Professional Documents

Culture Documents

Dismantling, Assembling and Adjusting: 9223-1/A1 Crank Angle Sensor Unit

Uploaded by

Gaby CrisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dismantling, Assembling and Adjusting: 9223-1/A1 Crank Angle Sensor Unit

Uploaded by

Gaby CrisCopyright:

Available Formats

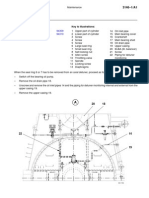

Maintenance 92231/A1

RTA82C

Wrtsil Switzerland Ltd 1/ 18

Tools: Key to Illustrations:

1 Feeler gauge 94122 1 Protection hood 36 Circlip

1 Hook spanner 94924 2 Covering cap 37 Disc

1 Hook spanner 94925 3 Screw 38 Key

4 Nut 39 Packing ring

5 Shaft 40 Locating pin

6 Crank angle sensor 41 Inspection cover

7 Holder 42 Compression spring

8 Screw 43 Lever

9 Toothed belt 44 Screw with locking plate

10 Protection plate 45 Throttle

11 Screw with locking plate 46 Housing

12 Angle holder 47 Screw

13 Outer shaft encoder 48 Screw

13a Inner shaft encoder 48a Locking plate

14 Bearing housing 49 Connecting unit

15(a) Screw 50 Locating pin

16 Washer 51 Coupling disc

17 Locking plate 52 Spring tensioner

18 Gear wheel 53 Screw with locking plate

19 Gear wheel 54 Adjusting screw

20 Waisted screw 55 Clamp screw w. tab washer

21 Screw with locking plate 56 Distance piece

22 Packing ring 57 Screw with locking plate

23 Adjusting disc 58 Locating pin

24 Locking plate 59 Spring balance

25 Shaft nut 60 O-ring

26 Locking plate

27 Shaft nut GL Tap hole

28 Circlip KD Cable clamp

29 Retaining ring KK Terminal box

30 Sealing ring MK Mark

31 Distance ring OE Oil inlet

32(a) Ball bearing SU Collar

33 Distance ring SH Protective sleeve

34 Distance sleeve SK Sensor cable

35 Disc spring SR Protective pipe

Overview

1. Removal of shaft encoder 2/18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Shaft encoder 3/18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Fitting the shaft encoder 4/18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Removal of crank angle sensor drive 7/18 . . . . . . . . . . . . . . . . . .

5. Dismantling the crank angle sensor drive 8/18 . . . . . . . . . . . . . .

6. Assembling the crank angle sensor drive 10/18 . . . . . . . . . . . . .

7. Fitting the crank angle sensor drive 13/18 . . . . . . . . . . . . . . . . . .

8. Removal and fitting of compression spring 14/18 . . . . . . . . . . .

9. Checks 17/18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crank Angle Sensor Unit

Dismantling, Assembling and Adjusting

2008

Maintenance 92231/A1 RTA82C

Wrtsil Switzerland Ltd 2/ 18

1. Removal of shaft encoder

008.758/00 008.725/00

1.1 Preparation

Pull out plug of sensor cable SK at terminal

box KK (Fig. A).

Unscrew protection hood 1 and remove it to-

gether with covering cap 2.

Unscrew cable clamps KD as well as protec-

tive sleeve SH and withdraw sensor cable

from protective pipes SR.

1.2 Outer shaft encoder

Loosen screws 3 and remove them together

with protection plates 10.

Loosen screws 11 and remove them together

with angle holder 12.

Loosen screws 15, 15a and remove outer

shaft encoder 13 together with toothed belt 9.

008.724/00

A

B

OE

SK

KK

SR

II

II

I

I

I - I

II - II

1 9 10

SH

KD SK

2

11 1 14

5 4

2

1

15 15a

13 13a

FREE END

11 12

3

CLEARANCE

2008

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

Maintenance 92231/A1

RTA82C

Wrtsil Switzerland Ltd 3/ 18

1.3 Inner shaft encoder

Removing the inner shaft encoder 13a is only possible after the toothed belt of the

outer shaft encoder 13 has been removed according to paragraph 1.2.

Removal of the inner shaft encoder 13a is carried out analogously to the outer one.

008.727/00

008.726/00

C

13a

SK

I

I 13

2. Shaft encoder

D Shaft encoders are only supplied complete (Fig. D). The crank angle sensor 6

is fastened to the holder 7 and set by the manufacturer.

Attention! Never loosen screw 8!

008.728/00

008.728/00

7

D

6 19

8

2008

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

Maintenance 92231/A1 RTA82C

Wrtsil Switzerland Ltd 4/ 18

3. Fitting the shaft encoder

3.1 Inner shaft encoder

Turn crankshaft to T.D.C. of Cyl. 1.

Mount shaft encoder 13a (Fig. D and E) on the guide plate of bearing hous-

ing 14 with screws 15, washers 16 and locking plates 17. Do not tighten

screws 15. Apply MOLYKOTE paste G to the threads and head seatings.

Slide shaft encoder along the guide plate to check that the shaft encoder is moving

freely.

Push shaft encoder inwards.

3.2 Fitting the toothed belt

Connect gear wheels 19 and 18 with toothed belt 9, paying attention to their

marks MK which must coincide according to Fig. F (zero position).

Push shaft encoder outwards till the toothed belt is lightly tensioned and

meshing properly with the gear wheels. Lightly tighten screws 15. Recheck

marks MK.

Fit screws 15a, washers 16 and locking plates 17. Apply MOLYKOTE paste G

to the threads and head seatings.

Align toothed belt exactly in running direction.

Attach spring balance 59 to the shaft encoder and slightly preload it according

to Fig. E.

Loosen all screws 15 and 15a, paying attention that the shaft encoder can still

move freely.

Tension toothed belt with 40 45 N indicated on spring balance, and fixate

shaft encoder with screws 15 and 15a.

Remark: Pull the spring balance exactly in tensioning direction, keeping the fric-

tion between the holder guide and screw surfaces as small as possible.

008.730/00 008.729/00

15a 9

E

MK

13a

59

17

I

I

15

SK

15a

58

16

2008

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

CHECK

Maintenance 92231/A1

RTA82C

Wrtsil Switzerland Ltd 5/ 18

In order to align toothed belt 9 on its running track, turn the crankshaft one to

two revolutions with the turning gear.

Recheck belt tension according to Fig. F and G as well as marks MK. Re-

peat tensioning procedure if belt slackened after crankshaft has been turned

or if marks MK are not matching.

Adjust and bend the long lugs of locking plates 17 according to Fig. F.

Tighten all screws 15 and 15a with a torque of 16 Nm and lock them.

Attention! Always use new locking plates, bending them once only!

3.3 Outer shaft encoder

Fitting the outer shaft encoder 13 is carried out analo-

gously to the inner one.

Attention! When fitting shaft encoders, toothed belts

or crank angle sensor drive (section 7) always pay

attention to the following points:

D Crankshaft at T.D.C. of Cyl. 1.

D Bore for locating pin 58 of the crank angle sensor

drive pointing downwards as shown in Fig. H.

D Mark MK (T.D.C. 1) of gear wheel 18 pointing up-

wards as shown in Fig. F and all other marks

aligned according to Fig. H. 008.733/01

008.732/00

008.731/00

T.D.C. 1

008.731/00

F

I

9

I

18 15a

19

17

G

TOOTHED BELT TENSIONED TOOTHED BELT LOOSE

MK

15 17

15a

H

MK

58

16

T.D.C. 1

SK

2008

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

Maintenance 92231/A1 RTA82C

Wrtsil Switzerland Ltd 6/ 18

3.4 Final works

Fit angle holder 12 using screws 11 with their locking plates. Subsequently

install protection plates 10 in such a way that they contact each other at the

centre without overlapping and touching any moveable parts, using screws 3

with their locking plates.

Tighten and lock screws 3 and 11.

After assembling fit carefully the sensor cables SK. Pay attention to the

clearance which must exist between sensor cables and housing (Fig. B, sec-

tion II).

Fit protection hood 1 together with covering cap 2.

3.5 Toothed belt change

If there should be changed only one toothed belt, proceed as follows:

Remove protection plate 10 and angle holder 12 (Fig. B).

Remove screws 15a with locking plates and washers.

Remove screws 15, replace locking plates and loosely refit the screws.

Push shaft encoder inwards and replace toothed belt.

D For fitting pay attention to paragraphs 3.1 to 3.4.

3.6 Rechecking of toothed belt tension

In accordance with Maintenance Schedule 03801 Crank angle sensor unit the

toothed belt tension must be visually rechecked as shown in Fig. F and G, and by

lightly tapping on the toothed belt with a finger.

If necessary or in case of doubt the toothed belt must be retensioned as described

in paragraph 3.2!

Attention! After every loosening of a shaft encoder the toothed belt tension must

be rechecked after about five operating hours!

2008

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

Maintenance 92231/A1

RTA82C

Wrtsil Switzerland Ltd 7/ 18

4. Removal of crank angle sensor drive

Preparation according to paragraph 1.1.

Loosen and remove nuts 4.

Attention! When loosening nut 4 hold up shaft 5 by means of an open end span-

ner AF27!

Remove screws 21 and withdraw the crank angle sensor from the waisted

screw 20 (view II).

Remark: Do not unscrew adjusting disc 23.

008.736/01

008.735/01

008.734/01

I

I

I

22 21

5 4 20

23

21

II

I - I

II

SK

2008

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

Maintenance 92231/A1 RTA82C

Wrtsil Switzerland Ltd 8/ 18

5. Dismantling the crank angle sensor drive

Recommendation: To ensure a high availability and quality standard we recom-

mend that a complete crank angle sensor drive according to Fig. I, view II (includ-

ing shaft encoder Fig. D) always be kept in stock. Maintenance works as de-

scribed in sections 5 and 6 may be carried out only by qualified manufacturers as a

matter of principle.

Remove shaft encoder according to paragraphs 1.2 and 1.3.

Unbend locking plate 24, loosen and remove shaft nut 25 using hook spanner

94924.

Withdraw gear wheel 18 from the shaft 5.

Remark: If withdrawing by hand is not possible, the gear wheel must be removed

by means of the two tap holes GL and suitable tools, however, without striking and

damaging the toothing.

008.737/01

K

18 25 24

5 GL

Remove circlip 28 using a snap ring tong.

Unbend locking plate 26, loosen and remove shaft nut 27 using hook spanner

94925.

Remove shaft 5, however, key 38 remains in situ.

008.738/01

L

38

28

27 26

2008

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

Maintenance 92231/A1

RTA82C

Wrtsil Switzerland Ltd 9/ 18

008.739/01

Retaining ring 29 (using tap holes GL) to-

gether with sealing ring 30 and O-ring 60.

Distance ring 31.

Ball bearing 32, distance ring 33, distance

sleeve 34 and disc springs 35.

Circlip 36.

Disc 37 together with ball bearing 32a.

Parts to be removed in the following sequence: M

31

30

29

34 35

33 32 32a 37 36

60 14

x

GL

2008

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

Maintenance 92231/A1 RTA82C

Wrtsil Switzerland Ltd 10/ 18

6. Assembling the crank angle sensor drive

Clean all parts and check their conditions prior to assembling.

Replace sealing ring 30, ball bearings 32, 32a and O-ring 60 (Fig. M).

6.1 Determining of thickness x of distance ring 33 (Fig. M)

Push ball bearing 32a, distance sleeve 34, ball bearing 32 and distance ring

31 onto the shaft 5 according to Fig. N.

Attention! Big collar SU on inner ring of the ball bearings must point outwards!

Screw shaft nut 27 onto shaft 5 and lightly tighten it by means of hook spanner

94925.

Measure and note down distance a.

008.741/01

008.740/01

Measure and note down distance b in housing 14.

According to the following formula determine thickness

x for distance ring 33 to be fitted:

Tolerance x amounts to " 0.2 mm.

O

b

14

x = a b 4.2 mm

N

32 34 32a 31 27 5

a

SU 38 SU

2008

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

Maintenance 92231/A1

RTA82C

Wrtsil Switzerland Ltd 11/ 18

008.744/01

008.744/01

008.743/01

008.742/01

6.2 Sub-assembly of bearing housing

Remove the parts which are fitted on shaft 5

as shown in Fig. N.

Oil ball bearing 32a and insert it into housing

14. Pay attention to the fitting position in

paragraph 6.1!

Place disc 37 with its smaller seating surface

pointing to the ball bearing and fit circlip 36.

6.3 Completing of the bearing housing

Oil all parts.

Fit shaft 5.

Push distance sleeve 34 onto the shaft.

Fit disc springs 35 according to view I.

Fit distance ring 33 with thickness x determined under paragraph 6.1.

Oil ball bearing 32 and insert it into housing 14. Pay attention to the fitting

position in paragraph 6.1!

Fit retaining ring 29 with new sealing ring 30 and O-ring 60 according to view

II.

Fit distance ring 31.

31

30

29

14

33

14

35

II

I

34

60

P

14 32a 37 36

Q

33

35 14 34

31 5

32

I

II

2008

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

Maintenance 92231/A1 RTA82C

Wrtsil Switzerland Ltd 12/ 18

6.4 Tightening the shaft nut

Apply MOLYKOTE paste G to the thread and seating surface of shaft nut 27.

Fit locking plate 26 and screw down shaft nut.

Put torque wrench with socket spanner AF27 on the hexagon of shaft 5 and

tighten the shaft nut with 25 Nm using hook spanner 94925.

Lock shaft nut with locking plate.

Fit circlip 28.

008.738/01

R

5

27 26

28

6.5 Fitting gear wheel 18

Oil bore and push gear wheel 18 onto shaft 5 till the stop.

Apply MOLYKOTE paste G to the thread and seating surface of shaft nut 25.

Fit locking plate 24 and screw down shaft nut 25.

Put torque wrench with socket spanner AF27 on the hexagon of shaft 5 and

tighten the shaft nut with 25 Nm using hook spanner 94924.

008.737/01

S

25

14

58

24

18 5

2008

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

Maintenance 92231/A1

RTA82C

Wrtsil Switzerland Ltd 13/ 18

6.6 Fitting the shaft encoder

For the purpose of improved accessibility the shaft encoders 13 and 13a may be

fitted onto the bearing housing 14 (Fig. S) outside the engine. For that proceed as

described under paragraphs 3.1 and 3.2 with the difference that shaft 5 must be

turned several times by hand in order to adapt it to its running track.

When fitting the toothed belt pay attention to the important points in paragraph 3.3!

7. Fitting the crank angle sensor drive

Push crank angle sensor drive with packing ring 22 a little onto waisted screw

20 and turn shaft 5 in such a way that locating pin 40 and the corresponding

bore in the shaft are in line.

Push crank angle sensor drive further till the locating pin fits into the corre-

sponding bore in shaft 5.

Fasten screws 21 with their locking plates.

Turn crankshaft to an appropriate position.

Remove inspection cover 41 and check through the opening the fitting positions of:

Compression springs 42, lever 43 and connection according to view I.

Apply MOLYKOTE paste G to the thread and seating surface of nut 4.

Screw nut onto waisted screw 20 and tighten it with a torque of 140 Nm.

008.745/01

008.734/01

Attention! When tightening nut 4 hold up shaft 5 by

means of an open end spanner!

Check adjustments according to paragraph 3.3.

7.1 Final works

Carry out final works according to paragraphs

3.4 and 9.1.

T

39

22

21

5

42 23

43

40

41

I

4 20

CHECK

40 43 5 20

44

I

NO CLEARANCE

58

2008

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

CHECK

Maintenance 92231/A1 RTA82C

Wrtsil Switzerland Ltd 14/ 18

8. Removal and fitting of compression spring

008.748/01

008.747/01

008.746/01

U

8.1 Preparation

Remove oil inlet OE (Fig. A).

Dismantle crank angle sensor drive according to

section 4.

Remove screws 47 and housing 46.

Remove screws 48 and connecting unit 49.

Remove screws 44 and withdraw waisted screw 20

from the lever 43.

47 46

20

43

40

50

48a

48

51 44

I - I

V

I

I

43

44

51 48

50

49

20

2008

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

Maintenance 92231/A1

RTA82C

Wrtsil Switzerland Ltd 15/ 18

008.751/01

008.750/01

008.749/01

8.2 Removing the compression spring

Loosen screws 53 and remove them together with

spring tensioner 52.

Remove and check compression springs.

Remark: When replacing only one compression spring

42, it is recommend to remove also the second spring

tensioner for carrying out further adjustments.

Check spring seating surface for wear.

X

I

x

54

55

52

54 52

W

I

53 52 51 54

55

42

57

FITTING

POSITION

8.3 Fitting of the lever

When fitting lever 43 pay attention to its fitting position (Fig. W).

Replace locking plates to screws 57.

Apply MOLYKOTE paste G to threads and seating surfaces of screws 57.

Tighten screws 57 with a torque of 60 Nm and lock them.

8.4 Fitting the compression spring

Loosen clamp screws 55 of spring tensioner

52 (Fig. W). Replace locking plates. Apply

MOLYKOTE paste G to threads and seating

surfaces of screws 55 and refit them.

Oil and adjust all adjusting screws 54 to

x = 10 " 0.10 mm (Fig. X).

Insert compression springs 42, fit spring ten-

sioner with screws 53 and new locking plates,

applying MOLYKOTE paste G to threads and

seating surfaces.

Tighten screws 53 with a torque of 60 Nm and

lock them.

CHECK

2008

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

Maintenance 92231/A1 RTA82C

Wrtsil Switzerland Ltd 16/ 18

8.5 Adjusting the compression spring

By means of synchronously adjusting screws 54 (i.e. if one of the adjusting

screws is screwed-in by e.g. turn, the opposite one must be screwed-out by

turn) move the relevant compression spring pair 42 until lever 43 shows the

same distance x between the stops on both sides (centering lever).

For measuring use feeler gauge 94122.

Tighten all clamp screws 55 with a torque of 35 Nm and lock them.

008.752/01

008.749/01

Y

II

II

II - II

42

55

43 56

x

x

54

40

50

8.6 Fitting the connecting unit (Fig. V)

Fit waisted screw 20 and screw 44 with new locking plates. Tighten and lock

the latter (Fig. T view I).

Remark: Screw 44 must not press against waisted screw 20!

Fit connecting unit 49 and screws 48 together with new locking plates 48a,

applying MOLYKOTE paste G to threads and seating surfaces.

Tighten screws 48 with a torque of 60 Nm and lock them.

Locating pin 40 and locating pin 50 must point upwards on cylinder No. 1 at T.D.C.

according to Fig. V and Y!

2008

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

CHECK

Maintenance 92231/A1

RTA82C

Wrtsil Switzerland Ltd 17/ 18

8.7 Final fitting the crank angle sensor unit

Fit housing 46 with joint and fasten with screws 47 (Fig. U).

Fitting of the crank angle sensor drive according to section 7.

Carry out final works according to paragraphs 3.4 and 9.1.

9. Checks

The periodical checks must be carried out according to Maintenance Schedule

03801 Crank angle sensor unit.

9.1 Lubricating oil flow in the crank angle sensor drive

Start main lubricating oil pump and adjust bearing oil pressure.

Remove inspection cover 41.

Turn crankshaft till the two oil outlets are good visible (view I-I).

With correct oil flow at operating temperature an oil spray results according to Fig.

A

1

. However, the oil outlets should be filled up.

Refit inspection cover 41.

008.754/01

008.753/01

008.725/00

Z

OIL SPRAY

41

I

I

A

1

OIL OUTLET

I - I

2008

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

Maintenance 92231/A1 RTA82C

Wrtsil Switzerland Ltd 18/ 18

9.2 Checking the throttle

Before reaching the crank angle sensor unit, the oil flows first through throttle 45,

which reduces the oil quantity and also keeps back larger oil particles.

Checking the throttle is carried out as follows:

Stop main lubricating pump.

Remove oil inlet OE from the throttle.

Unscrew throttle and check its oil spray holes for free passage. Clean if nec-

essary.

Reinstall all parts.

008.724/00

008.756/01

008.755/01

I

II - II

II

II

OIL INLET

45

I

B

1

OE

2008

Crank Angle Sensor Unit: Dismantling, Assembling and Adjusting

You might also like

- Electrical Work PermitDocument1 pageElectrical Work PermitGaby Cris50% (2)

- 2002 Nissan Altima 2.5 Timing Chain MarksDocument16 pages2002 Nissan Altima 2.5 Timing Chain MarksInternal88100% (1)

- WSM 0000003 01Document52 pagesWSM 0000003 01Anderson Bombista90% (10)

- Volvo Penta Workshop Manual Part BDocument60 pagesVolvo Penta Workshop Manual Part BMišo Vučko100% (1)

- RT-flex82 WECS-9520 Control Rev.00Document60 pagesRT-flex82 WECS-9520 Control Rev.00Gaby CrisNo ratings yet

- ManualDocument4 pagesManualMano Negra100% (1)

- Clutch: SectionDocument22 pagesClutch: SectionMatea Virgil SorinNo ratings yet

- SNOW BLADE (Standard) (60'' 6107) (72'' 2231) (84'' 6836) (96'' 6838)Document4 pagesSNOW BLADE (Standard) (60'' 6107) (72'' 2231) (84'' 6836) (96'' 6838)PetarbrateNo ratings yet

- Enviando - VDOPS Manual NEW - 2 GPM Through 100 GPM (Rev. 3-27-15) PDFDocument28 pagesEnviando - VDOPS Manual NEW - 2 GPM Through 100 GPM (Rev. 3-27-15) PDFcarlosorizabaNo ratings yet

- Genie GS-2668/3268 RT Parts ManualDocument238 pagesGenie GS-2668/3268 RT Parts ManualAnonymous Pk3VzhXUGBNo ratings yet

- Remo TBDocument5 pagesRemo TBTyler MacNo ratings yet

- Toyota Celica GT L4 1.8L 1ZZ FEDocument21 pagesToyota Celica GT L4 1.8L 1ZZ FEWolfgang WilliamsNo ratings yet

- Toyota Truck RAV4 2WD L4-2.0L (1AZ-FE) 2002: Timing Chain: Service and RepairDocument15 pagesToyota Truck RAV4 2WD L4-2.0L (1AZ-FE) 2002: Timing Chain: Service and RepairyosnielNo ratings yet

- Https 127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print PageDocument9 pagesHttps 127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print Pagep.motortechNo ratings yet

- Cambio Arbol de LevasDocument12 pagesCambio Arbol de LevasgenaroNo ratings yet

- Toyota Celica l4 2.2l Dohc 5s Fe 1990Document16 pagesToyota Celica l4 2.2l Dohc 5s Fe 1990ORLANDO0301No ratings yet

- Removing and Installing Camshafts and Camshaft Adjuster - Cylinder Head (Left Side)Document7 pagesRemoving and Installing Camshafts and Camshaft Adjuster - Cylinder Head (Left Side)Julien VasilevNo ratings yet

- 2001 Toyota Prius L4-1.5L (1NZ-FXE) Hybrid: Timing Chain: Service and RepairDocument13 pages2001 Toyota Prius L4-1.5L (1NZ-FXE) Hybrid: Timing Chain: Service and Repairfernando ortizNo ratings yet

- Toyota MR2 Spyder L4-1.8L (1ZZ-FE) 2001: Timing Chain: Service and RepairDocument18 pagesToyota MR2 Spyder L4-1.8L (1ZZ-FE) 2001: Timing Chain: Service and RepairROSA GIMENEZNo ratings yet

- Toyota Celica ST Sport Coupe L4 1.8L DOHC MFI 1997Document11 pagesToyota Celica ST Sport Coupe L4 1.8L DOHC MFI 1997carlos martinezNo ratings yet

- Removing and Installing Camshafts and Camshaft Adjuster - Cylinder Head (Right Side)Document7 pagesRemoving and Installing Camshafts and Camshaft Adjuster - Cylinder Head (Right Side)Julien VasilevNo ratings yet

- Volvo D13H Shop Armed Vol2Document34 pagesVolvo D13H Shop Armed Vol2Juan José AldanaNo ratings yet

- Toyota Truck SequoiaDocument16 pagesToyota Truck SequoiaD3NYNo ratings yet

- VR-Vs V8 Distributor Remove-ReplaceDocument7 pagesVR-Vs V8 Distributor Remove-ReplaceJames MirfinNo ratings yet

- Axial Detuner MaintenanceDocument5 pagesAxial Detuner MaintenanceKarthik ReddiarNo ratings yet

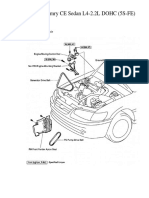

- Toyota Camry CE Sedan L4-2.2L DOHC (5S-FE) MFI 2001: Timing Belt: Service and RepairDocument17 pagesToyota Camry CE Sedan L4-2.2L DOHC (5S-FE) MFI 2001: Timing Belt: Service and RepairWenceslao Francisco Mejía EspinozaNo ratings yet

- Removing and Installing Toothed BeltDocument12 pagesRemoving and Installing Toothed BeltJulien VasilevNo ratings yet

- Toyota Truck Highlander 2WD L4-2.4L (2AZ-FE) 2002: Timing Chain: Service and RepairDocument14 pagesToyota Truck Highlander 2WD L4-2.4L (2AZ-FE) 2002: Timing Chain: Service and RepairOscar jhonyffer Pereda RiscoNo ratings yet

- Toyota Tundra (2UZ FE) 2002Document16 pagesToyota Tundra (2UZ FE) 2002Isaac Castillo100% (1)

- Convertidor de Torque D5BDocument13 pagesConvertidor de Torque D5BDeyner PerezNo ratings yet

- Cluth k2 ReconditioningDocument16 pagesCluth k2 ReconditioningPetrus Kanisius WiratnoNo ratings yet

- Toyota Truck Tacoma 2002Document17 pagesToyota Truck Tacoma 2002FlorentinoChoquehuancaNo ratings yet

- Acura TSX Sport Wagon L4-2.4L 2011 Timing Chain: Service and RepairDocument11 pagesAcura TSX Sport Wagon L4-2.4L 2011 Timing Chain: Service and RepairCarlos Gunter Tamayo MoralesNo ratings yet

- ZF 2Document49 pagesZF 2Silvio Roman100% (2)

- Ac Compressor ServicingDocument25 pagesAc Compressor Servicingsonny1234100% (1)

- Toyota Camry LE Sedan V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairDocument14 pagesToyota Camry LE Sedan V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairEutério SilvaNo ratings yet

- Sis 2.0Document32 pagesSis 2.0Edgar Eli Carmona Zocón100% (1)

- Mangueta de Dirección Del Eje Delantero Con Frenos y RótulaDocument5 pagesMangueta de Dirección Del Eje Delantero Con Frenos y RótulaLuis Jose Molina GarciaNo ratings yet

- RZT ServiceDocument30 pagesRZT ServiceFloyd SellersNo ratings yet

- Toyota Avalon XL V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairDocument15 pagesToyota Avalon XL V6-3.0L (1MZ-FE) 2001: Timing Belt: Service and RepairFrancisco Guillen-DorantesNo ratings yet

- Corolla 1ZZFE Valve Seal ReplacementDocument11 pagesCorolla 1ZZFE Valve Seal ReplacementAlan Dell SnyderNo ratings yet

- Timing Chain: Service and Repair Acura TSX 2.4 L4 2008Document10 pagesTiming Chain: Service and Repair Acura TSX 2.4 L4 2008Carlos Gunter Tamayo MoralesNo ratings yet

- Mercedes - 220 - Workshop Manual - 1994 - 1995 - 2Document13,111 pagesMercedes - 220 - Workshop Manual - 1994 - 1995 - 2Juan Harmond Bambang WirawanNo ratings yet

- Cadenas de Tiempo Pontiac G5Document17 pagesCadenas de Tiempo Pontiac G5Jorge Antonio GuillenNo ratings yet

- 10 - Timing Chain - InstallationDocument7 pages10 - Timing Chain - Installation08088338No ratings yet

- Pto Volvo A35Document8 pagesPto Volvo A35FilipposNo ratings yet

- 12M Montagem Freio de ServiçoDocument10 pages12M Montagem Freio de ServiçoPaulo_GleriaNo ratings yet

- Inst Cylinder HeadDocument8 pagesInst Cylinder Headmanuel1357100% (1)

- Cat 3176c Montagem Da Cabeça.Document7 pagesCat 3176c Montagem Da Cabeça.César PérezNo ratings yet

- Sti Timing Belt InstructionsDocument19 pagesSti Timing Belt InstructionsPablo DpNo ratings yet

- Transmission Planetary - Disassemble: Disassembly and AssemblyDocument23 pagesTransmission Planetary - Disassemble: Disassembly and AssemblyMbahdiro KolenxNo ratings yet

- Toyota Matrix L4 2008Document16 pagesToyota Matrix L4 2008Gesco EscobarNo ratings yet

- Service Bulletin: ProductionDocument11 pagesService Bulletin: ProductionVictor PinedoNo ratings yet

- (TM) Toyota Manual de Motor Toyota Yaris Verso 2001 en InglesDocument11 pages(TM) Toyota Manual de Motor Toyota Yaris Verso 2001 en Inglesjonathan matusNo ratings yet

- 001 - Valvuals, AjustarDocument6 pages001 - Valvuals, AjustarAparecidaMarquesNo ratings yet

- Engine PDFDocument19 pagesEngine PDFRojascometNo ratings yet

- Engine (WL, WL Turbo, WL-3, WLT-3) : Drive BeltDocument16 pagesEngine (WL, WL Turbo, WL-3, WLT-3) : Drive Beltpavel35No ratings yet

- Wheelhorse Snow Attachments ManualsDocument35 pagesWheelhorse Snow Attachments ManualsKevins Small Engine and Tractor Service100% (10)

- Front AxleDocument63 pagesFront AxleGreg HannaNo ratings yet

- Bevel and Transfer Gears - AssembleDocument14 pagesBevel and Transfer Gears - AssembleIginio Malaver VargasNo ratings yet

- Front Axle: SectionDocument24 pagesFront Axle: SectionMihai IavorschiNo ratings yet

- File 94catalogo SumitomoDocument28 pagesFile 94catalogo SumitomoJaime Arreola100% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- RT FlexDocument3 pagesRT FlexGaby CrisNo ratings yet

- Service Bulletin RTA-43.3 RT-flex-05Document12 pagesService Bulletin RTA-43.3 RT-flex-05Gaby CrisNo ratings yet

- SL - RT-01!06!27.01.2006 - Catalytic Fines and Separation EfficiencyDocument4 pagesSL - RT-01!06!27.01.2006 - Catalytic Fines and Separation EfficiencyGaby CrisNo ratings yet

- Service Bulletin RTA-43.3 RT-flex-05Document12 pagesService Bulletin RTA-43.3 RT-flex-05Gaby CrisNo ratings yet

- RT-flex82 Flexview-9520 Rev.00Document64 pagesRT-flex82 Flexview-9520 Rev.00Gaby Cris100% (2)

- AE Parameter ListDocument1 pageAE Parameter ListGaby CrisNo ratings yet

- Aqua Signal EXXDocument1 pageAqua Signal EXXGaby CrisNo ratings yet

- The Technical Data Will Convince You!: SpecificationDocument3 pagesThe Technical Data Will Convince You!: SpecificationGaby CrisNo ratings yet

- Electrical Engineering IIIDocument60 pagesElectrical Engineering IIIGaby CrisNo ratings yet

- AE Fuel Pump OverhaulDocument3 pagesAE Fuel Pump OverhaulGaby CrisNo ratings yet

- SECTION 0 1-02 Body Panels-Front End: Vehicle ApplicationDocument14 pagesSECTION 0 1-02 Body Panels-Front End: Vehicle ApplicationKyra EleisonNo ratings yet

- PWD SR Book 2015-16Document475 pagesPWD SR Book 2015-16Harish Kumar MahavarNo ratings yet

- Open Terrain System Sigma I: Installation ManualDocument13 pagesOpen Terrain System Sigma I: Installation ManualMurat ToygarNo ratings yet

- CCI C330 Positioner ManualDocument37 pagesCCI C330 Positioner ManualInstrumentacion CotinavecNo ratings yet

- Mechanical Drives 1 Lap 3Document77 pagesMechanical Drives 1 Lap 3j.bbarnesNo ratings yet

- Rep 24Document330 pagesRep 24ArturNo ratings yet

- Flat Washers Standard MetricDocument4 pagesFlat Washers Standard MetricsivaNo ratings yet

- Building Technology 2 Answer KeyDocument4 pagesBuilding Technology 2 Answer KeyFlorisel Joy AntoniNo ratings yet

- POWERPACKDocument31 pagesPOWERPACKcristianNo ratings yet

- GP 7 Series Two Post Lift Manual 5900209 BendPakDocument84 pagesGP 7 Series Two Post Lift Manual 5900209 BendPakLê Xuân SangNo ratings yet

- Despiece Batidora Globe SP8Document14 pagesDespiece Batidora Globe SP8Victor Hugo Quiñonez QuintanaNo ratings yet

- H 231Document18 pagesH 231EdirwinJoseChirinosNo ratings yet

- Trex Telley HandlerDocument156 pagesTrex Telley HandlerMilesNMoreNo ratings yet

- 14'' BANDSAW Instruction Manual: MODEL G1019Document48 pages14'' BANDSAW Instruction Manual: MODEL G1019godhybridNo ratings yet

- SERVICE MANUAL. Permobil C500. Power WheelchairDocument68 pagesSERVICE MANUAL. Permobil C500. Power Wheelchairwilson de jesus mirandaNo ratings yet

- Vmax 2007Document92 pagesVmax 2007DiegoFonsecaNo ratings yet

- Bobcat 963 Skid Steer Loader Master Illustrated Parts List Manual Book G SeriesDocument409 pagesBobcat 963 Skid Steer Loader Master Illustrated Parts List Manual Book G Seriesjakecall73% (11)

- Pioneers in Welding Manipulation and Automation in IndiaDocument23 pagesPioneers in Welding Manipulation and Automation in IndiaKathir VelNo ratings yet

- InspireYourBusiness Bro-00253 EN PDFDocument32 pagesInspireYourBusiness Bro-00253 EN PDFAravind VishweshwaraNo ratings yet

- Analysis of LGS - Ferrocement Composite Construction Technology As A Cost-Effective & Sustainable Alternative To RCCDocument8 pagesAnalysis of LGS - Ferrocement Composite Construction Technology As A Cost-Effective & Sustainable Alternative To RCCErnandes Macêdo PaivaNo ratings yet

- RCP - Canteen Building - OTS - Structure-BOQ - 26 - 6 - 20Document31 pagesRCP - Canteen Building - OTS - Structure-BOQ - 26 - 6 - 20Bhavanishankar shettyNo ratings yet

- Ludhiana Industries-658Document100 pagesLudhiana Industries-658maxisinc.inNo ratings yet

- Columbus - Catalogo Geral 2013Document116 pagesColumbus - Catalogo Geral 2013Marco ViniciusNo ratings yet

- 330CL UhdDocument40 pages330CL UhdFgaier AhmedNo ratings yet

- K 604192 - 11 - Varidor 30AP C2 PDFDocument61 pagesK 604192 - 11 - Varidor 30AP C2 PDFTaufik Hidayat KurniansyahNo ratings yet

- Element of CNC MachinesDocument63 pagesElement of CNC MachinesmahavircNo ratings yet