlfalfaarizalNo ratings yet

- Dynamic Arrays With The Arraylist Class Chapter Xii TopicsDocument38 pagesDynamic Arrays With The Arraylist Class Chapter Xii TopicsRocket FireNo ratings yet

- Torsion MEDocument24 pagesTorsion MEmohamed.hassan031No ratings yet

- Steering Wheel Slip - Check: Pruebas y AjustesDocument2 pagesSteering Wheel Slip - Check: Pruebas y AjustesLENIN JHAIR VALDERRAMA SEGURANo ratings yet

- Amadeus Web ServicesDocument2 pagesAmadeus Web ServicesBoris ChoiNo ratings yet

- Literature ReviewDocument2 pagesLiterature ReviewkhairulNo ratings yet

- Unit-1 - Spur Gears - Lecture - 6 - Problems Spur Gear - Mahesh GaikwadDocument13 pagesUnit-1 - Spur Gears - Lecture - 6 - Problems Spur Gear - Mahesh GaikwadNikhil JadhavNo ratings yet

- A Study of Chemical Structure of Soft and Hardwood andDocument7 pagesA Study of Chemical Structure of Soft and Hardwood andBruna BarraNo ratings yet

- Lec8 SecondOrder PDFDocument61 pagesLec8 SecondOrder PDFPhan Phuong NgocNo ratings yet

- MSM Carbon FibreDocument35 pagesMSM Carbon FibrelokeshkrkushwahaNo ratings yet

- 010 Zircoat MDocument3 pages010 Zircoat MvsdeepakchandraNo ratings yet

- Analysis Procedure K2co3 PDFDocument3 pagesAnalysis Procedure K2co3 PDFPiyush PatelNo ratings yet

- Pre Check: 1. Vgrs System DescriptionDocument8 pagesPre Check: 1. Vgrs System DescriptionNickNo ratings yet

- (Pasig) Certificate of OccupancyDocument12 pages(Pasig) Certificate of OccupancyAndrew MarasiganNo ratings yet

- STK412 150 Sanyo PDFDocument4 pagesSTK412 150 Sanyo PDFroger.No ratings yet

- Fatwa Darul Uloom Deoband - Vol 1Document276 pagesFatwa Darul Uloom Deoband - Vol 1Ahlehaq100% (3)

- Physics I Problems PDFDocument1 pagePhysics I Problems PDFbosschellenNo ratings yet

- TDG11Document100 pagesTDG11Splycho GoranNo ratings yet

- Bearing Detail PDFDocument1,152 pagesBearing Detail PDFJayesh MachhiNo ratings yet