Professional Documents

Culture Documents

Energy Optimization of Steam Turbines

Uploaded by

karuna3460 ratings0% found this document useful (0 votes)

39 views6 pagesEnergy Optimization of Steam Turbines

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentEnergy Optimization of Steam Turbines

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views6 pagesEnergy Optimization of Steam Turbines

Uploaded by

karuna346Energy Optimization of Steam Turbines

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

60

Energy Optimization of Steam Turbines by Audit

Dr. I.P.S. Paul

1

, Prof. I.P. Sharma

2

and S.K. Choudhary

3

1,2

Department of Mechanical Engineering, Ajay Kumar Garg Engineering College, PO Adhyatmic Nagar, Ghaziabad 201009 UP

3

National Power Training Institute, Sector 33 Faridabad 121003 Haryana

1,

paulcpri@yahoo.co.in,

2

ipsharma55@yahoo.co.in,

3

skc557@gmail.com

_________________________________________________________________________________________________________

Abstract-- This paper is basically aimed at optimizing the

turbine efficiency and turbine heat rate. The techniques

can be the type of solution and finance involved. Typical

design turbine efficiencies are in the range of 39.63 - 44.0

per cent while the operating efficiencies are in the range of

34.0 - 42.0%. New technological solutions give

improvements of as much as 2.5 % in turbine efficiency or

over 6.6 % in heat rate or 14 MW for a 210 MW unit. The

aspects of energy audit of steam turbines can be classified

as follows:

Basic aspects of turbines: Maximum efficiency, Efficiency of

components and Losses in turbines; Performance

evaluation of steam turbines through acceptance tests or

routine tests; Evaluation of component efficiencies; Willans

line of a steam turbine; Turbine diagnostics- Pressure,

temperature and flow profiles in turbines; Technological

improvements in turbines and Energy conservation

measures.

Keywords: Energy optimization, Turbine efficiency, Willans

line, Turbine diagnostics.

1. INTRODUCTION

The power station and auditors jointly decide the dates for

energy audit. The data analysis and processing is done at

auditors works and a report prepared taking into

consideration the realistic economic cost factors associated

with repairs and modifications if any.

The draft report is released within 1-2 weeks of conducting

the energy audit. After interaction with the sponsors, a jointly

agreed final report is prepared and released.

The efficiency of individual circuit/equipment like water

circuit, turbine piping, turbine, generator is evaluated and

compared with the design value. The deviation in efficiency is

diagnosed (using the overhaul data provided by the plant) and

reported. The performance indices and losses in equipment are

computed and presented. The extent to which the efficiency

can be improved by implementing various energy conserving

measures is discussed along with the economic implications

considering the present level of interest rate on the capital.

The savings envisaged will be also be quantified.

The potential for energy conservation can be estimated from

knowing the state-of-the art performance indices as given in

Table 1.

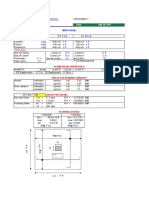

TABLE 1-- PERFORMANCE INDICES OF VARIOUS

EQUIPMENTS

S.

N.

Performance index Unit Value of

State of

the art

equipment

1 Boiler efficiency % 89.0

2 Turbine efficiency % 44.0

3 Turbine heat rate kJ /kWh

kcal/kWh

8182

1955

4 Gross overall efficiency % 39.0

5 Net overall efficiency % 36.6

6 Auxiliary power % of gross

power

6.0

7 Specific fuel consumption kg/kWh 0.6

8 Specific secondary oil

consumption

ml/kWh 1.0

9 Gross unit heat rate kJ /kWh

kcal/kWh

9231

2205

II. METHODOLOGY

The detailed methodology is given as follows.

Plant Evaluation: The first phase of energy audit consists of

plant specifications, schematics, operating ratings,

performance data (such as plant load factor, design efficiency,

auxiliary power consumption) from the records based on the

questionnaire to be filled by the power station and returned to

the energy auditor before the energy audit is commenced.

Preliminary data about the individual circuit/equipment like

water circuit turbine piping, turbine, generator, transformers

and auxiliaries; past data of plant load factor, plant availability

factor, auxiliary power consumption, and planned/forced

outages; is collected for past 5 years.

The data for the past 5 years is studied. The energy auditors

and the plant engineers hold detailed discussions during their

visit to the station.

61

AKGEC JOURNAL OF TECHNOLOGY, Vol. 2, No. 1

Thus, this phase is basically an information gathering and

processing step whereby a better understanding of the plant

and its operation is obtained.

Performance Evaluation: The detailed energy audit consists

of the following :

Efficiency tests on turbo-generator at rated loads and

at part loads.

Efficiency tests on turbine auxiliaries at rated loads

and at part loads.

Auxiliary power consumption: Evaluation of

efficiencies of the pumps and fans, etc.

The turbines are tested as per ASME ptc-6-1996. The other

Annexure to the test code are Appendix A to the test code for

steam turbine. A procedure is also available for routine

performance tests of steam turbines (ASME-ptc 6S-1988). A

number of parameters are kept constant during the test period

of 2 hours. These include plant load, dearator level, condenser

level, drain levels, feed heater drain levels, positions of

bypass, etc.

The losses in each stage of the blade can be classified as:

a. Flow friction over the blades.

b. Secondary re-circulation flow losses.

c. Tip leakage.

The total of the above three losses gives the blading losses.

xiii. The other stage related losses are calculated as follows:

Moisture losses: The local wetness is averaged out and the

wetness of the bulk of fluid is determined from which the

moisture loss is computed. The moisture loss is given by the

product of the mass flow rate of moisture in steam (bulk of

fluid) and the enthalpy gain across the stage.

Loss from Baumann stage due to bypass of last stage: This is

calculated on the basis of the difference between the losses

when 50 % of the flow is through the last stage (with the rest

of the flow entering the condenser through the Baumann

exhaust) and when the full flow is through the last stage using

conventional blading. This loss stage is given by the product

of the mass flow rate bypassing the last stage and the enthalpy

gain across the last stage.

Exhaust outflow and extraction losses: This is based on the

averaged values of the fluid parameters at the LPT blade

section outlet. This loss is given by the product of the mass

flow rate of the exhaust steam and the square of the exit

velocity component of the bulk of fluid.

Losses from clearance seals of blading and shafts: This is

calculated on the basis of engineering practice based on

guidelines given by turbine designers.

Cross-over pipes: This is calculated based on the frictional

pressure drop across the flow length of the piping.

Studies At Auditors Works: The turbine efficiency of unit is

determined. The losses of the generator are modeled and thus

the generator is determined. This is used as a basis for

determining the turbine efficiency from the experimental

turbo-generator efficiency. Thus, the efficiencies of the

generator and turbine are estimated while the efficiency of the

overall unit is experimentally determined based on the boiler

efficiency, auxiliary power, etc.

In case of efficiencies lower than design, the causes for the

deviation in efficiency will be looked into by studying the data

and the annual overhaul reports of the power stations.

The studies at the auditors works involves:

Analysis of past data, efficiency evaluation and

performance study of the plant at partial loading.

Evaluation of plant performance based on different

parameters obtained from the present data at rated/ tested

level.

Comparison of the plant performance with the design

parameters and computation of the deviations.

Study of the reports of overhaul, manufacturer data

and other data associated with the system.

Modeling of the losses in the generator.

Establishment of energy balance for the system and

understanding where and how the losses are occurring.

Evolution of proposals for energy conservation

measures and the

feasibility study of implementation.

Economic analysis of energy conservation measures.

Maximum Efficiency Of A Steam Turbine: If the entrance

enthalpy of steam into a turbine is 3,600 kJ /kg (say), it is not

possible to extract the entire amount of energy as in a boiler

because of the conversion of heat into work. The enthalpy of

steam and water at the exit pressure (decided by the saturation

pressure corresponding to lowest cooling water temperature)

is 2250 kJ /kg and 850 kJ /kg.

Testing A Steam Turbine By ASME-PTC

Various aspects of tests are given as follows.

i. Agreements between owner and concerned parties

The agreements will be on the following issues:

Specific objective of the tests

Timing of tests, operating conditions and guarantees.

Location of primary flow measuring devices

Method of handling leaks, continuous drains, blow

downs, etc.

Frequency of observations and deviations of test

runs, no. of test runs.

Calculation of heat rate, efficiency

Conditions under which the tests are declared as

unsatisfactory and terminated.

62

ii. Timing of the tests: for acceptance tests it is 8 weeks from

the date of synchronization

iii. Bench marks beyond 8 weeks: The bench marks will be for

heat rate, capacity, isentropic efficiency, etc.

iv. Test requirements:

These include:

Preliminary test runs to check the instruments,

training of personnel, confirming cycle isolation, confirm

operation of valves.

Isolation of cycle

External isolation includes: auxiliary flows that enter

or leave the cycle such as condensate, auxiliary seam, etc.

the external flows should be below 0.1 % of the main

steam flow.

Internal flow isolation includes: drains, flows which

do not leave the cycle but bypass components.

Isolation of flows includes:

Storage tanks

Auxiliary steam lines

Turbine spray

Drains on Stop, interceptor and control

valves.

Drains on MS & RH piping

Interconnecting steam lines

Auxiliary steam

Heater, drains and bypass vents

Emergency blow down.

Where it is not possible to isolate then it must be

calculated. These include: shaft packing leakage, valve

stem leakage, internal turbine leakage, turbine drain flows,

etc.

Isolation of flows is through: blank flanges, leak

proof valves, monitoring through acoustic techniques such

as engineers stethoscopes, etc.

Valve points: This can be through pressure

measurement, maximum HPT efficiency (isentropic) (by

increasing p,t in small increments), valve stem positions,

pressure ratio.

v. No. of test runs: Minimum number is 2. the heat rate from

each must not differ by more than 0.25 %. Otherwise 3

rd

test

run will have to be undertaken.

vi. Period of operation before test: minimum 24 hours and

during each hour interval the temperature and pressure

variation must be below 3 %. The load must be constant

during the pre-test period. The control valve must be open and

closed only under emergency or upset conditions.

vi. The parameters (main steam temperature, main steam

pressure, reheat steam temperature, reheat steam pressure,

condenser vacuum , etc.) must be as near to the design value

as possible to avoid correction factors.

vii. Hydrogen purity must be maximized.

viii. Specified constant speed must be maintained.

ENERGY OPTIMIZATION OF STEAM TURBINES

ix. Nozzle, bypass, extraction and secondary flow valves shall

be in the position contemplated in the specified performance.

Typical locations for flow nozzles are between last LP heater

and deaerator, between deaerator and BFP, between BFP and

HP heater and between final HP heater and entrance of boiler.

III. IDENTIFICATION OF ENERGY CONSERVATION

MEASURES

Typical design and operating efficiencies are given in Table 2.

TABLE 2 -- TYPICAL DESIGN & OPERATING TURBINE

EFFICIENCIES.

S.

N.

Performance index Unit Value

1 Turbine efficiency- Design % 39.63-44.0

2 Turbine efficiency-operating % 34.0-42.0

The techniques for identifying energy conservation measures

are as follows:

Operational optimization

Repairs

Overhauls

Simple modifications

Renovation, retrofitting, revamps, re-powering,

refurbishment

Modernization

Operational optimization: The operational optimization of the

turbines involves the following:

i. Maintaining MS & RH temperatures and pressures; exit

pressure and wetness fraction at the design conditions.

ii. Minimizing work losses in auxiliary steam by using

extraction steam instead of main steam for auxiliary tasks.

iii. Use of steam from the last stages for steam coil air pre-

heating instead of exhausting in the condenser.

iv. Maintaining valve wide open (VWO) conditions in the entire

operating range thereby reducing the irreversibility due to

work done against the valves.

v. Optimization of control valve sequence-full arc/partial arc

sequences.

vi. Cold washing of turbine to remove soluble deposits. The

steam parameters are so maintained that it condenses before

the regular condensing conditions enabling dissolution of

soluble deposits. The success of a cold wash is indicated by

a fall in the silica in condensate, axial shift, differential

63

AKGEC JOURNAL OF TECHNOLOGY, Vol. 2, No. 1

expansion and bearing vibration.

vii. Timely evacuation of condensate drains based on

temperature sensing.

The operational optimization of the condensers involves the

following:

i. Maintaining condenser vacuum as close to the design as

possible.

ii. Controlled operation of air removal devices to match the air

requirement. These equipment are of fixed capacity and their

optimal operation can be achieved by their capacity control.

iii. Optimal operation of cleaning systems such as condenser ball

cleaning system, debris separator, trash rack, etc.. Condenser

cooling water deserves equally important attention as the

feed water and steam.

iv. If the O

2

in the condensate is over 5 ppb, the water leaving

the condenser must be deaerated by injecting auxiliary steam

into the condenser hot well.

The operational optimisation of cooling towers involves the

following:

i. Maximisation of temperature drop and minimising the

evaporative losses in the cooling tower by adjustment of the

grills and avoiding by-pass of cooling water.

ii. Minimisation of temperature gain in the water flow between

the cold well and the condenser inlet (maximisation of the

CW loop efficiency).

iii. Minimising the CW blow down to below 3 %.

The operational optimization of the feed water heaters

involves the following:

i. Optimisation of the condensate level on the shell side. If the

level is too high feed water heating surface will be reduced.

If it is too low steam will blow through the condensate drain

leading to corrosion and operational instability. The level is

adjusted by observing the TTD and DCA to the optimal

point. The limits of drain velocity to avoid flashing of steam

are 0.6 m/s at the inlet and 1.2 m/s at the outlet.

ii. In case one of the heaters is out of service, the design

temperature gain across the heater train must be obtained

through the other heaters.

iii. Ensuring adequate oxygen is removed in the deaerator tank

by ensuring that the temperature corresponds to the

saturation temperature at the deaerator pressure.

iv. Design limits of feed water velocities for erosion and

corrosion resistance are 2.4 m/s for CS tubes and 3.0 m/.s for

SS tubes. However, tube corrosion can be avoided and

protective oxide will be preserved if the velocities do not

exceed 2.1 m/s for CS tubes and 2.7 m/s for SS tubes.

v. Temperatures at the outlet of the de-superheating zone

should be above the saturation temperature of steam under all

conditions to avoid erosion due to water impingement and

tube vibration.

vi. Air venting rate of 0.5 % of the steam extracted to a heater

must be maintained.

Retrofitting, revamps, re-powering, refurbishment:

The retrofits suggested for the turbines of 30 MW to 120 MW

are as follows:

i. LP turbine retrofits (using 12 % Cr steel blades with

induction hardened leading edges) are recommended to

overcome mechanical problems due to stress corrosion

cracking, torsional vibration or erosion (water droplet impact

erosion or surface corrosion/erosion). As an offshoot, by

introduction of advanced aerodynamically designed retrofits,

efficiency and availability of the plant will improve.

LPT retrofits include improved blades as well as optimised

diffuser, extraction nozzle and steam exit in the casing of the

older turbines. Improved blade efficiency is achieved by

increase in the hub reaction, avoidance of the loss intensive

channelled shock at the hub section of the last stage blades,

optimisation of radial exit angle, improved resolution of flow

at end walls, conical flow passage instead of stair

configuration, use of integral shrouded rotor blades. High

efficiency diffusers aim at retarding the exit flow velocities

and recover as much of the kinetic energy as possible.

ii. High performance reaction blades characterized by twisted,

bowed and tapered airfoils have been developed which can

be used for retrofitting or re-powering older units. These

have features of insensitivity to inlet angle variations,

optimised controlled diffusion and have a thin trailing edge.

iii. Endoscopes for admission, exhaust and extraction chambers.

iv. Expert systems for continuous vibration signature analysis.

v. Information technology based turbine heat rate monitoring to

indicate the various losses.

The retrofits suggested for the turbines of 210 MW and 500 MW are

as follows:

i. Variable pressure operation retrofit.

ii. Endoscopes for admission, exhaust and extraction chambers.

iii. Expert systems for continuous vibration signature analysis.

iv. Information technology based turbine heat rate monitoring to

indicate the various losses.

64

v. Water-induction detection systembased on acoustic transducers.

The retrofits suggested for the condensers are as follows:

i. Automated monitoring and chemical control of condenser

leaks.

ii. Installation of on-line cleaning with reverse flow

valve/rubber sponge ball /nylon brush system.

iii. Installation of automated debris filters which not only

screens materials above 1.5 mm but conveys the debris from

the inlet of the CW pipe to its outlet (at the point of discharge

from the condenser) based on sensing the differential

pressure across the CW line or through timer operation.

iv. Installation of trash rack and screens wherever river water or

sea water are used.

v. Installation of on-line condensate polishing unit especially

where sea water or river water is used for cooling.

The retrofits suggested for regenerative feed water heaters are

as follows:

i. Installation for on-line sensing of TTD, DCA, drain level,

drain temperature, etc..

ii. Introduction of 100 % HP/LP group and individual by-pass

in older units where these are not present.

iii. Installation of heat recovery devices such as gland steam

condenser, stack steam condenser and vent steam condenser

for older units where these are not present.

Modernisation : For achieving turbine efficiencies of as high

as 41-42 %, the steam turbine (HP, IP and LP cylinders) of old

units may be replaced with standard 3-d stage specific bladed

turbines with 3-d modeled exhaust diffuser, improved tip to

tip sealing, modified exhaust hood spray and a turbine

supervisory system.

The standard added features of the retrofitted turbines are as

follows:

i. Heating system for the surface of the last stationary

stage of hollow blades of LPT by injection of steam

from an earlier extraction.

ii. Modification in location of exhaust hood spray such

that the excessive ventilation heating (during low

load operation and load rejection) is not experienced

in the LPT on the generator side.

iii. Endoscopes for examination of blading without

opening of the casing.

ENERGY OPTIMIZATION OF STEAM TURBINES

IV. IMPLEMENTATION OF ENERGY

CONSERVATION MEASURES

The methods of implementing energy conservation measures

are preparation of a DPR, detailed engineering of the proposed

scheme, financial arrangements and project execution.

V. CONCLUDING REMARKS

Energy audit is a primary tool for assessing the energy

conservation potential and the routes to achieve it through

targeting performance indices. The state of the art technology

should be used as a basis for assessing the energy conserving

potential. After implementation of the energy conservation

scheme constant monitoring of the performance indices is a

pre-requisite for efficient operation. A combination of various

methods of energy conservation such as operational

optimization, repair, overhauling, simple modifications,

upgradation, etc., must be used to economically achieve the

targeted performance indices.

VI. REFERENCES

[1]. ASME-ptc-6-1996, Performance Test code 6 on steam

turbines, American Society of Mechanical Engineers, New

York.

[2]. ASME-ptc-6SReport 1988, Procedures for routine

performance tests opf steam turbines, American Society of

Mechanical Engineers, New York.

[3]. Bhatt, M.S. and Rajkumar, N. (1999), Performance

enhancement in coal fired thermal power plants. Part II: Steam

turbines, Int. J. Energy Res., 23, pp 489-515.

[4]. I.P.S. Paul (1998), Systematic approaches for energy

Conservation in Thermal Power Generation, J . Karnataka

Electricity Board, Bangalore, pp 1-12.

Dr. I P S Paul is currently a Professor

at the Department of Mechanical

Engineering, Ajay Kumar Garg

Engineering College, Ghaziabad.

Obtained BE (Mech) from NIT

Bhopal, MBA from University of

Delhi, Diploma in Energy

Management, Italy and Ph.D. fromIIT

Delhi.

He has served as power, research

engineer and trainer in PSEB, NPTI,

NTPC and CPRI. He has guided

Ph.D., M.Tech and MBA thesis and

has 108 research papers to his credit.

65

Prof. I.P Sharma (b.

15.6.1955) is currently

Professor and Head of the

Department of Mechanical

Engineering, Ajay Kumar

Garg Engineering College,

Ghaziabad.

He has 28 years experience in

Maintenance and Quality

Control of Aircraft and related

support systems.

He has 10 years experience in

Education

(Teaching/Examination/

Coordination).

S.K. Choudhary is currently

Director with National Power

Training Institute, Faridabad. He has

over 30 years of industry-wide

experience with last 21 years in

training and human resource

development. He is a certified

instructor fromCity and Guilds, UK

and has undergone certificate course

on Neuro-Linguistic programming

from St. J oseph College, Bangalore.

He is a regular faculty in MBA

programs and conducts training

workshops for enhancing individual/

organizational effectiveness.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Quick Check On Piping FlexibilityDocument8 pagesQuick Check On Piping Flexibilitysateesh chandNo ratings yet

- Iam Good at ExaplesDocument1 pageIam Good at Exapleskaruna346No ratings yet

- Limit, Fits and ToleranceDocument13 pagesLimit, Fits and ToleranceAnkit NautiyalNo ratings yet

- Use of Branch Connections: Standard Practice ForDocument5 pagesUse of Branch Connections: Standard Practice ForFelix Rodriguez LiraNo ratings yet

- How Was + (Noun)Document1 pageHow Was + (Noun)karuna346No ratings yet

- Iam Getting ExeciseDocument1 pageIam Getting Execisekaruna346No ratings yet

- Expansion Joint in CAESARDocument5 pagesExpansion Joint in CAESARkaruna346No ratings yet

- If I Were You ExamplesDocument1 pageIf I Were You Exampleskaruna346No ratings yet

- I Am Gonna + Verb ExeDocument1 pageI Am Gonna + Verb Exekaruna346No ratings yet

- I Have + Noun ExamplesDocument1 pageI Have + Noun Exampleskaruna346No ratings yet

- I Have +PP ExamplesDocument1 pageI Have +PP Exampleskaruna346No ratings yet

- I Have To + Verb ExamplesDocument1 pageI Have To + Verb Exampleskaruna346No ratings yet

- I Am +verb ExerciseDocument1 pageI Am +verb Exercisekaruna346No ratings yet

- I Am At, In, On ExamplesDocument1 pageI Am At, In, On Exampleskaruna346No ratings yet

- Plant DesignDocument17 pagesPlant Designkaruna346No ratings yet

- Energy Audits in Thermal Power StationDocument62 pagesEnergy Audits in Thermal Power Stationfiroj_khan995% (22)

- Ash Fusion TemperatureDocument2 pagesAsh Fusion Temperaturekaruna346No ratings yet

- CRH Line FailuresDocument3 pagesCRH Line Failureskaruna346No ratings yet

- Turbine Heat Rate CalculationDocument2 pagesTurbine Heat Rate Calculationkaruna34650% (2)

- Easy Control Valve SelectionDocument5 pagesEasy Control Valve SelectionhrtoroNo ratings yet

- Asme Code For Ultrasonic Testing The Knowledge Sinequation: Ashok J. TrivediDocument7 pagesAsme Code For Ultrasonic Testing The Knowledge Sinequation: Ashok J. TrivediMax Celis CNo ratings yet

- Common Irregular Verb ListDocument4 pagesCommon Irregular Verb Listapi-27488371100% (1)

- Thermal Considerations in Pipe FlowsDocument11 pagesThermal Considerations in Pipe FlowsWaqas AhmadNo ratings yet

- Pressure DropDocument5 pagesPressure Dropkaruna346No ratings yet

- Performance Impacts VKADocument5 pagesPerformance Impacts VKASherif Mohamed KhattabNo ratings yet

- Feed Water Control ValveDocument3 pagesFeed Water Control Valvekaruna346No ratings yet

- NetworksDocument31 pagesNetworksSumeet JethraNo ratings yet

- Component Material Equivalent ASTMDocument1 pageComponent Material Equivalent ASTMkaruna346No ratings yet

- CCI Power ApplicationsDocument57 pagesCCI Power Applicationssukanya_ravichandran100% (1)

- Industrial Process Control ValvesDocument36 pagesIndustrial Process Control Valvesffown100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- LIDAR For IpipelineDocument8 pagesLIDAR For Ipipelinewiwiz2000No ratings yet

- Piping PresentationDocument144 pagesPiping PresentationSUNIL TVNo ratings yet

- Liquid Ring Compressor and Vac Pumps SIHIDocument11 pagesLiquid Ring Compressor and Vac Pumps SIHImdtaheri100% (2)

- GRAVITATIONAL CONCENTRATION (Autosaved)Document14 pagesGRAVITATIONAL CONCENTRATION (Autosaved)Cristiano RonaldoNo ratings yet

- UH Materials Science and Engineering - Courses - 2016-03-23Document3 pagesUH Materials Science and Engineering - Courses - 2016-03-23Tabish KamranNo ratings yet

- Carwasher - RenjetDocument6 pagesCarwasher - RenjetAndrew StanleyNo ratings yet

- Non - Conventional Energy Sources: 2 TopicDocument25 pagesNon - Conventional Energy Sources: 2 Topicshubham sharmaNo ratings yet

- Construction Materials and Testing Apparatus & Equipment: Essential QuestionsDocument9 pagesConstruction Materials and Testing Apparatus & Equipment: Essential QuestionsDiane de OcampoNo ratings yet

- FactSheets EN PDFDocument12 pagesFactSheets EN PDFJom VillNo ratings yet

- Ultimate Capacity FractionatorsDocument26 pagesUltimate Capacity Fractionatorsrvkumar61No ratings yet

- Thermal Modelling of Cylindrical Li BatteryDocument10 pagesThermal Modelling of Cylindrical Li BatteryAbid HussainNo ratings yet

- Aerodynamics ExperimentDocument7 pagesAerodynamics ExperimentabhaygaulechhaNo ratings yet

- XPS de AluminioDocument6 pagesXPS de AluminioBeatriz BrachettiNo ratings yet

- Applied Thermal Engineering: D. Meresse, S. Harmand, M. Siroux, M. Watremez, L. DubarDocument9 pagesApplied Thermal Engineering: D. Meresse, S. Harmand, M. Siroux, M. Watremez, L. DubarYemane TesfayeNo ratings yet

- Fatigue of RiserDocument55 pagesFatigue of RiserDao DungNo ratings yet

- Science Activity Sheet Quarter 3 - MELC 1 Week 1: Particle Nature of MatterDocument8 pagesScience Activity Sheet Quarter 3 - MELC 1 Week 1: Particle Nature of MatterEver Villar0% (1)

- Angle of Shearing ResistanceDocument3 pagesAngle of Shearing Resistancezarakkhan masoodNo ratings yet

- Petroleum Production Engineering Ii: Sucker Rod PumpingDocument27 pagesPetroleum Production Engineering Ii: Sucker Rod PumpingMohammed Khaled Al-ThobhaniNo ratings yet

- Gen Sci ReviewerDocument2 pagesGen Sci ReviewerBerlin AlonzoNo ratings yet

- Isolated Footing DesignDocument7 pagesIsolated Footing DesignRamadanNo ratings yet

- Self-Healing Concrete With Crystalline AdmixtureDocument8 pagesSelf-Healing Concrete With Crystalline AdmixtureAlexander HierroNo ratings yet

- Composite Action of Ferrocement Slabs Under Static and Cyclic Loading-Composite Action of Ferrocement Slabs Under Static and Cyclic LoadingDocument6 pagesComposite Action of Ferrocement Slabs Under Static and Cyclic Loading-Composite Action of Ferrocement Slabs Under Static and Cyclic LoadingKarrar MonarchNo ratings yet

- Fiitjee Solution - Answer Keys - Nsep - 2022-23Document17 pagesFiitjee Solution - Answer Keys - Nsep - 2022-23Royal BedukoNo ratings yet

- Liftoff TechniquesDocument4 pagesLiftoff TechniquesSwarnava SanyalNo ratings yet

- Effect of Shot Peening Operation On Gears PDFDocument9 pagesEffect of Shot Peening Operation On Gears PDFasdNo ratings yet

- Dynamic Balancing Machines, Soft-Bearing vs. Hard-BearingDocument2 pagesDynamic Balancing Machines, Soft-Bearing vs. Hard-BearingS Kumar Pa VeluNo ratings yet

- 987 9 PDFDocument205 pages987 9 PDFHerman JamalNo ratings yet

- Chapter 7 Ferrous and Non-Ferrous MetalsDocument60 pagesChapter 7 Ferrous and Non-Ferrous MetalsStephen IgatNo ratings yet

- Five Essentials of Gel Refrigerant Design and Specification PDFDocument10 pagesFive Essentials of Gel Refrigerant Design and Specification PDFtantibaNo ratings yet