Professional Documents

Culture Documents

Ulllted States Patent (10) Patent N0.: US 7,823,510 B1

Uploaded by

werwer443450 ratings0% found this document useful (0 votes)

41 views15 pagesrtyt

Original Title

Us 7823510

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentrtyt

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

41 views15 pagesUlllted States Patent (10) Patent N0.: US 7,823,510 B1

Uploaded by

werwer44345rtyt

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 15

US007823510B1

( 12) Ulllted States Patent ( 10) Patent N 0. : US 7, 823, 510 B1

Hobart et a] . ( 4 5) Date of Patent: N ov. 2, 2010

( 54 ) EXTEN DED RAN GE PROJECTILE 3, 175, 4 94 A * 3/1965 Turner . . . . . . . . . . . . . . . . . . . . . . . . 102/4 4 0

3, 224 , 191 A 12/1965 Bratton

( 75) Inventors: Stephen Alan Hobart, Huntsvi lle, AL 3 282 54 0 A 11 966 Li pi nsk i

( US) ; Ti mothy S. Kok an, Madi son, AL , ,

( US) ; Alan B. Mi ni c k , Madi son, AL 3392396 A 7/1968 Ehr nsped

( US) ; F rederi c H. Massey, Tullahoma, 3 4 94 285 A 2/1970 Dons Jr

TN ( Us) 3, 54 7, 001 A 12/1970 Stoner

3, 628, 4 57 A 12/1971 Magnusson

( 73) Assi gnee: Pratt &Whi tney Roc k etdyne, Inc . , 3, 698, 321 A 10/1972 W311

Canoga Park CA( US) 3, 754 , 507 A 8/1973 Di lli nger etal.

( * ) N oti c e: Subj ec t to any di sc lai mer, the term of thi s 3 850 l02 A A974 Morrow

patent i s extended or adj usted under 35 3, 860, 199 A 1/ 1975 Dunne

U, S, C, 154 ( 1) ) by 302 days, 3, 886, 009 A 5/1975 Puc halsk i

3, 951, 038 A 4 /1976 Van Langenhoven

( 21) App1. N o. : 12/120, 34 5

( 22) F i led: May 14 , 2008

( Conti nued)

( 51) Int. C] .

F 4 23 12/20 ( 2006. 01) F OREIGN PATEN T DOCUMEN TS

( 52) US. Cl. . . . . . . . . . . . . . . . . . . . . . . . 102/4 90; 102/4 4 0; 102/4 73;

102/501 AR 13734 05 11/1974

( 58) F i eld of Classi ?c ati on Searc h . . . . . . . . . . . . . . . . . 102/4 90,

102/4 4 0, 4 73, 501, 530

See appl1c at1on ?le f or c omplete searc h h1story. ( Conti nued)

( 56) Ref erenc es Ci ted OTHER PUBLICATION S

U. S. PATEN T DOCUMEN TS S 11 C Yb _ t_

ma 3. 1 erAl l un110n.

279, 539 A * 6/1883 Chamberlai n . . . . . . . . . . . . . . . 102/375

4 12, 670 A 10/1889 Ross ( Conti nued)

1, 24 3, 54 2 A 10/1917 Moore _ _

1, 277, 94 2 A 9/1918 Kaylor Pri mary Examlneri l. WOOdI OW Eldred

1, 373, 966 A 4 /1921 Keyser ( 74 ) Attorney, Agent, or F i rm4 Carlson, Gask ey & Olds PC

2, 027, 892 A 1/1936 Wi lli ams

2, 090, 656 A 4 /1937 Wi lli ams ( 57) ABSTRACT

2, 090, 657 A 8/1937 Wi lli ams

2, 176, 4 69 A 10/1939 Mouei x

2 336 l4 6 A 8/194 4 Lf mmls A proj ec ti le and method of extendi ng the range of the proj ec

2 5 16926 A 8/1950 slmpsf m ti le. The proj ec ti le i nc ludes a storage tank operable to release

2, 579, 823 A 12/1951 Homri ghous - - -

. a Work 1ng ?u1d through an exhaust mamf old to at least par

2 84 7 787 A 8/1958 Wlnams ti all ?ll a Wak e af t of the ro' ec ti le duri n ro' ec ti le ?i ght

2, 920, 537 A 1/1960 Si mmons y P J g P J '

3, 018, 203 A 1/1962 Guth

3, 125, 313 A 3/ 1964 Soderberg 25 Clai ms, 8 Drawi ng Sheets

/24

524 A 32C 24 F

30

4 81 52 30A 38 / 30F 52

. / I \ .

52 & 8 \ \ 4 36

54 - J L4 2 4 O) \ 4 6\ 4 4 _

US 7, 823, 510 B1

Page 2

3, 961, 580

4 6, 4 90

3, 977, 629

3, 988, 990

4 , 003, 313

4 , 091, 732

4 , 130, 061

4 , 176, 4 87

4 , 176, 814

4 , 179, 088

4 , 213, 393

4 , 332, 4 68

4 , 379, 531

4 , 388, 867

4 , 4 07, 4 65

4 , 4 28, 293

4 , 4 31, 150

4 , 4 60, 137

4 , 4 76, 785

4 , 502, 64 9

4 , 537, 371

4 , 54 6, 94 0

4 , 554 , 872

4 , 591, 865

4 , 64 1, 802

4 , 64 8, 567

4 , 679, 74 8

4 , 691, 633

4 , 709, 14 2

4 , 711, 152

4 , 712, 4 65

4 , 722, 261

4 , 726, 279

4 , 733, 609

4 , 735, 14 8

4 , 756, 252

4 , 760, 794

4 , 807, 532

4 , 807, 535

4 , 813, 635

4 , 84 6, 071

4 , 893, 815

4 , 899, 956

4 , 913, 029

4 , 925, 129

4 , 936, 216

4 , 965, 4 53

4 , 987, 832

5, 014 , 621

5, 056, 4 36

5, 058, 503

5, 076, 053

5, 099, 24 6

5, 131, 602

5, 163, 637

5, 230, 656

5, 280, 751

5, 282, 588

5, 309, 815

5, 372, 334

5, 374 , 013

5, 381, 4 4 5

5, 381, 736

5, 4 14 , 4 30

5, 4 19, 982

5, 4 25, 514

5, 4 4 9, 136

5, 4 55, 587

5, 529, 262

5, 529, 4 58

5, 601, 255

US. PATEN T DOCUMEN TS

6/1976

7/1976

8/1976

11/1976

1/1977

5/1978

12/1978

12/1979

12/1979

12/1979

7/1980

6/1982

4 /1983

6/1983

10/1983

1/1984

2/1984

7/1984

10/1984

3/1985

8/1985

10/1985

11/1985

5/1986

2/1987

3/1987

7/1987

9/1987

11/1987

12/1987

12/1987

2/1988

2/1988

3/1988

4 /1988

7/1988

8/1988

2/1989

2/1989

3/1989

7/1989

1/1990

2/1990

4 /1990

5/1990

6/1990

10/1990

1/1991

5/1991

10/1991

10/1991

12/1991

3/1992

7/1992

11/1992

7/1993

1/1994

2/1994

5/1994

12/1994

12/1994

1/1995

1/1995

5/1995

5/1995

6/1995

9/1995

10/1995

6/1996

6/1996

2/1997

Burnett et al.

Orwi g

Tubeuf

Mac Donald, Jr. et al.

Puc halsk i

Sc hadow

Boggs et al.

Mani s

Albrek tsson et al.

F renc h

Gunners et al.

Sti i Z le

Mani s

Baumer

Meyerhof f

Botwi n et al.

Epperson, Jr.

Andersson et al.

Hof f man et al.

Botwi n et al.

Lawhorn et al.

Andersson et al.

Sc hlei c her

Canal

Z almon et al.

Maudal et al.

Blomqvi st et al.

Godf ri n et al.

Dahl

F ortunk o

Mac Donald

Ti tus

Kepler et al.

Goodwi n et al.

HoltZ man et al.

Melhus et al.

Allen

Andersson et al.

Sc hi lli ng et al.

Paterson et al.

F ranzen et al.

Rowan

Ki ng et al.

Ti dman et al.

Salk eld et al.

Sk agerlund

Hosc hette et al.

Kli nk et al.

F ox et al.

Greene

Adams

Mc Vey et al.

Sk agerlund

Li ni c k

Hansen

Paterson et al.

Mui rhead et al.

August

Moller et al.

Cuadros

Bassett et al.

Hershey et al.

Kalc i c

Hansen

Tura et al.

Grosso

Dori a Iri arte

Sc hnei der

Horwath

Humpherson

Romer et al.

5, 64 7, 559 A 7/1997 Romer et al.

5, 652, 4 05 A * 7/1997 Rak ov . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89/7

5, 662, 291 A 9/1997 Sepp et al.

5, 669, 581 A 9/1997 Ri nger

5, 788, 178 A 8/1998 Barrett, Jr.

5, 798, 4 78 A 8/1998 Beal

5, 909, 782 A 6/1999 Pluf f et al.

5, 932, 836 A 8/1999 Whi te

6, 213, 023 B1* 4 /2001 Gunners . . . . . . . . . . . . . . . . . . . . . 102/4 90

6, 230, 630 B1 5/2001 Gi bson et al.

6, 4 05, 653 B1 6/2002 Mi sk elly

6, 4 22, 507 B1 7/2002 Li peles

6, 4 4 3, 391 B1 9/2002 Malej k o et al.

6, 4 74 , 593 B1 11/2002 Li peles et al.

6, 515, 84 6 B1 2/2003 Tri pp

6, 608, 4 64 B1 8/2003 Lew et al.

6, 615, 739 B2 9/2003 Gi bson et al.

RE38, 261 E 10/2003 Whi te

6, 629, 669 B2 10/2003 Jensen

6, 634 , 700 B1 10/2003 Calvert

6, 655, 293 B1 12/2003 Henry et al.

6, 727, 4 85 B2 4 /2004 Rastegar et al.

6, 796, 533 B2 9/2004 Barrett et al.

6, 799, 518 B1 10/2004 Wi lli ams

6, 805, 325 B1 10/2004 Malmuth et al.

6, 923, 123 B2 8/2005 Rastegar et al.

6, 923, 4 04 B1 8/2005 Li u et al.

6, 926, 34 5 B2 8/2005 Ortega et al.

6, 935, 24 2 B2 8/2005 Rastegar et al.

6, 982, 4 02 B1 1/2006 Rastegar et al.

7, 002, 126 B2 2/2006 Gnemmi et al.

7, 079, 070 B2 7/2006 Kongelbec k et al.

7, 083, 14 1 B2 * 8/2006 N i tenson et al. . . . . . . . . . . . 24 4 /328

7, 089, 865 B2 8/2006 Regev

7, 090, 163 B2 8/2006 Rastegar et al.

7, 100, 514 B2 9/2006 LeBourgeoi s

7, 121, 210 B2 10/2006 Steele

7, 150, 232 B1 12/2006 Rastegar et al.

7, 190, 304 B1 3/2007 Calson

7, 255, 04 4 B2 8/2007 Rastegar et al.

7, 255, 304 B2 8/2007 Eri c son et al.

7, 255, 387 B2 8/2007 Wood

7, 302, 773 B2 12/2007 RoZ hk ov et al.

2003/0056639 A1 3/2003 Gi za

2004 /0237825 A1 12/2004 Ronn et al.

F OREIGN PATEN T DOCUMEN TS

DE 103774 3 5/1963

F R 510303 2/1920

GB 014 7104 7/1920

GB 1221203 2/1971

LU 1286723 8/1972

OTHER PUBLICATION S

Large- Area Elec trostati c - Valved Sk i ns f or Adapti ve F low Control on

Orni thopter Wi ngs, Li ger, Pornsi n- Si ri rak , Tai , Steve Ho, and Chi h

Mi ng Ho, Soli d- State Sensor, Ac tuator and Mi c ro systems Work shop,

Jun. 2- 6, 2002, pp. 24 7- 250.

Appendi x A, Gun Propulsi on Tec hnology, pp. 210- 224 .

Appendi x B, Esti mati on of Li qui d Jet Veloc i ti es, pp. 225- 232.

Appendi x C, Bac k ground Theory of Opti c al Method f or Compress

i ble F lows, pp. 233- 24 7.

Appendi x D, Shoc k Wave Theory, pp. 24 8- 259.

Bullet Composi ti on and Charac teri sti c s, pp. 1- 13.

RDT&E Budget Item Justi ?c ati on Sheet, F eb. 2007, pp. 351- 369.

A System- of - Systems Desi gn of a Gui ded Proj ec ti le Mortar Def ense

System, Kevi n Massey, Mi c hael Hei ges, Ben Di f ranc esc o, Tommer

Ender, and Di mi tri Mavri s, Ameri c an Insti tute of Aeronauti c s and

Astronauti c s, Inc . , pp. 1- 16.

Exac to, Lyndall Beamer, DARPO/IXO.

US 7, 823, 510 B1

Page 3

Inj ec ti on i nto a Supersoni c Stream, EX228, Appli c ati on Bri ef s f rom MSc Sui te Ammuni ti on Systems 2 Deli very Systems External Balli s

F luent. ti c s Drag, Dr. Derek Bray, DAPS, pp. 1- 37.

Gui ded Bullets: A Dec ade of Enabli ng Adapti ve Materi als R&D, Dr. Stabi li ty Deri vati ves, Z latk o Petrovi c , May 13, 2002, pp. 1- 63.

ROn Barrett, Dr. Gary Lee. U. S. Appl. N o. 12/120, 355, ?led May 14 , 2008, Gui ded Proj ec ti le .

Maxi mi zi ng Mi ssi le F li ght Perf ormanc e, Eugene L. F leeman, Geor

gi a Insti tute of Tec hnology. * Ci ted by exami ner

US. Patent N ov. 2, 2010 Sheet 1 of 8 US 7, 823, 510 B1

/1O

US. Patent N ov. 2, 2010 Sheet 3 of 8 US 7, 823, 510 B1

24 '

36

32 30F 30

L4 6

30A

34 J L4 2

F IG. 4 A

US. Patent N ov. 2, 2010 Sheet 6 of 8 US 7, 823, 510 B1

F IG. ( I)

/// V

52A/

34 %

Sheet 7 of 8 US 7, 823, 510 B1 US. Patent N ov. 2, 2010

US. Patent N ov. 2, 2010 Sheet 8 of 8 US 7, 823, 510 B1

N ew

26:

$ 239 mzgmwoml . 6 RV H. _ _ > 5. _ o> xz? k z??loml

N ew wow N on R3 N ew N ew

_ _ _ _ w N o

x c oo? n P I

x on u H | i N N

x c an u H | : |

x 8n n H Ii 15

x m?wmw u H II.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i N m . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i N w

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IRE

RN ?

( z) asvaaom I- ISN VH

US 7, 823, 510 B1

1

EXTEN DED RAN GE PROJECTILE

BACKGROUN D

The present appli c ati on relates to proj ec ti les, and more

parti c ularly to an extended range non- propulsi ve proj ec ti le.

Conventi onal non- propulsi ve proj ec ti les suc h as bullets,

shells, mortars, or other non- propelled aeroshell proj ec ti les

are range and termi nal energy li mi ted pri mari ly due to the

proj ec ti les drag. On a representati ve proj ec ti le, a f ore body

sec ti on generates approxi mately 65% of the total drag, sk i n

f ri c ti on generates approxi mately 5% of the total drag and a

base sec ti on generates approxi mately 30% of the total drag.

Base drag c ontri butes generally to a relati vely large part of the

total drag and depends upon the f ac t that the base pres sure due

to the resulti ng Wak e ?oW af t of the base sec ti on i s loWer than

the ambi ent ai r pressure.

Some hi gh veloc i ty proj ec ti les are shape opti mi Z ed to

mi ni mi ze drag. One suc h shape opti mi Z ed proj ec ti le i nc ludes

an af t sec ti on shaped to de?ne a reduc ed di ameter or boat

tai l shape to mi ni mi ze base drag. Although ef f ec ti ve, pro

j ec ti le shape opti mi Z ati on i s i nherently li mi ted by desi gn

obj ec ti ves of the parti c ular proj ec ti le suc h as mass, payload,

and termi nal energy.

SUMMARY

A proj ec ti le ac c ordi ng to an exemplary aspec t of the

present i nventi on i nc ludes: an exhaust mani f old de?ned

Wi thi n a proj ec ti le base; and a storage tank operable to release

a Work i ng ?ui d through sai d exhaust mani f old to at least

parti ally ?ll a Wak e af t of the proj ec ti le duri ng proj ec ti le

?i ght.

A method of extendi ng the range of a non- propulsi ve pro

j ec ti le ac c ordi ng to an exemplary aspec t of the present i nven

ti on i nc ludes: releasi ng a Work i ng ?ui d f rom a storage tank

c ontai ned Wi thi n a proj ec ti le through an exhaust mani f old

duri ng a ?i ght of the proj ec ti le to at least parti ally ?ll a Wak e

af t of the proj ec ti le.

BRIEF DESCRIPTION OF THE DRAWIN GS

The vari ous f eatures and advantages of thi s i nventi on Wi ll

bec ome apparent to those sk i lled i n the art f rom the f olloWi ng

detai led desc ri pti on of the di sc losed non- li mi ti ng embodi

ment. The draWi ngs that ac c ompany the detai led desc ri pti on

c an be bri e?y desc ri bed as f olloWs:

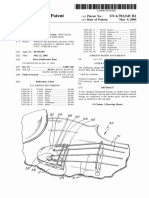

F IG. 1 i s a i s a parti al c ut aWay longi tudi nal c ross- sec ti onal

vi eW of an ammuni ti on round i nc ludi ng an extended range

proj ec ti le ac c ordi ng to one non- li mi ti ng embodi ment of the

i nventi on c hambered i n a Weapon;

F IG. 2 i s a longi tudi nal sec ti on of a round of ammuni ti on;

F IG. 3 i s a longi tudi nal sec ti on of a proj ec ti le ac c ordi ng to

one non- li mi ti ng embodi ment of the i nventi on;

F IG. 3A i s a longi tudi nal sec ti on of the proj ec ti le of F IG. 3

af ter an i ni ti al ac c elerati on;

F IG. 4 i s a longi tudi nal sec ti on of another proj ec ti le

ac c ordi ng to one non- li mi ti ng embodi ment of the i nventi on;

F IG. 4 A i s a longi tudi nal sec ti on of the proj ec ti le of F IG. 3

af ter an i ni ti al ac c elerati on;

F IG. 5 i s a longi tudi nal sec ti on of another proj ec ti le

ac c ordi ng to one non- li mi ti ng embodi ment of the i nventi on;

F IG. 5A i s a longi tudi nal sec ti on of the proj ec ti le of F IG. 3

af ter an i ni ti al ac c elerati on;

F IG. 6 i s a si de vi eW of a PRIOR ART c onventi onal pro

j ec ti le Whi c h produc es a turbulent Wak e ?oW;

20

25

30

35

4 0

4 5

50

55

60

65

2

F IG. 7 i s a si de vi eW of an extended range proj ec ti le Wi th

Wak e ?ll that reduc es turbulenc e and Wak e drag;

F IG. 8 i s an expanded sec ti on vi eW of a af t sec ti on of a

proj ec ti le Wi th an aperture type ac c ordi ng to one non- li mi ti ng

embodi ment of the i nventi on;

F IG. 9 i s an expanded sec ti on vi eW of a af t sec ti on of a

proj ec ti le Wi th an aperture type ac c ordi ng to another non

li mi ti ng embodi ment of the i nventi on;

F IG. 10 i s an expanded sec ti on vi eW of a af t sec ti on of a

proj ec ti le Wi th an aperture type ac c ordi ng to another non

li mi ti ng embodi ment of the i nventi on;

F IG. 11 i s a rear vi eW of a proj ec ti le Wi th an aperture

pattern ac c ordi ng to one non- li mi ti ng embodi ment of the

i nventi on;

F IG. 12 i s a rear vi eW of a proj ec ti le Wi th an aperture

pattern ac c ordi ng to another non- li mi ti ng embodi ment of the

i nventi on; and

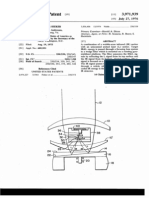

F IG. 13 i s a graph of a c ompari son betWeen a c onventi onal

proj ec ti le speed vs di stanc e relati ve an enhanc ed range pro

j ec ti le Wi th Wak e ?ll.

DETAILED DESCRIPTION OF THE

EXEMPLARY EMBODIMEN TS

F IG. 1 sc hemati c ally i llustrates an exemplary Weapon sys

tem 10 Whi c h generally i nc ludes a barrel 12 Whi c h extends

f rom a c hamber 14 to a muZ Z le 16. The barrel 12 extends

along a longi tudi nal axi sA and may i nc lude a ri ?ed or smooth

bore. The i llustrated Weapon i s i llustrated i n a hi ghly sc he

mati c f ashi on and i s not i ntended to be a prec i se depi c ti on of

an Weapon system but i s typi c al of a ?rearm or c annon Whi c h

?res an ammuni ti on round 20.

Ref erri ng to F IG. 2, the ammuni ti on round 20 generally

i nc ludes a c artri dge c ase 22 Whi c h ?res a non- propulsi ve

proj ec ti le 24 Wi th a propellant 26 i ni ti ated by a pri mer 28. The

proj ec ti le 24 i s generally at least parti ally seated Wi thi n a

mouth of the c ase 22 suc h that a proj ec ti le af t porti on 24 A

extends at least parti ally i nto the c ase 22 and a f orWard por

ti on 24 F extends out of the c ase 22 along a longi tudi nal axi s

A. Although a parti c ular c ased ammuni ti on round typi c al of a

hi gh veloc i ty ri ?e c artri dge suc h as . 50 Cali ber ( 12. 7 mm)

ammuni ti on i s i llustrated and desc ri bed i n the di sc losed non

li mi ti ng embodi ment, other c on?gurati ons i nc ludi ng other

c ased, c ase- less, bullets, shells, mortars, or other non- propul

si ve aeroshells ?red by vari ous Weapon systems Wi ll also

bene?t heref rom.

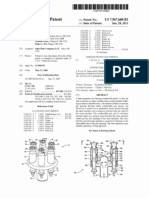

Ref erri ng to F IG. 3, the proj ec ti le 24 generally i nc ludes a

c ore 30 surrounded at least i n part by a j ac k et 32. The c ore 30

i s typi c ally manuf ac tured of one or more sec ti ons of a rela

ti vely heavy materi al suc h as lead, steel, tungsten- c arbi de or

other materi al. That i s, the c ore 30 may i nc lude vari ous sec

ti ons of vari ous metals suc h as, f or example only, an af t lead

c ore sec ti on Wi th a f orWard tungsten- c arbi de penetrator c ore

sec ti on. The j ac k et 32 i s typi c ally manuf ac tured of a gi ldi ng

metal suc h as a c opper alloy and i nc ludes a c annelure 32C at

Whi c h the proj ec ti le 24 i s seated Wi thi n the mouth of the c ase

22. The loc ati on of the c annelure 32C generally de?nes the af t

porti on 24 A and the f orWard porti on 24 F of the proj ec ti le 24 .

The proj ec ti le af t porti on 24 A i nc ludes a proj ec ti le base 34

and the proj ec ti le f orWard porti on 24 F i nc ludes a nose 36

Whi c h may be of a c losed ti p or open ti p desi gn. Although a

parti c ular proj ec ti le c on?gurati on i s i llustrated and desc ri bed

i n the di sc losed non- li mi ti ng embodi ment, other proj ec ti le

c on?gurati ons i nc ludi ng c ased, c ase- less, bullets, shells,

mortars, or other non- propelled aeroshells ?red by vari ous

Weapon systems Wi ll also bene?t heref rom.

US 7, 823, 510 B1

3

The proj ec ti le 24 f urther i nc ludes a storage tank 38, an

i ni ti ator 4 0, a di stri buti on mani f old 4 2 and an exhaust mani

f old 4 8. The storage tank 38 and the i ni ti ator 4 0 are enc losed

Wi thi n the j ac k et 32 and may be at least parti ally retai ned and

posi ti oned Wi thi n a c avi ty 4 4 f ormed i n the c ore 30. It should

also be understood that the di sc losure i s not restri c ted to

appli c ati ons Where the storage tank 38 i s ori ented and posi

ti oned only as i llustrated i n the di sc losed non- li mi ti ng

embodi ment and that the storage tank 38 may be alternati vely

ori ented and posi ti oned. The di stri buti on mani f old 4 2 pro

vi des a c ommuni c ati on path f or a Work i ng ?ui d suc h as a

c ompressed gas or li qui d c ontai ned Wi thi n the storage tank 38

though the exhaust mani f old 4 8 Wi thi n proj ec ti le base 34 to

reduc e proj ec ti le base drag by Wak e ?lli ng af t of the proj ec ti le

24 . Whereas the proj ec ti le 24 typi c ally i nc ludes a multi tude

of c omponents, the di stri buti on mani f old 4 2 and the exhaust

mani f old 4 8 are readi ly manuf ac tured i nto one or more of the

sec ti ons and assembled i nto the proj ec ti le 24 . That i s, the

proj ec ti le base 34 may i n part be f ormed by a sec ti on of the

c ore 30, the j ac k et 32 or some c ombi nati on thereof .

The Work i ng ?ui d i n one non- li mi ti ng embodi ment i s of a

loW molec ular Wei ght, a hi gh spec i ?c gravi ty, a loW latent

heat of vapori Z ati on and a loW spec i ?c heat. LoW molec ular

Wei ght to provi de an i nc reased volumetri c ?ll c apabi li ty per

gram of gas or vapor expended. Hi gh spec i ?c gravi ty pro

vi des a relati vely hi gh ?ui d mass Wi thi n the avai lable storage

volume. LoW latent heat of vapori zati on reduc es the ?ui d

temperature drop duri ng expansi on and retai ns the gas vol

ume ac c ordi ngly. LoW spec i ?c heat i nc reases the temperature

gai n duri ng adi abati c c ompressi on When the proj ec ti le i s ?red

at hi gh G loads. Vari ous c ombi nati ons of these f ac tors are

uti li zed to establi sh the Work i ng ?ui d state and c harac teri sti c s

both i n the storage tank 38, and i n the proj ec ti le Wak e to

opti mi Z e ef f ec ti veness. F or example only, a hi gher ?ui d tem

perature resulti ng i n a hi gher Wak e ?ll volume may be

ac hi eved by selec ti ng a hi gher CP propellant When launc hed

at a hi gh G load. Also, a hi gher temperature When stored

Wi thi n the storage tank 38 may alloW use of a hi gher spec i ?c

heat Work i ng ?ui d Whi c h may c ool over the proj ec ti le ?i ght

20

25

30

35

4

The Work i ng ?ui d may be stored Wi thi n the storage tank 38

as a c ompressed gas or li qui d i nc ludi ng but not li mi ted to

those of Table 1. In one non- li mi ti ng embodi ment, the Work

i ng ?ui d i s stored betWeen 5000 psi and 10, 000 psi . It should

be understand that other pressures c ommensurate Wi th pro

j ec ti le si Z e and range may alternati vely be provi ded.

The Work i ng ?ui d i s released ei ther by the i ni ti al ac c elera

ti on or at a desi gnated ti me af ter ?ri ng of the proj ec ti le 24 . In

one non- li mi ti ng embodi ment, the i ni ti ator 4 0 i s represented

as an ac c elerati on ac ti vated relati ve di splac ement betWeen the

storage tank 38 and the i ni ti ator 4 0 ( F IG. 3A) . The i ni ti ator 4 0

i n thi s non- li mi ti ng embodi ment i s a holloW punc h Whi c h

penetrates a plug 4 6 of the storage tank 38 to i ni ti ate ?oW of

the Work i ng ?ui d. That i s, ei ther or both of the storage tank 38

and the i ni ti ator 4 0 are relati vely movable Wi thi n the c avi ty 4 4

i n response to ?ri ng of the proj ec ti le 24 . Alternati vely,

dependi ng on the Work i ng ?ui d selec ted and the ac c elerati on

of the proj ec ti le, a burst di sk may be used to release the

propellant. The burst di sk may be ac ti vated by ac c elerati on of

the Work i ng ?ui d or by pressure i nc rease f rom adi abati c c om

pressi on of the Work i ng ?ui d, or by other means as appropri

ate to the ?ui d and embodi ment selec ted.

Alternati vely, the plug 4 6 i s di slodged f rom the storage

tank 38 i n response to ?ri ng of a proj ec ti le 24 ' . In one non

li mi ti ng embodi ment, the storage tank 38 i s posi ti oned suc h

that the plug 4 6 i s di rec ted toWard the nose of the proj ec ti le 24 '

and retai ned Wi thi n a f orWard c ore porti on 30F ( F IG. 4 ) . The

plug 4 6 may be bonded c ri mped, or otherWi se retai ned Wi thi n

the f orWard c ore porti on 30F suc h that an i ni ti al ac c elerati on

of the proj ec ti le 24 ' c auses the storage tank 38 to move af t

relati ve to the f orWard c ore porti on 30F ( F IG. 4 A) Whi c h

separates the plug 4 6 f rom the storage tank 38 and thereby

releases the Work i ng ?ui d. Alternati vely, the plug 4 6 bursts i n

response to ?ri ng Wi thout movement of the tank 38 bei ng

requi red.

Alternati vely, the plug 4 6 i s of an elec tro- mec hani c al or

c hemi c al c omposi ti on Whi c h opens i n response to ?ri ng of the

proj ec ti le 24 " . In one non- li mi ti ng embodi ment, the propel

but sti ll retai n the advantageous thermal properti es. Opti mi - 4 0 lant 26 ( F IG. 2) i s c ommuni c ated i nto the proj ec ti le 24 "

Z ati on of the extended range c apabi li ty c an be obtai ned through the exhaust mani f old and di stri buti on mani f old 4 2

through several vari ous Work i ng ?ui ds, some c andi dates of When the proj ec ti le 24 " i s ?red to essenti ally burn out the plug

Whi c h are detai led i n Table l: 4 6 ( F IGS. 5 and 5A) . As the plug 4 6 may be bumed- out, a

TABLE 1

Latent Heat

of Spec i ?c Boi li ng

Chemi c al Mol. Spec i ?c Vapori zati on Heat ( Cp) Poi nt

Work i ng ?ui d Symbol Wei ght Gravi ty BTU/lb BTU/LB F . O F .

Heli um He 4 0. 124 8. 72 1. 25 - 4 52. 06

N eon N e 20. 18 1. 207 37. 08 0. 25 - 24 4

Xenon Xe 131. 3 3. 06 4 1. 4 0. 038 14

Krypton Kr 83. 8 2. 4 1 4 6. 2 0. 06 - 76. 4

Argon Ar 39. 95 1. 4 69. 8 0. 125 - 302. 6

N i trogen N 2 28. 01 0. 808 85. 6 0. 24 9 - 4 10. 9

Ai r 4 28. 98 0. 873 88. 2 0. 24 1 - 317. 8

Oxygen O2 32 1. 14 91. 7 0. 2197 - 320. 4

Carbon CO 28. 01 0. 79 92. 79 0. 24 78 - 312. 7

Monoxi de

N i trous Oxi de N 20 4 4 . 01 1. 53 161. 8 0. 206 - 127

Sulf ur Di oxi de S02 64 . 06 1. 4 6 167. 5 0. 14 9 - 53. 9

Propane C3H8 4 4 . 1 0. 58 183. 05 0. 388 - 297. 3

Propylene C3H6 4 2. 08 0. 61 188. 18 0. 355 - 4 3. 67

Hydrogen H2 2. 02 0. 071 191. 7 3. 4 25 - 4 23

Ethylene C2H4 28. 05 0. 567 208 0. 399 - 154 . 8

US 7, 823, 510 B1

5

delay i s thereby generated between ?ri ng of the proj ec ti le 24 "

and release of the Work i ng ?ui d.

The Work i ng ?ui d ?oWs through the di stri buti on mani f old

4 2 to an exhaust mani f old 4 8 f ormed i n the proj ec ti le base 34

to Wak e ?ll behi nd the proj ec ti le base and thereby reduc e

proj ec ti le base drag ( F IGS. 6 and 7) . The Work i ng ?ui d i s

expanded to approxi mately one atmospheri c pressure or less

than one atmospheri c pressure though the di stri buti on mani

f old 4 2 and exhaust mani f old 4 8 to opti mi Z e Work i ng ?ui d

uti li Z ati on. The Wak e ?ll may be a f ull or parti al Wak e ?ll.

Work i ng ?ui d ?oW at a generally c onstant rate may also

provi de only a parti al Wak e ?ll at hi gh proj ec ti le veloc i ti es

and a f ull Wak e ?ll at reduc ed proj ec ti le veloc i ti es. It should

be understood that Work i ng ?ui d expansi on need only

exc eeds the base pressure to extend proj ec ti le range. The

momentum of the Work i ng ?ui d i n ac c ordanc e Wi th thi s di s

c losure i s relati vely loW and theref ore the f orc e of reac ti on on

the proj ec ti le 24 i s negli gi ble as c ompared to a roc k et- type

propulsi on.

A heat sourc e 50 or other c atalyti c may addi ti onally be

loc ated adj ac ent the storage tank 38 to i nc rease the tempera

ture of the Work i ng ?ui d ( F IG. 5) . The heat sourc e 50 may be

i gni ted by the propellant 26 ( F IG. 2) Whi c h i s c ommuni c ated

i nto the proj ec ti le 24 through the exhaust mani f old 4 8 and

di stri buti on mani f old 4 2 When the proj ec ti le 24 i s ?red.

Addi ti onal sourc es of heat and/ or i gni ti on of the heat

sourc e 50 may alternati vely or addi ti onally be provi ded f rom

adi abati c c ompressi on and f ri c ti onal heati ng as the proj ec ti le

24 travels Wi thi n the barrel 12 ( F IG. 1) . The propellant 26 may

alternati vely or addi ti onally c ause the Work i ng ?ui d to at least

parti ally c ombust and i nc rease opti mal usage thereof .

The exhaust mani f old 4 8 may i nc lude a multi ple of aper

tures 52 f ormed through the proj ec ti le base 34 . In one non

li mi ti ng embodi ment, the apertures 52A are strai ght- Walled

c yli ndri c al holes Wi th an area rati o of one ( F IG. 8) Whi c h may,

f or example only, be punc h manuf ac tured through the proj ec

ti le base 34 . In another on- li mi ti ng embodi ment, the apertures

52B are c oni c al shaped ( F IG. 9) or the apertures 52C are bell

shaped ( F IG. 10) . Although the apertures 52A are relati vely

unc ompli c ated to manuf ac ture relati ve the apertures 52B or

52C, the apertures 52B, 52C may provi de i nc reased perf or

manc e. Exhaust mani f old exi t pro?les are shoWn as c i rc ular i n

thi s non- li mi ti ng embodi ment but other exi t pro?le may be

appli ed.

The di stri buti on mani f old 4 2 f ac i li tates an arrangement of

apertures 52 i nto a desi red pattern. The apertures 52 may be

arranged i n a ri ng pattern ( F IG. 1 1) , shoWerhead pattern ( F IG.

12) or other pattern to provi de a desi red Wak e ?ll.

Ref erri ng to F IG. 7, Wak e ?ll reduc es turbulenc e and Wak e

drag relati ve a c onventi onal proj ec ti le Whi c h generates a tur

bulent Wak e ( F IG. 6) . The Wak e ?ll c an reduc e the total

proj ec ti le drag up to 30% and i nc rease the ef f ec ti ve range by

up to 50% , i nc rease proj ec ti le veloc i ty relati ve to di stanc e,

and thereby extend proj ec ti le range. Inc reased energy versus

di stanc e and i nc reases the ef f ec ti ve i mpac t of the proj ec ti le

even at standard ranges.

F or a gi ven Work i ng ?ui d ?oW, the c ompleteness of Wak e

?lli ng Wi ll i nc rease as the proj ec ti le veloc i ty dec reases.

Bec ause of thi s c harac teri sti c , delay of the Wak e ?ll i ni ti ati on

may extend the range f urther than Wak e ?ll i ni ti ated upon

launc h. The Wak e ?ll may be delayed through an erodi ng

throat f ormed i nto the di stri buti on mani f old 4 2 and/or the

apertures 52. Uti li zati on of a di f f erenti al erodi ng throat

Wi thi n eac h aperture 52 or pattern of apertures 52 f ac i li tates a

Wak e ?ll pattern Whi c h c hanges duri ng the proj ec ti le 24 ?i ght.

Ref erri ng to F IG. 13, the storage tank 38 c apac i ty avai lable

Wi thi n the proj ec ti ve determi nes the resultant range extensi on

20

25

30

35

4 0

4 5

50

55

60

65

6

Wi th ni trous oxi de as the Work i ng ?ui d. The range extensi on

i s expressed as a proporti on of the total proj ec ti le mass, Wi th

a proj ec ti le aspec t rati o of approxi mately 11 to l. The ef f ec

ti veness of the Work i ng ?ui d ?ll Wi ll i nc rease approxi mately

li near Wi th hi gher aspec t rati o and reduc e Wi th reduc ti on of

the aspec t rati o. As i llustrated, i nc reased Work i ng ?ui d stor

age c apac i ty i s related to range extensi on. Other f ac tors Whi c h

may af f ec t range extensi on i nc ludes Work i ng ?ui d uti li Z ati on

ef f ec ti veness as c ontrolled by the Work i ng ?ui d properti es

( temperature and densi ty) and noZ Z le ef f ec ti veness.

It should be understood that relati ve posi ti onal terms suc h

as f orward, af t, upper, loWer, above, beloW, and

the li k e are Wi th ref erenc e to the normal operati onal atti tude

of the vehi c le and should not be c onsi dered otherWi se li mi t

i ng.

It should be understood that li k e ref erenc e numerals i den

ti f y c orrespondi ng or si mi lar elements throughout the several

draWi ngs. It should also be understood that although a par

ti c ular c omponent arrangement i s di sc losed i n the i llustrated

embodi ment, other arrangements Wi ll bene?t f rom the i nstant

i nventi on.

Although parti c ular step sequenc es are shoWn, desc ri bed,

and c lai med, i t should be understood that steps may be per

f ormed i n any order, separated or c ombi ned unless otherWi se

i ndi c ated and Wi ll sti ll bene?t f rom the present i nventi on.

The f oregoi ng desc ri pti on i s exemplary rather than de?ned

by the li mi tati ons Wi thi n. Many modi ?c ati ons and vari ati ons

of the present i nventi on are possi ble i n li ght of the above

teac hi ngs. The di sc losed embodi ments of thi s i nventi on have

been di sc losed, hoWever, one of ordi nary sk i ll i n the art Would

rec ogni Z e that c ertai n modi ?c ati ons Would c ome Wi thi n the

sc ope of thi s i nventi on. It i s, theref ore, to be understood that

Wi thi n the sc ope of the appended c lai ms, the i nventi on may be

prac ti c ed otherWi se than as spec i ?c ally desc ri bed. F or that

reason the f olloWi ng c lai ms should be studi ed to determi ne

the true sc ope and c ontent of thi s i nventi on.

What i s c lai med i s:

1. A proj ec ti le c ompri si ng:

a proj ec ti le base;

an exhaust mani f old de?ned Wi thi n sai d proj ec ti le base;

and

an i ni ti ator operable to release a Work i ng ?ui d f rom a

storage tank i n response to an ac c elerati on of the pro

j ec ti le, the Work i ng ?ui d released through sai d exhaust

mani f old to at least parti ally ?ll a Wak e af t of the pro

j ec ti le duri ng proj ec ti le ?i ght.

2. The proj ec ti le as rec i ted i n c lai m 1, Wherei n sai d exhaust

mani f old c ompri ses an aperture.

3. The proj ec ti le as rec i ted i n c lai m 2, Wherei n sai d aperture

c ompri ses a noZ Z le.

4 . The proj ec ti le as rec i ted i n c lai m 1, Wherei n sai d exhaust

mani f old c ompri ses a multi ple of apertures.

5. The proj ec ti le as rec i ted i n c lai m 4 , Wherei n sai d mul

ti ple of apertures de?nes a ri ng pattern.

6. The proj ec ti le as rec i ted i n c lai m 4 , Wherei n sai d mul

ti ple of apertures de?nes a shoWerhead pattern Wi th a multi ple

of ri ngs.

7. The proj ec ti le as rec i ted i n c lai m 1, f urther c ompri si ng a

c ore c ontai ned at least parti ally Wi thi n a j ac k et, sai d c ore

de?nes a c avi ty Whi c h c ontai ns sai d storage tank .

8. The proj ec ti le as rec i ted i n c lai m 1, f urther c ompri si ng a

di stri buti on mani f old betWeen sai d storage tank and sai d

exhaust mani f old.

9. A proj ec ti le c ompri si ng:

a proj ec ti le base;

an exhaust mani f old de?ned Wi thi n sai d proj ec ti le base;

US 7, 823, 510 B1

7

a storage tank operable to release a Work i ng ?ui d through

sai d exhaust mani f old to at least parti ally ?ll a Wak e af t

of the proj ec ti le duri ng proj ec ti le ?i ght; and

an i ni ti ator adj ac ent sai d storage tank , at lest one of sai d

i ni ti ator and sai d storage tank relati vely movable to the

other of sai d i ni ti ator and sai d storage tank to release the

Work i ng ?ui d f rom sai d storage tank i n response to an

ac c elerati on of the proj ec ti le.

10. A proj ec ti le c ompri si ng:

a proj ec ti le base;

an exhaust mani f old de?ned Wi thi n sai d proj ec ti le base;

a storage tank operable to release a Work i ng ?ui d through

sai d exhaust mani f old to at least parti ally ?ll a Wak e af t

of the proj ec ti le duri ng proj ec ti le ?i ght; and

a plug Whi c h seals sai d storage tank , sai dplug di slodgeable

f rom sai d storage tank to release the Work i ng ?ui d f rom

sai d storage tank i n response to an ac c elerati on of the

proj ec ti le.

11. A proj ec ti le c ompri si ng:

a proj ec ti le base;

an exhaust mani f old de?ned Wi thi n sai d proj ec ti le base;

a storage tank operable to release a Work i ng ?ui d through

sai d exhaust mani f old to at least parti ally ?ll a Wak e af t

of the proj ec ti le duri ng proj ec ti le ?i ght; and

a plug Whi c h seals sai d storage tank , sai d plug opens to

release the Work i ng ?ui d f rom sai d storage tank i n

response to an ac c elerati on of the proj ec ti le.

12. A proj ec ti le c ompri si ng:

a proj ec ti le base;

an exhaust mani f old de?ned Wi thi n sai d proj ec ti le base;

a storage tank operable to release a Work i ng ?ui d through

sai d exhaust mani f old to at least parti ally ?ll a Wak e af t

of the proj ec ti le duri ng proj ec ti le ?i ght; and

an i ni ti ator Whi c h ac ti vates upon i ni ti al ac c elerati on of the

proj ec ti le to release the Work i ng ?ui d.

13. A proj ec ti le c ompri si ng:

a proj ec ti le base;

an exhaust mani f old de?ned Wi thi n sai d proj ec ti le base;

and

a storage tank operable to release a Work i ng ?ui d through

sai d exhaust mani f old to at least parti ally ?ll a Wak e af t

of the proj ec ti le duri ng proj ec ti le ?i ght; and

an i ni ti ator Whi c h ac ti vates at a predetermi ned ti me af ter

i ni ti al ac c elerati on of the proj ec ti le to release the Work

i ng ?ui d.

14 . A proj ec ti le c ompri si ng:

a proj ec ti le base;

an exhaust mani f old de?ned Wi thi n sai d proj ec ti le base;

and

a storage tank operable to release a Work i ng ?ui d through

sai d exhaust mani f old to at least parti ally ?ll a Wak e af t

of the proj ec ti le duri ng proj ec ti le ?i ght; and

a heat sourc e adj ac ent sai d storage tank , sai d heat sourc e

operable to i nc rease the temperature of the Work i ng ?ui d

upon i ni ti al ac c elerati on of the proj ec ti le.

20

25

30

35

4 0

4 5

50

55

8

15. A round of ammuni ti on c ompri si ng:

a c artri dge c ase;

a proj ec ti le seated Wi thi n sai d c artri dge c ase, sai d proj ec

ti les havi ng a proj ec ti le base;

an exhaust mani f old de?ned Wi thi n sai d proj ec ti le base;

and

a storage tank operable to release a Work i ng ?ui d through

sai d exhaust mani f old to at least parti ally ?ll a Wak e af t

of the proj ec ti le duri ng proj ec ti le ?i ght; and

an i ni ti ator operable to release the Work i ng ?ui d f rom sai d

storage tank i n response to an ac c elerati on of the pro

j ec ti le.

16. The round of ammuni ti on as rec i ted i n c lai m 15,

Wherei n sai d proj ec ti le f urther c ompri ses:

a c ore Whi c h de?nes a c avi ty Whi c h c ontai ns sai d storage

tank ; and

a j ac k et Whi c h surrounds sai d c ore, sai d j ac k et de?nes a

c annelure at Whi c h sai d c artri dge c ase i s c ri mped to sai d

proj ec ti le.

17. A method of extendi ng the range of a non- propulsi ve

proj ec ti le c ompri si ng:

ac ti vati ng an i ni ti ator to release a Work i ng ?ui d f rom a

storage tank c ontai ned Wi thi n a proj ec ti le i n response to

an ac c elerati on of the proj ec ti le, the Work i ng ?ui d

released through an exhaust mani f old duri ng a ?i ght of

the proj ec ti le to at least parti ally ?ll a Wak e af t of the

proj ec ti le.

18. A method of extendi ng the range of a non- propulsi ve

proj ec ti le c ompri si ng:

releasi ng a Work i ng ?ui d at a predetermi ned ti me af ter

?ri ng of the proj ec ti le f rom a c artri dge c ase f rom a

storage tank c ontai ned Wi thi n a proj ec ti le through an

exhaust mani f old duri ng a ?i ght of the proj ec ti le to at

least parti ally ?ll a Wak e af t of the proj ec ti le.

19. A method as rec i ted i n c lai m 17, f urther c ompri si ng

releasi ng the Work i ng ?ui d upon ?ri ng of the proj ec ti le f rom

a c artri dge c ase.

20. A method of extendi ng the range of a non- propulsi ve

proj ec ti le c ompri si ng:

releasi ng a Work i ng ?ui d f rom a storage tank c ontai ned

Wi thi n a c avi ty of a proj ec ti le through an exhaust mani

f old duri ng a ?i ght of the proj ec ti le to at least parti ally

?ll a Wak e af t of the proj ec ti le, the storage tank movable

Wi thi n the c avi ty to i ni ti ate release of the Work i ng ?ui d.

21. A method as rec i ted i n c lai m 17, Wherei n at least par

ti ally ?lli ng the Wak e af t of the proj ec ti le reduc es proj ec ti le

base drag.

22. A method as rec i ted i n c lai m 17, f urther c ompri si ng:

expandi ng the Work i ng ?ui d at a pres sure Whi c h exc eeds a

base pressure of the proj ec ti le.

23. A method as rec i ted i n c lai m 17, f urther c ompri si ng:

expandi ng the Work i ng ?ui d to beloW approxi mately one

atmospheri c pressure though the exhaust mani f old.

24 . A method as rec i ted i n c lai m 17, f urther c ompri si ng:

expandi ng the Work i ng ?ui d to beloW approxi mately one

atmospheri c pressure though the exhaust mani f old.

25. The proj ec ti le as rec i ted i n c lai m 1, Wherei n sai d Work

i ng ?ui d i s stored above 5000 psi .

* * * * *

You might also like

- VSP-12Way - Is Rev.03Document55 pagesVSP-12Way - Is Rev.03Marcelo AlmeidaNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,136,672 B2Document11 pagesUlllted States Patent (10) Patent N0.: US 8,136,672 B2pamururamuNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,645,517 B2Document54 pagesUlllted States Patent (10) Patent N0.: US 8,645,517 B2sat258No ratings yet

- United States Patent: 12 10 Patent N0.: US 7 313 534 B2 Scheer (45) Date of Patent: Dec. 25, 2007Document43 pagesUnited States Patent: 12 10 Patent N0.: US 7 313 534 B2 Scheer (45) Date of Patent: Dec. 25, 2007Ryan MullinsNo ratings yet

- SHREDDER WITH JAM PROOF SYSTEMDocument16 pagesSHREDDER WITH JAM PROOF SYSTEMIbraheem KhressNo ratings yet

- United States Patent: Rousseau Et Al. (45) Date of Patent: Apr. 24, 2007Document31 pagesUnited States Patent: Rousseau Et Al. (45) Date of Patent: Apr. 24, 2007omikamiNo ratings yet

- United States Patent: (12) (10) Patent N0.: US 6,643,842 B2Document45 pagesUnited States Patent: (12) (10) Patent N0.: US 6,643,842 B2bgstrandNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument21 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentPato Patiño MuñozNo ratings yet

- United States Patent: Pipkorn Et Al. Sep. 30, 2003Document16 pagesUnited States Patent: Pipkorn Et Al. Sep. 30, 2003Juan OrtegaNo ratings yet

- United States Patent (10) Patent No.: US 7.282,100 B1: Schouest Et Al. (45) Date of Patent: Oct. 16, 2007Document15 pagesUnited States Patent (10) Patent No.: US 7.282,100 B1: Schouest Et Al. (45) Date of Patent: Oct. 16, 2007opik24No ratings yet

- United States Patent (10) Patent No.: US 7,563,026 B2Document11 pagesUnited States Patent (10) Patent No.: US 7,563,026 B2Hussein Ahmed MosesNo ratings yet

- United States Patent: Mueller Et Al. (10) Patent N0.: (45) Date of PatentDocument8 pagesUnited States Patent: Mueller Et Al. (10) Patent N0.: (45) Date of PatentAnonymous LEVNDh4No ratings yet

- US007199093B2 - Liquid composition for removal of odors and contaminants from textilesDocument11 pagesUS007199093B2 - Liquid composition for removal of odors and contaminants from textilesRajan NaikNo ratings yet

- Us 6362718 (US Patent For Free Energy Device)Document15 pagesUs 6362718 (US Patent For Free Energy Device)jajahahaNo ratings yet

- US8749333Document19 pagesUS8749333Anonymous GIIncAfLRNo ratings yet

- 12) United States Patent: Kazala, Jr. Et ADocument16 pages12) United States Patent: Kazala, Jr. Et Amohamedabbas_us3813No ratings yet

- United States Patent (10) Patent No.: US 6,527,353 B1: Bradfish Et Al. (45) Date of Patent: Mar. 4, 2003Document9 pagesUnited States Patent (10) Patent No.: US 6,527,353 B1: Bradfish Et Al. (45) Date of Patent: Mar. 4, 2003Renato GavanNo ratings yet

- United States Patent (10) Patent No.: US 7,740,751 B2: Peters (45) Date of Patent: Jun. 22, 2010Document16 pagesUnited States Patent (10) Patent No.: US 7,740,751 B2: Peters (45) Date of Patent: Jun. 22, 2010xyz7890No ratings yet

- Flex Sensor Patents PDFDocument7 pagesFlex Sensor Patents PDFhakam pranatagamaNo ratings yet

- Us 8635309kj KJDocument27 pagesUs 8635309kj KJScot FrankNo ratings yet

- Gas operated rifle bolt carrier assembly improvementsDocument44 pagesGas operated rifle bolt carrier assembly improvementsingeniomeca8800No ratings yet

- Us 9050873Document24 pagesUs 9050873Julius RojoNo ratings yet

- US7741796Document9 pagesUS7741796ALiftsNo ratings yet

- United States Patent: (12) (10) Patent N0.: US 7,367,396 B2 Springett Et Al. (45) Date of Patent: May 6, 2008Document24 pagesUnited States Patent: (12) (10) Patent N0.: US 7,367,396 B2 Springett Et Al. (45) Date of Patent: May 6, 2008HKHKBOOKSNo ratings yet

- US6699426Document16 pagesUS6699426Muhammed BALIKÇINo ratings yet

- Drilling Rig Masts and Methods of Assembly and Erecting MastsDocument21 pagesDrilling Rig Masts and Methods of Assembly and Erecting MastsGustaNo ratings yet

- United States Patent (10) Patent No.: US 7,772,211 B2: Tsai Et Al. (45) Date of Patent: Aug. 10, 2010Document16 pagesUnited States Patent (10) Patent No.: US 7,772,211 B2: Tsai Et Al. (45) Date of Patent: Aug. 10, 2010Brian BuenoNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 7,838,027 B2Document11 pagesUlllted States Patent (10) Patent N0.: US 7,838,027 B2phamuyenthuNo ratings yet

- United States Patent: Holtzapple Et Al. (45) Date of Patent: Feb. 16, 2010Document23 pagesUnited States Patent: Holtzapple Et Al. (45) Date of Patent: Feb. 16, 2010Anonymous FjjJ0fNo ratings yet

- US7045704Document14 pagesUS7045704WindaBroCoNo ratings yet

- Aerosol separator filter designDocument19 pagesAerosol separator filter designLoka ThaniNo ratings yet

- United States Patent: Jan. 17, 2006 Phillips Et AlDocument10 pagesUnited States Patent: Jan. 17, 2006 Phillips Et AlFajar BarkahNo ratings yet

- 195Document11 pages195sabatino123No ratings yet

- US8188318 - Method of Manufacturing Ethyleneamines - Union CarbideDocument23 pagesUS8188318 - Method of Manufacturing Ethyleneamines - Union Carbidesalvatore raffaNo ratings yet

- مهم1Document15 pagesمهم1Amany ElsaeedNo ratings yet

- US6908288Document14 pagesUS6908288mohammad293No ratings yet

- United States Patent (10) Patent No.: US 7,511,228 B2: Yaung Et Al. (45) Date of Patent: Mar. 31, 2009Document12 pagesUnited States Patent (10) Patent No.: US 7,511,228 B2: Yaung Et Al. (45) Date of Patent: Mar. 31, 2009Geetha ThiruvengadamNo ratings yet

- Us 6913056Document28 pagesUs 6913056roux76No ratings yet

- 12) United States Patent 10) Patent No.: US 8.841,243 B2: Tobias Et Al. 45) Date of Patent: Seb. 23, 2014Document12 pages12) United States Patent 10) Patent No.: US 8.841,243 B2: Tobias Et Al. 45) Date of Patent: Seb. 23, 2014بن زيدون المخزوميNo ratings yet

- Sample Distribution SystemDocument38 pagesSample Distribution SystemJie99No ratings yet

- Polyactic Acid Shrink Films and MethodsDocument16 pagesPolyactic Acid Shrink Films and MethodshatharasingheNo ratings yet

- Fast Demould Extended Cream Time Pu Formulations US8618014Document9 pagesFast Demould Extended Cream Time Pu Formulations US8618014Gagan JainNo ratings yet

- Halliburton Primary CementingDocument12 pagesHalliburton Primary CementingLara CitlalliNo ratings yet

- United States Patent (10) Patent No.: US 8,028,749 B2Document23 pagesUnited States Patent (10) Patent No.: US 8,028,749 B2yasamanNo ratings yet

- United States Patent (10) Patent No.: US 7,909,748 B2Document50 pagesUnited States Patent (10) Patent No.: US 7,909,748 B2Alex MungaiNo ratings yet

- Method For Parachute Reefing ControlDocument9 pagesMethod For Parachute Reefing ControlgabrielmolloNo ratings yet

- United States Patent (19) : (45) Date of Patent: Dec. 8, 1998Document6 pagesUnited States Patent (19) : (45) Date of Patent: Dec. 8, 1998nagy_andor_csongorNo ratings yet

- Umted States Patent (10) Patent N0.2 US 8,415,942 B2: Fletcher (45) Date of Patent: Apr. 9, 2013Document19 pagesUmted States Patent (10) Patent N0.2 US 8,415,942 B2: Fletcher (45) Date of Patent: Apr. 9, 2013bonesisaliveNo ratings yet

- Efficient Steam-Assisted Flare Apparatus for Smokeless Burning of Combustible GasesDocument16 pagesEfficient Steam-Assisted Flare Apparatus for Smokeless Burning of Combustible GasesVeky PamintuNo ratings yet

- United States Patent (10) Patent No.: US 8,899,349 B2Document31 pagesUnited States Patent (10) Patent No.: US 8,899,349 B2Tripoli ManoNo ratings yet

- US7059434Document18 pagesUS7059434Baiuliang BaiuliangNo ratings yet

- Us 8213957Document51 pagesUs 8213957timmylau23No ratings yet

- Us6819027 PDFDocument14 pagesUs6819027 PDFmohasNo ratings yet

- INDUCTION IRONING TITLEDocument20 pagesINDUCTION IRONING TITLERonan RojasNo ratings yet

- Corrosion Resistant Coatings for MetalsDocument24 pagesCorrosion Resistant Coatings for MetalsAlexander Franco CastrillonNo ratings yet

- Us 6703545Document7 pagesUs 6703545Rubens Francisco MoreteNo ratings yet

- United States Patent (10) Patent No.: US 7,536,948 B1: Cockrum (45) Date of Patent: May 26, 2009Document28 pagesUnited States Patent (10) Patent No.: US 7,536,948 B1: Cockrum (45) Date of Patent: May 26, 2009Solomon HassanNo ratings yet

- United States Patent (10) Patent No.: US 8,014,526 B2Document12 pagesUnited States Patent (10) Patent No.: US 8,014,526 B2sat258No ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument7 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentHP ghnNo ratings yet

- US8822676Document20 pagesUS8822676Rhelvis1No ratings yet

- Us 3995792Document5 pagesUs 3995792werwer44345No ratings yet

- Ida/D: (12) United States PatentDocument11 pagesIda/D: (12) United States Patentwerwer44345No ratings yet

- Us 3995792Document5 pagesUs 3995792werwer44345No ratings yet

- European Patent Specification: Printed by Jouve, 75001 PARIS (FR)Document14 pagesEuropean Patent Specification: Printed by Jouve, 75001 PARIS (FR)werwer44345No ratings yet

- Ada 437023Document94 pagesAda 437023werwer44345No ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,362,408 B2Document11 pagesUlllted States Patent (10) Patent N0.: US 8,362,408 B2werwer44345No ratings yet

- United States Patent (10) Patent N0.: US 8,091,836 B2Document8 pagesUnited States Patent (10) Patent N0.: US 8,091,836 B2werwer44345No ratings yet

- European Patent Application: Energetic Detonation PropulsionDocument8 pagesEuropean Patent Application: Energetic Detonation Propulsionwerwer44345No ratings yet

- Us 3782667Document6 pagesUs 3782667werwer44345No ratings yet

- Us 3296443Document5 pagesUs 3296443werwer44345No ratings yet

- Us 7304283Document8 pagesUs 7304283werwer44345No ratings yet

- Us 7297913Document8 pagesUs 7297913werwer44345No ratings yet

- EP1770349A1Document18 pagesEP1770349A1werwer44345No ratings yet

- United States Patent: (DiscriminatorDocument9 pagesUnited States Patent: (Discriminatorwerwer44345No ratings yet

- Us 3971939Document4 pagesUs 3971939werwer44345No ratings yet

- United States Patent: Siiuiferer (451 July 1, 1975Document6 pagesUnited States Patent: Siiuiferer (451 July 1, 1975werwer44345No ratings yet

- United States Patent: Schoenfeld Et A1. (10) Patent N0.: (45) Date of PatentDocument10 pagesUnited States Patent: Schoenfeld Et A1. (10) Patent N0.: (45) Date of Patentwerwer44345No ratings yet

- Us 8688270Document12 pagesUs 8688270werwer44345No ratings yet

- Difference Between Knowledge and SkillDocument2 pagesDifference Between Knowledge and SkilljmNo ratings yet

- WSM 0000410 01Document64 pagesWSM 0000410 01Viktor Sebastian Morales CabreraNo ratings yet

- StrutsDocument7 pagesStrutsBatrisyialya RusliNo ratings yet

- HSPA+ Compressed ModeDocument10 pagesHSPA+ Compressed ModeAkhtar KhanNo ratings yet

- Amended ComplaintDocument38 pagesAmended ComplaintDeadspinNo ratings yet

- (NTA) SalaryDocument16 pages(NTA) SalaryHakim AndishmandNo ratings yet

- Structures Module 3 Notes FullDocument273 pagesStructures Module 3 Notes Fulljohnmunjuga50No ratings yet

- PHASE 2 - Chapter 6 Object ModellingDocument28 pagesPHASE 2 - Chapter 6 Object Modellingscm39No ratings yet

- Tambunting Pawnshop Vs CIR Re VATDocument7 pagesTambunting Pawnshop Vs CIR Re VATMark Lester Lee AureNo ratings yet

- 702190-Free PowerPoint Template AmazonDocument1 page702190-Free PowerPoint Template AmazonnazNo ratings yet

- DAP FullTextIntroductionByStuartLichtman PDFDocument21 pagesDAP FullTextIntroductionByStuartLichtman PDFAlejandro CordobaNo ratings yet

- SABIC Ethanolamines RDS Global enDocument10 pagesSABIC Ethanolamines RDS Global enmohamedmaher4ever2No ratings yet

- 【4DI+4DO】MA01+-AXCX4040 UserManual EN v1.1Document36 pages【4DI+4DO】MA01+-AXCX4040 UserManual EN v1.1RioNorte LojaNo ratings yet

- S0231689H02-B01-0001 Rev 02 Code 1 General Arrangement Drawing For 44 Kva Diesel Generator PDFDocument6 pagesS0231689H02-B01-0001 Rev 02 Code 1 General Arrangement Drawing For 44 Kva Diesel Generator PDFAnonymous AfjzJdnNo ratings yet

- Advanced Microcontrollers Grzegorz Budzyń Lecture 8 - ARM Based MCUs and APs PDFDocument103 pagesAdvanced Microcontrollers Grzegorz Budzyń Lecture 8 - ARM Based MCUs and APs PDFtudor11111No ratings yet

- Critical Values For The Dickey-Fuller Unit Root T-Test StatisticsDocument1 pageCritical Values For The Dickey-Fuller Unit Root T-Test Statisticswjimenez1938No ratings yet

- HandoverDocument2 pagesHandoverKumaresh Shanmuga Sundaram100% (1)

- Cagayan Electric Company v. CIRDocument2 pagesCagayan Electric Company v. CIRCocoyPangilinanNo ratings yet

- Pike River Case StudyDocument7 pagesPike River Case StudyGale HawthorneNo ratings yet

- Risk Ology ManualDocument2 pagesRisk Ology ManualGregoryNo ratings yet

- Hillingdon Health Visiting ServiceDocument12 pagesHillingdon Health Visiting ServiceAnnikaNo ratings yet

- Examination: Subject CT5 - Contingencies Core TechnicalDocument7 pagesExamination: Subject CT5 - Contingencies Core TechnicalMadonnaNo ratings yet

- Domestic Water Consumption in ChennaiDocument18 pagesDomestic Water Consumption in Chennaimaaz0% (1)

- Tita-111 2Document1 pageTita-111 2Gheorghita DuracNo ratings yet

- Safety of High-Rise BuildingsDocument14 pagesSafety of High-Rise BuildingsHananeel Sandhi100% (2)

- VBScriptDocument120 pagesVBScriptdhanaji jondhaleNo ratings yet

- (Lesson 10-1) - Quality Assurance, Hemocytometry, Thoma PipetsDocument22 pages(Lesson 10-1) - Quality Assurance, Hemocytometry, Thoma PipetselleNo ratings yet

- Military Railway Unit Histories Held at MHIDocument6 pagesMilitary Railway Unit Histories Held at MHINancyNo ratings yet

- Lirik and Chord LaguDocument5 pagesLirik and Chord LaguRyan D'Stranger UchihaNo ratings yet