Professional Documents

Culture Documents

Tensile Strength Conversion Sheet For Slab On Grade Fiber Dosage Calculations

Uploaded by

Burhan KanjetaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tensile Strength Conversion Sheet For Slab On Grade Fiber Dosage Calculations

Uploaded by

Burhan KanjetaCopyright:

Available Formats

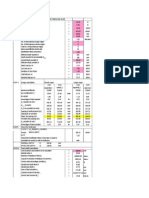

Tensile Strength Conversion Sheet for Slab on Grade Fiber Dosage Calculations

Instructions: Select the desired Units of Measurement from the "pull-down" menu. input required data

Fill in the required information in the "yellow" shaded blocks. constants - change only if necessary

calculated data

final dosage requirements

Units of Measurement

Required Information: Project Description:

Reinforcing Details:

bar diameter 0.1920 mm* * - for information related to wire and bar sizings, please refer to chart on Tab 2 (tab below)

bar spacing 6.0 mm

Slab Thickness, t 4.0 mm Minimum requirements:

concrete compressive strength, f'

c

4000 MPa PCA (note: other documents may provide different minimums)

typical steel strength, f

y

60000 MPa Minimum % of reinforcing steel for shrinkage reinforcing 0.100

Q. is the steel ratio provided greater than the minimum? yes

Unit width of measure, b 1000 mm

Area of steel provided, A

s

4.825 mm2/m Estimated concrete flexural strength (change if necessary) 47.4

Steel reinforcing ratio, r 0.121 % Spread Tensile Strength provided by steel reinforcing, f

wwm

62.9

R

e3

value required to match spread tensile strength 198.9

Required Volume of TUF-STRAND SF to match: 17.6 kg/m3 **

Estimated cost of TUF-STRAND SF solution

Cost Estimator: Area of slab 465 m2 0.28 $ / m2

Price of TUF-STRAND SF (installed)* 4.00 $ /kg compare this price to the fully installed WWM or steel option

Note: This spreadsheet is only valid for

WWM and steel designs where the

thickness of the slab will support the

loading conditions and the steel is located

in the top half of the slab only.

slab on grade construction

W2.9 WWM on 4" slab mid depth

** - Conversion of fiber dosage from required

performance established from ASTM C 1018 testing

NOTICE: Be sure that all manual entries are in the correct units and values as this will have a significant impact on the final dosage and cost.

The value of the TUF-STRAND SF dosage may be adjusted if necessary (depending upon the mixing, safety and performance requirements).

This spreadsheet is only valid to calculated dosage rates up to 11.5 lbs/yd.

NOTE: The solutions provided are to be treated as a recommendation only.

- For more information, please contact The Euclid Chemical Company at 1-800-321-7628.

Notations:

f'

c

compressive strength of concrete, psi (Mpa)

f

y

yield strength of reinforcing steel, psi (Mpa)

A

s Area of steel per unit area* - Usually expressed per ft length if b is set to 12 in, in

2

/ft (mm

2

/m)

t height (thickness) of cross section, in (mm)

b unit width of cross section* - Usually set to 12 in if steel is expressed in in

2

/ft (1000 mm)

f

wwm

Spread tensile strength provided by steel reinforcing, psi (Mpa)

R

e3

Post-crack performance as percentage of flexural strength for fiber reinforced concrete

ASTM C 1018 - Flexural Toughness of Fiber Reinforced Concrete (using beam under third point loading)

Tensile Strength Conversion Sheet for Slab on Grade Fiber Dosage Calculations

constants - change only if necessary

* - for information related to wire and bar sizings, please refer to chart on Tab 2 (tab below)

%

MPa

MPa

%

compare this price to the fully installed WWM or steel option

slab on grade construction

W2.9 WWM on 4" slab mid depth

** - Conversion of fiber dosage from required

performance established from ASTM C 1018 testing

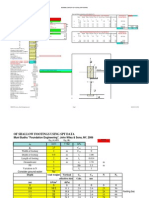

WWM and Reinforcing Bar Size Chart

Input the corresponding value of "bar diameter" into the appropriate shaded box on the slab design page.

Converted Values are shown for each chart (Imperial vs metric)

Imperial Units (US) Metric Units

Reinforcing Bars Reinforcing Bars

bar size bar diameter bar diameter bar size bar diameter bar diameter

(in) (mm) (mm) (in)

#3 (3/8") 0.375 9.5 10M 11.3 0.44

#4 (1/2") 0.5 12.7 15M 16.0 0.63

#5 (5/8") 0.625 15.9 20M 19.5 0.77

#6 (3/4") 0.75 19.1 25M 25.2 0.99

Welded Wire Mesh Welded Wire Mesh

wire size bar diameter bar diameter wire size bar diameter bar diameter

(in) (mm) (mm) (in)

W1.4 (10 Ga.) 0.134 3.40 MW 9.1 (W1.4) 3.40 0.134

W1.5 0.138 3.51 MW11.1 (W1.7) 3.76 0.148

W1.7 (9 Ga.) 0.148 3.76 MW 13.3 (W2.1) 3.80 0.150

W2.0 0.160 4.06 MW 16.0 (W2.5) 4.52 0.178

W2.1 (8 Ga.) 0.162 4.11 MW 18.7 (W2.9) 4.88 0.192

W2.5 (7 Ga.) 0.178 4.52 MW 19.2 (W3.0) 4.95 0.195

W2.9 (6 Ga.) 0.192 4.88 MW 22.6 (W3.5) 5.36 0.211

W3 0.195 4.95 MW 25.8 (W4.0) 5.74 0.226

5 Ga. 0.207 5.26 MW 28.9 (W4.5) 6.07 0.239

W3.5 0.211 5.36 MW 32.3 (W5.0) 6.40 0.252

W4 (4 Ga.) 0.226 5.74 MW35.5 (W5.5) 6.73 0.265

W4.5 0.239 6.07 MW 38.7 (W6.0) 7.01 0.276

3 Ga. 0.244 6.20 MW42.1 (W6.5) 7.32 0.288

W5.0 0.252 6.40 MW 45.2 (W7.0) 7.60 0.299

2 Ga. 0.263 6.68 MW 48.4 (W7.5) 7.85 0.309

W5.5 0.265 6.73 MW 51.6 (W8.0) 8.10 0.319

W6 .0 0.276 7.01

1 Ga. 0.283 7.19

W6.5 0.288 7.32

W7.0 0.299 7.59

W7.5 0.309 7.85

W8 .0 0.319 8.10

shaded blocks denote more common wire sizings

You might also like

- Aci 239R 18 PDFDocument28 pagesAci 239R 18 PDFeric altacid100% (2)

- (Duerr, D.,2006) - Pinned Connection Strength and BehaviorDocument14 pages(Duerr, D.,2006) - Pinned Connection Strength and Behaviorchristos032No ratings yet

- Base Plate Design AISC 360-10Document3 pagesBase Plate Design AISC 360-10dantevariasNo ratings yet

- RCC Railing To OHSRDocument24 pagesRCC Railing To OHSRNaga Bharath ReddyNo ratings yet

- Tensile Strength Conversion Sheet For Slab On Grade Fiber Dosage CalculationsDocument6 pagesTensile Strength Conversion Sheet For Slab On Grade Fiber Dosage CalculationsImranSohailNo ratings yet

- Astm A668 Tensile ReqDocument1 pageAstm A668 Tensile ReqDilip Gajanan Namjoshi100% (1)

- Naval Architecture II Theory Detailed NotesDocument96 pagesNaval Architecture II Theory Detailed NotesAnkit Maurya100% (1)

- Bolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryDocument2 pagesBolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryRayodcNo ratings yet

- Punch Typ C4Document10 pagesPunch Typ C4Suhail AhamedNo ratings yet

- Rigid Pavement Design PDFDocument14 pagesRigid Pavement Design PDFNaqvi ANo ratings yet

- Two Way Slab DesignDocument2 pagesTwo Way Slab DesignAjith Chandran100% (1)

- WallDocument44 pagesWallUmesh ChamaraNo ratings yet

- Ground Floor Columns at B1, B2 EtcDocument12 pagesGround Floor Columns at B1, B2 EtcRennie Dourado PlateroNo ratings yet

- Analysis of Steel ShutterDocument30 pagesAnalysis of Steel Shuttersalahuddin sakuNo ratings yet

- Retain Wall Counter FortDocument48 pagesRetain Wall Counter FortMarlon Martinez100% (1)

- 2F Floor (S4)Document6 pages2F Floor (S4)Zulkiflee TaugNo ratings yet

- Riverbank Protection MeasuresDocument11 pagesRiverbank Protection MeasuresHrisikeshNo ratings yet

- Material Properties:: Main Builtup Girder Flexural CheckDocument22 pagesMaterial Properties:: Main Builtup Girder Flexural CheckDipak BorsaikiaNo ratings yet

- Setha's CV & Cover LetterDocument10 pagesSetha's CV & Cover LetterMen Keo RathaNo ratings yet

- Block Name Value Units Calcvalue Edit FieldDocument21 pagesBlock Name Value Units Calcvalue Edit FieldsdewssNo ratings yet

- Design of Dome: Type: ProjectDocument9 pagesDesign of Dome: Type: ProjectdeponkkarNo ratings yet

- Cantilever SlabDocument3 pagesCantilever SlabMatiur Rahman BasumNo ratings yet

- Ass 4 Cofferdam Solution 12 13 PTDocument1 pageAss 4 Cofferdam Solution 12 13 PTsyakirohNo ratings yet

- Spreadsheets To BS 8110etc: Advisory Group Grid Line 1 ST 25-Dec-2017 1 - 4068Document4 pagesSpreadsheets To BS 8110etc: Advisory Group Grid Line 1 ST 25-Dec-2017 1 - 4068vaideehNo ratings yet

- Cantilever SlabDocument16 pagesCantilever SlabMukhlish AkhatarNo ratings yet

- CAL PDF: Water TableDocument3 pagesCAL PDF: Water TableSES DESIGNNo ratings yet

- Analysis On The Causes of Cracks in BridgesDocument14 pagesAnalysis On The Causes of Cracks in BridgesNguyễn Văn MinhNo ratings yet

- Column Biaxial ProblemsDocument25 pagesColumn Biaxial ProblemsRajanvmNo ratings yet

- Samer Fawzi CV 2Document6 pagesSamer Fawzi CV 2Samer SulimanNo ratings yet

- DesignDocument25 pagesDesignMelchorRdzNo ratings yet

- PadfootDocument3 pagesPadfootfazila fauzi100% (1)

- As Per RCC Design (B.C. Punmia) Page 184 Example 7.6 Design of Cantilever ChajjaDocument32 pagesAs Per RCC Design (B.C. Punmia) Page 184 Example 7.6 Design of Cantilever ChajjajaffnaNo ratings yet

- Trial ExcelDocument15 pagesTrial ExcelCyndrille John BragatNo ratings yet

- Isolated Footing DesignDocument19 pagesIsolated Footing Designmohanty_anantakumar6332No ratings yet

- Deep FoundatioDocument49 pagesDeep FoundatioSanthosh PurushothamanNo ratings yet

- Duct Drain Section RCC DesignDocument1 pageDuct Drain Section RCC Designhammad jagirdarNo ratings yet

- Single Column FootingDocument6 pagesSingle Column Footingtopukuet100% (1)

- PILE FOUNDATION DESIGN Manual Cal - CommentsDocument6 pagesPILE FOUNDATION DESIGN Manual Cal - CommentsDilip PatelNo ratings yet

- Beam Design (SSB)Document6 pagesBeam Design (SSB)Er Sai KiranNo ratings yet

- Axial Load Capacity For Deep Foundations Piles: Sand Input ResultsDocument8 pagesAxial Load Capacity For Deep Foundations Piles: Sand Input Resultsacidrisamuel2656No ratings yet

- AASHTO - Prestressed Beams AASHTO ExamplesDocument29 pagesAASHTO - Prestressed Beams AASHTO ExamplesAli ÖztürkNo ratings yet

- Name of Work:-: M /sec M /sec M /sec M /sec M /sec M /sec M /secDocument9 pagesName of Work:-: M /sec M /sec M /sec M /sec M /sec M /sec M /secChauhan UjjvalNo ratings yet

- Slab Design-ExcelDocument2 pagesSlab Design-ExceltechnopreneurvizagNo ratings yet

- Bearing CapacityDocument7 pagesBearing CapacityLaura HernandezNo ratings yet

- Drain Design MetricDocument31 pagesDrain Design MetricEmre MermerNo ratings yet

- UntitledDocument13 pagesUntitledViji NpNo ratings yet

- Slab Manual DesignDocument1 pageSlab Manual DesignAtul ShrivastavaNo ratings yet

- Spreadsheets To BS 8110Document12 pagesSpreadsheets To BS 8110mr jack theuriNo ratings yet

- One Way SlabDocument3 pagesOne Way SlabMuhammad Sulaiman100% (1)

- Two Way Slab Design Excel SheetDocument13 pagesTwo Way Slab Design Excel Sheetቀዳሚሃ ለጥበብ ፈሪሃ እግዚያብሔርNo ratings yet

- Bay 1 Soil SpringDocument1 pageBay 1 Soil SpringVegetable BunNo ratings yet

- A23.3-04 Precast Corbel Design Spreadsheet Jan 2008Document6 pagesA23.3-04 Precast Corbel Design Spreadsheet Jan 2008mukhleshNo ratings yet

- Feasibility Study and Construction of Two No Bridges at KM 23 & 27 On Ara Bigwani Road Dera Ismail KhanDocument10 pagesFeasibility Study and Construction of Two No Bridges at KM 23 & 27 On Ara Bigwani Road Dera Ismail KhanAziz ul HakeemNo ratings yet

- Pipe CulvertDocument8 pagesPipe CulvertKrishna DixitNo ratings yet

- Project Area Sub Area Plant/Unit Code Se-Spml (JV) RevDocument13 pagesProject Area Sub Area Plant/Unit Code Se-Spml (JV) RevBanwari Lal GuptaNo ratings yet

- Concrete Pavement Calculation Given or Known Data: From Table-11 AASTHODocument3 pagesConcrete Pavement Calculation Given or Known Data: From Table-11 AASTHOZulfikar N JoelNo ratings yet

- Slab Design of Partially Fixed Circular SlabDocument4 pagesSlab Design of Partially Fixed Circular SlabBithika DattaNo ratings yet

- Water Tank Analysis Using STAAD PRO: Mainak GhosalDocument9 pagesWater Tank Analysis Using STAAD PRO: Mainak GhosalEr Bhavesh IngaleNo ratings yet

- Immediate Settlement (Mat)Document4 pagesImmediate Settlement (Mat)MUHAMMAD ALINo ratings yet

- Well FoundationDocument10 pagesWell FoundationGopal SinghNo ratings yet

- Design of Shear Connector For Composite Bending ActionDocument2 pagesDesign of Shear Connector For Composite Bending ActionankitNo ratings yet

- Ce4014 - 1 Bond Anchorage & Development LengthDocument31 pagesCe4014 - 1 Bond Anchorage & Development Lengthprakashcg123100% (1)

- Culverts and Low Level CrossingsDocument3 pagesCulverts and Low Level CrossingsAbdykafy ShibruNo ratings yet

- Tensile Strength Conversion Sheet For Slab On Grade Fiber Dosage CalculationsDocument5 pagesTensile Strength Conversion Sheet For Slab On Grade Fiber Dosage Calculationsjana zongerNo ratings yet

- 06HQGR0192 PDFDocument40 pages06HQGR0192 PDFBurhan KanjetaNo ratings yet

- Retaining Wall (Limit)Document9 pagesRetaining Wall (Limit)Burhan KanjetaNo ratings yet

- 3 Final Man - 131 PDFDocument17 pages3 Final Man - 131 PDFBurhan KanjetaNo ratings yet

- 5 - TabatabaieDocument31 pages5 - TabatabaieAhmed ArafaNo ratings yet

- Lecture Notes PDFDocument73 pagesLecture Notes PDFBurhan KanjetaNo ratings yet

- Black Panel v2 19523 14 0160 Cin PDFDocument9 pagesBlack Panel v2 19523 14 0160 Cin PDFBurhan KanjetaNo ratings yet

- BLDGDocument43 pagesBLDGBurhan KanjetaNo ratings yet

- Shakib A 10 183 1 9e3c0a5Document42 pagesShakib A 10 183 1 9e3c0a5Burhan KanjetaNo ratings yet

- Design of RCC T - Girder Deck Using Morice & Little MethodDocument33 pagesDesign of RCC T - Girder Deck Using Morice & Little Methodvasu7900100% (4)

- Title 2. Structural AnalysisDocument56 pagesTitle 2. Structural AnalysisAbu HasanNo ratings yet

- Cable Bolt Anchorage CharacteristicsDocument8 pagesCable Bolt Anchorage CharacteristicsPaul GauthierNo ratings yet

- OKFlux 1062Document10 pagesOKFlux 1062parkkkNo ratings yet

- Sci p360 SecureDocument15 pagesSci p360 SecureOktayNo ratings yet

- Happy PadDocument18 pagesHappy PadmailbkraoNo ratings yet

- SteelDocument64 pagesSteelSangeet Karna100% (1)

- Mil C 14550BDocument4 pagesMil C 14550BKris PathinatherNo ratings yet

- Project: Project No: AuthorDocument37 pagesProject: Project No: Authorabdullah_23320666No ratings yet

- Technical Data Sheet Eurobent Nt-35 (Zakładka)Document1 pageTechnical Data Sheet Eurobent Nt-35 (Zakładka)Dannyamil AriasNo ratings yet

- (Jay Shoemaker) Moldflow Design Guide 'A ResourcDocument3 pages(Jay Shoemaker) Moldflow Design Guide 'A ResourcFahri ibişoğluNo ratings yet

- Syncure™ S1054A Natural: Crosslinked PolyethyleneDocument2 pagesSyncure™ S1054A Natural: Crosslinked PolyethyleneHomero RamosNo ratings yet

- Tensile Test ReportDocument4 pagesTensile Test Reportahmed IsmailNo ratings yet

- Is 15060:2001/iso 10321-1992Document13 pagesIs 15060:2001/iso 10321-1992Antonette LimNo ratings yet

- Haynes: Hastelloy W AlloyDocument4 pagesHaynes: Hastelloy W AlloyLuiz FernandoNo ratings yet

- Aluminum-Beryllium Alloys For Aerospace Applications: Materion Corporation Materion Beryllium & Composites 14710Document7 pagesAluminum-Beryllium Alloys For Aerospace Applications: Materion Corporation Materion Beryllium & Composites 14710roshniNo ratings yet

- FRP Strengthening of Concrete Structures - DesignDocument15 pagesFRP Strengthening of Concrete Structures - Designshafiullah100% (1)

- 13 CR Data SheetDocument5 pages13 CR Data SheetMartin MweembaNo ratings yet

- Design of Welded StructuresDocument837 pagesDesign of Welded StructuresManuelGonzalesNo ratings yet

- TABLACOMPARATIVADocument12 pagesTABLACOMPARATIVADyno CrowlyNo ratings yet

- Material Data Sheet Thermally Broken Steel USADocument2 pagesMaterial Data Sheet Thermally Broken Steel USAYungfang HuangNo ratings yet

- EED2014 Lab2n3 Tensile Brinell 2Document11 pagesEED2014 Lab2n3 Tensile Brinell 2Pavitra Rajaveloo50% (2)

- DPT1 - 02 - Drill String DesignDocument109 pagesDPT1 - 02 - Drill String DesignBrahim Letaief100% (1)

- Febby Fauziah - Pengaruh Persentase Reduksi Terhadap Sifat Mekanik Dan Struktur Mikro FixDocument11 pagesFebby Fauziah - Pengaruh Persentase Reduksi Terhadap Sifat Mekanik Dan Struktur Mikro FixAmmi AndamNo ratings yet

- Bridge - Concrete StructuresDocument71 pagesBridge - Concrete Structuresကိုနေဝင်းNo ratings yet

- Cataloge of DengFeng Weld PDFDocument143 pagesCataloge of DengFeng Weld PDFLeo SembiringNo ratings yet

- Leak Off TestDocument80 pagesLeak Off Testb4rfNo ratings yet