Professional Documents

Culture Documents

Printing

Uploaded by

Mohammad HossainCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Printing

Uploaded by

Mohammad HossainCopyright:

Available Formats

PRINTING

TEXTILE PRINTING

Textile printing is used to signify the production,

by various means of colored patterns on designs

upon all sorts of textile fiber.

Textile printing is the most important and versatile

of the techniques used to add design, color, and

specialty to textile fabrics.

2

K

W

M

:

P

r

i

n

t

i

n

g

STEPS OF PRINTING

The basic steps in the printing process are as

follows:

Preparation of the fabric

Preparation of the print paste.

Printing the fabric.

Drying the printed fabric.

Fixation of the printed dye or pigment.

Afterwashing. 3

PRINT PASTE AND ITS INGREDIENTS

Print paste is a viscous solution of printing ingredients

referred below that is used for textile printing. The main

three printing ingredients are:

Dyestuff or pigments

Thickeners: Thickener can be defined as a substance

used to increase the viscosity of a print paste or other

fluid, in order to control its flow properties.

Chemicals and waters: The main types of chemicals

used for textile printing are wetting agents, solvents,

solution acids, dispersing agents, hygroscopic agents,

oxidizing & reducing agents, defoamers, acids, alkalis,

catalyst & carriers, swelling agents etc. 4

PLASTISOL VS. WATER-BASED INK

There are two main types of ink that are used for textile

printing.

Water-based ink utilizes either dyes or pigments in a

suspension with water as the solvent. The evaporation of the

water is necessary to set or cure the ink. Plastisol ink is a PVC

based system that essentially contains no solvent at all.

Usage Recommendations Plastisol Water-base

T-Shirts/light colors Excellent Excellent

T-Shirts/dark colored Good Poor

Nylon Jackets Good Poor

Towels Poor Excellent

Yard goods Poor Excellent

Sporting Goods Excellent Poor

5

STYLE OF PRINTING

Metal style of printing: In the metal style of printing

fabric is printed with silver or gold solution or non-

removable resins.

Resist Printing: In this method, the fabric is first printed

in a design with a chemical that resists dye. The fabric is

then dyed. The resist will leave the fabric white or some

other color in the print areas. One of the advantages of

this method is that dyes with very high colorfastness can

be used.

Flock Printing: Flock printing is a process in which a

flock is fixed on to a cloth by means of adhesive to form

printed pattern. It produces a pile or velvety effect on the

fabric similar to form a printed pattern.

6

STYLE OF PRINTING (CONTD.)

Discharge Printing: Discharge means removal and

Discharge style refers process which can produce a

white or colored effects on a dyed ground by printing

paste containing a chemical capable of removing the

ground color called discharging agents. It could be of

two types

White Discharge: the printed part remains

white after destroying the dyed color

Color Discharge: With a dye incorporated in

the print paste which is resistant to discharging agents.

When printed the discharging agents removes the

ground color and at the same time deposit color on the

dyed ground.

7

METHOD OF PRINTING

Block printing: In this method the wooden or metal block with a

negative and raised design (i.e. in relief) is first stamped on the

print paste and then on the cloth and an impression of positive

design is made on the cloth.

Screen printing: In hand screen printing the fabric is stretched

out on a long table. The screens are moved methodically along

the fabric. When a screen is in position the dye paste is pressed

through the open mesh with a squeegee blade.

Transfer printing: Transfer printing is defined as any process by

which a design is transferred from paper to another substrate.

Selected disperse dyes transfer in vapor form to thermoplastic

fibers when the printed paper and fabric are brought into close

contact in a transfer press at 170-220C.

8

FLAT BED SCREEN PRINTING

9

FLAT BED SCREEN PRINTING

10

ROTARY SCREEN PRINTING

11

ROTARY SCREEN PRINTING

12

PIGMENT PRINTING

In pigment printing, insoluble pigments, which have no affinity

for the fiber, are fixed on to the textile with binding agents in

the pattern required.

Importance of pigment printing

Pigments, of course, are used for the production of

plain-colored fabrics, but are of much greater importance in

printing.

The pigment can be applied to all fibers potentially and it is

the only coloration to glass fiber, fabric and polyester

No wet treatment is required, so drying and curing is

applicable to all fiber.

Extensive color range of highly light fast colors

Possible to produce good combination shades on blended

fiber in one padding operation

Application procedure is simple

Less expensive

13

FOIL PRINTING

This printing method is based on

the use of metallic foil paper of

aluminum or copper one. A foil

layer is affixed to a certain

material by a heating process.

14

K

W

M

:

P

r

i

n

t

i

n

g

WATER BASED GEL PRINT

A rapidly drying aqueous

printing ink containing a gel

forming polymer soluble in

the ink but which rapidly

gels upon application of the

ink to a substrate during a

printing process. Gel ink

gives high gloss wet

looking prints that have a

three-dimensional feel to

15

SPRAY PRINTING

A spray gun forces the color

through a screen

16

HIGH DENSITY PRINTING

K

W

M

:

P

r

i

n

t

i

n

g

High Density printing is the

process of printing a

specially formulated ink

through a very thick stencil

to achieve a raised, glossy

smooth print with very sharp

edges.

17

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Dye StructureDocument14 pagesDye StructureMohammad HossainNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Color Physics-1st Class PDFDocument74 pagesColor Physics-1st Class PDFMohammad HossainNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Fibre DegradationDocument32 pagesFibre DegradationMohammad HossainNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Printing ReportDocument34 pagesPrinting ReportMohammad HossainNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Strategic Management Analysis On HSBC Ba PDFDocument19 pagesStrategic Management Analysis On HSBC Ba PDFMohammad Hossain0% (1)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Analysis of Strategic Approaches of HSBC PDFDocument26 pagesAnalysis of Strategic Approaches of HSBC PDFMohammad HossainNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Apparel MerchandisingDocument29 pagesApparel MerchandisingMohammad Hossain100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Biomedical TextilesDocument6 pagesBiomedical TextilesMohammad HossainNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- YarnDocument37 pagesYarnMohammad HossainNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Ifugao Crafts: Torajan Sulawesi Indonesia Resist DyeingDocument3 pagesIfugao Crafts: Torajan Sulawesi Indonesia Resist DyeingJerald-Edz Tam AbonNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- An Introduction To Swirl and Daisy by m81170 PDFDocument447 pagesAn Introduction To Swirl and Daisy by m81170 PDFNelly RaspinoNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Emerging Trends in Retail FormatDocument5 pagesEmerging Trends in Retail FormatVenkat GVNo ratings yet

- ArongDocument9 pagesArongHridoy Biswas100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Catalog ConstructionDocument48 pagesCatalog ConstructionJohn Jairo Camacho100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Arnis Rule BookDocument30 pagesArnis Rule BookJenor Ricafort83% (6)

- Online Class House RulesDocument12 pagesOnline Class House RulesIM AM THE ONENo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Two Character PlayDocument6 pagesThe Two Character Playmaria ferreiraNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

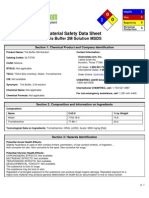

- MSDS Tris BufferDocument6 pagesMSDS Tris BuffervombyNo ratings yet

- SHS Intramurals 2023 Official GuidelinesDocument21 pagesSHS Intramurals 2023 Official Guidelinessniper the whaleNo ratings yet

- Student Workbook - Level 1 Modulo 1Document21 pagesStudent Workbook - Level 1 Modulo 1Ginna VelandiaNo ratings yet

- Anthropology Earth and The Universe Time Track According To L Ron HubbardDocument125 pagesAnthropology Earth and The Universe Time Track According To L Ron HubbardZsuzsa KomlóNo ratings yet

- Industrial Safety Helmets A Brief Guide To BS EN 397:2012+A1:2012Document2 pagesIndustrial Safety Helmets A Brief Guide To BS EN 397:2012+A1:2012Ajesh mohanNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Shopkeeper - Customer Dialogue (29-10-19)Document2 pagesShopkeeper - Customer Dialogue (29-10-19)TheEmpressNo ratings yet

- E FlatironDocument29 pagesE FlatironAnonymous jJQbkLNo ratings yet

- Tle H.E Periodical TestDocument4 pagesTle H.E Periodical TestVINA ARIETANo ratings yet

- Corset Making ManualDocument21 pagesCorset Making Manualpolkadotsquare100% (8)

- Leveraging Secondary Brand AssociationDocument9 pagesLeveraging Secondary Brand AssociationNadil HaqueNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Novel The Importance of Being EarnestDocument117 pagesNovel The Importance of Being EarnestNiftyNo ratings yet

- Cuckoo Craft - UmaruDocument10 pagesCuckoo Craft - UmaruAndrea CordovaNo ratings yet

- Snow Cabin Dolphin Crochet Pattern by PerozuDocument2 pagesSnow Cabin Dolphin Crochet Pattern by PerozushribsNo ratings yet

- Salesforce Knowledge Dev GuideDocument60 pagesSalesforce Knowledge Dev GuideGaurav SaraswatNo ratings yet

- WFRP Adventure Butcher BakerDocument75 pagesWFRP Adventure Butcher BakerGabber4193100% (1)

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument11 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingGouse MohideenNo ratings yet

- Bunny PatternnewDocument10 pagesBunny PatternnewPetra Bella100% (3)

- The Adventures of Sherlock Holmes by Sir Arthur Conan DoyleDocument152 pagesThe Adventures of Sherlock Holmes by Sir Arthur Conan DoyleBooks67% (3)

- Bacon y FreudDocument13 pagesBacon y FreudencapacidadNo ratings yet

- Bagalamukhi - The Goddess of Hypnotic PowerDocument7 pagesBagalamukhi - The Goddess of Hypnotic PowercantuscantusNo ratings yet

- 2013 English Grammar and Usages MCQDocument10 pages2013 English Grammar and Usages MCQsunnykalair16100% (5)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 2024 Ahg Camp GTR HandbookDocument8 pages2024 Ahg Camp GTR Handbookapi-245625563No ratings yet