Professional Documents

Culture Documents

Tutorial Chemsep

Uploaded by

Eduardo Camarena Sullca0 ratings0% found this document useful (0 votes)

157 views4 pagesTutorial Chemsep

Tutorial Chemsep

Tutorial Chemsep

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTutorial Chemsep

Tutorial Chemsep

Tutorial Chemsep

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

157 views4 pagesTutorial Chemsep

Uploaded by

Eduardo Camarena SullcaTutorial Chemsep

Tutorial Chemsep

Tutorial Chemsep

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

i-

ChemSep Tutorial: Extraction

-

Ross Taylor and Harry Kooijman

Here we consider the modeling of an extraction column using ChemSep. This tutorial is derived

from Exercise 10,43 in Separation Process Principles (2^d Edition) by J.D. Seader and E.J. Henley

(Wiley,2006).

Tutorial 1: Setting up a Simple Extractor

Ethyl Acetate is to be used as the solvent in an extraction process to recover acetic acid from a

blnary liquid mixture that is predominantly water. The exercise calls for us to determine the number

of equilibrium stages needed to recover 99.5% of the acetic acid in the feed. ln Exercise 10.43

Seader and Henley refer back to Figure 8.1 (on page 296) where a flowsheet for the entire

extraction process is shown (with considerable accompanying discussion). The component flow

rates into and from the extraction column to be used in this example are taken from Figure 8.1 and

summarized in Table 1.

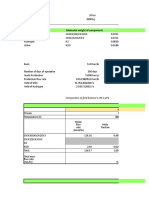

Table 1: Extractor Stream Flows: Feed Specifications and Products

Stream

Stage

Pressure (psia)

Light phase fraction

Temperature (oF)

Mass Flows (lb/h)

EthylAcetate

Water

Acetic Acid

Feed Solvent Etract Raffinate

1

15

0

100

23,600

6,660

10

15

1

100

68,600

2,500

1 921

1252

1

'15

1

100

67,112

6,660

6,649

c;\cheroepcd\r 87

c:\chemsep\pcd\t 1 4

c\chmep\pcd\r 48

10

4E

IJ

0

100

1,488

19,440

11

We begin by clicking on the Cornponents Panel and selecting the components that are listed in

Table 1 (the components should be selected in the order in which they appear in Table 1).

shctad comborts,in siRbr

Comprer{}

,+{4

,1

'n.n vl

Next, select the Operation tab and choose Equilibrium Column. Complete the specification of

the column configuration as shown in the screen shot below:

./Comporer*s

,/@

U X Prcptie

X Feeds

E X SPecificatiss

X Besdts

. Urts

,

Sd options

Pths

.rl

0ccration

I

-Sdea Tpc of SimJatron--

---

--.--

,

l. Fhsh

li EquTbimcotm

1'Cdm Cfrguaim*-'

*--:-".-

"

opo.tion,

ffiJiit,iJi-l

Nmbotof stagasle.g. 10J

li6'-

Fecd stasdsl (c.g 5,7)

ljl,

Sibslrean rtagalsl,[as. l9J

f--

-,.,i;:...,1n1ii;;;,i.

r i

f-

i Charpad ;Notmmged

The next step is to select the appropriate ihermodynamic models. The property models selection

and and the interaction parameters are shown in the screen shot below:

'Sdecl

Thamodfmic Modc&

Activity coellbian

EnthaFry

i;;;-=

f howrnthahy/ffie!*tip

r------f

INRTL

-----

IJ

lN*-----

[if---l

xnrr Uds

F-----=

f

r:

,.....,:'i:

jtc.:'|:.s"::

1 65.360

Rogt

I

,^*

|

s*"

I

3m

.30630

1190.r0 0.200m0

EEilozooooo

t.68300 o.zoffno

Bffid inl"reti$ pddam n ttx-tatrtd

Seader and Henley provide parameters for the NRTL activity coeffcient model.*

*The

units for the parameters are not provided so we have guessed that the f rst two parameters on each row are in K (simply because

that is the unit used most often for reporting liquidJiquid parameters. When we solve this problem we will find that this choice was

correct

-

an incorrect choice would lead to ridiculous answers or no solution at all.

F

The ext step is to provide the details of the two feeds. Click on the Feeds line and complete the

feeds panel

so that it appears as it does in the screen shot below:

-Faed Strea{sJ Spe

----- *

-

---T

,,ry1-r.,1,

lqy:,.l

,Jffi

.

I

Entl

llp

gglais-of cach fagd dr.-E_aTl

It is important to note that we have entered the feeds in mass units (because the problem

specification by Seader and Henley provided the stream data in mass units). Note also that the

default names of the feed streams have been changed.

For liquid-liquid systems we must choose the light phase fraction (rather than the vapor fraetion

that could be specified for gas/vapor-liquid

systems). The feed to the top of the column (stage 1)

musf have a light phase fraction of zero (in order to force it to flow down the column) and the feed

to the boom of the column must have a light phase of one (in order to force it to flow up the

column).

The column pressure is set to 15 psia:

!{qoo.u"

,,,.. E .

l;eeryy1" :, :

.'

.r.,ilE-00--..fnse1,'

The column specifications are completed by setting the heat losses to zero and the default

efficienry to one. There are no Column Spefications as such, we do however, rename the lop and

Bottom product streams as Extract and Raffinafe respectively.

Prior to solving the problem it is wise to check the Solve Options panel, the upper part of which

should look like this:

000000 68600.0

'r

25@.00

99 0 omm

Ne$mdep

Fbw ]i0000

-

lma

[1noar*we

8m6-

'

Corpositim

[fuoo-

Flux

limo--

(-)

IoF)

t.l

{-}

The next step is to save the file (using the File menu

-

note that the file name will appear on the

blue bar at the top of the ChemSep window).

zF\-\

Click on the green arrow head icon to start the calculations. This will bring up the solve window:

Acetic acid

fecd condfions

irtiC flow Profihs

initial cqlposilim rolils

milisaconds

Newlons mthod

will trrmin6tc e(acon

Enor

0

1

2

3

4

5

6

7

70 rhecords

divcr done

aded

click on Done to close the window and bring up the results panel.

Edt SdY! [nafab:

.Prr**s H+

2.9522E+08

4.SS2E.01

5.6653E.01

- 7.7288E.01

1.6873E.01

1.97,78{.2

1.8620E-04

2.47m.-O8

obtained in 7 lerdim

y'Spacirctiom

:

' y'

Analysis

i

:y'Prsures

i

y'Huters/Cmkrsr

l/ Etficencia

:i y'

column speclici

./Themodynmic'i

/

Physic.l prcpeil:

y'

Beactitms

:

/ raed

\/ Tirb

:y'Comporants

'

y''Operation

Li rf

Propstes

|1

y'Results

@

'

Graphs

Hng

Urits

S olve options

Paths

Stncil

St!Ee

Pressurc

(psi a)

LiOirt

phase frction (-)

Temperture

(oF)

{o1c florr (1brc]/h)

Ettyl acetate

hat er

cetic acid

Total rc'lar flow

i'lo1e f ractions (-)

Etlryl acetate

I'lat er

accti c aci d

Mass flom (1blh)

Ethyl cetat.

llat.r

Aceti c ci d

Totai mss f low

l{-Iffi- l

:

' , Sc"dt"H"

lsr.*r

vl

xL I .Edrt I

CoPY

Fr

I ,Prr{l

--J

--l

:

Raffi nat

10

15.OOOO

0.000000

100.m2

16. 8194

107A.75

0,00335030

1095.58

0,or5351

o.98/.64.5

, .05 EOE-06

1481.89

1943!.8

0, ?o1195

20915 . B

Ferd

a

t4 .6959

0.000000

100.000

o, ooo000

1t10.02

r10. 902

L4ZO,92

0. oo0000

0. 9195 1

0.07804 91

0.000000

2t 500.0

66s9.99

30260,0

5o]vert Extract

10 1

14.6959 15.OOOO

1.00000 0,000000

100.000 99-9678

778,608 76L.7eB

738.773 370,O41

0.000000 110.899

917.180 L24?.73

o.84e729 0.612997

0.151271 0.297765

0.000000 0.0892380

68600.0 67118.1

2500,00 6666.30

0,000000 6659.79

71100.0 ao444.Z

!.

I Saed

Cmvaged

\S ep-Files\S tandadT et\LlX\S eaderl 43.sep

lf we compare the mass flows shown here with those in Table 1 we will see that we have

recovered more than the 99.5% of the ac;tic acid

present in the Feed stream. WeFffilb'as an

exercise for readers to determine how many stages are, in fact, necessary to recovef 98.5%.

l'q

i

a:

_ (:t

You might also like

- Modeling and Simulation Study of The CSTR For Complex Reation Usong POLYMATHDocument7 pagesModeling and Simulation Study of The CSTR For Complex Reation Usong POLYMATHtocinopNo ratings yet

- International Thermodynamic Tables of the Fluid State: Propylene (Propene)From EverandInternational Thermodynamic Tables of the Fluid State: Propylene (Propene)No ratings yet

- Sieve Tray ColumnDocument18 pagesSieve Tray ColumnDonsius MarbunNo ratings yet

- Chapter 1 PDFDocument74 pagesChapter 1 PDFLi Tan100% (1)

- SITI SOLEHAH BINTI OMAR (2015834112) /EH224 7A1 Heuristics of ReactorDocument2 pagesSITI SOLEHAH BINTI OMAR (2015834112) /EH224 7A1 Heuristics of ReactorSolehah OmarNo ratings yet

- 8 3 Packed Bed ReactorsDocument20 pages8 3 Packed Bed ReactorsridhajamelNo ratings yet

- Material Balance of Styrene Production PDocument12 pagesMaterial Balance of Styrene Production PSteve WanNo ratings yet

- Group 1 Mass & Energy BalanceDocument98 pagesGroup 1 Mass & Energy BalanceDianah NajeebNo ratings yet

- Catalysis and Catalytic ReactorsDocument7 pagesCatalysis and Catalytic ReactorsEmanoel FrazãoNo ratings yet

- Answers For Tutorial 23Document11 pagesAnswers For Tutorial 23Thurgah VshinyNo ratings yet

- 6.multiple ReactionsDocument22 pages6.multiple ReactionsFarah Talib Al-sudaniNo ratings yet

- Modeling and Simulation of CSTR For Manufacture of Propylene GlycolDocument6 pagesModeling and Simulation of CSTR For Manufacture of Propylene Glycolantoojacome100% (1)

- Lab Report Cstr-Intro Appa ProceDocument6 pagesLab Report Cstr-Intro Appa Procesolehah misniNo ratings yet

- Lecture 6Document48 pagesLecture 6tkjingNo ratings yet

- Notes5 Simple ReactorsDocument40 pagesNotes5 Simple ReactorsstorkjjNo ratings yet

- ChE422 Topic 8Document40 pagesChE422 Topic 8Elle EmmNo ratings yet

- Recycle. Process EngineeringDocument20 pagesRecycle. Process EngineeringDarel WilliamsNo ratings yet

- 8.3 - Packed-Bed ReactorsDocument20 pages8.3 - Packed-Bed ReactorscarolinacmleiteNo ratings yet

- Cassava FAO I9181EN PDFDocument296 pagesCassava FAO I9181EN PDFgiambi-1No ratings yet

- Chapter 9 ChE 126Document94 pagesChapter 9 ChE 126Roque LeccioNo ratings yet

- Advanced Polymer TechnologyDocument4 pagesAdvanced Polymer Technologykhoa chauNo ratings yet

- MembranasDocument69 pagesMembranasCristina SilvaNo ratings yet

- Tutorial For Chapter 23Document9 pagesTutorial For Chapter 23Thurgah VshinyNo ratings yet

- 1 - PBRDocument26 pages1 - PBRAgithaNo ratings yet

- Assignment 2Document25 pagesAssignment 2Ahmet Samet ÖzdilekNo ratings yet

- CHE3044F, 2013: Reactor Design 1: TUTORIAL 6Document4 pagesCHE3044F, 2013: Reactor Design 1: TUTORIAL 6nmhatityeNo ratings yet

- Homework 1Document9 pagesHomework 1AgithaNo ratings yet

- Lecture 9 - Collection and Analysis of Rate DataDocument13 pagesLecture 9 - Collection and Analysis of Rate DataSabrina AzharNo ratings yet

- Set8ans 10Document5 pagesSet8ans 10Agustina Evania DewiNo ratings yet

- Rate LawsDocument19 pagesRate LawsEli BerkowitzNo ratings yet

- Design of Fixed Bed Adsorption Columns: CENG 4710 Environmental ControlDocument17 pagesDesign of Fixed Bed Adsorption Columns: CENG 4710 Environmental ControlchetanNo ratings yet

- Pressure DropDocument42 pagesPressure DropSói Con100% (1)

- Lab 4 SimulationDocument8 pagesLab 4 SimulationaziziNo ratings yet

- Introduction To Gas-Solid Fluidized Bed ReactorsDocument69 pagesIntroduction To Gas-Solid Fluidized Bed ReactorsCandraNo ratings yet

- Chapter 6Document41 pagesChapter 6Hotib PerwiraNo ratings yet

- Tutorial Questions On Heat Ex ChangersDocument3 pagesTutorial Questions On Heat Ex ChangersPuneet Garg100% (1)

- Chemical Reaction Engineering10 - 2010Document33 pagesChemical Reaction Engineering10 - 2010Ingrid Claudia ElianneNo ratings yet

- Tutorial 1 SolutionDocument3 pagesTutorial 1 Solutionpleco4meNo ratings yet

- Total NH NH NH NH 53306.524011 Q (KW) - 145.23864592945: Energy Balance For ConverterDocument3 pagesTotal NH NH NH NH 53306.524011 Q (KW) - 145.23864592945: Energy Balance For ConverterAhmed Qutb AkmalNo ratings yet

- Curso EMSO 2engDocument48 pagesCurso EMSO 2enghelenoNo ratings yet

- CRE I Assignment - 250919Document11 pagesCRE I Assignment - 250919UpanyaaNo ratings yet

- Report TemplateDocument9 pagesReport Templatedmscott10No ratings yet

- CHME 314 Lecture 11 Isothermal Reactor Design 2Document28 pagesCHME 314 Lecture 11 Isothermal Reactor Design 2AmroKashtNo ratings yet

- 3K4 2013 Assignment 2 SolutionsDocument9 pages3K4 2013 Assignment 2 SolutionsKhalil LasferNo ratings yet

- Heat Ingeration of ReactorsDocument29 pagesHeat Ingeration of ReactorsSharmimi RazakNo ratings yet

- Adiabatic FBR DesignDocument10 pagesAdiabatic FBR DesignRana UzairNo ratings yet

- 04 Distillation SequencingDocument36 pages04 Distillation SequencingHasnin ArifianiNo ratings yet

- Non Ideal ReactorsDocument17 pagesNon Ideal Reactorserjayenv7346No ratings yet

- Tutorial 4 - AdsorptionDocument3 pagesTutorial 4 - AdsorptionDinesh Kumar VijeyanNo ratings yet

- Heat Ingeration of Distillation ColumnsDocument36 pagesHeat Ingeration of Distillation ColumnsNorzaifee NizamudinNo ratings yet

- Solutions For Reactor KineticsDocument2 pagesSolutions For Reactor Kineticszy_yfNo ratings yet

- CHE3164 Assignment 1 2016 - Rev 2Document3 pagesCHE3164 Assignment 1 2016 - Rev 2Mashroof AhmedNo ratings yet

- 3K4 2013 Assignment 2 Solutions PDFDocument9 pages3K4 2013 Assignment 2 Solutions PDFHanjin SeoNo ratings yet

- 10 PDFDocument23 pages10 PDFTysir SarhanNo ratings yet

- Developing and Using Stio Tables NotesDocument27 pagesDeveloping and Using Stio Tables NotesThabangNo ratings yet

- Smit Ds Chapter 2Document29 pagesSmit Ds Chapter 2alinoriNo ratings yet

- Acid Digestion ProcedureDocument2 pagesAcid Digestion ProcedureSolehah OmarNo ratings yet

- Chapter 3 ConSol PPT by E.cusslerDocument39 pagesChapter 3 ConSol PPT by E.cusslerheena_scottNo ratings yet

- CRE AssignmentDocument5 pagesCRE AssignmentKuldeepChoudharyNo ratings yet

- Main CharacterDocument5 pagesMain CharacterFluffy RabbitNo ratings yet

- Articles On Philippine Obligation and ContractsDocument114 pagesArticles On Philippine Obligation and ContractsKriz Batoto100% (1)

- Out To Lunch: © This Worksheet Is FromDocument1 pageOut To Lunch: © This Worksheet Is FromResian Garalde BiscoNo ratings yet

- Old Book Buy or SellDocument41 pagesOld Book Buy or SellPallavi Pallu50% (4)

- FICCI-BCG Report On Railway Station RedevelopmentDocument47 pagesFICCI-BCG Report On Railway Station RedevelopmentRahul MehrotraNo ratings yet

- Traverse AdjustmentDocument22 pagesTraverse AdjustmenthabteNo ratings yet

- Apollo Hospital Chennai: NO: 16, BSNL TELESHOPPE, Greams Road 044 2999 1606Document9 pagesApollo Hospital Chennai: NO: 16, BSNL TELESHOPPE, Greams Road 044 2999 1606Manas ChandaNo ratings yet

- Dolphin Is An a-WPS OfficeDocument3 pagesDolphin Is An a-WPS Officeinova ilhamiNo ratings yet

- Unit 5 Performance ManagementDocument20 pagesUnit 5 Performance Managementbhavisha_30kNo ratings yet

- Monthly Film Bulletin: 1T1IcqDocument12 pagesMonthly Film Bulletin: 1T1IcqAlfred_HitzkopfNo ratings yet

- Sleeping GarmentsDocument1 pageSleeping GarmentsRosalie LazaroNo ratings yet

- PI SQC 2015 R3 User GuideDocument50 pagesPI SQC 2015 R3 User Guideislam ahmedNo ratings yet

- Derivative Pakistan PerspectiveDocument99 pagesDerivative Pakistan PerspectiveUrooj KhanNo ratings yet

- Sensitivity Training 2020 ErnieDocument17 pagesSensitivity Training 2020 ErnieNeo MialaNo ratings yet

- Student's Lab Pack: Preteens 02 11 Weeks CourseDocument30 pagesStudent's Lab Pack: Preteens 02 11 Weeks CourseMi KaNo ratings yet

- PDF - 6 - 2852 COMMERCE-w-2022Document13 pagesPDF - 6 - 2852 COMMERCE-w-2022Anurag DwivediNo ratings yet

- Towards (De-) Financialisation: The Role of The State: Ewa KarwowskiDocument27 pagesTowards (De-) Financialisation: The Role of The State: Ewa KarwowskieconstudentNo ratings yet

- Online Book Store System: Bachelor of Computer EngineeringDocument31 pagesOnline Book Store System: Bachelor of Computer Engineeringkalpesh mayekarNo ratings yet

- Introduction To Motor DrivesDocument24 pagesIntroduction To Motor Drivessukhbat sodnomdorjNo ratings yet

- Sustainable Building: Submitted By-Naitik JaiswalDocument17 pagesSustainable Building: Submitted By-Naitik JaiswalNaitik JaiswalNo ratings yet

- The Liberal Welfare Reforms 1906Document5 pagesThe Liberal Welfare Reforms 1906Skye G-sNo ratings yet

- Technical English For Mining (L3)Document21 pagesTechnical English For Mining (L3)Tō Rā YhNo ratings yet

- (Promotion Policy of APDCL) by Debasish Choudhury: RecommendationDocument1 page(Promotion Policy of APDCL) by Debasish Choudhury: RecommendationDebasish ChoudhuryNo ratings yet

- Mps Item Analysis Template TleDocument11 pagesMps Item Analysis Template TleRose Arianne DesalitNo ratings yet

- Birhane, E. 2014. Agroforestry Governance in Ethiopa Report WP 5Document50 pagesBirhane, E. 2014. Agroforestry Governance in Ethiopa Report WP 5woubshetNo ratings yet

- Doanh Nghiep Viet Nam Quang CaoDocument1 pageDoanh Nghiep Viet Nam Quang Caodoanhnghiep100% (1)

- Family Advent Devotions 1Document3 pagesFamily Advent Devotions 1collingdalenazNo ratings yet

- MLOG GX CMXA75 v4.05 322985e0 UM-EN PDFDocument342 pagesMLOG GX CMXA75 v4.05 322985e0 UM-EN PDFGandalf cimarillonNo ratings yet

- The Til Pat YearsDocument1 pageThe Til Pat Yearsrajkumarvpost6508No ratings yet

- Understanding The School Curriculum Close Encounter With The School Curriculum SPARK Your InterestDocument12 pagesUnderstanding The School Curriculum Close Encounter With The School Curriculum SPARK Your InterestJoshua Lander Soquita CadayonaNo ratings yet

- The Fabric of Civilization: How Textiles Made the WorldFrom EverandThe Fabric of Civilization: How Textiles Made the WorldRating: 4.5 out of 5 stars4.5/5 (58)

- The End of Craving: Recovering the Lost Wisdom of Eating WellFrom EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellRating: 4.5 out of 5 stars4.5/5 (82)

- Sully: The Untold Story Behind the Miracle on the HudsonFrom EverandSully: The Untold Story Behind the Miracle on the HudsonRating: 4 out of 5 stars4/5 (103)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- Permaculture for the Rest of Us: Abundant Living on Less than an AcreFrom EverandPermaculture for the Rest of Us: Abundant Living on Less than an AcreRating: 4.5 out of 5 stars4.5/5 (33)

- When the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachFrom EverandWhen the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachRating: 3.5 out of 5 stars3.5/5 (6)

- Hero Found: The Greatest POW Escape of the Vietnam WarFrom EverandHero Found: The Greatest POW Escape of the Vietnam WarRating: 4 out of 5 stars4/5 (19)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureFrom EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureRating: 5 out of 5 stars5/5 (125)

- The Future of Geography: How the Competition in Space Will Change Our WorldFrom EverandThe Future of Geography: How the Competition in Space Will Change Our WorldRating: 4 out of 5 stars4/5 (6)

- Four Battlegrounds: Power in the Age of Artificial IntelligenceFrom EverandFour Battlegrounds: Power in the Age of Artificial IntelligenceRating: 5 out of 5 stars5/5 (5)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaFrom EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo ratings yet

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyFrom EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNo ratings yet

- Pale Blue Dot: A Vision of the Human Future in SpaceFrom EverandPale Blue Dot: A Vision of the Human Future in SpaceRating: 4.5 out of 5 stars4.5/5 (588)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationFrom EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationRating: 4.5 out of 5 stars4.5/5 (46)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Mini Farming: Self-Sufficiency on 1/4 AcreFrom EverandMini Farming: Self-Sufficiency on 1/4 AcreRating: 4 out of 5 stars4/5 (76)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (54)

- The Weather Machine: A Journey Inside the ForecastFrom EverandThe Weather Machine: A Journey Inside the ForecastRating: 3.5 out of 5 stars3.5/5 (31)

- Reality+: Virtual Worlds and the Problems of PhilosophyFrom EverandReality+: Virtual Worlds and the Problems of PhilosophyRating: 4 out of 5 stars4/5 (24)