Professional Documents

Culture Documents

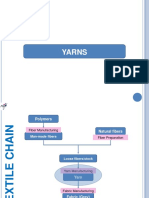

Yarn

Uploaded by

Mohammad HossainOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yarn

Uploaded by

Mohammad HossainCopyright:

Available Formats

Textile Yarn

Yarn

A yarn is an assemblage of fibers that are laid or twisted together to form

a continuous strand.

Yarns may be made from either staple fibers or filament fibers.

The type and length of fiber, the type, ply, and size of yarns, and the

amount of twist given to yarns determine many of the characteristics of

fabrics made from the yarns.

Yarn

Spun Formed by

twisting staple yarn.

filament fibers need

little or no twist to

hold them together

in yarns.

Staple Yarn

Staple fibers are short

fibers measured in inches

or centimeters.

A staple yarn is a strand of

short fibers (typically

several hundred in cross-

section), in which the

lateral coherence is

provided mainly by inter-

fiber friction through

twisting.

Continuous filament

Filament

Filaments are long, continuous fiber strands of indefinite length,

measured in yards or meters.

For a continuous filament yarn the individual fibers may be 1km long and

therefore little or no twisting may be required to provide coherence.

SINGLE, PLY AND CORD YARN

Single Yarns are made from single

filaments or from group of staple

or filament fibers twisted

together to form the desired

yarn. Monofilament,

multifilament and spun yarns are

all single yarns.

Ply Yarns are made by twisting

together two or more single

yarns. Each part of the yarn is

called a ply.

Cord Yarns are ply yarns twisted

together. They are seldom used in

conventional fabrics.

CARDED YARN AND COMBED YARN

Carded yarn: A yarn produced from fibers that have been carded but not

combed.

Carding is a process, which eliminates fibers too short for inclusion in the

spun yarn. The process also removes dirt and foreign matter still

remaining in the fiber mass, and arranges the fibers into a very thin layer.

Combed yarn: Yarn produced from fibers that have been carded (or

prepared) and combed.

The combing process is an additional step beyond carding. In this process

the fibers are arranged in a highly parallel form, and additional short fibers

are removed, producing high quality yarns with excellent strength,

fineness, and uniformity.

Single yarn or Blend yarn

Yarns may be made entirely of one fiber and be classified as such by the

name of the fiber used.

Or yarns may be a blend of two or more fibers the names of which are

included in the description of the yarn.

Blended yarns may be combined or blended in any of these ways:

by mixing staples fibers before they are spun

by combining filament fibers before adding twist

by combining simple yarns of different fiber content into a ply yarn

100% COTTON, PC/TC, CVC & CORE YARN

100% Cotton: The yarn has 100% cotton fiber.

P/C or T/C : (polyester/cotton or Terelyne/cotton): Yarn produced by

blending cotton and polyester fibers

CVC(Chief value cotton): A blended yarn having more percentage of cotton

as compared to that of polyester. For example, Cotton: Polyester 70 : 30

or 60 : 40.

Core yarn: Yarn consisting of a central thread surrounded by staple fibers.

The yarn has the strength and elongation of the central thread whilst

exhibiting most of the other characteristics of the surface staple fibers.

Yarn Characteristics

The basic structural features discussed above collectively

determine the different yarn characteristics that include:

Yarn fineness (count)

Yarn twist

Yarn strength

Yarn evenness and imperfections

hairiness and abrasion resistance

Yarn count

The 'count' of yarn defines its fineness.

Definition given by The Textile Institute says "Count:

A number indicating the mass per unit length or the

length per unit mass of yarn."

Yarn Count: Direct and Indirect

There are two types of counting systems-

Direct system: In a direct yarn counting system the yarn

number or count is the weight of a unit length of yarn.

Example: Tex, Denier (D).

Indirect system: In an indirect system the yarn number or

count is the number of 'units of length' per 'unit of weight'.

Example: English count (N

e

), Metric count (N

m

).

Conversion Factors of Count

From To Formula

Tex Denier 9xtex= Denier

Tex English or cotton count (Ne) 590.5/Tex= Ne

Tex Metric (Nm) 1000/Tex = Nm

Ne Denier 5315/Ne=Denier

Ne Metric (Nm) Ne/0.59=Nm

Twist of yarns

Twisting is the primary binding mechanism of spun yarns.

In general, twist is defined as a measure of spiral

turns given to a yarn in order to hold the constituent fibers together.

The direction of twist influences the appearance of fabric particularly in

twill fabric

Twist direction will also have a great influence on fabric stability,

Twist of yarns

Yarn strength

Yarn strength is considered as one of the main criteria

characterizing yarn quality

During knitting, the yarn is subject to tension, which may reach

levels of more than 30% of the average breaking force of the

yarn.

Yarn evenness and imperfections

hairiness and abrasion resistance

Abrasion is generally defined as the wearing away of any part of the

material by rubbing against another surface.

Yarn hairiness may generally be defined as the extent of hairs protruding

from the yarn body.

Basic Yarn Manufacturing Processes

Blending Opening Carding

Combing Drawing Roving

Spinning

Spinning

Major yarn faults

Contamination (length more

than 20 mm should be nil)

Thickand thin places

Unevenness and periodicity

High hairiness

Neps

Stiff yarn higher TPI

white specs (Immature fibers)

Lower elongation and elasticity

Yarn Faults contributed to the 25% of knitted fabric rejection

You might also like

- Advancements in Garment Manufacturing TechnologyDocument19 pagesAdvancements in Garment Manufacturing TechnologyShanmugeshwari MuthiahNo ratings yet

- Modal FibreDocument10 pagesModal Fibresaran7ran100% (5)

- Yarns Fabric KnowledgeDocument15 pagesYarns Fabric Knowledgeishajain11No ratings yet

- Textile-Yarns Lap FormationDocument21 pagesTextile-Yarns Lap FormationLAXMAN SINGH SANKHLANo ratings yet

- Yarn Spinning For BeginnersDocument5 pagesYarn Spinning For BeginnersSoumen ChowdhuryNo ratings yet

- Classification of YarnDocument28 pagesClassification of YarnSofiane SouNo ratings yet

- YarnsDocument38 pagesYarnsAbhinav VermaNo ratings yet

- 5 Technological Developments in Yarn IndDocument28 pages5 Technological Developments in Yarn Indmahek ajugiaNo ratings yet

- Cotton Spinning Lecture Notes For Students (07 Mart 2011)Document144 pagesCotton Spinning Lecture Notes For Students (07 Mart 2011)Onur ErbasNo ratings yet

- Fiber PropertiesDocument24 pagesFiber Propertiessatheeshpag12367% (3)

- 1 # Introduction: Principles of Fashion Marketing - Yarn SectorDocument22 pages1 # Introduction: Principles of Fashion Marketing - Yarn SectorSeveshNo ratings yet

- Fabric Studies - 2nd SetDocument32 pagesFabric Studies - 2nd SetP. Lakshmanakanth100% (3)

- Cotton - Diff Types of Cotton Fabrics and Its BehaviorDocument58 pagesCotton - Diff Types of Cotton Fabrics and Its BehaviorP. Lakshmanakanth100% (2)

- R101 Lesson 7 Fabrics, Finishes and FurnishingsDocument44 pagesR101 Lesson 7 Fabrics, Finishes and FurnishingsAman KeltaNo ratings yet

- Technical Knitted Fabric StructuresDocument32 pagesTechnical Knitted Fabric StructuresSujit GulhaneNo ratings yet

- 6.crepe WeaveDocument8 pages6.crepe WeaveSwamyi Swami100% (1)

- Factors Affecting Yarn StrengthDocument11 pagesFactors Affecting Yarn StrengthAbhishek ThakurNo ratings yet

- Innovation in YarnDocument6 pagesInnovation in YarnDevendra VashisthNo ratings yet

- Introduction To FabricsDocument10 pagesIntroduction To FabricsP. LakshmanakanthNo ratings yet

- Textile Testing and Product EvaluationDocument64 pagesTextile Testing and Product EvaluationBhaswati PandaNo ratings yet

- Different Types of Knitted FabricsDocument11 pagesDifferent Types of Knitted FabricsDevashish BakshiNo ratings yet

- Seam Classes: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKDocument12 pagesSeam Classes: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKP. Lakshmanakanth100% (2)

- Textile Yarns: Prepared by P.Lakshmana Kanth Senior Faculty - IFTKDocument52 pagesTextile Yarns: Prepared by P.Lakshmana Kanth Senior Faculty - IFTKP. Lakshmanakanth100% (1)

- Fabric Testing - ThicknessDocument5 pagesFabric Testing - ThicknessTarang Mathur100% (1)

- Cotton, Polyester & Cotton Polyester BlendDocument4 pagesCotton, Polyester & Cotton Polyester BlendTanaji Santra100% (1)

- Properties Natural FibresDocument46 pagesProperties Natural FibresanishaNo ratings yet

- Textile Yarns PDFDocument35 pagesTextile Yarns PDFVu Ngo Tuan100% (1)

- ReportDocument45 pagesReportabhijith msNo ratings yet

- Nannu Spinning Mills Limited Quality Control Department: Melange YarnDocument10 pagesNannu Spinning Mills Limited Quality Control Department: Melange YarnAhmed LikhonNo ratings yet

- YarnsDocument27 pagesYarnsnitishkohli75% (4)

- Fabric Supplier Quality & Process Guide: Updated Date: 5-20-2015Document37 pagesFabric Supplier Quality & Process Guide: Updated Date: 5-20-2015Anastasia LovaNo ratings yet

- Commonly Used Finishing Methods On FabricsDocument4 pagesCommonly Used Finishing Methods On FabricsRajesh Dwivedi100% (1)

- Project On Knitted Fabric ParametreDocument58 pagesProject On Knitted Fabric ParametreMozzammal Hossain Shaown100% (3)

- Advanced Nonwoven - Part 4Document47 pagesAdvanced Nonwoven - Part 4vamshi SiddharthNo ratings yet

- Denim: Presented By:-Ashok Kumar Naresh KumarDocument23 pagesDenim: Presented By:-Ashok Kumar Naresh Kumarknishant8No ratings yet

- Fabric Manufacturing StepsDocument15 pagesFabric Manufacturing StepsFazlul AzimNo ratings yet

- Fabric StrengthDocument7 pagesFabric StrengthShailendra MishraNo ratings yet

- Textile TestingDocument20 pagesTextile Testingjayantver67% (3)

- Spinit SystemsDocument21 pagesSpinit SystemsKathirrveluSubramainan100% (1)

- Circular KnittingDocument13 pagesCircular KnittingZahid HossainNo ratings yet

- Training Report of Gcti Tarinees MS WORDDocument55 pagesTraining Report of Gcti Tarinees MS WORDAakash NagpalNo ratings yet

- Denim by WeaveDocument23 pagesDenim by WeaveAbdullah Al HafizNo ratings yet

- New Fibres For Home TextilesDocument4 pagesNew Fibres For Home TextilesVasant KothariNo ratings yet

- Stitch: Methods of Stitch FormationDocument7 pagesStitch: Methods of Stitch FormationM SarfrazNo ratings yet

- General Knitting1Document22 pagesGeneral Knitting1nitishkohliNo ratings yet

- Textile TestingDocument3 pagesTextile TestingLakshmi Challa0% (1)

- Yarn StudentsDocument32 pagesYarn Studentskartika ranaNo ratings yet

- F Ancy Yarn Production: Chapters 2 3Document19 pagesF Ancy Yarn Production: Chapters 2 3TKK-TEXTILE PSG CT100% (1)

- Carpets: BY, Sushma RoyDocument34 pagesCarpets: BY, Sushma Royharshal kushwahNo ratings yet

- Efficiency Losses Calculation and Identify Causes of Losses of Circular Knitting Machine During Knit Fabric ProductionDocument4 pagesEfficiency Losses Calculation and Identify Causes of Losses of Circular Knitting Machine During Knit Fabric ProductionElias KhalilNo ratings yet

- What Is Deference Between Feeder Stripe Knit Fabric With Engeenering Stripe Knit FabricsDocument1 pageWhat Is Deference Between Feeder Stripe Knit Fabric With Engeenering Stripe Knit FabricsMoktar Hossain0% (1)

- Spinning Norms: Prof. R. Chattopadhyay IIT, DelhiDocument39 pagesSpinning Norms: Prof. R. Chattopadhyay IIT, Delhiapi-26494555100% (5)

- Viva Questions and Answers For Garments and Merchandising Job (Part-1) - Textile Learner PDFDocument1 pageViva Questions and Answers For Garments and Merchandising Job (Part-1) - Textile Learner PDFMABVUTO TEMBONo ratings yet

- Determining Fabric Quality: Prepared By: Riza Leigh I. FiguesDocument55 pagesDetermining Fabric Quality: Prepared By: Riza Leigh I. FiguesRizaLeighFiguesNo ratings yet

- Spacer FabricDocument6 pagesSpacer FabricAnonymous 1pZlqV100% (1)

- Advance Fibre and Yarn Testing InstrumentsDocument112 pagesAdvance Fibre and Yarn Testing Instrumentsmeghana raj100% (1)

- Color Physics-1st Class PDFDocument74 pagesColor Physics-1st Class PDFMohammad HossainNo ratings yet

- Fibre DegradationDocument32 pagesFibre DegradationMohammad HossainNo ratings yet

- Dye StructureDocument14 pagesDye StructureMohammad HossainNo ratings yet

- Printing ReportDocument34 pagesPrinting ReportMohammad HossainNo ratings yet

- Strategic Management Analysis On HSBC Ba PDFDocument19 pagesStrategic Management Analysis On HSBC Ba PDFMohammad Hossain0% (1)

- Apparel MerchandisingDocument29 pagesApparel MerchandisingMohammad Hossain100% (1)

- Analysis of Strategic Approaches of HSBC PDFDocument26 pagesAnalysis of Strategic Approaches of HSBC PDFMohammad HossainNo ratings yet

- Biomedical TextilesDocument6 pagesBiomedical TextilesMohammad HossainNo ratings yet

- MCE Cambridge Primary Maths 2E Stage6 PPT C05Document25 pagesMCE Cambridge Primary Maths 2E Stage6 PPT C05Novi YufitriNo ratings yet

- Parts Catalog: Imagerunner Advance 6075/6065/6055 SeriesDocument201 pagesParts Catalog: Imagerunner Advance 6075/6065/6055 SeriesTally LeonNo ratings yet

- Aravindhan PT CV CSWIP TrainerDocument4 pagesAravindhan PT CV CSWIP TrainerGanesan RamamoorthyNo ratings yet

- Application For Petitioned Class: College of Engineering and ArchitectureDocument2 pagesApplication For Petitioned Class: College of Engineering and ArchitectureJohn A. CenizaNo ratings yet

- 6553 Unit No 1 EmaadDocument26 pages6553 Unit No 1 Emaaduzma gulNo ratings yet

- Dynasylan BSM 40%Document3 pagesDynasylan BSM 40%Francois-No ratings yet

- 03 QPythons Main FeaturesDocument4 pages03 QPythons Main FeaturesJack Ahm PeaceNo ratings yet

- Iready at Home Activity Packets Student Math Grade 5 2020Document32 pagesIready at Home Activity Packets Student Math Grade 5 2020Jennifer HongNo ratings yet

- BPMDocument3 pagesBPMarunsawaiyanNo ratings yet

- Research On Hydraulic Jump Model For A Sluice Gate in A Rectangular Channel Using Laboratory SetupDocument44 pagesResearch On Hydraulic Jump Model For A Sluice Gate in A Rectangular Channel Using Laboratory Setupjerico habitanNo ratings yet

- 839-4816 (Office) or (770) 301-8648 (Cell) : Corporate Finance: A Focused Approach, by Michael C. Ehrhardt / Eugene FDocument1 page839-4816 (Office) or (770) 301-8648 (Cell) : Corporate Finance: A Focused Approach, by Michael C. Ehrhardt / Eugene FlilbouyinNo ratings yet

- Flutter WidgetsDocument43 pagesFlutter WidgetsSangakkara WarriorsNo ratings yet

- Exam2SampleProblems SP17 - 1507832832437Document5 pagesExam2SampleProblems SP17 - 1507832832437rohitrgt4uNo ratings yet

- Layout Proposal CSD 17 5613Document1 pageLayout Proposal CSD 17 5613Cesar Garay RangelNo ratings yet

- Problem E - Ouroboros SnakeDocument1 pageProblem E - Ouroboros SnakeManea SilviuNo ratings yet

- LR Chapter 5 - Input and OutputDocument6 pagesLR Chapter 5 - Input and OutputAakash KumarNo ratings yet

- 941112-001 Instal Q310 Rev4Document72 pages941112-001 Instal Q310 Rev4Sebin Kv0% (1)

- A & A Food NutritionDocument2 pagesA & A Food NutritionAnil SodhaNo ratings yet

- Adc 0808Document14 pagesAdc 0808Vikas PatelNo ratings yet

- Etha FoamDocument4 pagesEtha Foaml561926No ratings yet

- Chapter 1 (Marketing Updated)Document9 pagesChapter 1 (Marketing Updated)i211416 Shizza KianiNo ratings yet

- Data Communication and Computer Networks (EIE418) : Prof. E. Adetiba (PH.D, R.Engr. (COREN) )Document52 pagesData Communication and Computer Networks (EIE418) : Prof. E. Adetiba (PH.D, R.Engr. (COREN) )John DavidNo ratings yet

- SQL Webinar FinalDocument21 pagesSQL Webinar FinalYaswanth ReddyNo ratings yet

- Project Risk ManagementDocument104 pagesProject Risk Managementtsrinivasan5083No ratings yet

- B.tech Project Stage-II Presentation - MidsemDocument25 pagesB.tech Project Stage-II Presentation - Midsemkaalin bhaiyaNo ratings yet

- Assignment Strategic ManagementDocument18 pagesAssignment Strategic ManagementDarmmini MiniNo ratings yet

- Astm A875m-Zinc 5 % Alum-13Document8 pagesAstm A875m-Zinc 5 % Alum-13Ahmed SalehNo ratings yet

- Geoforum Volume 51 Issue 2014 (Doi 10.1016/j.geoforum.2013.09.018) Braverman, Irus - Conservation Without Nature - The Trouble WithDocument11 pagesGeoforum Volume 51 Issue 2014 (Doi 10.1016/j.geoforum.2013.09.018) Braverman, Irus - Conservation Without Nature - The Trouble WithrobertoitoNo ratings yet

- Elastic CollisionDocument1 pageElastic CollisionTeo Hui pingNo ratings yet

- Demographics Data Table: Lesson 1: Step 1Document3 pagesDemographics Data Table: Lesson 1: Step 1Julia AbreuNo ratings yet