Professional Documents

Culture Documents

Airport Visit Report

Uploaded by

MM OrvinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Airport Visit Report

Uploaded by

MM OrvinCopyright:

Available Formats

Report on Airport Visit of Shahjalal International Airport (DHAKA)

Introduction:

Air transportation is the most prominent and technologically advanced

transportation system in the world. Since the invention of aircraft by Wright

brothers in 1903, aircrafts had gone under major changes along with significant

changes in airports and its facilities.

The main airport of Bangladesh is Hajrat Shahjalal International Airport. Being a

major airport in the country; it is a very busy airport and is classified as KPI (Key

Point Installation) with maximum security.

The main objective of visiting the airport is to get acquainted with airport

transportation system, components of airport, observing reconstruction of runway

and taxiway pavement.

Visit to the airport was arranged by Professor Dr. Md. Mazharul Hoque with

association from Abdul Monem Group, Contractor Company appointed for

upgrading the runway pavement.

Airport:

Main components of an airport

a) Terminals

b) Runway

c) Taxiway

d) Apron

Runway Terminals Apron

Shahjalal International Airport:

Fig: Hajrat Shahjalal International Airport.

This airport has single runway. It consists of four taxiways. For boarding, alighting

of passengers and freight, terminal building is used.

Evaluation of airport site selection:

There are several criteria for selecting airport site. They are discussed below

(1) Type of development of the surrounding area: Significant noise at airport cause

disturbance to people. Residential areas and schools not avoided. No buffer zones

between runways, taxiways, aprons and boundary

(2) Atmospheric conditions: Flat Topography. Land-use pattern does not reduce

capacity of airport.

(3) Accessibility to ground transport: No good public transport. Poor accessibility to

ground transport. But adequate parking facilities are provided.

(4) There are some available lands for future expansion.

(5) Height restriction is imposed on surrounding tall structures.

(6) Utilities (Electricity, water etc.) are available.

Considering above options for the airport, it can be said that this airport has the

potential to be the Hub of south Asian countries if proper planning and

implementation is done.

Observation of Hajrat Shahjalal International Airport:

Aircraft Gear

Configuration:

We have seen several gear configurations. These are :-

Fig: Aircraft I

The major generic gear configurations is following

2 Duals in Tandem, 2D

Fig: Aircraft II

All gear configurations are Dual D

Fig: Aircraft III

The generic gear configurations are following

3 Duals in Tandem, 3D

Fig: Aircraft II/

The main generic gear configurations is following

2 Duals in Tandem, 2D

RUNWAY:

Length of runway is 3200 meters

Runway designation 14/32

Single runway

ABDUL MONEM LTD :

Abdul Monem Limited-Contractor Company appointed for upgrading the runway

pavement, guides us regarding the pavement reconstruction process, technical and

engineering issues, challenges, method applied to overcome the challenges etc.

Abdul Monem Limited is one of the leading diversified business conglomerates of

Bangladesh which was established in 1956. They began as a construction contractor

soon became a trusted name and ultimately a synonym of quality, reliability and

commitment. For 56 years Abdul Monem Ltd. Has successfully accomplished

numerous projects including those aided by World Bank, Japan Bank, Asian

Development Bank, Islamic Development Bank etc.

Among the ongoing Projects the Mymensing 4-lane Highway project, Padma

Bridge Project are mentionable. They have one of the best construction equipment

here in Bangladesh.

The Authority In-Charge brief us about the reconstruction and improvement of the

runway project. From him we learned a lot regarding the construction process.

Fig: Authority In-charge of Abdul Monem Ltd briefing us about

Airfield Pavement construction

RUNWAY PAVEMENT

RECONSTRUCTION :

Two asphalt plants were used for the runway pavement overlay. These plants were

used for mass construction of asphalt within a short period of time. In order to

meet the specification, these plants were used. Setup for this plant took around one

month. A single plant costs around 7 to 10 core taka. This type of plants was

introduced for the very first time in Bangladesh by one of the most prominent

construction companies in Bangladesh ABDUL MONEM LTD. This plant is

developed by German company named AMMANN.

Fig: Asphalt mixing plant

Theoretically, capacity of a single plant is 160 ton/hour. But practically about 135

ton/hour asphalt mix can be manufactured. After the setting of plant, trial and error

of batch mix was done to achieve the accurate batch mix. This process is computer

based and can be operated by a single operator. This plant is run by Ferrari engine

Fig: Some of the components of asphalt mixing plant

Grooving:

In the runway grooving was provided transversely from 150 m to 3050 m of

runway. Thickness of grooving is 6 mm and spacing is 5 inch. Grooving is done

in order to

Provide optimum friction

Provide easy drainage

Increase asphalt pavement life

As 6 mm thick grooving acts as top surface for runway that ensures not only

safety of aircraft but also safety of runway. This grooving exists 5 to 7 years

Fig: Grooving was checked before applying on runway

Taxiway :

Length of taxiway 6 Kilometers

Four taxiways (South , High speed/rapid exit ,Center ,North)

We observed the construction of North taxiway

The taxiway pavement reconstruction was going on funded by Denmark

Govt. We have got an opportunity to familiarize with the several features of

the taxiway pavement re-construction by talking with a pavement Engineer

from Palestine appointed by the Denmark contractor company.

Fig: Pavement Engineer informing us regarding the taxiway pavement re-

construction process.

Reconstruction and

Improvement

Of taxiway pavement:

Reconstruction of taxiways is funded by Denmark government. The

equipment and the contractor are from Denmark. The project commenced

from Feb 2013. Initially taxiways were rigid pavement but now they are

making it flexible pavement.

With a view of constructing the flexible pavement:-

Existing soil was modified

CBR value was improved for soil layers until the required value was

obtained

Different soil tests include CBR test, Plate load test for modulus of

subgrade reaction (k) were done

The soil layer was extracted and improved soil layer was provided

Base CBR = min 80 , sub-base CBR = min 30 was attained

Key features :

The thickness of the pavement was 480 mm. It consists of five layers.

The base layer and binder layer has maximum aggregate size of 37 mm or

1.5

Top surface has maximum aggregate size of or 12.25 mm

Fig : Taxiway Pavement

For the first time in Bangladesh improved asphalt is used. Chemical is

used in the asphalt

Bitumen was made more harder by adding special type of rubber.

For binder around 7 kg of rubber was used for each ton of asphalt

Resulting bitumen with rubber becomes more strong , more tough

One of the major challenges of overlaying bitumen during warm and hot

weather is the melting of bitumen.

This improved asphalt is used for the first time in Bangladesh as well as in

South Asia

Fig: Overlay of asphalt in the North taxiway Pavement

Various tests for bitumen was done in Denmark and the quality control

was maintained by doing various test

Fig: Quality Control is maintained by doing tests on cylinder specimen

Base layer is improved to provide adequate support to bitumen layer.

Another key feature is that recycled asphalt is used. Recycled asphalt

was melted and mixed with new asphalt. As a result improved and

environmental friendly construction process was attained

In the current construction 15 % to 20 % recycled asphalt was used. But

in European countries around 50% recycled asphalt was applied.

Plastic sheets were provided in order to prevent cracks from propagating

to the upper layer.

Fig: Plastic sheets

At the intersection of runway and taxiway, rigid pavement is provided in

order to prevent the undulation of pavement during load is applied

Fig: At intersection rigid pavement is provided

Compaction was done by number of modern rollers. Grease was

provided on the wheels of roller so that the hot asphalt does not cling to

the wheels

Fig : Compaction done by Rollers

Lighting System :

PAPI ( Precision Approach Path Indicator) is provided.

Previously this airport was Category I .After upgrading lighting system

now it is Category II

In Category II pilot is assisted with more lighting facilities.

Previously lights were spaced 30 m apart, now the spacing is halved that

is 15 m

Illumination of approach light is raised

Touch down zone lights as well as center lights are increased

Fig: Threshold and approach lighting system

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Flat Slab DesignDocument76 pagesFlat Slab Designyunuswsa97% (36)

- Asphalt Concrete PavingDocument16 pagesAsphalt Concrete Pavingprobook450_ehsanNo ratings yet

- Lancashire Residential Road Design GuideDocument42 pagesLancashire Residential Road Design Guidesweptpath2012No ratings yet

- CIRCLY 7.0 Workshop September 2018 ONE - Slide - Per - Page PDFDocument264 pagesCIRCLY 7.0 Workshop September 2018 ONE - Slide - Per - Page PDFAdy Nugraha100% (1)

- Concrete Pavement RepairDocument10 pagesConcrete Pavement Repairgorafd449No ratings yet

- Man8 PDFDocument72 pagesMan8 PDFCarel De JagerNo ratings yet

- Positioning of Irc Live LoadsDocument3 pagesPositioning of Irc Live Loadsvasu7900100% (1)

- Positioning of Irc Live LoadsDocument3 pagesPositioning of Irc Live Loadsvasu7900100% (1)

- CTSB Presentation-FinalDocument19 pagesCTSB Presentation-FinalBidur JhaNo ratings yet

- ROADS 2014 Edition8webDocument28 pagesROADS 2014 Edition8webJanice Bana Chabota ChipoNo ratings yet

- Structural Design of Flexible Pavement-ATJ 5-85 Pindaan 2013Document38 pagesStructural Design of Flexible Pavement-ATJ 5-85 Pindaan 2013Mohammad Yunus Salehi50% (2)

- Preliminary Pavement Design CalculationsDocument4 pagesPreliminary Pavement Design CalculationsLekins Sefiu Yekini100% (1)

- 3.0 Data Analysis 3.1Document8 pages3.0 Data Analysis 3.1Azrin YusopNo ratings yet

- NLOGIT Short Student Manual PDFDocument141 pagesNLOGIT Short Student Manual PDFMM OrvinNo ratings yet

- UBC Okanagan Calendar College of Graduate StudiesDocument79 pagesUBC Okanagan Calendar College of Graduate StudiesMM OrvinNo ratings yet

- Author Guidelines 2012Document8 pagesAuthor Guidelines 2012MM OrvinNo ratings yet

- Author Guidelines 2012Document8 pagesAuthor Guidelines 2012MM OrvinNo ratings yet

- New Microsoft Word DocumentDocument1 pageNew Microsoft Word DocumentMM OrvinNo ratings yet

- Logo of MistDocument1 pageLogo of MistMM OrvinNo ratings yet

- Orientation Visit to MIST Highlights Key AspectsDocument112 pagesOrientation Visit to MIST Highlights Key AspectsMM OrvinNo ratings yet

- 1st Portion (Description) (2017)Document42 pages1st Portion (Description) (2017)MM OrvinNo ratings yet

- Ce 351Document1 pageCe 351MM OrvinNo ratings yet

- JournalsDocument2 pagesJournalsMM OrvinNo ratings yet

- VISSIM Tutorial for Simulating Traffic at a Signalized IntersectionDocument17 pagesVISSIM Tutorial for Simulating Traffic at a Signalized Intersectiontekbir1981No ratings yet

- Objectives and Scope of The StudyDocument10 pagesObjectives and Scope of The StudyMM OrvinNo ratings yet

- VISSIM 530 eDocument680 pagesVISSIM 530 eAntonio Corona HernandezNo ratings yet

- 4 Load & Load CombinationDocument10 pages4 Load & Load CombinationAnonymous b9fkTYfEoRNo ratings yet

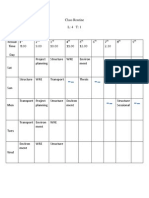

- Class RoutineDocument1 pageClass RoutineMM OrvinNo ratings yet

- BCube - BTCL Broadband RateDocument2 pagesBCube - BTCL Broadband RateApparel IntelligenceNo ratings yet

- PasswordDocument1 pagePasswordMM OrvinNo ratings yet

- Crushed concrete sub-base field performance and lab testsDocument10 pagesCrushed concrete sub-base field performance and lab testsJohnyReubenNo ratings yet

- 2018 Standard SpecificationsDocument997 pages2018 Standard SpecificationsjoseNo ratings yet

- DmrbcontDocument52 pagesDmrbcontAnonymous ngZFjKn2fZNo ratings yet

- D5581 PDFDocument5 pagesD5581 PDFsujeeth kumarNo ratings yet

- 1547708711खड्केटारि-पञ्चासे दोबिल्ला सडक DPR (Volume-1)Document134 pages1547708711खड्केटारि-पञ्चासे दोबिल्ला सडक DPR (Volume-1)Anil GautamNo ratings yet

- PH: 9326863164,9823080325, 8275289096, 9404417042, 9595542887 Pune, Amravati, Akola, Badnera, Mumbai, NagpurDocument6 pagesPH: 9326863164,9823080325, 8275289096, 9404417042, 9595542887 Pune, Amravati, Akola, Badnera, Mumbai, NagpurPushpak MahakalkarNo ratings yet

- Usman 2020 IOP Conf. Ser. Earth Environ. Sci. 476 0120641Document14 pagesUsman 2020 IOP Conf. Ser. Earth Environ. Sci. 476 0120641junaa AlbayatiNo ratings yet

- Pipe Log, ExcelDocument5 pagesPipe Log, ExcelMasar Abdul RakmanNo ratings yet

- Environmental Screening and Scoping Report for Road Project in MaharashtraDocument94 pagesEnvironmental Screening and Scoping Report for Road Project in MaharashtraRahul RanaNo ratings yet

- Pavement Performance Evaluation: Annex VDocument11 pagesPavement Performance Evaluation: Annex VJaspal AryaNo ratings yet

- Pavement Management Implementation: Standard Guide ForDocument4 pagesPavement Management Implementation: Standard Guide ForDannyChaconNo ratings yet

- HPD Mod 3Document58 pagesHPD Mod 3Swathy MohanNo ratings yet

- DPWH Approves Epoxy Asphalt Pavement TechnologyDocument5 pagesDPWH Approves Epoxy Asphalt Pavement TechnologyFaustino AbadNo ratings yet

- Pavement Maintenance: DR Nor Faizah BawadiDocument29 pagesPavement Maintenance: DR Nor Faizah BawadiAinur Sya IrahNo ratings yet

- Catalogo Actualizado SullairDocument12 pagesCatalogo Actualizado Sullairalain2dubeNo ratings yet

- First-Year Field Performance of Epoxy-Modified AsphaltDocument13 pagesFirst-Year Field Performance of Epoxy-Modified AsphaltAKINMADE OLUWATOSINNo ratings yet

- BRP Road Patch Application Procedure & EquipmentDocument13 pagesBRP Road Patch Application Procedure & EquipmentskelleyreskicNo ratings yet

- Geogrid stabilisation calculation method for asphalt roadsDocument92 pagesGeogrid stabilisation calculation method for asphalt roadsKartik oNo ratings yet

- C 174 .C 174M Test Method For Measuring Length of Drilled Concrete CoresDocument2 pagesC 174 .C 174M Test Method For Measuring Length of Drilled Concrete Coresjjaavenido100% (1)

- 1 s2.0 S0959652622045309 MainDocument17 pages1 s2.0 S0959652622045309 MainLaura MjkNo ratings yet