Professional Documents

Culture Documents

Valvula Esferica Criogenica TBV

Uploaded by

frankz89Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valvula Esferica Criogenica TBV

Uploaded by

frankz89Copyright:

Available Formats

TBV

Valves

TBV

VALVES & MEASUREMENT

VALVES & MEASUREMENT

CT-TBV-02

2/12-SWP-3M

TBV

2

VALVES & MEASUREMENT VALVES & MEASUREMENT

CT-TBV-02

2/12-SWP-3M

TBV

3

TBV VALVES

Introduction .......................................................................................... 4

Instrument Valves ................................................................................. 5

Flanged Ball Valves ............................................................................... 7

Three-Piece Ball Valves .......................................................................... 8

Diverter Valves ...................................................................................... 9

Cryogenic Ball Valves ............................................................................ 10

Special Service ...................................................................................... 12

Check Valves ........................................................................................ 13

Instrument Installation Details ............................................................... 14

Instrument and Process Valves .............................................................. 14

Seat Rating Chart .................................................................................. 15

How to Order ....................................................................................... 16

Aftermarket Services ............................................................................. 17

Trademark Information ......................................................................... 18

TABLE OF CONTENTS

VALVES & MEASUREMENT

CT-TBV-02

2/12-SWP-3M

TBV

4

Camerons Valves & Measurement (V&M) group is a leading provider of valves and

measurement systems to the oil and gas industry. The groups products are primarily used to

control, direct and measure the flow of oil and gas as it is moved from individual wellheads

through flow lines, gathering lines and transmission systems to refineries, petrochemical plants

and industrial centers for processing.

The Engineered & Process Valves division provides a wide range of valves for use in natural gas,

LNG, crude oil and refined products transmission lines. The traditional CAMERON

fully-welded

ball valve product line has been combined with the GROVE

, RING-O

, TOM WHEATLEY

,

ENTECH

and TK

product lines. This broad offering has significantly strengthened Camerons

ability to serve as a single source for a wide scope of customer requirements. The division also

provides critical service valves for refinery, chemical and petrochemical processing businesses

and for associated storage terminal applications, particularly through the ORBIT

and GENERAL

VALVE

. These brands are complimented by WKM

and TBV

valve products and considerably

expand the scope of this divisions product offerings.

TBV valve products are manufactured and assembled at Camerons new facility in Millbury,

Massachusetts. The TBV facility offers 100,000 ft

2

of space of which 80,000 ft

2

is dedicated to

manufacturing, assembling, testing, shipping, and quality assurance. The increased

manufacturing space has afforded Cameron the opportunity to expand its product offering

and size ranges. TBV is now competitive in the LNG, mining and petrochemical markets with

its ability to offer larger size ranges in its line of products.

Mi l l bury, MA

CT-TBV-02

2/12-SWP-3M

TBV

5

VALVES & MEASUREMENT VALVES & MEASUREMENT

TBV VALVES

I NSTRUMENT VALVES

Series 4100

The TBV series 4100 is an all welded, double female instrument or process valve

which meets API 607 4th Edition fire safe requirements. Standard sizes include

1/4 in. - 1 in. (8 mm - 25 mm). Material options include all commercially

available alloys.

Series 41/61

The TBV series 41/61 is an all welded design with one female NPT end and

one male end. The male end is available with screwed, butt weld, socket

weld, and flanged connections. Male and female ends may be different sizes

upon request.

Series 5500

The TBV series 5500 is a true dual ball block-and-bleed valve used for primary

isolation for both instrumentation and process. There are two closure

members on each side of the bleed valve. For the bleed, a standard TBV

instrument ball valve is recommended. Non-TBV brands can be utilized for the

bleed, such as needle or gate valves, depending on customer preference. The

series 5500 is available up through 3 and ASME 600 pressure class in any

commercially available material.

Series 6100

The TBV series 6100 is fully rodable and provides three 1/2 female ports with

one male end for attachment to an orifice flange. The TBV series 6100 allows

for different sized male ends up to 1 in size and is available in a variety

materials. The valve can be installed in pairs on 2 1/8 centers.

Series 61/41/61

The double male end TBV series 61/41/61 valve is a natural offshoot of the TBV

series 4100 which eliminates the need for nipples to be used with female end

valves. The all welded design reduces the number of leak paths and extended

male ends are available upon request.

CT-TBV-02

2/12-SWP-3M

TBV

6

VALVES & MEASUREMENT

TBV VALVES

I NSTRUMENT VALVES

Series 6400

The TBV series 6400 valve includes all of the advanced TBV ball valve features

in a fire safe design that meets API 607 4th Edition. The TBV series 6400 is

available with a variety of seat materials in a carbon steel or stainless forged

body from 1/2 - 1. Other materials are available upon request. The TBV series

6400 is furnished with one NPT end and allows a choice of NPT, socket weld,

or IREB end connections for the other end. This 1/4 turn ball valve replaces

leaky extended body gate valves in process, block, bleed and drain applications.

Series 6500

The TBV series 6500 cast body process transmitter valve replaces gate valves

with advanced TBV ball valve features in a fire safe design meeting stringent

refinery and chemical plant requirements. The TBV series 6500 features all

welded tamper proof construction, an internal blow-out proof stem and an oval

safety handle to prevent accidental operation. The unique design of the TBV

series 6500 incorporates back-up metal fire lips to provide sealing should the

soft seals sublimate in the event of fire and optional graphoil stem seals

ensuring fire safe protection. TBVs series 6500 offers reliability, safety, visibility,

unique mounting capability, quality and unsurpassed leakage protection.

Series 6800

The TBV series 6800 is an instrument valve with a cast body that incorporates

an integral lockout pad and a high performance stem packing. The valve comes

equipped with a locking oval handle as a standard feature. It is seal welded to

prevent tampering or accidental unthreading when removing from the line.

The TBV series 6800 is fire safe when ordered with appropriate seals, and is fully

rodable. Because of the cast lockout pad, it cannot be turned on 2 1/8 centers.

Series 6900

An instrument valve similar to the TBV series 6100 valve, the TBV series 6900

valve uses a cast body that incorporates an integral lockout pad and a high

performance stem packing. Like the TBV series 6100, the TBV series 6900 is

intended as a gage isolation valve, with tapped NPT side ports for flush and

drain functions. It incorporates all of the other features of the TBV series 6100

valve; rodability, fire safety, and seal welding. The valve comes equipped with a

locking oval handle as a standard feature. Because of the cast lockout pad, it

cannot be turned on 2 1/8 centers.

CT-TBV-02

2/12-SWP-3M

TBV

7

VALVES & MEASUREMENT

TBV VALVES

FLANGED BALL VALVES

Series 2000

The TBV series 2000 is a uniquely designed, reduced port flanged ball valve

offering unlimited versatility with respect to materials, features, and modifiers

to satisfy todays sophisticated process valve requirements. Where corrosion,

high temperatures, slurries, and flow control applications are to be met, the

TBV series 2000 is a clear choice. The valve body is designed to facilitate ease of

automation by including both ISO and flange boss mounting capabilities as

standard. The TBV series 2000 is available in 1/2 - 8, ASME 150, 300.

Valve safety is also addressed by utilizing the standard blow-out proof stem

design in conjunction with optional features such as oval safety handle for sizes

up to 1 1/2, lock-out device, fugitive emission and bellows seal bonnets. They

are designed to comply with the fire safe standards of major oil refineries and

API 607. As with all TBV valves, quality, flexibility, long service life, and safety

make this valve the best choice for integrity and application satisfaction.

Series 1800

The TBV series 1800 flanged valve, available in standard or full port design, is a

high integrity two-piece design. The leak proof design is enhanced through the

use of an optional high performance bonnet which eliminates all possibility of

release of toxic media. The TBV series 1800 also provides a stop plate with

open/closed indication and a tapped actuator mounting plate which allows

actuator installation without disturbing the stem packing. This unique design

allows the valve to be manufactured from bar stock, thereby maintaining

flexibility of manufacture. It is available from 1/2 to 10 in a variety of body

and seat materials with ASME 150 - 1500 flanges.

Series FE2000 and Series FE1800

The TBV series FE2000 and TBV series FE1800 valves incorporate all of the

features of the TBV series 2000 and TBV series 1800 Flange valves, plus the

ability to be used in critical applications where handling of toxic emissions is

required. The bonnet is welded to the valve body eliminating a potential leak

path, utilizing either double chevron or wedge packing with lantern ring,

optional monitoring, leak off port, and maintenance free-extended cycle life.

Finally, our unique live loaded floating stem design preserves the FE seal

integrity even in fire safe applications. The valve is available in 1/2 to 8sizes

for the TBV series FE2000 and 1/2 to 10 sizes for the TBV series FE1800.

FE1800 FE2000

CT-TBV-02

2/12-SWP-3M

TBV

8

VALVES & MEASUREMENT

TBV VALVES

FLANGED BALL VALVES

Series 2800

The TBV series 2800 two-piece, cast full port flanged ball valve is specifically

designed to tackle severe service applications. This design includes a Live

Loaded dual stem seal (primary and secondary seal) as standard. The body and

bonnet are cast as a single piece with no welds or crevices. The TBV series 2800

is available from 1 to 8 with ASME 150 - 300 flanges (3- 8 ASME 600

available). Materials include cast stainless steel, monel, hastelloy, alloy 20, nickel

and others as required.

Series 3300

An enhanced version of the TBV series 1800, the TBV series 3300 is suited for

highly corrosive and erosive applications. Design includes a secured

downstream seat, spring loaded upstream seat and enhanced ball / stem

engagement. This valve is manufactured from barstock from any commercially

available material. It is available from 1 to 14 ASME 150 - 1500.

Series 1100

Along with all of the features and versatility of a three-piece valve, the TBV

series 1100 valve incorporates a raised face on the seat bearing side of the

endplate which assures positive alignment of the components and positive

preset. The body seal is 100% enclosed, extending the temperature range of

virgin TFE. Rugged construction features a heavy duty handle and stop plate,

and oversize body bolts with a variety of material options. The TBV series 1100

is 1500 WOG rated and is available in a wide variety of materials with NPT,

socket weld, butt weld, and flanged end connections in 1/4 through 10

sizes. Other special end connections are available upon request.

Series 3100

The TBV series 3100 wafer three-piece valve combines the benefits of a

standard three piece with additional wafer features. The three-piece design

utilizes raised face end plates to ensure correct alignment with the body, totally

encapsulated body seals, and a bottom entry blow-out proof stem. The wafer

configuration provides additional benefits, including reduction of the material

mass of the valve and lower cost. The TBV series 3100 can be used between

ASME 150 - 600 flanges with a 1500 psi pressure rating and is available from

1/2 - 8 in a wide variety of alloys.

THREE-PI ECE BALL VALVES

CT-TBV-02

2/12-SWP-3M

TBV

9

VALVES & MEASUREMENT

TBV VALVES

DI VERTER VALVES

Series 5100 (fabricated from a Series 1100)

TBV offers the series 5100 Diverter valve to accomplish what would otherwise

require two or more two-way valves. The diverter valve utilizes all of the

benefits of the two-way, three-piece TBV valve: a blow-out proof stem, raised

face end plates to eliminate radial piping stresses that could cause body seal

leakage, a wide variety of seals, and a large selection of end connections. The

TBV series 5100 is also available in either a diverter or a three-way format with

bottom or side porting, and for 90 or 180 operation, from 1/4 through 6,

making it valuable for a multitude of applications.

Four-Way

TBVs Four-Way valve is manufactured to our highest standards for use where

several two-way valves would otherwise be needed. It is available in a wide

array of flow patterns utilizing an L port, a T port or a double L ball. Four seats

ensure leak tight sealing. The four-way can be produced in a large variety of

body and seat materials from 1/2 - 6 and is available with screwed, socket

weld, butt weld or flanged end connections. Consult factory for specific

application.

Series 51/20 (fabricated from a Series 2000)

The TBV series 51/20 flanged, unibody diverter valve is an integrally flange

design for use in applications which would normally require two or more

two-way valves. It is available with side or bottom porting in 90 or 180

operation. The 90 operation allows diverting from the bottom or side port to

either of the other two ports with a 90 turn of the handle, but the flow can

never be shut-off. The 180 operation allows diverting with a 180 turn of the

handle and flow can be shut-off at the 90 position. The TBV series 51/20 is

available from 1/2 to 8 with ASME 150 - 300 flanges and in a variety of alloys.

CT-TBV-02

2/12-SWP-3M

TBV

10

VALVES & MEASUREMENT

TBV VALVES

CRYOGENI C BALL VALVES

Series 2100 (fabricated from a Series 1100)

The unique design of TBVs series 2100 three-piece cryogenic valve incorporates

features that provide long life, safety and low torque. The high strength,

blowout proof stem is used in conjunction with an all welded extended bonnet

and a five chevron V-ring packing to provide leak proof stem seal integrity, as

well as providing live loaded self-adjustment. TBVs specially designed and

formulated Cryofil seats provide low operating torque at cryogenic

temperatures. The TBV series 2100 has a temperature rating down to -452F

and is available up to ASME 1500. It is available in 316L stainless steel, brass

and other commercially available materials with NPT, socket weld, butt weld or

ASME 150 - 1500 flanged end connections, in 1/4 through 8 sizes. For

applications such as vent and bleed lines or intermittent cryogenic service, TBV

offers the non-extended stem. This valve incorporates all of the unique features

of our standard TBV series 2100 cryogenic ball valve.

Series 21/18, 21/20 and 21/28 Flanged Cryogenic Valves

TBV flanged cryogenic valves provide chatter free operation down to -452F

through the use of our exclusively formulated Cryofil seat. The integrity of the

valve is further enhanced by the all welded bonnet design and upstream cavity

relief. The stem is blowout proof and self adjusting to wear and pressure due to

live loading. The standard body materials are 316L stainless steel and are available

with ASME 150-1500 flanges, model dependent, in through 8 sizes.

Series 21/20 Series 21/18 Series 21/28

CT-TBV-02

2/12-SWP-3M

TBV

11

VALVES & MEASUREMENT

TBV VALVES

CRYOGENI C BALL VALVES

Series 21/80

The TBV series 21/80 is the large bore (10 - 16), cryogenic valve available

from ASME 150 through 900. This series of valve is full port, trunnion, split

body design. The valve is low temperature tested per Bechtel 3PS-PV00-F0001

and Chevron, specification for testing requirements for qualification of valves in

low temperature and cryogenic service.

Series 21/51 (fabricated from a Series 1100)

The TBV series 21/51 Cryogenic Diverter incorporates all features found in the

TBV series 2100 and provides diverting capabilities for use where two or more

two-way valves would normally be necessary, specifically in dual safety relief.

The TBV series 21/51 is available in two porting arrangements: 90 operation

and 180 operation. The 90 operation allows flow from a bottom port to be

diverted to either of two outlet ports over a 90 turn of the handle, but can

never shut-off the flow. The 180 operation also diverts a flow from the bottom

port to either of two outlet ports, but uses a 180 turn of the handle, allowing

the flow to be shut-off completely at the 90 position.

The TBV series 21/51 is available in full port or standard port from 1/2 through

8, in 316L stainless or brass, with or without an extended stem. Screw ends,

socket weld ends, butt weld ends or ASME 150-600 flanged ends are also

available.

Series 21/51A

The TBV series 21/51A high flow cryogenic diverter valve assembly for dual

safety relief systems is designed to meet the high flow requirements of

stationary cryogenic containers. This valve features foolproof 180 operation,

provides positive porting with consistently high Cv during transfer and is suitable

for tank pressures to 600 psi. The TBV series 21/51A combines TBVs compact,

modular design virtually eliminating the necessity of costly field fabrication.

CT-TBV-02

2/12-SWP-3M

TBV

12

VALVES & MEASUREMENT

TBV VALVES

SPECI AL SERVI CE

Actuation and Gear Operators

TBVs pneumatic and electric actuation packages compliment our complete valve

line. Pneumatic actuation is available with spring return or double acting. Electric

actuation includes all standard voltages. TBV can provide a total control package

including limit switches and positioners to meet customer requirements.

Oxygen Service

TBV valves are commonly applied on oxygen service in either the liquid (cryogenic)

or gaseous phase. Because of the danger of oxygen reacting explosively with any

grease, oil or combustible material left in the piping system, TBV valves provided

for oxygen service are:

Inspected for chips, burrs, foreign matter and any other defects

in workmanship

Cleaned and degreased prior to assembly

All tools and handling apparatus degreased as above

Purged and dried with filtered, non-lubricated air

Seats and seals are lubricated with an oxygen compatible lubricant

(Fluorolube) on gaseous O

2

valves. Cryogenic valves are not lubricated

Black light inspected before assembly

Assembled, tested and air dried in a clean room

Capped on each end

Tagged Cleaned for Oxygen Service

Poly bagged and sealed closed

Complies with praxair standard GS-38

Chlorine Service

For the handling of chorine compounds, TBV has developed special designs to

withstand these harsh applications. TBV chlorine valves feature Inconel Belleville

loaded stem seals for automatic compensation of temperature and pressure

fluctuations, an upstream pressure relief hole in the ball or a slotted upstream

end plate to allow expanding chlorine to escape harmlessly upstream, and a wide

variety of available materials to suit each individual application. TBV chlorine

valves are assembled, cleaned and bagged following the recommendations of the

Chlorine Institute Pamphlet 6. The chlorine service option is available for all of

TBVs ball valves and can be tailored to fit any application.

CT-TBV-02

2/12-SWP-3M

TBV

13

VALVES & MEASUREMENT

FE Bonnet for High Performance

For critical applications in which leakage of toxic or volatile organic compounds

cannot be tolerated, TBV provides the fugitive emissions bonnet. The bonnet

utilizes a unique design in which the stem packing is live loaded between the

threads on the top of the stem and a shoulder on the stem, rather than a

shoulder in the packing box. Through this floating stem design, TBV has

eliminated the effect of temperature cycles on the packing arrangement. The

packing consists of a stack of up to ten chevron v-ring sandwiched between

top and bottom adapter rings, or wedge style packing and can be modified to

accept a leak off with a lantern ring. This unique design has been proven in

hundreds of installations in services including phosgene and chlorine. Available

for our entire ball valve line with an optional fire safe version, this fully welded

or integrally cast bonnet can be used with any valve series in any configuration

to prevent the release of dangerous media.

1/4 Turn Bellows Seal

This product line demonstrates the utmost in sealing capabilities (zero leakage)

for processes involving volatile organic compounds. Available on most TBV

valves, the ASME 300 is uniquely designed for endurance, and backup

secondary standard sealing as well as all welded integrity. A standard mounting

plate allows automation with linear or 90 electrical and pneumatic actuators.

Series 7100

The TBV series 7100 swing check valve utilizes our special toggle arm and disc

arrangement. This valve is available with integral metal seats. The TBV series

7300 wafer swing check valve can be supplied for use with all ASME flanges up

to ASME 600 as standard. Both the TBV series 7100 swing check and the TBV

series 7300 wafer swing check valves are available in sizes ranging from 2

through 8.

Series 9100

TBVs series 9100 ball check is available from 1/2 to 2 in a wide variety of

material choices such as stainless, monel, hastelloy and titanium. TBV can

provide the TBV series 9100 with all available end connections including socket

weld, butt weld, screw end or ASME 150 - 900 flanged ends. The TBV series

9100 is controlled by back pressure and can be supplied with a spring set

calibrated from 5-25 psi.

TBV VALVES

SEVERE SERVI CE

CHECK VALVES

VALVES & MEASUREMENT

CT-TBV-02

2/12-SWP-3M

TBV

14

TBV VALVES

I NSTRUMENT I NSTALLATI ON DETAI LS

TBVs instrument installation details combine optimum measurement technology, proven mounting practices (close coupling)

and hardware integration to produce not only the specified 0.075 or 0.05% accuracy and zero stability, but a low installed

cost unequalled in performance and constructability. This system can reduce installation costs by modularizing, pre-

engineering, pre-fabricating, and locking in the optimum transmitter installation in a tamper-proof, foolproof system that

guarantees the rated performance of the transmitter, while lowering the installed cost per instrument loop by 30 to 80%.

I NSTRUMENT AND PROCESS VALVES

TBV instrument valves were developed in response

to concerns expressed by plant engineers. Common

problems such as center-to-center spacing in DP

installations, visual position indication, plunging of

impulse lines and tamper proofing have been eliminated

in our instrument valve line. The center-to-center spacing

problem arises in competitive designs since the bonnet

must be removed from the body in order to screw the

valve into the orifice flange next to another valve.

TBV has solved this problem since our instrument valves

can be installed on 2 1/8 centers* by simply removing

the mating valve handle, leaving the valves factory

integrity intact.

Visual position indication is achieved through the use of

an oval safety handle. This handle allows easy position

identification while maintaining safety. These tamper-

proof valves incorporate additional safety through a full

penetration, all welded design which assures that the

body parts can never be separated. Standard valves have

been subjected to bending loads exceeding 27,000 lbs.

without weld failure.

To avoid plunging of impulse lines, all of TBVs Instrument

valves are fully rodable. The bore through the ball and

seats is larger than the body bore. This failure prevents

accidental damage to the ball or seats during the rodding

operation. TBVs ball valves are available in any

commercially produced alloy. In fact, we regularly produce

valves in Alloy 20, Monel, Hastelloy C22, Hastelloy C276,

316L Stainless, Titanium, Zirconium and more. TBV can

also accommodate the entire spectrum of end

connections on our instrument product line. All are

available with threaded, socket weld, butt weld or flanged

end connections and all can be ordered as fire safe.

* With exception of the TBV series 6800 + 6900.

Flow Applications Pressure Applications Level Applications

CT-TBV-02

2/12-SWP-3M

TBV

15

VALVES & MEASUREMENT VALVES & MEASUREMENT

TBV VALVES

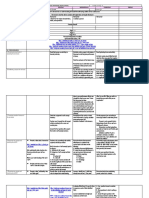

SEAT RATI NG CHART

psig (BAR)

4000 (276)

3500 (241)

3300 (207)

2500 (172)

2000 (138)

1500 (103)

1000 (69)

500 (34)

0 (0)

F 0 100 200 300 400 500 600 700 800 900 1000 1100

C (-18) (38) (93) (149) (204) (260) (316) (371) (427) (482) (538) (593)

TEMPERATURE F (C)

P

R

E

S

S

U

R

E

p

s

i

g

(

B

A

R

)

Extended pressures and temperatures may be achieved by altering design for specific applications.

Consult factory with service conditions.

Seat Material Identification Code

T-Virgin PTFE White

G-Reinforced PTFE White (Red speckles)

U-Ultrafil Black

C-Cryofil* White (Identifying groove)

F-Thermafil (PEEK) Light Brown

P-U.H.M.W.P. Translucent White

D-Delrin Dark Brown

K-CTFE Translucent

M-Metal Silver

H-Graphite Black

Graphite and metal seats are available for services up to 1000F, at varying pressures, dependant on media and service

conditions. Consult factory for specific rating.

* Registered trademark of TBV.

Extended pressures and temperatures may be achieved by altering designs for specific applications. Consult factory with

service conditions.

Metal

Thermafil

Delrin AF Kel-F

UHMW

Polyethelyne

Glass Filled

PTFE

Virgin

PTFE

Ultrafil

VALVES & MEASUREMENT

CT-TBV-02

2/12-SWP-3M

TBV

16

TBV VALVES

HOW TO ORDER

* For valves with different end connections indicate upstream (first), downstream (second).

** Special O.D. Wall Thickness and Length.

01 = 1/8

02 = 1/4

03 = 3/8

05 = 1/2

07 = 3/4

10 = 1

12 = 1 1/4

15 = 1 1/2

17 = 1 x 3/4

20 = 2

21 = 2 x 1

23 = 1/4 x 3/8

25 = 2 1/2

30 = 3

32 = 3/8 x 1/4

35 = 3 1/2

40 = 4

51 = 1/2 x 1

52 = 1/2 x 1/4

57 = 1/2 x 3/4

60 = 6

71 = 3/4 x 1

75 = 3/4 x 1/2

80 = 8

X0 = 10

X2 = 12

X4 = 14

X6 = 16

1A = 1 x 1/2

2A = 1/4 x 1/2

S = Standard Port

F = Full Port

11 = 1100-3 Piece

16 = 1600-Tank Bottom

18 = 1800-2 Piece

ASME Flange

20 = 2000-Unibody

Flange

21 = 2100-Cryogenic

2B = 21/20-Cryogenic

Unibody Flanged

2C = 21/31 Cryogenic

Wafer

2D = 21/51 Cryogenic

Diverter

2F = 21/51/20

Cryogenic Unibody

Flanged Diverter

2G = 21/18-Cryogenic

2-piece ASME

Flanged

2H = 21/61 Series Cryo

2K = 21/65 Series Cryo

2L = 21/64 Series Cryo

2P = 21/51/18 Split

body Flanged

Cryogenic Diverter

2R = Switching Diverter

Non-Extended

Stem - Bottom Port

2S = Switching Diverter

Extended Stem

- Side Port

2T = Switching Diverter

Non-Extended

Stem - Side Port

2V = Cryogenic 2800

2W = Cryogenic Large

Bore, Split Body

28 = 2800-Cast Full Port

31 = 3100-Wafer

32 = 3200-Steam Let

Down

33 = Severe Service

Valve

3L = 3100L-Lugged

Wafer

41 = 4100-Welded

43 = 4300-Welded w /

ds Relief on Ball

46 = 41/61-Male End

4100 Unibody

50 = 51/20-Diverter

Unibody Flanged

51 = 5100-Diverter

53 = 51/18 Diverter

61 = 6100-Orifice Tap

Gauge

66 = 61/41/61-Double

Male End All

Welded

71 = 7100-Swing Check

73 = 71/31-Wafer

Swing Check

91 = 9100-Ball Check

BWT = Buttweld Ext. &

Tube Ends**

B_ = Buttweld +

Schedule

(B40 = Schedule 40)

CPE = CPI Ends

FSE = NPT Female Thread

FSW = Female Socket

Weld

GRE = Graylok Ends

MFD = Manifold

Connection

MLS = Metal Seal

MSE = NPT Male Thread

MST = Straight Thread

with O-Ring

MSW= Male Socket Weld

MWE = Male Weld End

SOE = O.D. Tube End

Socket Weld

SPL = Special

TCE = Ladish End

TE_ = Tube End (K,L,M)

Socket Weld

UNE = Union End

150 = ASME 150 Flng RF

15L = ASME150 Lap Joint

Flanged

15R = ASME 150 RTJ

300 = ASME 300 Flng RF

30L = ASME 300 Lap

Joint Flanged

30R = ASME 300 RTJ

600 = ASME 600 Flng RF

60R = ASME 600 RTJ

900 = ASME 900 Flng RF

005 = ASME 1500 Flng

RF

05R = ASME 1500 RTJ

0 = IREB

1 = MSE

2 = MSW

3 = FSE

4 = FSW

5 = I-Flange

6 = BW80

7 = BW40

8 = BW160

9 = I-Flange Neutral

EXAMPLE:

1 x 3 = MSE X FSE

A2 = Alloy 20

AL = Aluminum

BR = Brass

CS = Carbon Steel

D2 = Super Duplex

Stainless

UNS-32750

D3 = Duplex

Stainless

UNS-S31803

HB = Hastelloy B

HC = Hastelloy C

H3 = Hastelloy B-3

H2 = Hastelloy

C-22

IN = Inconel

IY = Incoloy

LC = LCB Carbon

Steel

M4 = Monel 400

M5 = Monel K500

N2 = Nickel 200

T2 = Titanium

Gr 2

T5 = Titanium

Gr 5

T7 = Titanium

Gr 7

T12 = Titanium

Gr 12

TN = Tantalum

ZR = Zirconium

34 = 304 SS

36 = 316 SS

37 = 317 SS

4L = 304L SS

6L = 316L SS

B = ASTM A193

B7M x A194 7M

C = ASTM A193 B8

CL2 x A194 Gr 8

D = Alloy 20

E = ASTM A193B8

CL1 x A194 Gr 8F

F = ASTM A540 B21 x

A194 Gr 2H

G = ASTM A320 L7 x

A194 Gr 4

H = Inconel 718

J = 410SS A193 Gr

B6

K = 304L SS

L = Hastelloy B2

M = Monel 400

N = ASTM A320 Gr

B8P

Q = A193 Gr B8 x

ASTM A194 Gr 8

W = All Welded

0 = None

1 = Carbon Steel

2 = 300 SS

3 = ASTM A193 B7 x

A194 2H

4 = ASTM A193 B8M

x A194 8M

5 = Monel K-500

6 = Hastelloy C

7 = 316 SS

8 = Gr 5 Titanium

9 = HAST C-276

01 = 90 Operation

(Diverter Valve)

02 = 180 Operation

(Diverter Valve)

04 = 4 Seated

AH = Act. Prep w/std

Handle

AI = Act. Installed

AP = Prepared for

Actuation

BS = Bellows Seal

CA = Cutaway Sample

CB = Enclosed Bolting

CD = Cleaned and

Degreased

CS = Crusher Seats

CF = Cavity Filler

CL = Chlorine Cleaning

EB = Extended Bonnet

EE = Extended Ends

EP = Electro Polish

ES = Extended Stem

FE = Fugitive Emissions

Bonnet

FG = Forged Material

FL = Fire Lip

FS = Fire Safe

GO = Gear Operator

GS = Grounding Spring

HF = Hydro-Fluoric Service

HP = High Pressure

LG = Locking Gear

Operator

LH = Locking Handle

LO = Locking Oval Handle

LR = Lantern Ring

LS = locking SS Oval

Handle

LV = Lever Handle

M1 = 15 Control Seat

M3 = 30 Control Seat

M6 = 60 Control Seat

M9 = 90 Control Seat

NE = Non-Extented

OH = Oval Handle

OS = Stainless Steel Oval

Handle

OX = Oxygen Cleaned

PC = Phosgene Cleaned

PM = Panel Mounted

RS = Self Relieving Seats

SJ = Steam Jacket

SL = Spring Loaded/9100

SP = Side Port/5100

SR = Spring Return Handle

TR = Trunnion

VB = Vented Ball

VS = Vacuum Service

W1 = Spiral Wound Body

Seal

W2 = Spiral Wound Body

Seal 316S Grafoil

W3 = Spiral Wound Body

Seal Ti Gr 2 TFE

W4 = Spiral Wound Body

Ti Gr 2 Grafoil

W5 = Spiral Wound Body

Gasket Hast C

Grafoil

A = Arlon 1555

PEEK

B = Buna

C = Cryofil

D = Delrin AF

E = E.P.R.

F = Thermafil

G = 15% GF TFE

H = Grafoil/Graphite

K = CTFE

L = Vespel

M = Metal

N = Nylon

P = UHMWP

Q = E.P.D.M.

S = Stellite

T = Virgin TFE

U = Ultrafil 25

V = Viton

1 = Tefzel

2 = Kalrex

3 = PFA

4 = FEP

5 = Ertelyte

(CERTAIN COMBINATIONS

NOT AVAILABLE)

VALVE SPECIFICATION CHART

Size Porting Series

End

Connections

Body / End

Material*

Ball / Stem

Material

Seat / Seal

Material

Bolting Modifiers

for mixed

combination

of end

plates

VALVES & MEASUREMENT VALVES & MEASUREMENT

CT-TBV-02

2/12-SWP-3M

TBV

17

CERTIFICATIONS

AFTERMARKET SERVICES

Aftermarket Servi ces

Supplies replacement valves and parts:

Maintains a full inventory of new and

reconditioned valves for immediate delivery

Provides factory warranty support for all

Cameron OEM brands as well as service for most

other valves

Field Service and Technical Support

Field service technicians on call 24 hours a day

7 days a week to handle service issues wherever

they arise

Provides equipment installation, field repairs,

as well as track and perform scheduled

maintenance

Customer Property Repair

The Customer Property Repair program allows

Cameron valve customers to store assets at our

service centers throughout the world

Valves tracked in electronic database accessible

through the Internet

Remanufactured Products

Offers a broad range of API-compliant

reconditioned equipment with fast delivery

Total Valve Management

Supply and service automation and control

packages

Assist with valve installation, commissioning and

start-up

Camerons Aftermarket Services goal is to help our

customers lower the total cost of valve ownership. To that

end we offer a full range of services from over twenty-five

Service Centers worldwide and can provide experienced

personnel trained to meet the specific service requirements

of each valve type.

VALVES & MEASUREMENT

CT-TBV-02

2/12-SWP-3M

TBV

18

TRADEMARK INFORMATION

TBV is a registered trademark which is owned by Cameron.

This document contains references to registered trademarks or product designations,

which are not owned by Cameron.

Trademark Owner

DELRIN E.I. DuPont De Nemours & Company

HASTELLOY Haynes International, Inc.

INCONEL INCO Nickel sales, Inc.

MONEL INCO Alloys International, Inc.

PEEK Vitrex PLC Corp United Kingdom

TEFLON E.I. DuPont De Nemours & Company

VITON E.I. DuPont De Nemours & Company

VALVES & MEASUREMENT VALVES & MEASUREMENT

CT-TBV-02

2/12-SWP-3M

TBV

19

Cameron Printed in USA 2/12-SWP-3M CT-TBV-02

VALVES & MEASUREMENT

Valves & Measurement

3250 Briarpark Drive, Suite 300

Houston, TX 77042

USA Toll 800 323 9160

For the most current contact and location information go to: www.c-a-m.com

Cameron stri ves for conti nuous i mprovement i n al l aspects of our busi ness. Cameron

reserves the ri ght to modi fy desi gns and speci fi cati ons wi thout noti ce or obl i gati on. Nothi ng

contai ned i n thi s brochure i s i ntended to extend any type of warranty, expressed or i mpl i ed.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Rev C Diagnostic Repair Manual AC Evolution 1.0 2.0 50 60 HZDocument254 pagesRev C Diagnostic Repair Manual AC Evolution 1.0 2.0 50 60 HZVariACK100% (1)

- Six Code Workbook 3.21.08Document30 pagesSix Code Workbook 3.21.08Omar Hernández0% (1)

- HANBOOK Jaw Crushers PDFDocument8 pagesHANBOOK Jaw Crushers PDFfrankz89No ratings yet

- Vent-O-Mat - Nozzle Check ValveDocument8 pagesVent-O-Mat - Nozzle Check Valvefrankz89No ratings yet

- Annexure 2 - Requisition For Pipe 4inch & AboveDocument11 pagesAnnexure 2 - Requisition For Pipe 4inch & Abovefrankz89No ratings yet

- Piping MineriaDocument2 pagesPiping Mineriafrankz890% (1)

- Tipos de Bombas CentrifugasDocument43 pagesTipos de Bombas Centrifugasfrankz89No ratings yet

- 06 Mantenimiento de Calderas Industriales BOSCH Fenercom 2013.desbloqueadoDocument43 pages06 Mantenimiento de Calderas Industriales BOSCH Fenercom 2013.desbloqueadoAlex H. De la CruzNo ratings yet

- HANDBOOK Blanket Gas Regulators PDFDocument8 pagesHANDBOOK Blanket Gas Regulators PDFfrankz89No ratings yet

- Pipe Systems PDFDocument108 pagesPipe Systems PDFfrankz89No ratings yet

- Cascho Modelo DDocument16 pagesCascho Modelo Dfrankz89No ratings yet

- HANDBOOK Blanket Gas Regulators PDFDocument8 pagesHANDBOOK Blanket Gas Regulators PDFfrankz89No ratings yet

- Manual - Dust Collector and Bin VentDocument13 pagesManual - Dust Collector and Bin Ventfrankz89No ratings yet

- Automatic Fuel Oil Transfer Pump Set - DatasheetDocument5 pagesAutomatic Fuel Oil Transfer Pump Set - Datasheetfrankz89No ratings yet

- Caldera FultonDocument76 pagesCaldera FultonFrancisco MendozaNo ratings yet

- Aeroenfriador PDFDocument26 pagesAeroenfriador PDFfrankz89No ratings yet

- Mezclador EstaticoDocument12 pagesMezclador Estaticofrankz89No ratings yet

- Gene SileningDocument30 pagesGene SileningSajjad AhmadNo ratings yet

- Mary Kay FinalDocument17 pagesMary Kay Finalharsh0695No ratings yet

- Major Laishram Jyotin SinghDocument3 pagesMajor Laishram Jyotin SinghSpongebob SquarepantsNo ratings yet

- Me22 M1a1Document2 pagesMe22 M1a1Jihoo JungNo ratings yet

- Draw-Through or Blow-Through: Components of Air Handling UnitDocument23 pagesDraw-Through or Blow-Through: Components of Air Handling Unityousuff0% (1)

- Research Paper CalamansiDocument7 pagesResearch Paper Calamansih040pass100% (1)

- The Necessity of Using Neurophysiological Methods For Diagnosing Communication Disorders. by Akhsaful To Tawhida Jahan MamDocument11 pagesThe Necessity of Using Neurophysiological Methods For Diagnosing Communication Disorders. by Akhsaful To Tawhida Jahan MamAkhsaful ImamNo ratings yet

- Textile Chemical Brochure 8.6.22 - 031Document1 pageTextile Chemical Brochure 8.6.22 - 031NIKESH PRAKASHNo ratings yet

- Decommissioning HSE PDFDocument105 pagesDecommissioning HSE PDFRafael Rocha100% (1)

- Disease PreventionDocument14 pagesDisease PreventionJoan InsonNo ratings yet

- Medical-Surgical Nursing Assessment and Management of Clinical Problems 9e Chapter 23Document5 pagesMedical-Surgical Nursing Assessment and Management of Clinical Problems 9e Chapter 23sarasjunkNo ratings yet

- Motivational Interviewing (MI) Refers To ADocument5 pagesMotivational Interviewing (MI) Refers To AJefri JohanesNo ratings yet

- CapsulesDocument60 pagesCapsulesprinceamitNo ratings yet

- Guidelines For Students Module 6 and 7Document4 pagesGuidelines For Students Module 6 and 7JasellePanteNo ratings yet

- 04 TitrimetryDocument7 pages04 TitrimetryDarwin Fetalbero ReyesNo ratings yet

- ЗОШИТ для ДЗ №2 Microsoft WordDocument44 pagesЗОШИТ для ДЗ №2 Microsoft WordдимаNo ratings yet

- Genie PDFDocument264 pagesGenie PDFjohanaNo ratings yet

- Endothermic ReactionDocument8 pagesEndothermic ReactionMibvase IkhuruvoseNo ratings yet

- G1 CurvedDocument16 pagesG1 CurvedElbert Ryan OcampoNo ratings yet

- Hygold 5000Bs: Base Oil Marketing SpecificationDocument1 pageHygold 5000Bs: Base Oil Marketing Specificationsamsoon80100% (1)

- Trombly - Pump Status PDFDocument8 pagesTrombly - Pump Status PDFilhamNo ratings yet

- Daily Lesson Log Personal Dev TDocument34 pagesDaily Lesson Log Personal Dev TRicky Canico ArotNo ratings yet

- Modeling, Control and Simulation of A Chain Link Statcom in Emtp-RvDocument8 pagesModeling, Control and Simulation of A Chain Link Statcom in Emtp-RvBožidar Filipović-GrčićNo ratings yet

- Tests Conducted On Under Water Battery - YaduDocument15 pagesTests Conducted On Under Water Battery - YadushuklahouseNo ratings yet

- TruEarth Case SolutionDocument6 pagesTruEarth Case SolutionUtkristSrivastavaNo ratings yet

- ES9-62 Ingestive Cleaning PDocument9 pagesES9-62 Ingestive Cleaning PIfran Sierra100% (1)

- A Hydrogen Generator You Can BuildDocument19 pagesA Hydrogen Generator You Can BuildTri Yuniarto0% (1)

- Homoeopathic Treatment of Complicated Sebaceous Cyst - A Case StudyDocument5 pagesHomoeopathic Treatment of Complicated Sebaceous Cyst - A Case StudyDr deepakNo ratings yet