Professional Documents

Culture Documents

02 E Line KB

Uploaded by

Sridhar Reddy GandraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02 E Line KB

Uploaded by

Sridhar Reddy GandraCopyright:

Available Formats

Busbar Systems

800 A.....6300 A

www.eae.com.tr

Akcaburgaz Mahallesi,

119. Sokak, No:10 34510

Esenyurt-Istanbul-TURKEY

Tel: +90 (212) 866 20 00

Fax: +90 (212) 886 24 20

T E

ME 04

IEC 60439-2 s

ISO

9001

14001

NTAL E M M A N N O A R G I E V M N E E N D T N S A Y YS TIT LE AM US Q

K

a

ta

lo

g

0

3

/ R

e

v

0

2

2

.0

0

0

A

d

. 0

6

/0

1

/2

0

0

9

A

T

A

M

A

T

B

A

A

C

IL

IK

6

1

2

4

0

6

6

/ A

.C

.E

./

E

A

E

h

a

s

fu

ll r

ig

h

t to

m

a

k

e

a

n

y

r

e

v

is

io

n

s

o

r

c

h

a

n

c

e

s

o

n

th

is

c

a

ta

lo

g

u

e

w

ith

o

u

t a

n

y

p

r

io

r

n

o

tic

e

.

w w w . e a e . c o m . t r

CONTENTS

2-3

4

5

6-9

10

11

12-15

16

17

18-20

21-22

23

23

24-25

26

27

28-29

30

31

32

Introduction

Design & Horizontal Distribution

Design & Vertical Distribution

Technical Characteristics

Order Code System

Standard Components

Elbows

Standard Components

Flexibles / Expansions

Panel Connections

Transformer Connections

Proposed Connection Details to EAE Transformer & Panelboard Modules

Determination of Special Length

Tap-off Boxes

Feeder Boxes

Selection Feeder Boxes

Fixing Elements

EC Conformity Certificate

Certificates

Product Overview

2

E KB LINE

EAE Electric manufactures, designs and provides

a wide range of busbar systems from 25 A to 6000 A

busbar systems have many advantages over wire

and conduit.

Lower total installed cost

Busbar material costs are often equal or less than

wire and conduit.

Lower life cycle cost

Busbar components can be added, deleted or relocated

after the initial installation, saving time and money.

Predictable characteristics

Busbar systems conform to common standards.

Readily published characteristics on busbar

short-circuit ratings, voltage drops, weights and

dimensions can be used.

Fast, flexible engineering

The large number of tap-off points makes it possible

to engineer the power supply systems at an early stage,

even before the final disposition of loads is known.

Flexible power supply

Tap-off points at short intervals make electrical power

available in all locations; the power supply can be

adapted to different production processes simply by

relocating the tap-off unit.

E-Line Busbar Systems; conform to EN standards

and are tested according to EN 60439-2 (200).

E-Line Busbar System

Wire Systems

Introduction

3

E KB LINE

Technical Features

General

The perfect design for high current busbar systems

is the "compact structure" where tin plated and insulated with B

class polyester film and extruded polypropylene sleeve polyester

film on conductors are tightly placed into the sheet metal

housing (Figure 1).

One bolt joint ensures safety and

easy installation

E-Line KB busbars are installed by tightening the

"one bolt joint". Belleville spring washers on both ends

of the bolt retains the original contact pressure, ensuring

a more secure, reliable and maintenance - free joint.

E-Line busbar systems are easily installed (Figures 2-3).

* The bolt is tightened to 83 Nm (60 lbft) using the torque spanner.

Heat Transfer

"In compact structure" there is no empty space filled with

air and heat is easily transferred to the environment by the

housing that works like a heat-shink (Figure 4).

High Short-Circuit Endurance

As there are no support points in "compact structure"

momentum levers are not formed.

This feature ensures high short-circuit endurance.

Minimum Voltage Drop

In E-Line KB, inductive reactance is very low due to

closely placed conductors (Figures 1-4).

The voltage drop comparison of compact and ventilated

busbar that have same cross sectional area prove

the importance of the compact structure (Figure 5).

Standard Prefabricated Structure

E-Line KB busbar system can be adapted to

any kind of building structure using.

Space-saving prefabricated components.

All necessary components and fitting elements

are manufactured items.

* Special components can be manufactured in one week on request.

No Need For Fire Barrier

There is no risk of chimney effect in E-Line KB's

compact structure. Internal fire barriers are not needed.

Figure 3

Figure 4

Figure 2

Insulators

L1

2

3

L

L

N

PE

Voltage Drop

Line length (m)

100 m 50 m

0

3

6

9

13,3

Figure 5

KBA1000 Busbar

Section: 700 mm

Ventilated Busbar

Section: 700 mm

I: 1000A

cos : 0,8

Figure 1

Conductors (Al, Cu)

Tin plated

50

60

83Nm

(60lbft)

Torqu Spanner

pregalvanized sheet metal or

epoxy polyester painted

pregalvanized sheet metal RAL 7038

B class

polyester film

extruded

polypropylene

sleeve

Aluminium Conductor (Al)

* New product group

Technical Characteristics

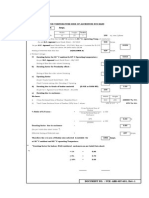

Voltage Drop Calculation

Voltage drop of a busbar system can be calculated

with the following formula taking into account the

"" load distribution constant.

U=3.L.I.(R .Cos+X .Sin) 10 1 1

-3

= Voltage Drop (V)

= Load Distribution Constant

= Line Length (m)

= Line Current (A)

= Resistance (m/m)

= Inductive Reactance (m/m)

= Load Factor

U

L

I

R

1

X

1

Cos

V

Load Distribution Factor

L

L1

L1

L1

L1

L2

L2

L2

L3

L3

L3

L2

L4

L4

L4

F

F

F

F

F F

L

F= Supply

L= Load

F= Supply

L1,L2,L3,L4

Load

F= Supply

L1,L2,L3,L4

Load

F= Supply

L1,L2,L3,L4

Load

F= Supply

L1,L2

Load

1.00

0.50

0.125

0.25

0.25

6 7

E KB LINE

1820

1820

910

910

1120 1050

1120 1050

1400

1400

2100

2100

3360 3640 2730 2240

3360 3640 2730 2240

44 22 24 29 36 53 70 83 62 46

49 24,5 27 32 40 59 79 93 69,5 51

2056 1028 1088 1836 1936 2904 3264 4112 3084 2176

910 455 560 525 700 1050 1680 1820 1365 1120

2(7x130) 7x130 7x160 2(7x75) 2(7x100) 3(7x100) 3(7x160) 4(7x130) 3(7x130) 2(7x160)

0,017 0,043 0,035 0,039 0,029 0,016 0,011 0,009 0,014 0,017

0,014 0,020 0,023 0,016 0,014 0,011 0,006 0,009 0,006 0,010

0,024 0,048 0,043 0,042 0,032 0,022 0,014 0,013 0,016 0,022

318,8 201,6 268,8 299,5 348 461,3 596,1 810 655,3 474,4

0,067

0,045

0,085

128,6

0,1104 0,2138 0,1822 0,1639 0,1344 0,0948 0,0738 0,0530 0,0839 0,0935

0,1672 0,3280 0,2806 0,2423 0,2037 0,1408 0,1132 0,1036 0,1255 0,1460

0,1255 0,2488 0,2133 0,1785 0,1529 0,1041 0,0858 0,0891 0,0933 0,1121

0,0412 0,0779 0,0694 0,0711 0,0528 0,0373 0,0248 0,0230 0,0306 0,0364

0,0525 0,0843 0,0707 0,0730 0,0569 0,0456 0,0450 0,0275 0,0397 0,0416

0,0674

700

700

19

21

968

350

7x100

0,054

0,030

0,065

162,0

0,2549

0,3835

0,2865

0,1035

0,1063

0,1502 0,1163 0,0999 0,1034 0,0789 0,0596 0,0515 0,0364 0,0508 0,0561

0,2934

0,4400

0,3279

0,1313

0,1311

0,1880

Ue 1000

Ui 1000

Icw

Icw

Ip

Ip

1

3I R

Ip

Icw

1 R

1 X

1 Z

Z

f 50 / 60

IP 55

0 R

0 R

X

X

0

Z

0

Z

In A 800 1000 1250 *1600 1600 2000 2500 *3050 3100 4000 *4250 *5000

08 10 12 13 16 20 25 27 30 40 41 50

50 50 50 50 100 100 100 100 120 120 120 120

110 110 110 110 220 220 220 220 264 264 264 264

30 30 30 30 60 60 60 60 72 72 72 72

63 63 63 63 132 132 132 132 158,4 158,4 158,4 158,4

30 30 30 30 60 60 60 60 72 72 72 72

63 63 63 63 132 132 132 132 158,4 158,4 158,4 158,4

0,076 0,055 0,044 0,038 0,037 0,027 0,021 0,017 0,018 0,014 0,012 0,011

525

525

262,5

918

7x75

16

17,5

mm

mm

kg/m

kg/m

mm

mmxmm

mm

V

V

m/m

m/m

m/m

kA

kA

kA

kA

W/m

kA

kA rms

20 R 0,055 0,041 0,032 0,026 0,028 0,021 0,016 0,013 0,014 0,011 0,009 0,008 m/m

m/m

Hz

m/m

m/m

m/m

m/m

m/m

m/m

IEC 60439-2: 2000

(1)

(1)

(1)

(1)

(1)

(1)

Short-circuit (peak)

0

0

0

0

Fault Loop Resistance (R PH-N)

Fault Loop Resistance (R PH-PE)

Fault Loop Reaktance (X PH-N)

Fault Loop Reactance (X PH-PE)

Fault Loop Impedance (Z PH-N)

Fault Loop Impedance (Z PH-PE)

L1, L2, L3, N

PE (for 5 conductors)

Weight - 4 Conductors

Weight - 5 Conductors

Housing Cross Section (Sheet Metal)

PE (for 4 conductors)

Conductor Size

Resistance (at Rated Current, at Steady State Op. Temp.)

Reactance (at Rated Current)

Impedance (at Rated Current)

Short-circuit Value of Neutral Conductor (1 sec)

Short-circuit Value of Protective Circuit (1 sec)

Short-circuit Value of Neutral Conductor (peak)

Short-circuit Value of Protective Circuit (peak)

Short-circuit (1 sec)

20 R 20C (Calculation)

Impedance

Housing Material

Measurements and calculations of fault-loop circuit is done according to EN 60439-2 appendix N2b.

(1)

Losses at Rated Current

1,50 mm pregalvanized sheet metal or epoxy polyester painted pregalvanized sheet metal RAL 7038

Busbar Code

Rated Current

Standards

Rated Operational Voltage

Rated Insulation Voltage

Rated Frequency

Protection Degree

Copper Conductor (Cu)

* New product group

Technical Characteristics

Measurements and calculations of fault-loop circuit is done according to EN 60439-2 appendix N2b.

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

Busbar Code

Rated Current

Fault Loop Resistance (R PH-N) 0

Fault Loop Resistance (R PH-N) 0

4 conductors

4 conductors

4 conductors

4,5 conductors

4,5 conductors

4,5 conductors

Fault Loop Resistance (R PH-PE) 0

Fault Loop Reaktance (X PH-N)

Fault Loop Reaktance (X PH-N)

Fault Loop Reactance (X PH-PE)

Fault Loop Impedance (Z PH-N) 0

Fault Loop Impedance (Z PH-N) 0

Fault Loop Impedance (Z PH-PE) 0

Standards

Rated Operational Voltage

Rated Insulation Voltage

Rated Frequency

Protection Degree

Housing Material

8 9

In A 1000 1250 1600 2000 *2250 2500 3000 3600 *4250 4400 5300 *6300

Short-circuit (peak)

Short-circuit Value of Neutral Conductor (1 sec)

Short-circuit Value of Protective Circuit (1 sec)

Short-circuit Value of Neutral Conductor (peak)

Short-circuit Value of Protective Circuit (peak)

Short-circuit (1 sec)

R 20 C(Calculation) 20

Impedance

Ue

Ui

Icw

Icw

Ip

Ip

Ip

Icw

20

20

R

Z

f

IP

V

V

kA

kA

kA

kA

kA

kA rms

m/m

m/m

Hz

IEC 60439-2: 2005-10

10 12 16 20 23 25 30 36 42 44 53 63

50

105

30

63

30

63

0,0350

0,0510

50

105

30

63

30

63

0,0260

0,0390

50

105

30

63

30

63

0,0200

0,0300

50

105

30

63

30

63

0,0160

0,0250

100

220

60

132

60

132

0,0170

0,0260

100

220

60

132

60

132

0,0130

0,0190

100

220

60

132

60

132

0,0100

0,0160

100

220

60

132

60

132

0,0080

0,0120

120

264

72

158

72

158

0,0090

0,0130

120

264

72

158

72

158

0,0070

0,0100

120

264

72

158

72

158

0,0050

0,0090

1000

1000

50/60

55

50

105

30

63

30

63

0,0400

0,0580

L1, L2, L3, N

PE (for 5 conductors)

Weight - 4 Conductors

Weight - 5 Conductors

Housing Cross Section (Sheet Metal)

PE (for 4 conductors)

Conductor Size

Resistance (at Rated Current, at Steady State Op. Temp.)

Reactance (at Rated Current)

Impedance (at Rated Current)

Losses at Rated Current

1

3I R

1 R

1 X

1 Z

0 R

0

0

R

R

X

X

X

0

Z

0

0

Z

Z

mm

mm

kg/m

kg/m

mm

mmxmm

mm

m/m

m/m

m/m

W/m

m/m

m/m

m/m

m/m

m/m

m/m

m/m

m/m

m/m

229,69

0,0490

0,0380

0,0620

525

525

262,5

918

7x75

28

33

0,0940

0,0990

0,1380

0,3050

0,1450

0,2470

0,1360

0,3940

0,2000

276,48

0,0360

0,0290

0,0460

700

700

350

968

7x100

36

42

0,0690

0,0790

0,1070

0,2600

0,1090

0,1530

0,1110

0,3040

0,1560

336,00

0,0280

0,0230

0,0360

910

910

455

1028

7x130

44

52

0,0540

0,0600

0,0830

0,2380

0,0870

0,1120

0,0870

0,2690

0,1240

349,31

0,0230

0,0190

0,0290

1120

1120

560

1088

7x160

52

60

0,0440

0,0580

0,0740

0,2110

0,0690

0,0810

0,0790

0,2330

0,1050

468,75

0,0250

0,0190

0,0310

1050

1050

525

1836

2x(7x75)

54

64

0,0480

0,0510

0,0710

0,1920

0,0680

0,1050

0,0710

0,2200

0,0990

513,00

0,0190

0,0140

0,0240

1400

1400

700

1936

2x(7x100)

70

82

0,0350

0,0410

0,0550

0,1840

0,0540

0,1440

0,0570

0,2380

0,0790

466,56

0,0120

0,0120

0,0170

1820

1820

910

2056

2x(7x130)

86

102

0,0260

0,0330

0,0430

0,1240

0,0400

0,1310

0,0460

0,1800

0,0620

541,88

0,0100

0,0090

0,0140

2240

2240

1120

2176

2x(7x160)

102

118

0,0250

0,0270

0,0370

0,1230

0,0390

0,1140

0,0360

0,1700

0,0530

638,88

0,0110

0,0100

0,0150

2100

2100

1050

2904

3x(7x100)

104

122

0,0240

0,0290

0,0380

0,1110

0,0360

0,1050

0,0420

0,1540

0,0560

589,89

0,0070

0,0080

0,0110

2730

2730

1365

3084

3x(7x130)

128

152

0,0180

0,0230

0,0300

0,0890

0,0290

0,1090

0,0330

0,1410

0,0440

714,42

0,0060

0,0070

0,0090

3360

3360

1680

3264

3x(7x160)

152

187

0,0130

0,0220

0,0250

0,0720

0,0200

0,0890

0,0310

0,1150

0,0380

174,00

0,0580

0,0410

0,0710

450

450

225

918

6x75

26

31

0,1120

0,0900

0,1470

0,3110

0,1540

0,2550

0,1290

0,4030

0,2020

E KBC- LINE

Voltage Drop Calculation

Voltage drop of a busbar system can be

calculated with the following formula taking

into account the "" load distribution

constant.

U=3.L.I.(R .Cos+X .Sin) 10 1 1

-3

= Voltage Drop (V)

= Load Distribution Constant

= Line Length (m)

= Line Current (A)

= Resistance (m/m)

= Inductive Reactance (m/m)

= Load Factor

U

L

I

R

1

X

1

Cos

V

Load Distribution Factor

L

L1

L1

L1

L1

L2

L2

L2

L3

L3

L3

L2

L4

L4

L4

F

F

F

F

F F

L

F= Supply

L= Load

F= Supply

L1,L2,L3,L4

Load

F= Supply

L1,L2,L3,L4

Load

F= Supply

L1,L2,L3,L4

Load

F= Supply

L1,L2

Load

1.00

0.50

0.125

0.25

0.25

1,50 mm epoxy polyester painted pregalvanized sheet metal RAL 7038 pregalvanized sheet metal or

KB A 16 5 0 T R 4 1

10

Feeder

Plug-in

Bolt-on

IP 55 5

Bolt-on

Plug-in

Fedeer

0

1

2

4 il. 5 il. 4+

3

4

5

6

7

8

KBA

Aluminium

Copper

(Al) A

(Cu)

Order Code System

E KB LINE

*TYPE Utilization Type

Energy is suplied

from the joints.

Energy is supplied either

from the joints or the

plug-in points.

Used where there is no need

to use tap-off boxes.

COMPONENTS

TYPE*

PROTECTION DEGREE

BUSBAR

CODE

CONDUCTOR TYPE

Unpainted -

Painted B

Conductors

Busbar Type

* New product group

Al

Conductor

Cu

Conductor

Conductor

Size

Rated

Current

Rated

Current

Busbar

Code

Busbar

Code

BUSBAR TYPE

CONDUCTOR TYPE

BUSBAR CODE

PROTECTION DEGREE

UTILIZATION TYPE

COMPONENT

UNPAINTED / PAINTED

Standard Length

Special Length

Upwards Elbow

Downwards Elbow

Right Elbow

Left Elbow

Upwards Vertical Offset

Downwards Vertical Offset

Right Horizontal Offset

Left Horizontal Offset

Right Upwards Combined Offset

Left Upwards Combined Offset

Right Downwards Combined Offset

Left Downwards Combined Offset

Upwards Right Combined Offset

Upwards Left Combined Offset

Downwards Right Combined Offset

Downwards Left Combined Offset

Left Side Feeder "T"

Right Side Feeder "T"

Central Feeder "T"

Horizontal Expansion

Vertical Expansion

Reduction

End Closer

End Closer

Panel Connection

Panel Connection

Upwards Panel Connection

Upwards Panel Connection

Downwards Panel Connection

Downwards Panel Connection

Right Panel Connection

Right Panel Connection

Left Panel Connection

Left Panel Connection

Panel Connection

Panel Connection

Transformer Connection

Upwards Transformer Connection

Downwards Transformer Connection

Transformer Connection

Transformer Connection

Right Transformer Connection

Left Transformer Connection

Transformer Connection

Flexible

Feeder Box

Feeder Box

Central Feeder Box

STD

X

U

D

R

L

UV

DV

RH

LH

KRU

KLU

KRD

KLD

KUR

KUL

KDR

KDL

TYL

TYR

TO

YDT

DDT

RD

S10

S11

P10

P11

PU20

PU21

PD20

PD21

PR30

PR31

PL30

PL31

P40

P41

TR11

TU21

TD21

TR31

TR41

TR51

TL51

TR61

F

B10

B11

BO

800

1000

1250

1600

1600

2000

2500

3050

3100

4000

4250

5000

*

*

*

*

6x75

7x75

7x100

7x130

7x160

2x(7x 75)

2x(7x100)

2x(7x130)

2x(7x160)

3x(7x100)

3x(7x130)

3x(7x160)

4x(7x130)

08

10

12

13

16

20

25

27

30

40

41

50

1000

1250

1600

2000

2250

2500

3000

3600

4250

4400

5300

6300

-------

10

12

16

20

23

25

30

36

42

44

53

63

---

*

*

*

- U

3

2

5

4

0

0

3

2

5

4

0

0

L1

L2

L3

N

3050 - D

- D 3

2

5

4

0

0

3

2

54

0

0 L1

L2

L3

N

- L

B

A

B

A

L1

L2

L3

N

KBA 2050 - R

- R

B

A

B

A

L1

L2

L3

N

3050 - U

2550 - L

12

KB

E KB LINE

Elbows

Please call us for non-standard components.

Sample Order:

3000 A, Copper, Bolt-on,

IP 55, 4 Conductors

Upwards Elbow

Sample Order:

3000 A, Copper, Bolt-on,

IP 55, 4 Conductors

Downwards Elbow

Sample Order:

2500 A, Copper, Bolt-on,

IP 55, 4 Conductors

Left Elbow

Sample Order:

2000 A, Aluminium, Bolt-on,

IP 55, 4 Conductors

Right Elbow

* New product group

BUSBAR TYPE

CONDUCTOR TYPE

BUSBAR CODE

PROTECTION DEGREE

TYPE

COMPONENT

UNPAINTED / PAINTED

The dimensions given above are minumum values.

800

1000

1250

1600

1600

2000

2500

3050

3100

4000

4250

5000

*

*

*

*

420

420

445

475

505

540

590

650

710

735

825

915

1000

355

355

367

383

398

415

440

470

500

512

558

603

645

08

10

12

13

16

20

25

27

30

40

41

50

KBA

1000

1250

1600

2000

2250

2500

3000

3600

4250

4400

5300

6300

------

10

12

16

20

23

25

30

36

42

44

53

63

---

A B

(mm) (mm)

*

*

*

Al

Conductor

Cu

Conductor

Rated

Current

Rated

Current

Busbar

Code

Busbar

Code

KBA 2050-UV45

- LH

- RH

- UV

- DV

x

x

Y

Y

(cm)

(cm)

(cm)

(cm)

B

B

B

B

A

A

X

X

A

A

Y

3

2

5

4

0

0

3

2

5

4

0

0

Y3

2

5

4

0

0

3

2

5

4

0

0

L1

L2

L3

N

L1

L2

L3

N

L1

L2

L3

N

L1

L2

L3

N

3050 - RH60

3050 - DV45

13

KB

E KB LINE

Elbows

X=min:20 cm,

max: *Please see table

Sample Order:

X=60 cm, 3000 A, Copper

Bolton, IP 55, 4 Conductors

X=min:20 cm,

max: *Please see table

Sample Order:

X=60 cm, 3000 A, Copper

Bolton, IP 55, 4 Conductors

Y=min:15 cm / max:64 cm

Sample Order:

Y=45 cm, 2000 A, Aluminium

Bolt-on, IP 55, 4 Conductors

Y=min:15cm / max:64 cm

Sample Order:

Y=45 cm, 3000 A, Copper

Bolt-on, IP 55, 4 Conductors

Left Horizontal Offset

Right Horizontal Offset

Upwards Vertical Offset

Downwards

Vertical Offset

* New product group

BUSBAR TYPE

CONDUCTOR TYPE

BUSBAR CODE

PROTECTION DEGREE

TYPE

COMPONENTS

UNPAINTED / PAINTED

The dimensions given above are minumum values.

3050 - LH60

800

1000

1250

1600

1600

2000

2500

3050

3100

4000

4250

5000

420

420

445

475

505

540

590

650

710

735

825

915

1000

355

355

367

383

398

415

440

470

500

512

558

603

645

70

70

73

76

78

82

87

93

99

102

111

120

128

08

10

12

13

16

20

25

27

30

40

41

50

KBA

1000

1250

1600

2000

2250

2500

3000

3600

4250

4400

5300

6300

------

10

12

16

20

23

25

30

36

42

44

53

63

---

A B X

(mm) (mm) (cm)

*

*

*

*

*

*

*

Al

Conductor

Cu

Conductor

Rated

Current

Rated

Current

Busbar

Code

Busbar

Code

KBA 3050-KDR

KBA 3050-KUR

- K D L

- K U L

KUL

KDL

KUR

KDR

- K D R

- K U R

3

2

5

4

0

0

B

3

0

0

A

3

2

5

4

0

0

B

3

0

0

A

3

2

5

4

0

0

B

3

0

0

A

3

2

5

4

0

0

B

3

0

0

A

L1

L2

L3

N

L1

L2

L3

N

L1

L2

L3

N

L1

L2

L3

N

3050 - KUL

3050 - KDL

14

KB

E KB LINE

Elbows

Please call us for non-standard components.

Sample Order:

3000 A, Copper

Bolt-on, IP 55, 4 Conductors

Sample Order:

3000 A, Aluminium

Bolt-on, IP 55, 4 Conductors

Sample Order:

3000 A, Copper

Bolt-on, IP 55, 4 Conductors

Sample Order:

3000 A, Aluminium

Bolt-on, IP 55, 4 Conductors

Upwards Right

Combined Offset

Downwards Right

Combined Offset

Upwards Left

Combined Offset

Downwards Left

Combined Offset

* New product group

BUSBAR TYPE

CONDUCTOR TYPE

BUSBAR CODE

PROTECTION DEGREE

TYPE

COMPONENT

UNPAINTED / PAINTED

The dimensions given above are minumum values.

800

1000

1250

1600

1600

2000

2500

3050

3100

4000

4250

5000

*

*

*

*

420

420

445

475

505

540

590

650

710

735

825

915

1000

355

355

367

383

398

415

440

470

500

512

558

603

645

08

10

12

13

16

20

25

27

30

40

41

50

KBA

1000

1250

1600

2000

2250

2500

3000

3600

4250

4400

5300

6300

------

10

12

16

20

23

25

30

36

42

44

53

63

---

A B

(mm) (mm)

*

*

*

Al

Conductor

Cu

Conductor

Rated

Current

Rated

Current

Busbar

Code

Busbar

Code

KBA 3050-KLD

KBA 3050-KLU

- K L D

- K L U

KLU

KLD

KRU

KRD

- K R D

- K R U

3

2

5

4

0

0

B

3

0

0

A

3

2

5

4

0

0

B

3

0

0

A

3

2

5 4

0

0

B

3

0

0

A

3

2

5

4

0

0

B

3

0

0

A

L1

L2

L3

N

L1

L2

L3

N

L1

L2

L3

N

L1

L2

L3

N

3050 - KRU

3050 - KRD

15

KB

E KB LINE

Elbows

Please call us for non-standard components.

Sample Order:

3000 A, Aluminium

Bolt-on, IP 55, 4 Conductors

Sample Order:

3000 A, Aluminium

Bolt-on, IP 55, 4 Conductors

Sample Order:

3000 A, Copper

Bolt-on, IP 55, 4 Conductors

Sample Order:

3000 A, Copper

Bolt-on, IP 55, 4 Conductors

Right Upwards

Combined Offset

Right Downwards

Combined Offset

Left Upwards

Combined Offset

Left Downwards

Combined Offset

* New product group

BUSBAR TYPE

CONDUCTOR TYPE

BUSBAR CODE

PROTECTION DEGREE

TYPE

COMPONENT

UNPAINTED / PAINTED

The dimensions given above are minumum values.

800

1000

1250

1600

1600

2000

2500

3050

3100

4000

4250

5000

*

*

*

*

420

420

445

475

505

540

590

650

710

735

825

915

1000

355

355

367

383

398

415

440

470

500

512

558

603

645

08

10

12

13

16

20

25

27

30

40

41

50

KBA

1000

1250

1600

2000

2250

2500

3000

3600

4250

4400

5300

6300

------

10

12

16

20

23

25

30

36

42

44

53

63

---

A B

(mm) (mm)

*

*

*

Al

Conductor

Cu

Conductor

Rated

Current

Rated

Current

Busbar

Code

Busbar

Code

B=.....mm

X=.....mm

Y=.....mm

Z=.....mm

=.....mm

L

(cm)

KBA 2550-YDT

KBA 0800-F40

- Y D T

- D D T

- F

*

Y

L

B

Z

X

7

0

0

1

5

0

0

L1

L2

L3

N

L1

L2

L3

N

4250 - DDT

17

KB

E KB LINE

Sample Order:

2500 A, Aluminium, Bolt-on, 4 Conductors

Sample Order:

4250 A, Copper, Bolt-on, 4 Conductors

Sample Order:

800 A, Aluminium

This side is punched according

to the needs of the custommer.

Used at every 40 m in horizontal

long lines and for crossing building

expansions.

For vertical application in many storey

building.

Transformer - busbar,

Panel - busbar connections.

One vertical expansion unit is advised

to be used at every floor between

fixed support points.

Horizontal Expansion

Vertical Expansion

Flexibles

Horizontal Expansion

Vertical Expansion

Flexible are used for

Flexibles & Expansions

Please call us for non-standard components.

BUSBAR TYPE

CONDUCTOR TYPE

BUSBAR CODE

PROTECTION DEGREE

TYPE

COMPONENT

UNPAINTED / PAINTED

Attention!

The total length of the module should be adjusted

to 1500 mm. after installation.

The dimensions given above are minumum values.

A

23

E KB LINE

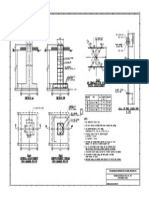

Proposed Connection Details to EAE Transformer & Panelboard Modules

Determination of Special Length

After the installation of standard 3m lengths, you will be in need of special lengths which are smaller than 3m. The minimum

length for these special elements can be 35 cm. Please measure the lengths of these modules as shown below.

busbar

"A" length should be indicated in cm. Measure the asistance from one end of the side housing to the other.

A=Length of Special Busbar

A

(mm)

B

(mm)

C

(mm)

E KB LINE

Tap-off Boxes

with Fused Switches (SYK)

KB

BUSBAR TYPE

CONDUCTOR

PROTECTION

DEGREE

RATED CURRENT

BOX TYPE

IP-55-5

4 - 0

5 - 1

160 A-16

250 A-25

400 A-40

630 A-63

Bolt on- B

Plug in- P

CABLE GLAND PLATES

Please call us for non-standard tap-off boxes.

Cable Gland Plates

Tap-off boxes are equipped with

EAE SYK fused switches

The tap-off boxes are in red RAL

3020 colour as standard.

EAE SYK

Can operate under load

Are equipped with NH fuse holders

Have interlock mechanism

SYK 160 A

SYK 250 A

SYK 400 A

SYK 630 A

Tap-off boxes can be equipped with any brand

of switches, circuit breakers and etc.

Sample Order:

Bolt-on / 630 A / IP-55 /

5 Conductors

Sample Order:

Plug-in / 400 A / IP-55 /

5 Conductors

KBB 6351

KBP 4051

Bolt-on

Tap-off Boxes

Plug-in

Tap-off Boxes

C

a

b

l

e

G

l

a

n

d

P

l

a

t

e

(

o

n

3

s

i

d

e

s

)

C

a

b

l

e

G

l

a

n

d

P

l

a

t

e

(

o

n

3

s

i

d

e

s

)

KB

KB

KB

KB

B

B

B

B

1

2

4

6

6 5 0

5 5 0

0 5 0

3 5 0

KB

KB

KB

KB

P

P

P

P

1

2

4

5

6 5 0

5 5 0

0 5 0

0 5 0

Mat.

Cable

Gland Type

Order

Code

Inner

Diameter

(mm)

Sheet RP0 ----

Sheet RP1 25 M32

M40 Sheet RP2 32

Sheet RP3 63 Special

AL RP4 63 2xSpecial

AL RP5 18 4xM25

AL RP6 25 4xM32

AL RP7 32 4xM40

AL RP8 25 8xM32

Tap-off

Boxes

Standard

Gland

Fuse

Size

24

KBB 16

KBB 25

KBB 40

KBB 63

KBP 16

KBP 25

KBP 40

KBP 50

520

670

670

700

520

670

670

750

300

380

380

420

300

380

380

420

190

240

255

255

190

240

255

255

RP2

RP3

RP4

RP4

RP2

RP3

RP4

RP4

NH00

NH 1

NH 2

NH 3

NH00

NH 1

NH 2

NH 3

C

A

B

L

1

L

2

L

3

N

L

1

L

2

L

3

N

C

B

A

70

20

40

40

A

A

5

0

5

0

25

E KB LINE

Tap-off Boxes

for MCCB's

Please call us for non-standard tap-off boxes.

Special Cable Gland Plates

Sheet RPK0 ---- ----

Sheet RPK1 18 M25

M32

M40

1xSpecial

Sheet

Sheet

Sheet

RPK2

RPK3

RPK4

25

32

63

* Tap-off boxes can be equipped with any brand

of MCCB's.

Cable Gland Plates

Mat.

Cable

Gland Type

Order

Code

Inner

Diameter

(mm)

Sheet RP0 ---- ----

Mat.

Cable

Gland Type

Order

Code

Inner

Diameter

(mm)

Sheet RP1 25 M32

M40 Sheet RP2 32

Sheet RP3 63 Special

AL RP4 63 2xSpecial

AL RP5 18 4xM25

AL RP6 25 4xM32

AL RP7 32 4xM40

AL RP8 25 8xM32

KB

BUSBAR TYPE

CONDUCTOR

PROTECTION DEGREE

RATED CURRENT

BOX TYPE

IP-55-5

4 letken-0

5 letken-1

160 A-16

250 A-25

400 A-40

630 A-63

800 A-80

1000 A-10

Bolt on- B

Plug in- P

CABLE GLAND PLATES

SWITCH TYPE M- MCCB / B- Empty

Bolt-on

Tap-off Boxes

KB

KB

KB

KB

KB

KB

KB

KB

KB

KB

KB

KB

KB

KB

KB

KB

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

1

2

4

6

1

2

4

6

8

8

1

1

8

8

1

1

6 5 0 - B1

5 5 0 - B1

0 5 0 - B1

3 5 0 - B1

6 5 0

5 5 0 - M1

0 5 0 - M1

3 5 0 - M1

- M1

0 4 0 - B1

0 5 0 - B1

0 4 0 - B1

0 5 0 - B1

0 4 0

0 5 0 - M1

0 4 0 - M1

0 5 0 - M1

- M1

Sample Order:

Bolt-on / 630 A / IP-55 /

5 Conductors, empty tap off box

Sample Order:

Bolt-on / 800 A / IP-55 /

5 Conductors,

empty tap off box

Sample Order:

Plug-in / 400 A / IP-55 /

5 Conductors, empty tap off box

KBB 6351 - B1

KBB 8051 - B1

KBP 4051 - B1

KB

KB

KB

KB

KB

KB

KB

KB

P

P

P

P

P

P

P

P

1

2

4

6

1

2

4

6

6 5 0 - B1

5 5 0 - B1

0 5 0 - B1

3 5 0 - B1

6 5 0 - M1

5 5 0 - M1

0 5 0 - M1

3 5 0 - M1

A

(mm)

B

(mm)

C

(mm)

RPK3

RPK4

RP4

RP4

RP4

RP4

RPK3

RPK4

RP4

RP4

500

500

700

700

950

950

500

500

700

700

300

300

300

300

350

350

300

300

300

300

KBB 160

KBB 250

KBB 400

KBB 630

KBB 800

KBB 1000

KBP 160

KBP 250

KBP 400

KBP 630

220

220

220

220

305

305

220

220

220

220

Tap-off

Boxes

Standard

Gland

70 40 A

20 40 A

C

a

b

l

e

G

l

a

n

d

P

l

a

t

e

(

o

n

3

s

i

d

e

s

)

L

1

L

2

L

3

N

C

B

A

5

0

C

a

b

l

e

G

l

a

n

d

P

l

a

t

e

(

o

n

3

s

i

d

e

s

)

L

1

L

2

L

3

N

C

B

5

0

C

a

b

l

e

G

l

a

n

d

P

l

a

t

e

(

o

n

3

s

i

d

e

s

)

Plug-in

Tap-off Boxes

L

1

L

2

L

3

N

C

B

A

5

0

A

BR4

300

400

500

600

200

BR

4

0

4

0

UDD

IDD

IDY

300

400

-----

2000

300

400

-----

2000

300

400

-----

2000

UDYB 300

400

...

1000

E KB LINE

Fixing Elements

ORDER CODE

LENGTH L (mm)

KB UT FIXING SET

Supports

Steel Dowel

Extension Unit

Theaded Rod

Steel Dowel

Extension Unit

Theaded Rod

IDT Fixing Element

Please call us for non-standard components.

* New product group

IDD

24

IDT

IDY

BR4

UDD

L

IDD

L

UDD

UDYB

UDYB

KB UT

IDY

28

1

5

x

3

5

1

5

x

3

5

1

5

5

1

0

5

L

L

1

0

5

1

5

5

350

350

350

400

450

450

500

550

600

650

750

800

900

L

(mm)

800

1000

1250

1600

1600

2000

2500

3050

3200

4000

4250

5000

*

*

*

*

1000

1250

1600

2000

2250

2500

3000

3600

4250

4400

5300

6300

------

08

10

12

13

16

20

25

27

30

40

41

50

10

12

16

20

23

25

30

36

42

44

53

63

---

*

*

*

Al

Conductor

Cu

Conductor

Rated

Current

Rated

Current

Busbar

Code

Busbar

Code

PDD 300

400

...

2000

PDDB

STK

UDY

STS

300

400

...

1000

200

300

400

300

400

-----

2000

200

300

400

L

29

E KB LINE

Fixing Elements

ORDER CODE

LENGTH L (mm)

Supports

Please call us for non-standard components.

BRA 12-05

BRA 12-10

BRA 14-05

BRA 14-10

BRA 13

BRA 13

BRA 9-3

BRA 9-4

Threaded Rod

Threaded Rod (M10x1000)

Threaded Rod (M12x500)

Threaded Rod (M12x1000)

Exstension Unit (M10)

Exstension Unit (M12)

Steel Dowel (M10)

Steel Dowel (M12)

(M10x500)

Threaded Rods

Exstension

Unit

Steel Dowel

Diameter of the

hole to be drilled

M10.....14

M12.....16

UDD

STS

STS

TMP 5

UDY

PDD

PDD

PDDB

PDDB

STK

IDD

STK

UDY

L

L

L

L

L

30

E L E K T R K

Directive

EAE Elektrik A.S.

EC DECLARATION OF CONFORMITY

Product Group

Standard :

Manufacturer

E-Line KB Busbar Energy Distribution System

IEC 60439-1

IEC 60439-2

EAE Elektrik Asansor End. Insaat San. ve Tic. A.S.

Akcaburgaz Mahallesi, 119. Sokak, No:10 34510 Esenyurt-Istanbul

Tel: +90 (212) 866 20 00 Fax: +90 (212) 886 24 20 http://www.eae.com.tr

EAE Elektrik Asansor End. Insaat San. ve Tic. A.S.

Akcaburgaz Mahallesi, 119. Sokak,

No:10 34510 Esenyurt-Istanbul

This is to attest, under our sole responsibility, that the aforementioned products conforms with

the regulations and guidelines of the following standards.

Date

11.09.2002

According to EC - Directive

73/23/EEC Low - Voltage - Directive

Tests

1- Temperature-rise limits

2- Dielectric properties

3- Short-circuit strength

4- Effectiveness of the protective circuit

5- Clearances and creepage distances

6- Mechanical operation

7- Degree of protection

8- Electrical Characteristics

9- Structural Strength

10- Crushing resistance

11- Resistance of insulating materials to abnormal heat

12- Fire barrier

31

Certificate

E KB LINE

32

Product Overview

E KB LINE

800A...6300A

COMPACT BUSBAR PRODUCT OVERVIEW (E-LINE KB)

1-Standards & Certification:

Busbar system shall be designed and manufactured as per IEC 60439-2 standard. Each busbar rating shall have a separate type test certificate

from an independent internationally accredited laboratory.

Each product shall have a Type Label, which indicates the brand, type of the unit, conductor number and electrical details.

2-General Structure of Products:

Busbar system shall have Sandwich-Compact structure. Aluminium or Copper conductors shall be tin plated along the entire length. Housing

shall be 1, 50 mm galvanized steel or if required housing shall be RAL7038-Electrostatic painted.

2.1- Electrical Characteristics:

Busbar systems nominal insulation voltage shall be 1000V.

As per ampere rates, minimum short circuit values shall be like below;

For Aluminium Conductors;

- 800, 1000 and 1250A:1sec/rms-50kA, Peak-110kA

- 1600, 2000 and 2500A: 1sec/rms-100kA, Peak-220kA

- 3000A and above: 1sec/rms-120kA, Peak-264kA

Temperature rise shall be maximum 50K over 40C ambient temperature for both tin plated Aluminium and Copper conductor busbars.

2.2- Housing and Structure:

Busbar system shall have Sandwich-Compact structure.

Compact structure of the housing shall be provided by M6 screws applied at every 10 cm along the entire length.

Busbar system shall have all necessary accessories (elbows, offsets, panel-transformer connections, reductions, etc). Manufacturer shall supply

special dimensioned units in short time, if the project conditions requires.

For horizontal runs, a horizontal expansion unit shall be used at every 40m and expansion points of the building.

For vertical applications, a vertical expansion unit shall be used at every floor. Busbar system shall be rigidly fixed by supports at every floor.

2.3- Conductors:

Compact busbar system shall have Nickel and Tin-plated EC grade aluminium conductors (800-4250A). / Compact busbar system shall have Tin-

plated Electrolytic copper conductors (1000-6300A).

Busbar system shall have below number of conductors and phase configuration;

a) 4 Conductors:(4 full size conductors + Housing (earthing) )

b) 4 Conductors:(4 full size conductors + earth conductor + Housing)

c) 5 Conductors:(5 full size conductors + Housing (earth)

d) 5 Conductors:(5 full size conductors, 5th bar shall be used as clean earth + Housing

Neutral conductor shall have the same cross-section (100%) of phase conductors.

Conductor and housing expansion differences shall be absorbed at the joints using Z shaped offsets.

2.4- Insulation:

For strong and long life time insulation system, there shall be 2 layers of extruded PP (Polypropylene) and 3 layers of B class polyester film

(Mylar) between neighbour conductors. Conductors shall be packed and placed into the housing without leaving any air gap for compact

(sandwich) structure.

2.5- Joint Structure:

Electrical and mechanical connection shall be made at joints by single bolt joint construction and each joint shall have two Belleville washers.

The joint shall be with direct overlapping of the conductors.

Insulators of the joint shall be manufactured of glass-reinforced polyester.

Joints shall be realized by a torque spanner (wrench) set at 80Nm.

To prevent the joints transportation damages, they shall be protected by plastic caps, which shall be removed before installation.

Joint bolt shall be locked from both sides (Bolt head and nut).

2.6- Protection:

Protection degree of the busbar system shall be IP55.

3-Tap Off Boxes:

Rating of plug-in tap off boxes shall start from160A and shall be up to and including 500A. Rating of Bolt-on tap off boxes shall start from160A and

shall be up to and including 1000A. Plug-in tap off boxes shall be installed, when the busbar line is energized.

Tap off boxes shall have an electrical interlock mechanism, which ensures that plug-in tap off box cannot be removed mechanically from the

busbar, when the switch is at ON position. Mechanical interlock mechanism shall prevent opening the door, when the switch is at ON position.

It shall be possible to install bolt-on tap off boxes up to 1000A to each joint of plug-in and bolt-on busbars. It shall be possible to install a bolt-on

tap off box only by removing the plastic contact distance pieces on the joints. The real contacts of the bolt-on tap off box shall be placed instead of

the contact distance pieces. The same bolt-on tap off box shall be installed to the joints of all busbar ratings without changing or adding any

pieces.

When the switch is at OFF position and the door is open, tap off box shall be at IP2X protection level. (There shall not be any accessible live part

in the box).

Tap Off boxes shall be suitable for any brand of MCCB.

Contacts of plug-in tap off box shall be silver-plated copper. Contacts of bolt-on tap off box shall be tin-plated copper.

While inserting the contacts of Plug-in tap off boxes, earth contact shall make first touch.

Any extra piece shall not be needed to install tap off boxes.

Tap off boxes shall be manufactured of sheet steel and epoxy painted RAL 3020.

4-Installation and Commissioning:

Busbar systems shall be installed as per Single-Line drawings respect to required ampere rates and manufacturer installation guide (torque

values, lockers, etc.). Electrical installator shall run an insulation test after installation according to manufacturer's test procedures. The results of

the test shall be reported to the manufacturer. Minimum insulation value shall be 1Mohm.

Manufacturing facility of busbar systems shall have ISO 9001 and ISO 14001 certification.

For Copper Conductors;

- 1000, 1250, 1600, 2000 and 2250A:1sec/rms-50kA, Peak-105kA

- 2500, 3000, 3600 and 4250A: 1sec/rms-100kA, Peak-220kA

- 4400A and above: 1sec/rms-120kA, Peak-264kA

Compact Busbar Distribution System

800...6300A

Plug-in Busbar Distribution System

160...800A

Small Power Plug-in Busbar Distribution System

100-160-225A

Plug-in Busbar Distribution System

40-63A

Multi-Conductor Lighting Busbar System

25-32-40A

Lighting Busbar System

25-32-40A

Multi Conductor Trolley Busbar System

35...250A

Underfloor Ducting Systems

Raised Floor Energy Distribution Systems

25...63A

Cable

Tray Systems

E-LINE KB

E-LINE KO

E-LINE MK

E-LINE KAP

E-LINE DL

E-LINE KAM

E-LINE TB

E-LINE DK

E-LINE DKY

E-LINE UK

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Lower Secondary Science 7 End-Of-Year TestDocument9 pagesLower Secondary Science 7 End-Of-Year Testleonard radyko90% (10)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Varalakshmi Vratham Pooja Vidhanam in TeluguDocument23 pagesVaralakshmi Vratham Pooja Vidhanam in Telugusatya_avanigadda69No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- JSS 50101 PDFDocument146 pagesJSS 50101 PDFAditya Srivatsav100% (1)

- Electronics CatalogDocument259 pagesElectronics CatalogmedrayaliNo ratings yet

- 50 TMSS 01 R0Document0 pages50 TMSS 01 R0renjithas2005No ratings yet

- KS 1876-2-2010 Overhead Power Lines For Kenya - SafetyDocument33 pagesKS 1876-2-2010 Overhead Power Lines For Kenya - SafetyomealNo ratings yet

- Survey No.328-1BDocument1 pageSurvey No.328-1BSridhar Reddy GandraNo ratings yet

- Process Flow Chart For The Solar1Document1 pageProcess Flow Chart For The Solar1Sridhar Reddy GandraNo ratings yet

- Jharkand RFS ObservationsDocument4 pagesJharkand RFS ObservationsSridhar Reddy GandraNo ratings yet

- Jharkand RFS ObservationsDocument4 pagesJharkand RFS ObservationsSridhar Reddy GandraNo ratings yet

- DP Yard Fencing ModelDocument1 pageDP Yard Fencing ModelSridhar Reddy GandraNo ratings yet

- House Rent Receipt Format 252Document1 pageHouse Rent Receipt Format 252kansjee100% (4)

- One-Line Diagram - OLV1 (Short-Circuit Analysis)Document1 pageOne-Line Diagram - OLV1 (Short-Circuit Analysis)Sridhar Reddy GandraNo ratings yet

- 33KV IsolatorDocument12 pages33KV IsolatorSridhar Reddy Gandra0% (1)

- Lvac and DC SLD Boards ModelDocument1 pageLvac and DC SLD Boards ModelSridhar Reddy GandraNo ratings yet

- Calculation For Tempreture RiseDocument7 pagesCalculation For Tempreture RiseSridhar Reddy GandraNo ratings yet

- 60909Document178 pages60909Sridhar Reddy GandraNo ratings yet

- Pole Earthing TypicalDocument1 pagePole Earthing TypicalSridhar Reddy GandraNo ratings yet

- One-Line Diagram - OLV1 (Short-Circuit Analysis)Document1 pageOne-Line Diagram - OLV1 (Short-Circuit Analysis)Sridhar Reddy GandraNo ratings yet

- Annexure IV: S.No. AssumptionsDocument1 pageAnnexure IV: S.No. AssumptionsSridhar Reddy GandraNo ratings yet

- 220-33KV Layout - Option-II PDFDocument1 page220-33KV Layout - Option-II PDFSridhar Reddy GandraNo ratings yet

- 06 10 05 LPH2 R3 ModelDocument1 page06 10 05 LPH2 R3 ModelSridhar Reddy GandraNo ratings yet

- Annexure II: S.No. Terminal PointsDocument1 pageAnnexure II: S.No. Terminal PointsSridhar Reddy GandraNo ratings yet

- Adopter Box Ultratech Sridhar 24-09-14Document1 pageAdopter Box Ultratech Sridhar 24-09-14Sridhar Reddy GandraNo ratings yet

- 220 33kv SLD Option IDocument1 page220 33kv SLD Option ISridhar Reddy GandraNo ratings yet

- 33kV CPL FoundationDocument5 pages33kV CPL FoundationSridhar Reddy GandraNo ratings yet

- Transmission Corporation of Andra Pradesh Ltd. Foundation Details of 220 KV CVT (For Normal Soils)Document1 pageTransmission Corporation of Andra Pradesh Ltd. Foundation Details of 220 KV CVT (For Normal Soils)Sridhar Reddy GandraNo ratings yet

- Installation Guidelines For C&I Erection of Cable TraysDocument7 pagesInstallation Guidelines For C&I Erection of Cable TraysCharu ChhabraNo ratings yet

- 220 33kv SLD Option IDocument1 page220 33kv SLD Option ISridhar Reddy GandraNo ratings yet

- Annexure III: S.No. ExclusionsDocument1 pageAnnexure III: S.No. ExclusionsSridhar Reddy GandraNo ratings yet

- Installation Guidelines For C&I Erection of Cable TraysDocument7 pagesInstallation Guidelines For C&I Erection of Cable TraysCharu ChhabraNo ratings yet

- PDFSig QFormal RepDocument1 pagePDFSig QFormal Repanon-549999100% (2)

- Street LightsDocument12 pagesStreet LightsSridhar Reddy GandraNo ratings yet

- Voltage REgulationDocument8 pagesVoltage REgulationJacob CarterNo ratings yet

- Street Light-Typical ModelDocument1 pageStreet Light-Typical ModelSridhar Reddy GandraNo ratings yet

- SF6 GCB 24 - 36 KVDocument4 pagesSF6 GCB 24 - 36 KVMichael Parohinog GregasNo ratings yet

- M04 Electrical WiringDocument65 pagesM04 Electrical WiringbilisummaaNo ratings yet

- Electrical Formulas: General InformationDocument1 pageElectrical Formulas: General InformationalbertoNo ratings yet

- BS 4607-5Document18 pagesBS 4607-5Jeff Anderson CollinsNo ratings yet

- Ansi C29.18Document28 pagesAnsi C29.18Maria Gallardo100% (1)

- TG 9780190700133 4Document124 pagesTG 9780190700133 4Madiha RubabNo ratings yet

- Electric Power Train Vehicles - CMVR Type Approval For Electric Power Train VehiclesDocument23 pagesElectric Power Train Vehicles - CMVR Type Approval For Electric Power Train Vehiclesvivekpattni100% (1)

- Insulation Resistance TestingDocument2 pagesInsulation Resistance TestingGuru PrasadNo ratings yet

- Building Services-II Module - 2Document24 pagesBuilding Services-II Module - 2Neha AlbertNo ratings yet

- 3ek7 e PDFDocument8 pages3ek7 e PDFHoracio BerniNo ratings yet

- Condensadores ElectroniconDocument22 pagesCondensadores ElectroniconVincent PorhelortNo ratings yet

- Impulse Voltage Generation Using MATLAB/Simulink and Its Integration in Undergraduate High Voltage Engineering CourseDocument6 pagesImpulse Voltage Generation Using MATLAB/Simulink and Its Integration in Undergraduate High Voltage Engineering CourseHamzah RezaNo ratings yet

- AWWA C200 Steel Water Pipe Standard Improvements 2013Document41 pagesAWWA C200 Steel Water Pipe Standard Improvements 2013inspetorfabiomadeiraNo ratings yet

- CTPT Catalogue 2022Document6 pagesCTPT Catalogue 2022Energy TecNo ratings yet

- Linkoln Ranger 300 DLXDocument56 pagesLinkoln Ranger 300 DLXkarimNo ratings yet

- LT Line I Busbar Trunking System Catalog - v01102022Document44 pagesLT Line I Busbar Trunking System Catalog - v01102022sie kingNo ratings yet

- Subsation BOQDocument22 pagesSubsation BOQNagendra Prasad chaudharyNo ratings yet

- Eaton 108792 ZB65 75 en - GBDocument8 pagesEaton 108792 ZB65 75 en - GBJavier JiménezNo ratings yet

- Design of 132 33KV SubstationDocument13 pagesDesign of 132 33KV SubstationAtabat Adudu50% (2)

- Division 01Document15 pagesDivision 01Geeryl TayoneNo ratings yet

- MEGGER GettingDownToEarthDocument33 pagesMEGGER GettingDownToEarthDavid100% (1)

- Transformer Installation & Commissioning With MaintenanceDocument106 pagesTransformer Installation & Commissioning With MaintenancerpshvjuNo ratings yet

- Stator Winding Fault in Induction Motor: Chapter OutlineDocument38 pagesStator Winding Fault in Induction Motor: Chapter OutlineChrisNo ratings yet

- Manufacturing Process XLPE CableDocument16 pagesManufacturing Process XLPE CableSRGNo ratings yet

- UF12A Series PDFDocument2 pagesUF12A Series PDFdrastir_777No ratings yet